PID Testing Controversy: Why 85°C/85% RH Doesn’t Match Real-World Conditions

JUL 22, 2025 |

Photovoltaic (PV) technology has become an integral part of the global shift towards renewable energy. However, like any technology, it faces challenges, one of which is potential-induced degradation (PID). PID can significantly affect the efficiency and lifespan of solar panels. To combat this, manufacturers have developed testing protocols to predict the durability and performance of PV modules. One such standard test is the 85°C/85% relative humidity (RH) test. Despite its widespread use, there is growing controversy surrounding this test's relevance to real-world conditions. This blog will delve into the reasons why this testing approach may not accurately reflect the environments solar panels typically encounter.

Understanding PID and Its Implications

Potential-induced degradation is a phenomenon where voltage stress leads to performance losses in solar modules. It is a crucial issue because it can lead to substantial efficiency reductions, impacting the return on investment for PV installations. Understanding the factors that contribute to PID is essential for developing effective mitigation strategies and ensuring the long-term reliability of solar panels.

The 85°C/85% RH Test: A Common Benchmark

The 85°C/85% RH test is a widely accepted standard in the industry for evaluating the potential durability of PV modules. The test subjects solar panels to a high-temperature, high-humidity environment to accelerate aging and identify vulnerabilities in module design and materials. The rationale is that by simulating extreme conditions, manufacturers can predict how their products will perform over time.

Limitations of the 85°C/85% RH Test

While the 85°C/85% RH test is a useful tool for identifying certain vulnerabilities, it has significant limitations when it comes to replicating real-world conditions. In actual installations, solar panels rarely encounter such consistent and extreme environments. Instead, they are subjected to varying temperatures, humidity levels, and other environmental factors such as wind, rain, and dust.

Furthermore, the static nature of the test fails to account for the dynamic stresses that panels undergo during daily temperature fluctuations and changes in humidity. These variable conditions can create different types of mechanical and chemical stresses, which may not be detected by the 85°C/85% RH test.

Real-World Conditions: A Complex Mix

In reality, the conditions that solar panels face are far more complex than those simulated in controlled testing environments. PV modules are exposed to a wide range of temperatures throughout the day and year, depending on their geographical location. They also face different humidity levels, which can vary significantly even over short periods.

Moreover, environmental factors like wind speed, dust accumulation, and precipitation can influence how solar panels degrade and perform. These conditions can lead to different types of wear and tear not adequately represented in the 85°C/85% RH test. As a result, relying solely on this test may lead to an incomplete understanding of a module's durability and performance.

The Need for Comprehensive Testing

Given the limitations of the 85°C/85% RH test, there is a growing consensus in the solar industry that more comprehensive testing protocols are needed. These should incorporate a broader range of environmental conditions and take into account the dynamic nature of outdoor environments. By developing testing methods that better mimic real-world conditions, manufacturers can gain a more accurate picture of how their products will perform over time.

Conclusion

The controversy surrounding the 85°C/85% RH test highlights the need for the solar industry to continually evolve its testing methodologies. While this test has been a valuable tool, it falls short of replicating the diverse and dynamic conditions that solar panels face in real-world installations. By adopting more comprehensive testing strategies, the industry can enhance the reliability and performance of PV modules, ensuring that they meet the demands of a rapidly growing renewable energy market.

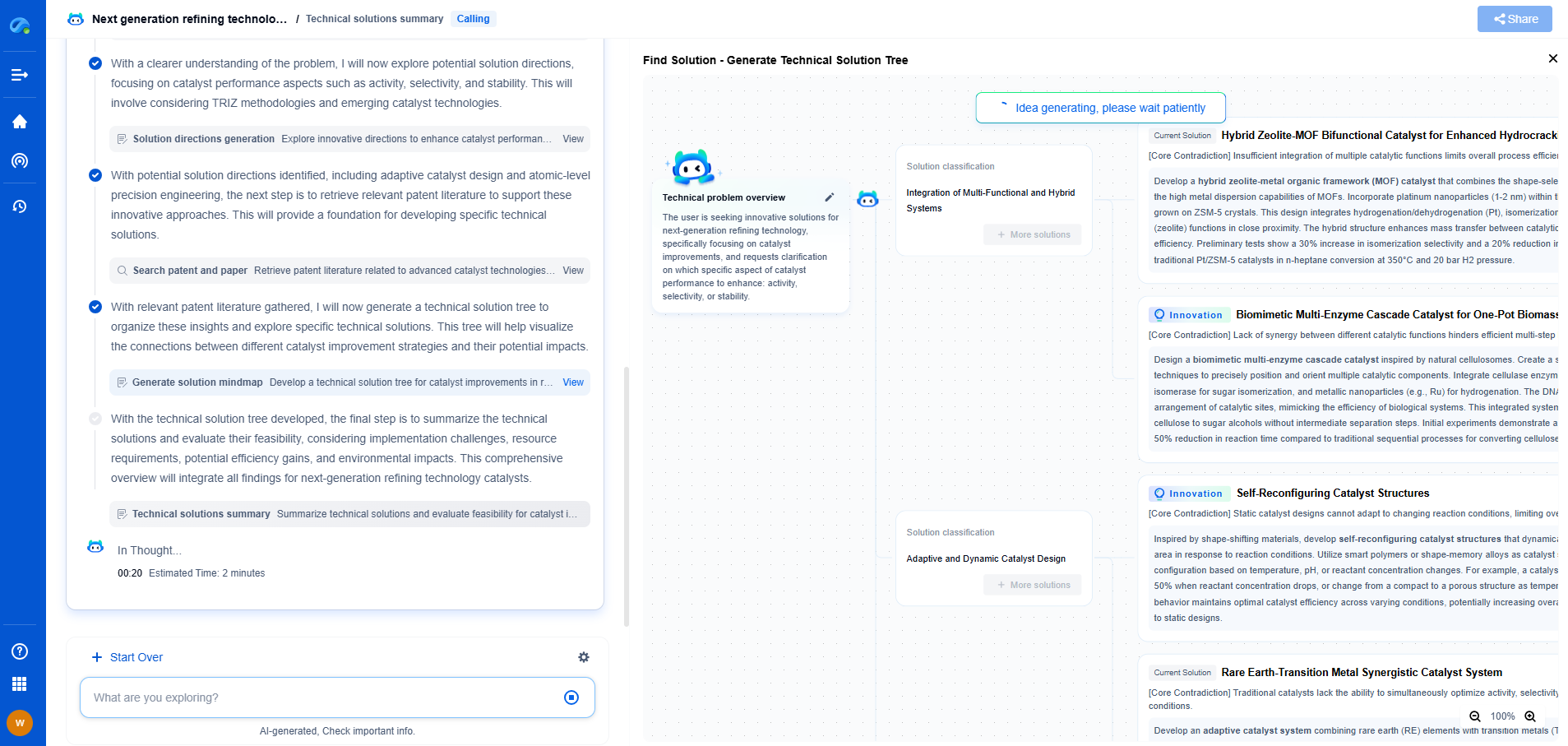

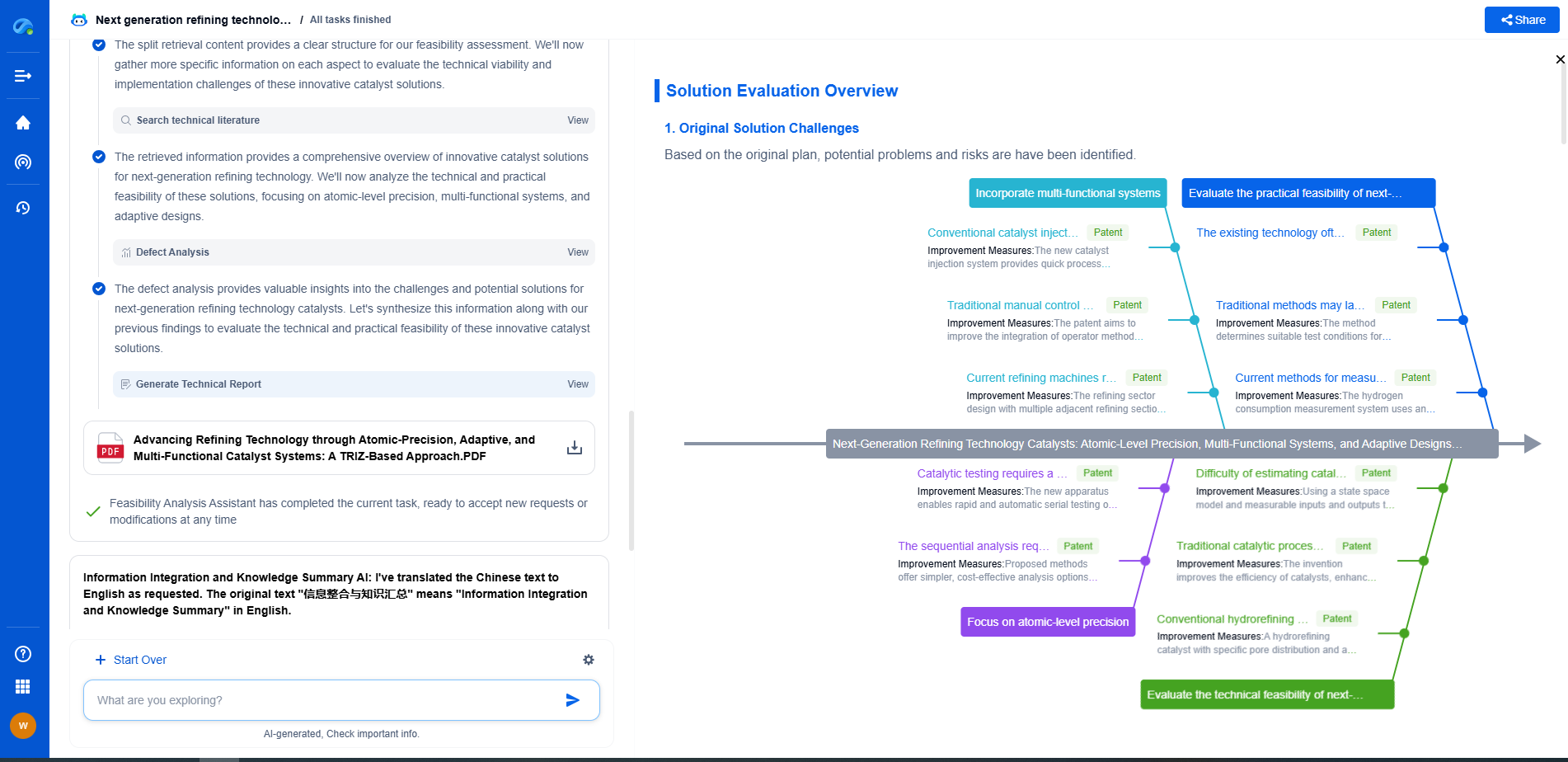

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com