PCB Thermal Analysis for High-Power Semiconductor Layouts

JUN 27, 2025 |

In the realm of high-power semiconductor design, effective thermal management is fundamental to ensuring operational reliability and longevity of electronic components. Printed Circuit Boards (PCBs) serve as the backbone for these devices, making their thermal analysis critical. This article delves into the essentials of PCB thermal analysis for high-power semiconductor layouts, covering methodologies, tools, and best practices.

The Importance of Thermal Management

As high-power semiconductors generate substantial heat, inadequate thermal management can lead to overheating, component failure, or reduced efficiency. It's vital to predict and mitigate these thermal issues during the design phase. Effective thermal management not only enhances performance but also prolongs the lifespan of electronic devices by preventing thermal stress and ensuring stable operation.

Thermal Conductivity and Material Selection

One of the first steps in thermal analysis is selecting appropriate materials for your PCB. The thermal conductivity of the substrate material plays a pivotal role in dissipating heat. Common materials like FR-4 have lower thermal conductivity, while ceramics and metals offer higher thermal conductivity, making them suitable for high-power applications. Choosing the right material impacts the effective dissipation of heat across the board.

Analyzing Thermal Vias and Heat Sinks

Thermal vias and heat sinks are essential components in managing heat dissipation. Thermal vias are plated through holes that conduct heat away from the surface to inner layers or to the opposite side of the board, where it can be dissipated further. Heat sinks provide additional surface area for heat dissipation. Properly placing and sizing these features during the design phase enhances thermal performance significantly.

Simulation Tools and Techniques

PCB thermal analysis relies heavily on simulation tools to predict and evaluate thermal behavior. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are commonly used techniques that simulate heat distribution and airflow across the PCB. These tools enable designers to visualize thermal profiles, identify hotspots, and optimize component placement and thermal management features before physical prototyping.

Design for Thermal Efficiency

Design considerations for thermal efficiency involve strategic component placement and layout optimization. Placing high-power components away from heat-sensitive areas and ensuring an even distribution of heat sources reduces thermal stress. Additionally, designing with thermal relief pads and optimizing trace widths can further enhance heat dissipation.

Effects of Environmental Conditions

Environmental factors such as ambient temperature, airflow, and humidity significantly affect thermal performance. Understanding the operating environment allows for better anticipation of thermal challenges. For instance, designs intended for high-temperature environments may require enhanced cooling systems or more robust materials to withstand thermal loads.

Prototyping and Testing

Once the design is finalized, prototyping and testing are crucial steps. Physical testing validates the simulations and ensures that the design performs as expected under real-world conditions. Thermal imaging and temperature monitoring tools are employed to check for any discrepancies between the simulated and actual thermal behavior.

Continuous Improvement and Iteration

PCB thermal analysis is not a one-time task but an iterative process. As technologies evolve and power demands increase, continuous refinement of thermal management strategies is necessary. Keeping up with advancements in materials, simulation tools, and design techniques can significantly bolster thermal performance in high-power semiconductor layouts.

Conclusion

Effective PCB thermal analysis is crucial for the reliability and performance of high-power semiconductor layouts. By understanding the interplay between materials, design, and environmental factors, designers can create layouts that manage heat efficiently. With the right tools and techniques, thermal challenges can be addressed proactively, ensuring the endurance and efficacy of electronic devices.

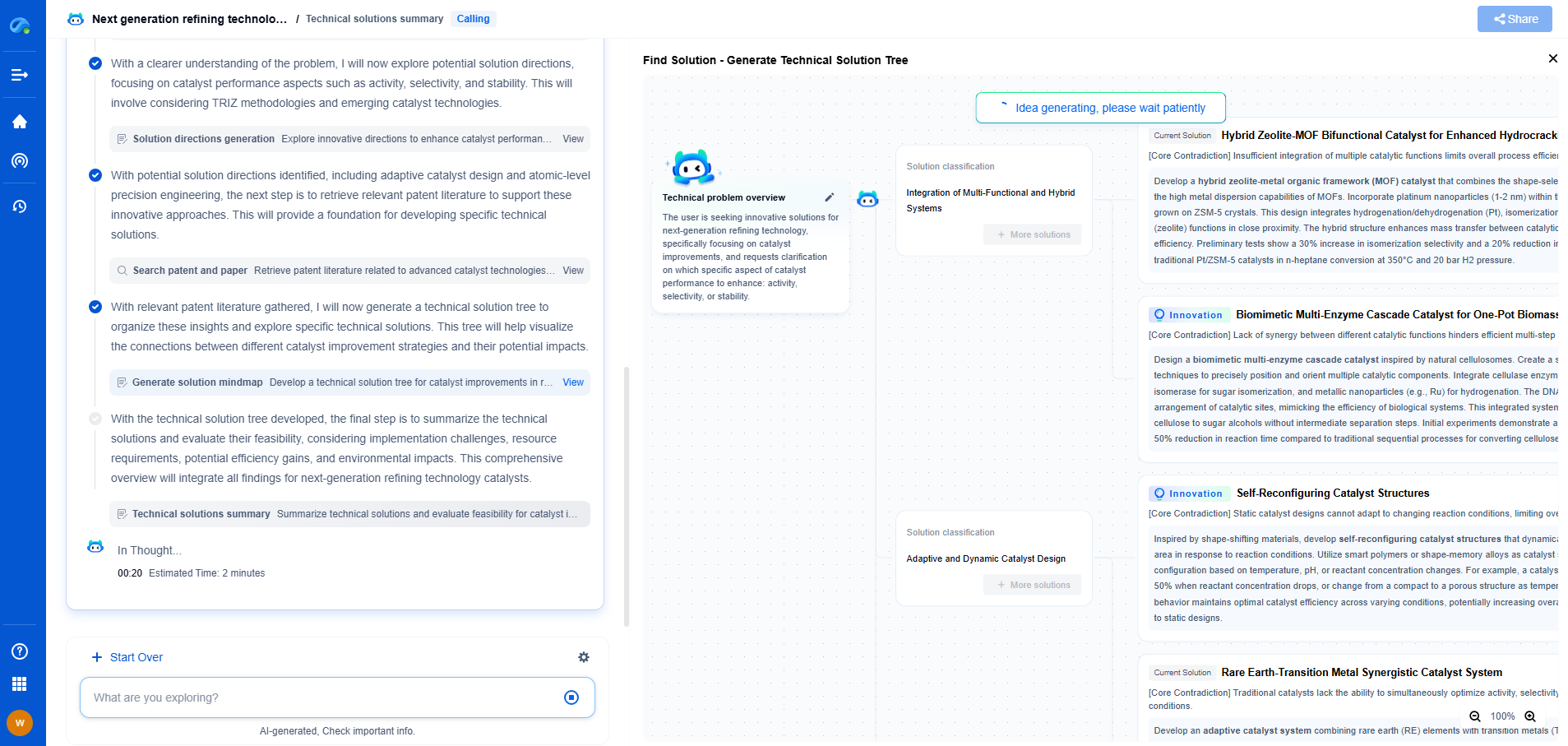

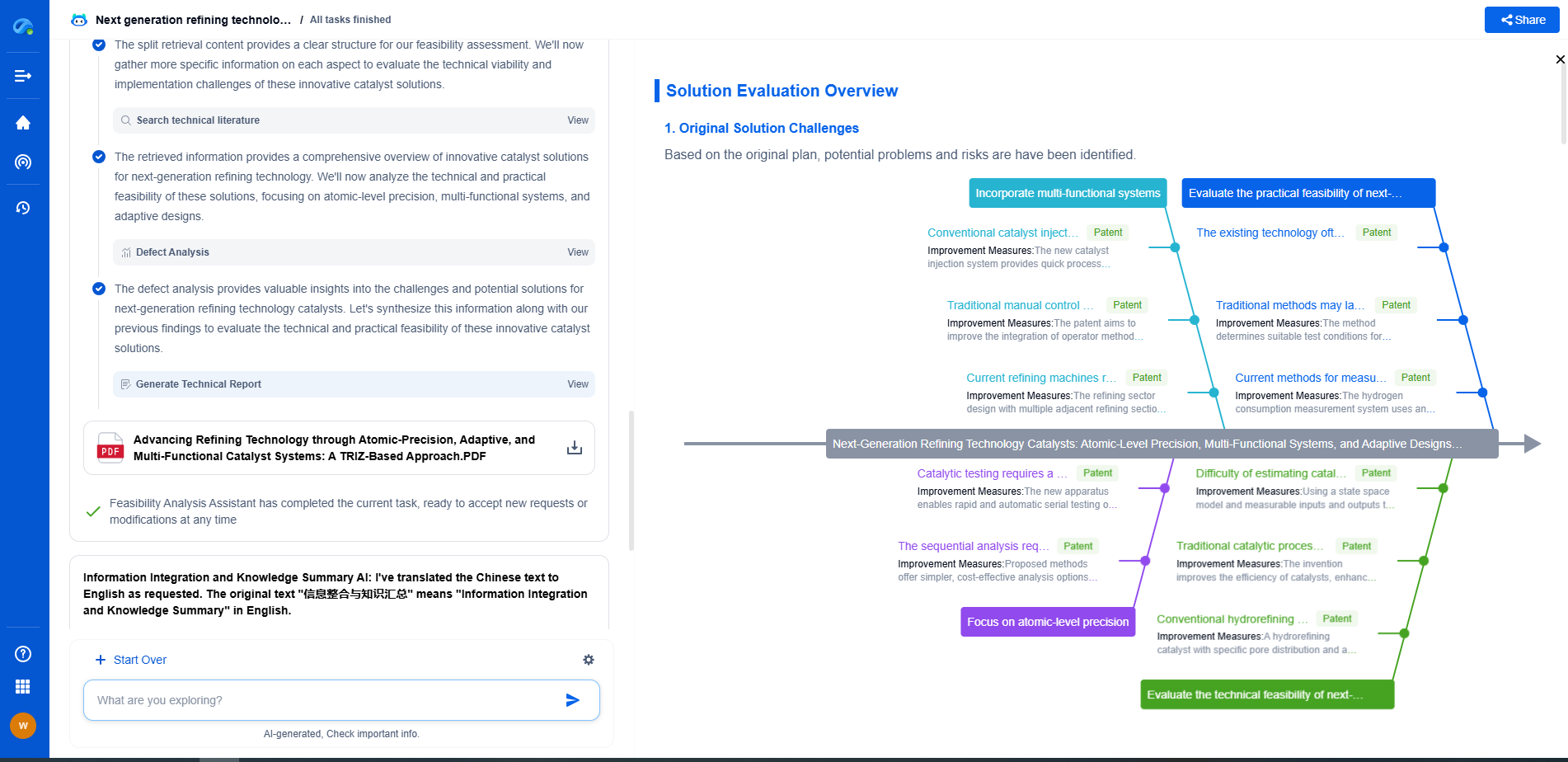

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com