Monocrystalline vs. Polycrystalline Silicon Solar Cells: Key Differences Explained

JUL 22, 2025 |

Solar energy has become a cornerstone of the global transition toward sustainable energy solutions. As the technology continues to evolve, consumers are increasingly faced with choices about which type of solar panel to install. Two of the most common types of solar cells are monocrystalline and polycrystalline silicon solar cells. Both types have unique characteristics, advantages, and disadvantages. Understanding these differences is crucial for making an informed decision.

Construction and Appearance

Monocrystalline solar cells are made from a single, continuous crystal structure. They are typically manufactured using the Czochralski process, which involves slicing wafers from a single cylindrical silicon ingot. This gives them their characteristic appearance of uniform black color and rounded edges.

In contrast, polycrystalline solar cells are made from silicon crystals that have been melted together. These cells are created using a cast ingot process, where blocks of silicon are melted and then allowed to cool and solidify. The manufacturing process results in a distinctive bluish hue with a more fragmented look due to the presence of multiple crystal boundaries.

Efficiency and Performance

When it comes to efficiency, monocrystalline solar cells generally have the upper hand. They have higher efficiency rates, often exceeding 20%, because they are made from high-purity silicon. The uniform crystal structure allows electrons to move more freely, leading to higher energy conversion rates. This makes them an excellent choice for installations where space is limited but maximum power output is desired.

Polycrystalline solar cells, on the other hand, tend to have lower efficiency rates, typically ranging from 15% to 17%. The presence of multiple crystals creates boundaries that can impede the flow of electrons, reducing their effectiveness. Despite this, polycrystalline panels have improved significantly over the years and still offer a solid performance at a lower cost.

Cost Considerations

Cost is often a determining factor for many consumers when choosing between monocrystalline and polycrystalline solar cells. Monocrystalline panels are more expensive due to the intricate production process and the use of high-purity silicon. Their superior efficiency can help offset the initial investment over time, especially in areas with high electricity prices or limited installation space.

Polycrystalline panels are generally more affordable because their manufacturing process is less complex and utilizes silicon more efficiently. This makes them a popular choice for larger installations where space is not a constraint and where cost-efficiency is a priority.

Durability and Longevity

Both monocrystalline and polycrystalline solar panels are designed to last for decades, with most manufacturers offering warranties of 25 years or more. However, monocrystalline panels tend to have a slight edge in longevity due to their robust construction and higher resistance to environmental factors. They typically degrade at a slower rate, maintaining higher efficiency throughout their lifespan.

Polycrystalline panels, while still durable, may experience a slightly higher rate of degradation over time. However, the difference is often negligible for most residential and commercial applications.

Environmental Impact

The environmental impact of manufacturing solar panels is an important consideration for eco-conscious consumers. Monocrystalline panels require more energy to produce due to their complex manufacturing process, which can result in a higher carbon footprint. However, their extended lifespan and higher efficiency can help mitigate this initial impact over time.

Polycrystalline panels have a less energy-intensive production process, leading to a lower initial environmental impact. They also make better use of silicon, minimizing waste during production. For those prioritizing immediate environmental benefits, polycrystalline panels may be the preferred option.

Conclusion: Choosing the Right Solar Cell

Ultimately, the choice between monocrystalline and polycrystalline solar cells depends on individual needs and priorities. Monocrystalline panels are ideal for those seeking maximum efficiency and willing to invest in higher initial costs. They are best suited for installations where space is limited and long-term energy savings are desired.

Polycrystalline panels offer a budget-friendly alternative with respectable performance and a lower environmental impact. They are well-suited for larger installations where cost-efficiency outweighs the need for the highest possible efficiency.

By carefully weighing these factors, consumers can choose the solar solution that aligns best with their energy goals and values.

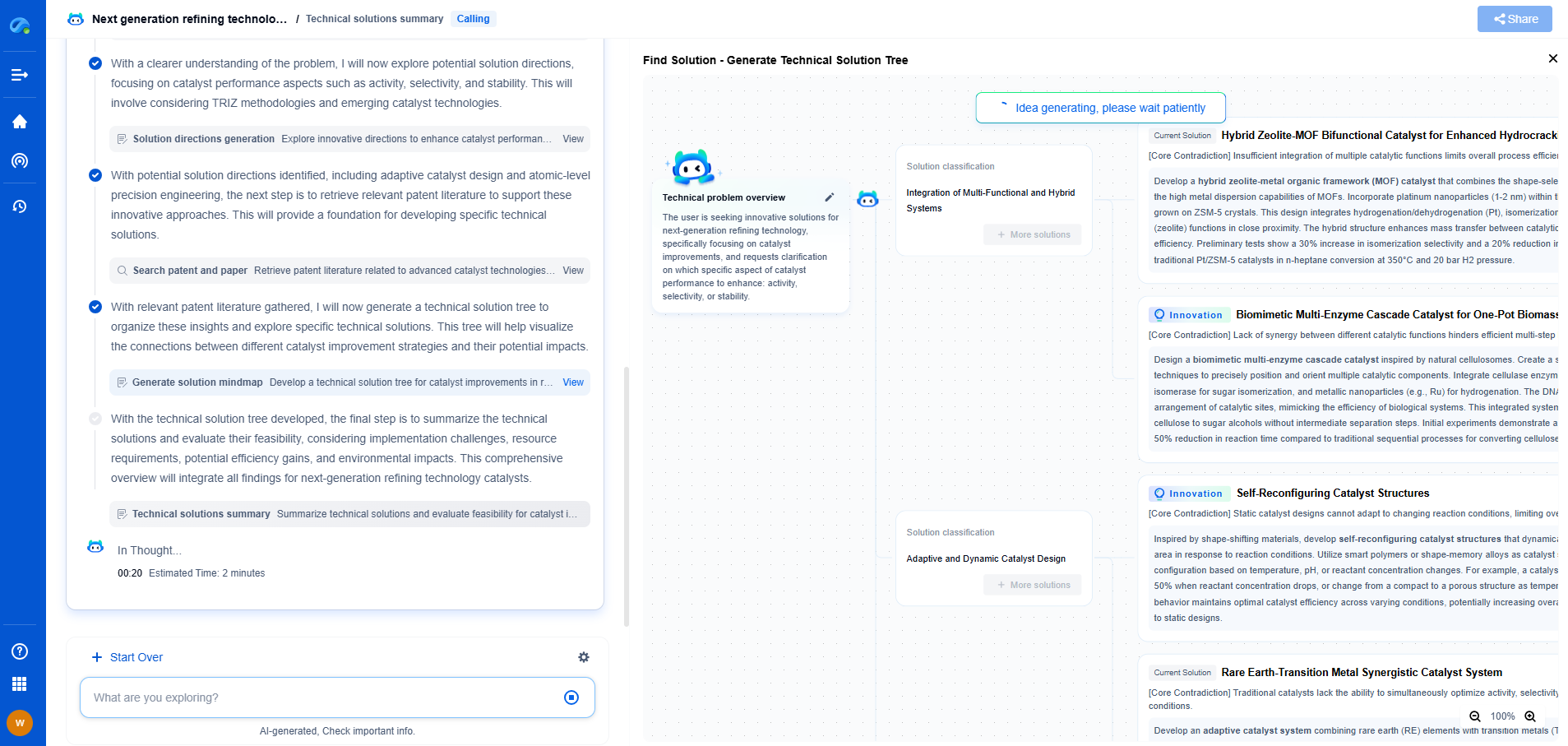

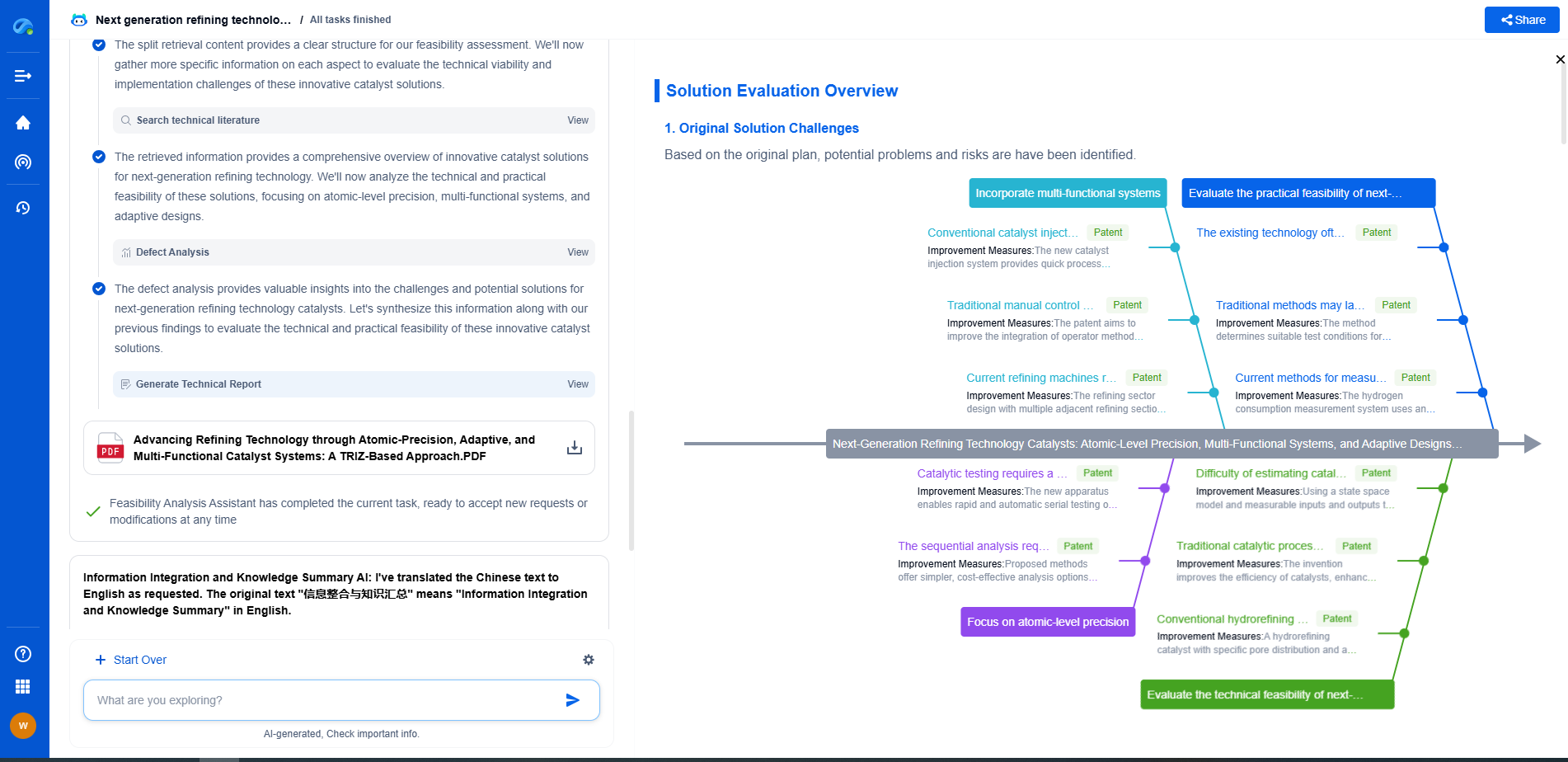

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com