PID Test Standards: IEC 62804 vs. UL 61730 Comparison

JUL 22, 2025 |

Potential-induced degradation (PID) is a significant concern for solar photovoltaic (PV) module manufacturers and operators. It can lead to a substantial reduction in the performance and efficiency of solar panels. To ensure the robustness and longevity of PV modules against PID, specific test standards have been developed. Among these, IEC 62804 and UL 61730 are two of the most recognized standards. This article aims to compare these two standards, highlighting their similarities, differences, and implications for the PV industry.

Understanding PID and Its Implications

PID occurs when voltage differences between the solar cells and the grounded frames lead to a leakage current, causing power losses and long-term damage to the PV modules. This degradation can severely impact the energy yield and economic returns of solar installations. Therefore, it is crucial for manufacturers to test their modules for PID resistance to ensure reliability and customer satisfaction.

Overview of IEC 62804

IEC 62804 is an international standard developed by the International Electrotechnical Commission (IEC). It provides a framework for testing the PID resistance of crystalline silicon PV modules. The standard specifies the test conditions, including environmental factors such as temperature and humidity, and the duration and applied voltage for the test. IEC 62804 aims to simulate real-world conditions as closely as possible to assess how the modules will perform over their lifespan.

Key Features of IEC 62804:

1. **Test Conditions**: IEC 62804 recommends testing at temperatures of 60°C and relative humidity of 85%, which are considered harsh environmental conditions to accelerate the degradation process.

2. **Voltage Application**: The standard usually involves applying a high voltage of up to 1,000 volts for 96 hours to test the module's resistance to PID.

3. **Assessment Criteria**: The performance of the module is evaluated based on power loss post-test, with a threshold typically set to ensure minimal degradation.

Overview of UL 61730

UL 61730 is a standard developed by Underwriters Laboratories (UL) specifically for the North American market. While it includes tests for PID, UL 61730 is broader in scope as it also addresses safety and construction requirements for PV modules.

Key Features of UL 61730:

1. **Holistic Approach**: UL 61730 focuses on both safety and performance, ensuring that modules meet stringent safety standards alongside their PID resistance.

2. **Test Conditions**: While similar in some respects to IEC 62804, UL 61730 may involve different environmental conditions and durations depending on specific requirements.

3. **Comprehensive Testing**: The standard includes various tests such as fire resistance, electrical insulation, and mechanical load tests, in addition to PID testing.

Comparative Analysis

While both IEC 62804 and UL 61730 serve to assess PID resistance, they differ in scope and application. IEC 62804 is more focused on replicating real-world environmental stresses, providing an in-depth analysis of PID under specific conditions. In contrast, UL 61730 offers a more comprehensive approach, integrating safety and construction standards alongside performance tests.

Implications for Manufacturers and Consumers

For manufacturers, choosing the appropriate standard depends on their target market and specific product goals. IEC 62804 is ideal for international markets where performance under harsh conditions is crucial. UL 61730 is essential for manufacturers targeting the North American market, ensuring compliance with safety and performance standards.

For consumers and solar project developers, understanding these standards can help in selecting reliable and long-lasting PV modules. Products certified under these standards are more likely to withstand PID and other environmental stresses, ensuring better energy yields and investment returns.

Conclusion

Both IEC 62804 and UL 61730 play vital roles in ensuring the quality and reliability of PV modules. While they have different focal points, they collectively contribute to enhancing the resilience of solar panels against PID. By understanding these standards, stakeholders in the solar industry can make informed decisions, ultimately driving the adoption of more durable and efficient solar technologies.

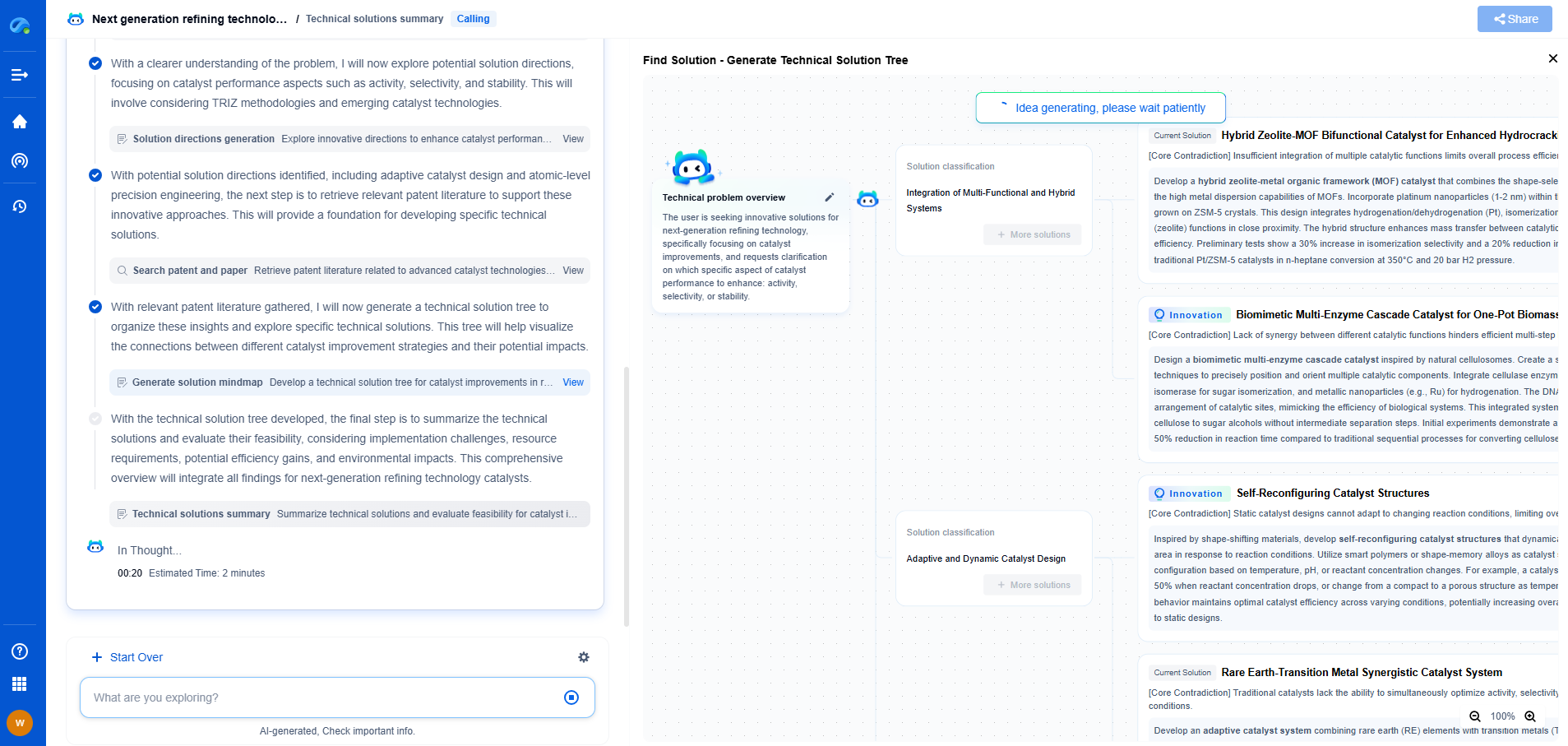

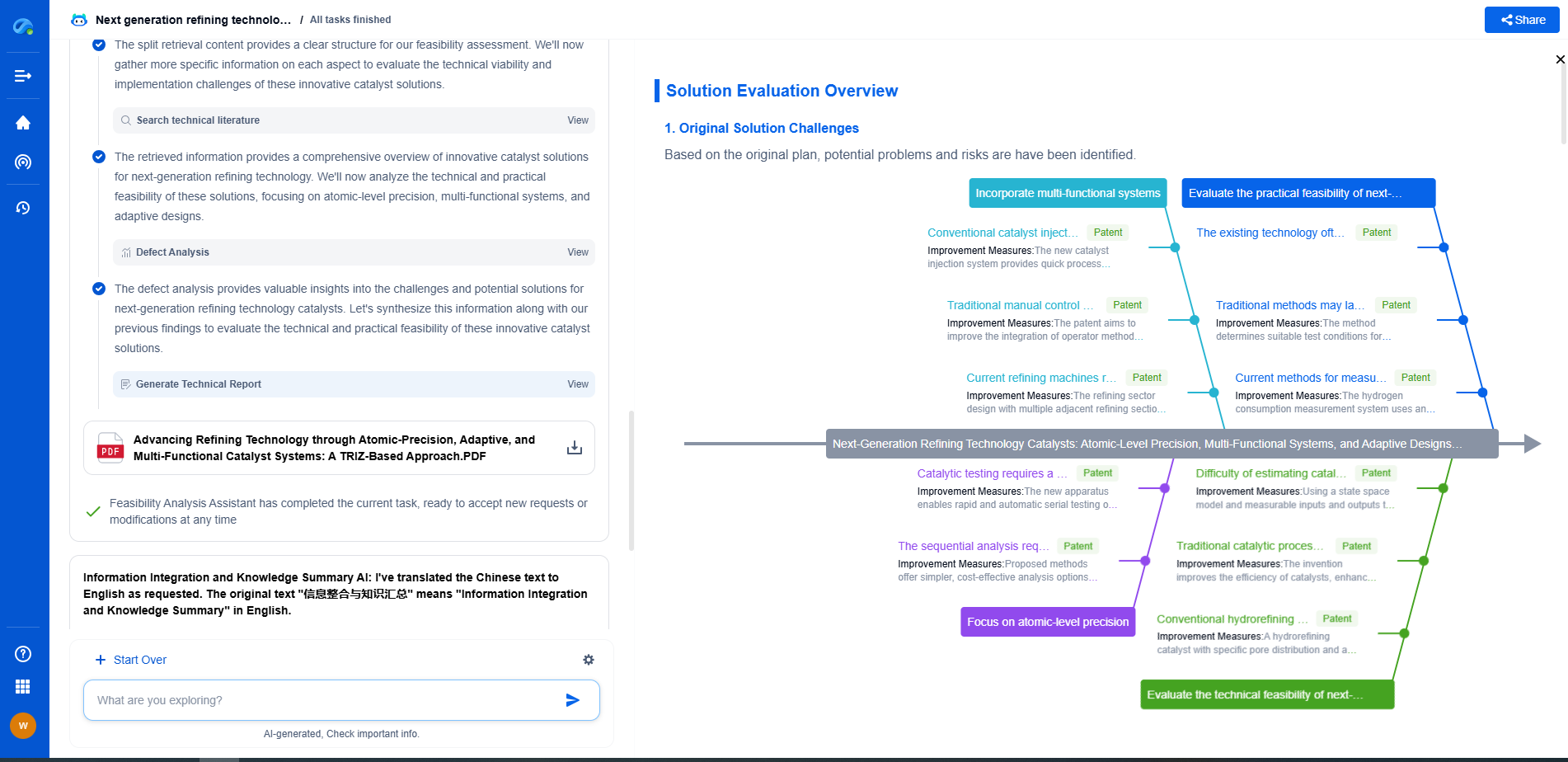

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com