Modbus TCP vs RTU: Industrial Power Monitoring Use Cases

JUN 26, 2025 |

Modbus is a communication protocol widely used in industrial settings for connecting electronic devices. Primarily, it facilitates communication between instrumentation and control systems. Modbus comes in different variants, with Modbus TCP and Modbus RTU being the most prevalent. Each of these has unique characteristics that make them suitable for specific use cases, particularly in industrial power monitoring.

Understanding Modbus TCP

Modbus TCP is a network-based protocol that uses Ethernet for communication. It encapsulates Modbus messages within TCP/IP packets, allowing for easy integration into existing IT networks. The principal advantage of Modbus TCP is its ability to connect a large number of devices over long distances without significant signal degradation. It supports high-speed data transmission and offers a broader bandwidth, accommodating more complex data exchanges.

Understanding Modbus RTU

Contrastingly, Modbus RTU is a serial communication protocol. It operates over RS-232 or RS-485 interfaces, making it ideal for connecting devices within a limited geographic area. Modbus RTU is known for its simplicity and reliability. It uses a compact message format that minimizes the required bandwidth, making it efficient for real-time monitoring applications. However, it is generally limited to short-distance communication due to the constraints of serial connections.

Industrial Power Monitoring: Key Considerations

When choosing between Modbus TCP and RTU for industrial power monitoring, several key factors need to be considered. These include the scale of the monitoring system, communication distance, data transmission speed, reliability, and existing infrastructure. Understanding the specific requirements can guide system designers in selecting the most suitable protocol for their needs.

Use Cases for Modbus TCP in Industrial Power Monitoring

Modbus TCP is particularly advantageous in large-scale industrial power monitoring systems. It allows for the integration of hundreds of devices, making it suitable for facilities with extensive networks of sensors and meters. In environments where real-time data is critical, Modbus TCP's high-speed transmission can provide timely insights into power consumption, aiding in the efficient management of energy resources.

Another significant use case for Modbus TCP is in remote monitoring applications. Through Ethernet networks, Modbus TCP can reliably transmit data over long distances, enabling centralized monitoring of geographically dispersed sites. This capability is invaluable for industries like manufacturing and energy, where plants and facilities may be spread across different locations.

Use Cases for Modbus RTU in Industrial Power Monitoring

Modbus RTU excels in smaller-scale applications where simplicity and reliability are paramount. Its straightforward implementation makes it an excellent choice for localized power monitoring systems, such as those found in small manufacturing units or individual building facilities. Modbus RTU's robust performance over serial lines ensures consistent data transmission, crucial for maintaining precise monitoring capabilities.

Furthermore, Modbus RTU is often favored in environments with challenging conditions, such as high electrical noise. Its compact message format and error-checking mechanisms provide resilient communication, minimizing data loss and ensuring dependable system performance.

Choosing the Right Protocol for Your Needs

The decision between Modbus TCP and RTU should be driven by the specific requirements of the industrial power monitoring system. For extensive networks requiring high-speed communication and remote monitoring, Modbus TCP is generally the preferred option. Meanwhile, for smaller, localized systems where reliability and simplicity are prioritized, Modbus RTU stands out as an ideal candidate.

Conclusion

Both Modbus TCP and RTU have their distinct advantages and serve specific use cases in industrial power monitoring. Understanding the differences between them allows system designers to make informed decisions, ensuring that their monitoring systems are both efficient and reliable. By leveraging the strengths of each protocol, industries can enhance their energy management processes, leading to improved operational performance and sustainability.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

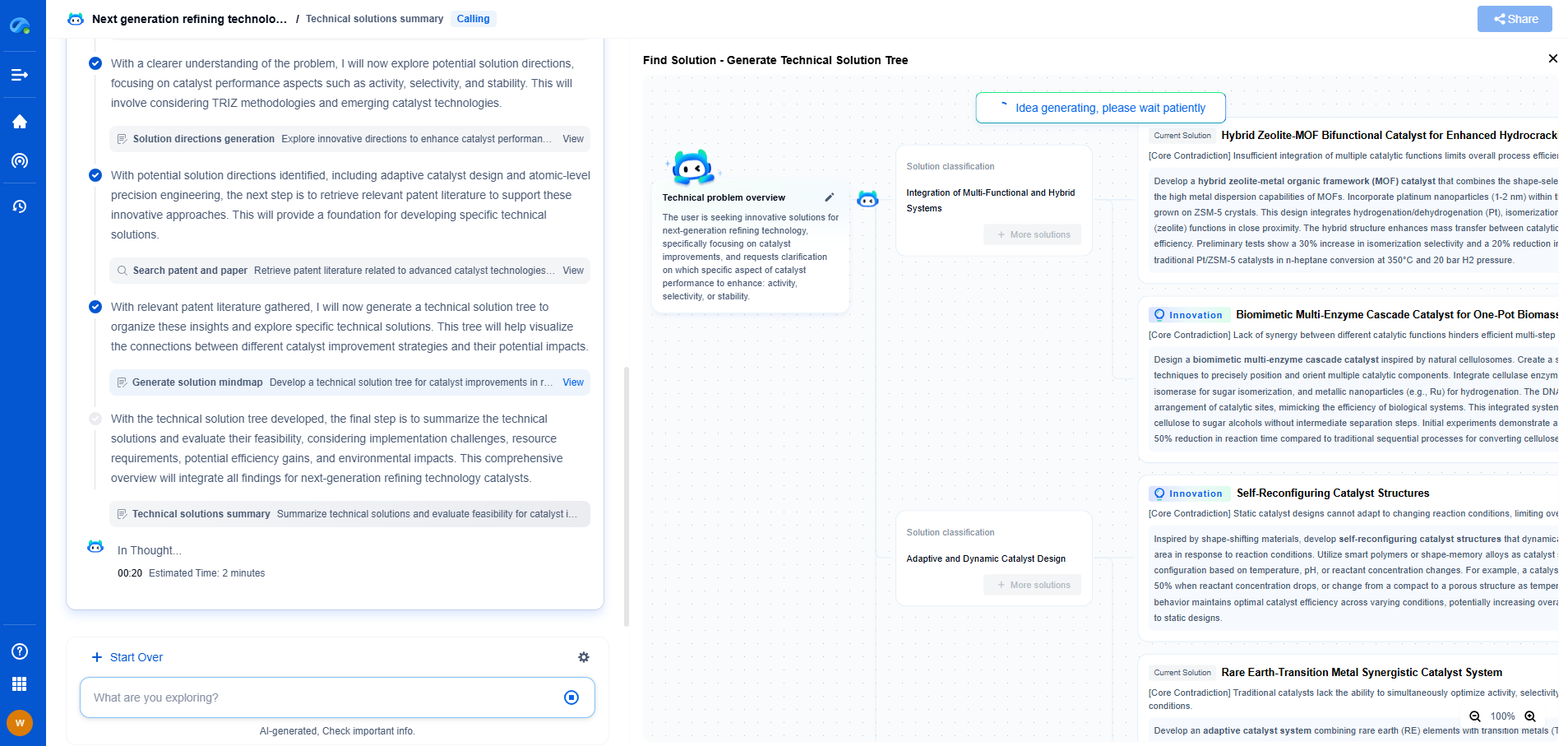

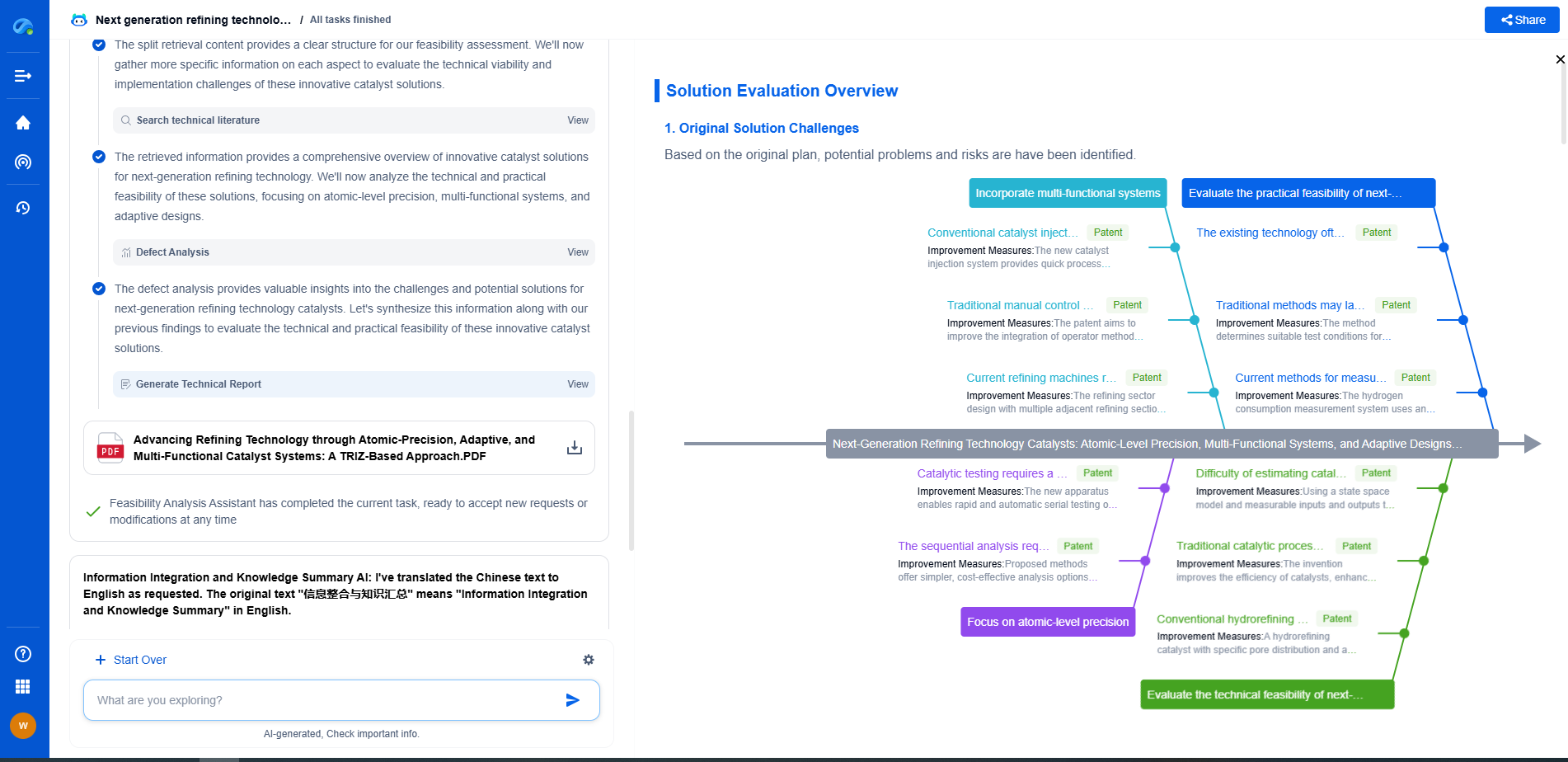

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com