PCB Shielding Techniques: When to Use Copper Tape vs. Shield Cans

JUN 27, 2025 |

Understanding EMI and RFI

Before diving into shielding techniques, it's essential to understand what EMI and RFI are, and their impact on electronic devices. EMI is unwanted noise or interference from external sources that disrupt the normal operation of electronic circuits. This interference can degrade the performance of a device, causing malfunctions or even complete failure. RFI, a subset of EMI, specifically involves the disruption caused by radio frequency signals. Effective shielding techniques are crucial to prevent these interferences from affecting sensitive electronic components.

Copper Tape Shielding

Copper tape is a versatile and cost-effective solution for EMI and RFI shielding in PCB design. It is a thin, adhesive-backed tape made of copper, which can be easily applied to various surfaces. Copper tape is particularly useful in applications where space is limited or when flexibility is required.

Advantages of Copper Tape

One of the primary advantages of copper tape is its ease of application. It can be cut to size and shape, allowing it to fit into small or irregular spaces on a PCB. Additionally, copper tape is highly conductive, which makes it effective in grounding and shielding applications. It also provides good attenuation of high-frequency signals, making it suitable for a wide range of applications.

Another significant advantage is the ability to use copper tape for prototyping and quick fixes. Engineers can apply it to evaluate the effectiveness of shielding in a specific area of the PCB without committing to more permanent solutions. This flexibility makes copper tape an attractive option during the design phase.

Limitations of Copper Tape

Despite its benefits, copper tape has limitations. It may not provide as robust a shielding as other methods, especially for high-frequency applications. The adhesive used in copper tape can degrade over time, particularly in high-temperature environments, leading to reduced effectiveness. Additionally, the tape may not be suitable for applications requiring a hermetic seal.

Shield Cans and Their Applications

Shield cans, also known as shielding enclosures or covers, are metal or metal-plated covers that encase an entire section of a PCB. These cans provide a more substantial and durable form of shielding compared to copper tape.

Advantages of Shield Cans

Shield cans offer superior shielding capabilities, particularly for high-frequency and high-power applications. They provide a reliable physical barrier that can prevent EMI and RFI from affecting sensitive components. Shield cans are also more durable than copper tape, making them suitable for long-term applications and harsh environments where mechanical protection is required.

Another advantage of shield cans is their ability to provide a hermetic seal, which is valuable in preventing moisture and other environmental factors from affecting the electronics. This makes them ideal for use in outdoor or industrial applications.

Limitations of Shield Cans

The primary drawback of shield cans is their cost. They are typically more expensive than copper tape, both in terms of materials and in the additional design considerations required to integrate them into the PCB layout. Shield cans also add weight and bulk to a design, which can be a disadvantage in applications where space and weight are critical considerations.

Choosing Between Copper Tape and Shield Cans

The decision between using copper tape and shield cans depends on several factors, including the specific requirements of the application, budget constraints, and design considerations.

For low-cost, flexible, and quick solutions, especially during the prototyping phase, copper tape is often the preferred choice. It allows engineers to experiment with different shielding configurations without significant investment.

For applications requiring robust, long-term shielding solutions, particularly in high-frequency and high-power environments, shield cans are usually the better option. They offer superior protection but require careful planning and design to integrate effectively into the PCB layout.

Conclusion

In summary, both copper tape and shield cans play critical roles in EMI and RFI shielding for PCBs. Understanding the advantages and limitations of each method allows engineers to make informed decisions about which technique is most suitable for their specific needs. By carefully considering factors such as cost, application environment, and design constraints, engineers can ensure that their electronic devices perform reliably and efficiently in the presence of electromagnetic interference.

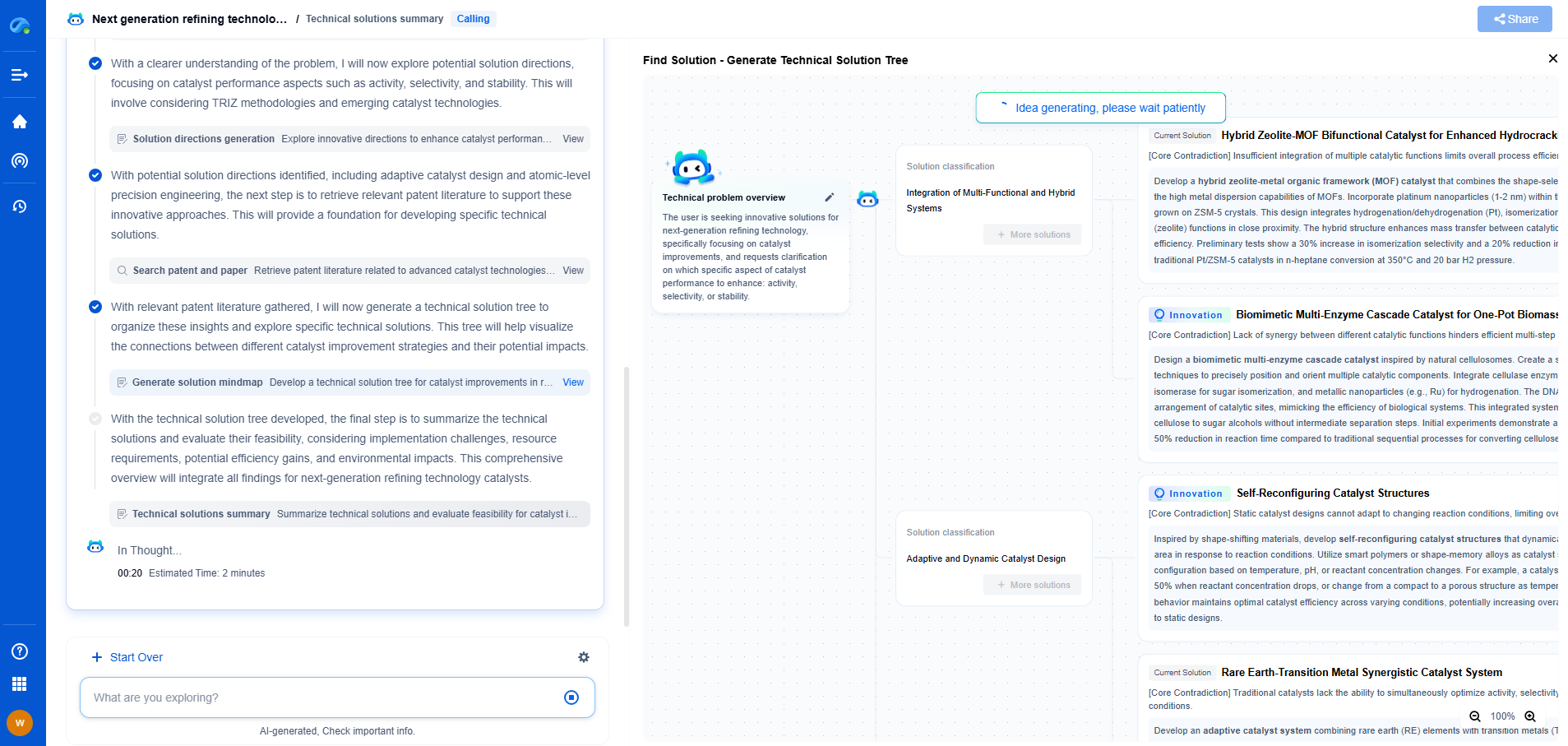

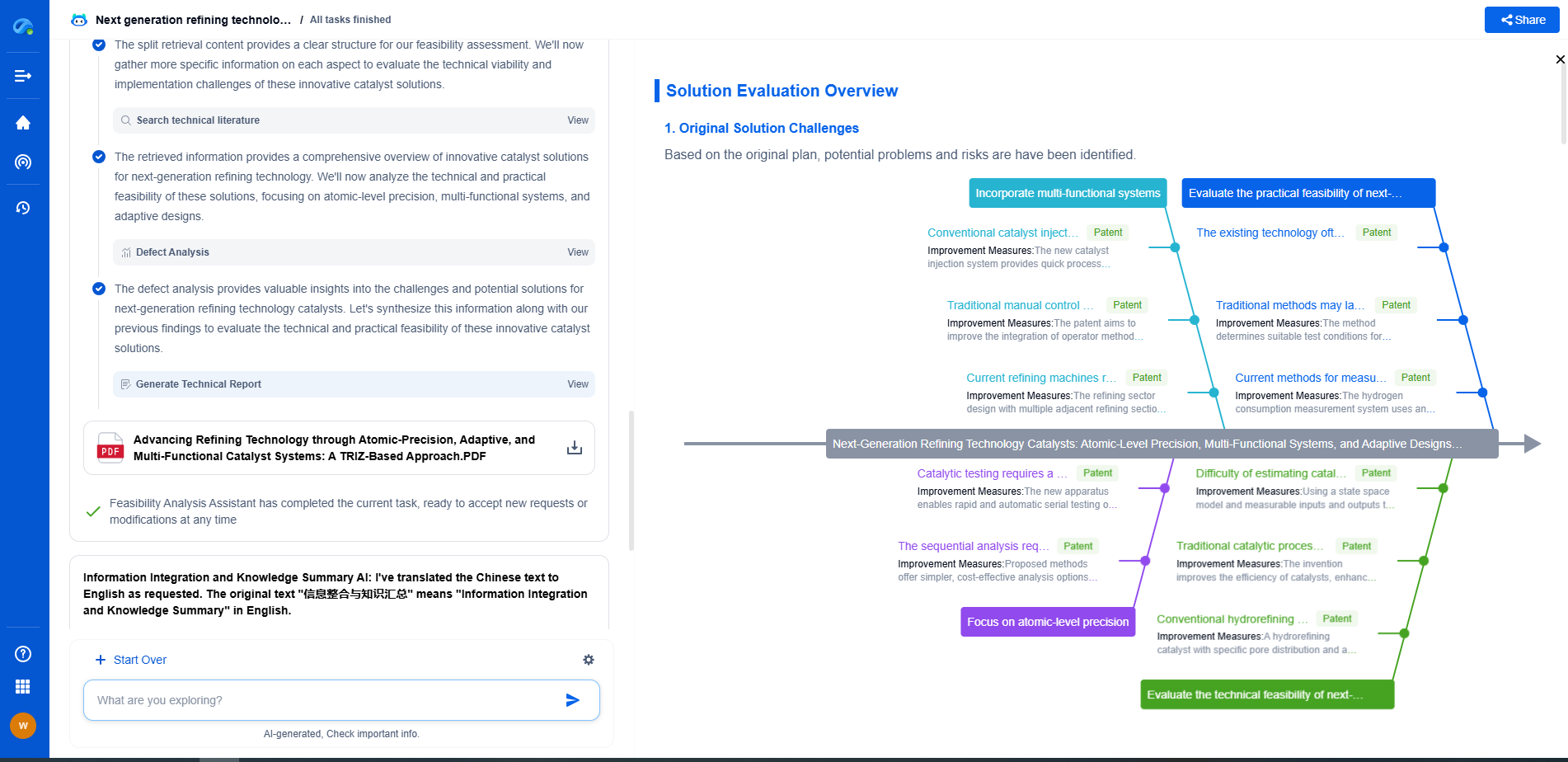

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com