North American vs European Low-Voltage Directive Compliance

JUN 26, 2025 |

Navigating the complexities of electrical safety and compliance is crucial for manufacturers and suppliers operating in different global markets. In North America and Europe, low-voltage directives form a critical part of the regulatory landscape for electrical equipment. Despite their shared goal of ensuring safety and reliability, these directives have significant differences in requirements and execution.

Overview of North American Low-Voltage Directive Compliance

In North America, electrical equipment must adhere to standards primarily developed by the National Electrical Code (NEC) in the United States and the Canadian Electrical Code (CEC) in Canada. Compliance is typically demonstrated through certification by recognized bodies such as Underwriters Laboratories (UL) in the U.S. and the Canadian Standards Association (CSA) in Canada.

The focus is on ensuring that products meet specific safety standards before they can be marketed. North American compliance is characterized by rigorous testing procedures. Electrical products undergo a series of evaluations to verify that they meet all applicable safety standards, including those related to fire, electrical shock, and mechanical hazards. The emphasis is on product-specific standards, which can sometimes lead to a more fragmented approach compared to the overarching directives seen in Europe.

Understanding the European Low-Voltage Directive (LVD)

The European approach to low-voltage safety is encapsulated in the Low Voltage Directive (LVD) 2014/35/EU. This directive applies to all electrical equipment with a voltage rating between 50 and 1000 volts for alternating current and between 75 and 1500 volts for direct current. The LVD is part of a broader framework that aims to facilitate the free movement of products across the EU while ensuring a high level of protection.

European compliance is based on self-declaration by manufacturers, who must ensure their products meet the essential health and safety requirements set out in the directive. This is often done through conformity assessment procedures and the creation of a technical file that documents how the product complies with the relevant standards. The CE marking is then affixed to demonstrate compliance. The approach in Europe tends to be more harmonized, with a focus on performance-based standards rather than prescriptive specifications.

Key Differences Between North American and European Directives

One of the primary differences between North American and European directives is the method of compliance verification. In North America, third-party testing and certification are essential, while Europe relies heavily on manufacturer self-certification and the CE marking. This difference reflects broader regulatory philosophies, with the U.S. and Canada emphasizing independent verification and Europe prioritizing streamlined market access.

Another notable difference is the scope of the directives. The LVD in Europe covers a wide range of products with a focus on ensuring safe design and construction. In contrast, North American standards may vary significantly depending on the product category, leading to more specialized standards that can be cumbersome for manufacturers dealing with a diverse product range.

Challenges and Considerations for Manufacturers

Manufacturers aiming to enter both North American and European markets must navigate these differing compliance landscapes carefully. Understanding the specific requirements of each region is crucial, as non-compliance can lead to product recalls, fines, and bans from the market.

In North America, building relationships with certification bodies can facilitate smoother compliance processes, while in Europe, developing a robust internal compliance program is essential for effective self-declaration. Manufacturers must stay updated on any changes to standards and directives to ensure ongoing compliance.

Conclusion

While both North American and European low-voltage directives seek to ensure the safety and reliability of electrical products, they do so through different mechanisms and philosophies. Manufacturers must be diligent in understanding these differences to successfully navigate compliance requirements in each region. By doing so, they can not only avoid costly compliance failures but also enhance their market reach and consumer trust.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

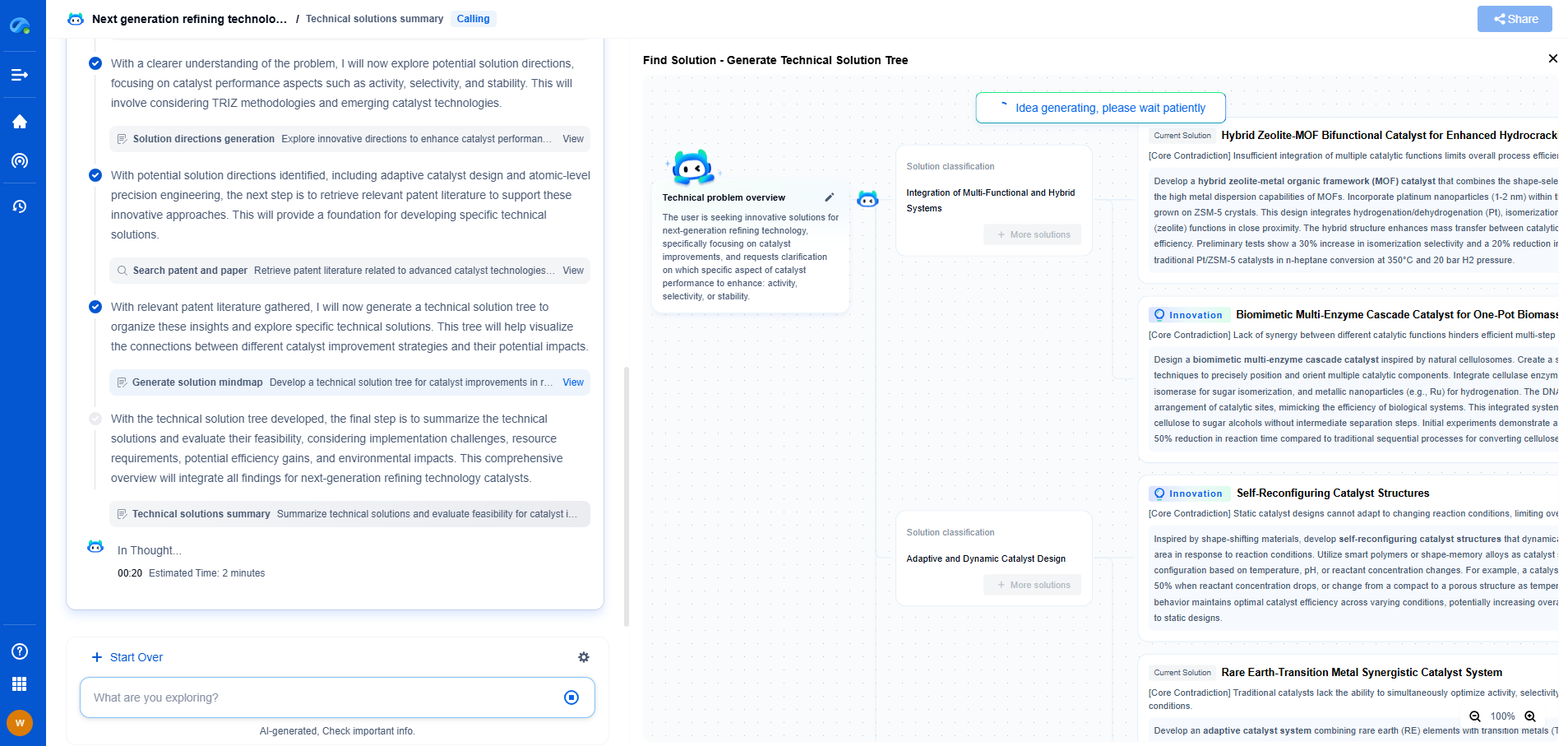

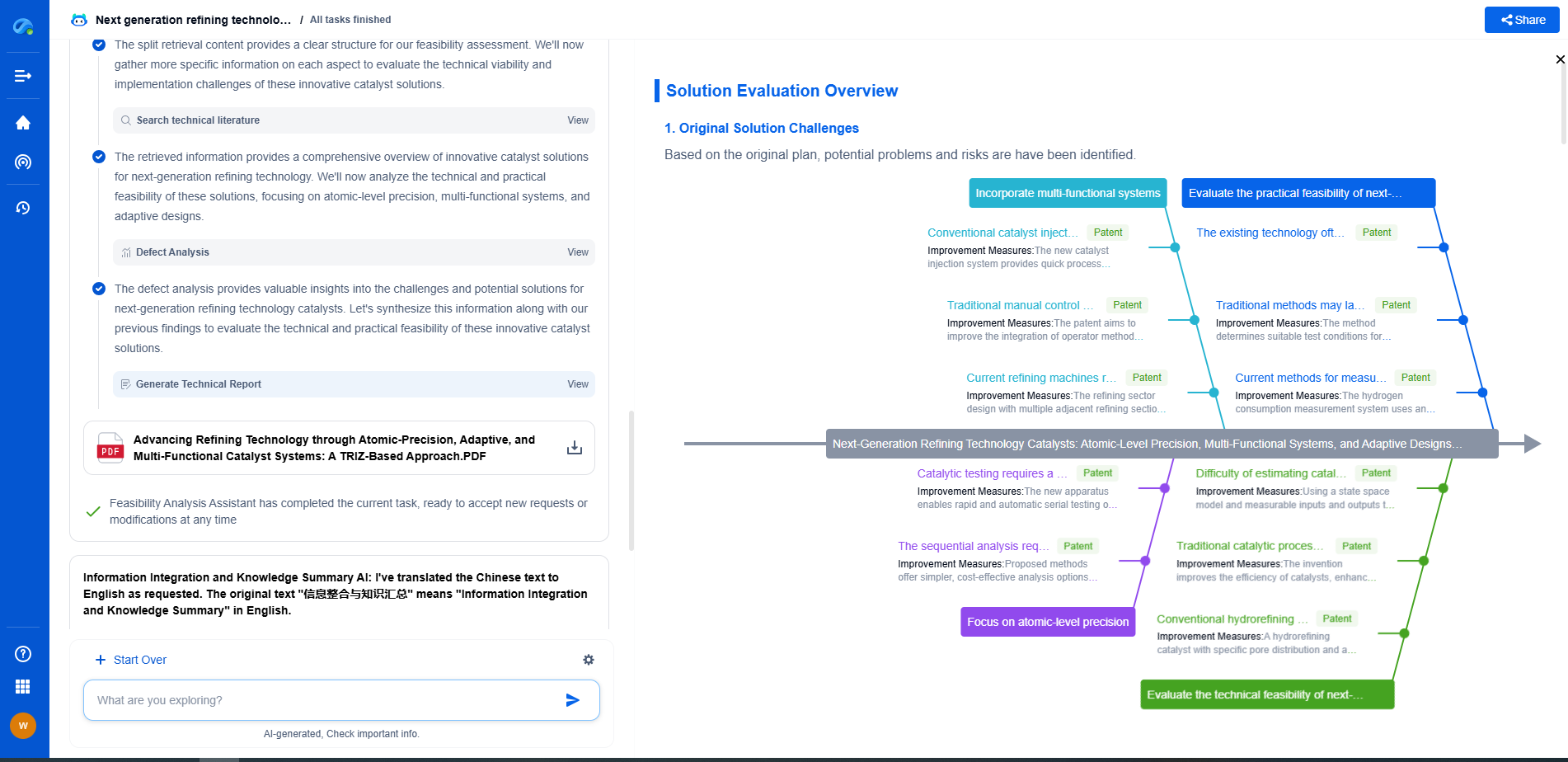

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com