Private 5G Networks: How Factories Are Going Wireless

JUN 27, 2025 |

In recent years, the advent of private 5G networks has marked a significant shift in the industrial landscape. As factories increasingly seek to enhance efficiency, safety, and productivity, wireless connectivity has emerged as a game-changer. This evolution is driven by the unparalleled speed, reliability, and low latency offered by 5G technology, which is now being tailored specifically to cater to the needs of manufacturing environments.

The Benefits of Going Wireless

Traditionally, factories have relied on wired networks or older wireless technologies that come with limitations in terms of scalability, flexibility, and speed. Private 5G networks address these issues by offering a robust platform for real-time data exchange and seamless communication between machines, systems, and personnel. The benefits of deploying private 5G networks in factories are abundant, including enhanced operational efficiencies, improved resource management, and the ability to quickly adapt to changing demands.

Implementing Smart Factory Solutions

One of the primary drivers for adopting private 5G networks is the implementation of smart factory solutions. Smart factories leverage the Internet of Things (IoT) devices, sensors, and automation systems to optimize production processes. With 5G's high-speed connectivity, factories can gather and analyze data from various sources instantaneously, allowing for predictive maintenance, quality control, and inventory management. This results in reduced downtime, increased productivity, and lowered operational costs.

Enhancing Safety and Security

Safety and security are paramount in manufacturing settings, and private 5G networks play a crucial role in enhancing both. With real-time monitoring and data transfer, factories can deploy advanced surveillance systems and safety protocols, ensuring a secure environment for workers. The low latency of 5G networks allows for immediate response to safety incidents, potentially preventing accidents and hazards. Additionally, private 5G networks offer better protection against cyber threats, as they are designed to operate independently from public networks.

Customization and Flexibility

Unlike public 5G networks, private 5G networks are customizable to meet the specific needs of a factory. This flexibility allows businesses to tailor the network architecture, bandwidth, and coverage to suit their unique operational requirements. Factories can prioritize critical applications and allocate resources efficiently, ensuring optimal performance and reliability. The ability to scale the network as the business grows further adds to the appeal of private 5G networks in the manufacturing sector.

Challenges to Overcome

Despite the numerous advantages, the implementation of private 5G networks is not without challenges. The initial setup and deployment costs can be significant, requiring substantial investment. Moreover, the integration of 5G technology with existing systems and infrastructure may pose technical challenges. Factories need to ensure that their workforce is adequately trained to manage and operate the new network. Addressing these challenges requires careful planning, strategic partnerships, and ongoing support from technology providers.

The Future of Manufacturing

The transition to private 5G networks is set to revolutionize the manufacturing industry. As technology continues to evolve, factories are likely to see even more advanced applications emerging, such as augmented reality (AR) for remote assistance, more sophisticated robotics, and AI-driven analytics. The integration of these technologies will lead to smarter, more efficient manufacturing processes, thereby enhancing competitiveness in the global market.

Conclusion

Private 5G networks are paving the way for factories to go wireless, offering unprecedented opportunities for innovation and improvement. By embracing this technology, manufacturers can achieve greater operational efficiencies, enhance safety and security, and customize their networks to meet specific needs. While challenges remain, the potential rewards are immense, promising a bright future for the manufacturing industry as it continues to evolve in the wireless era.

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

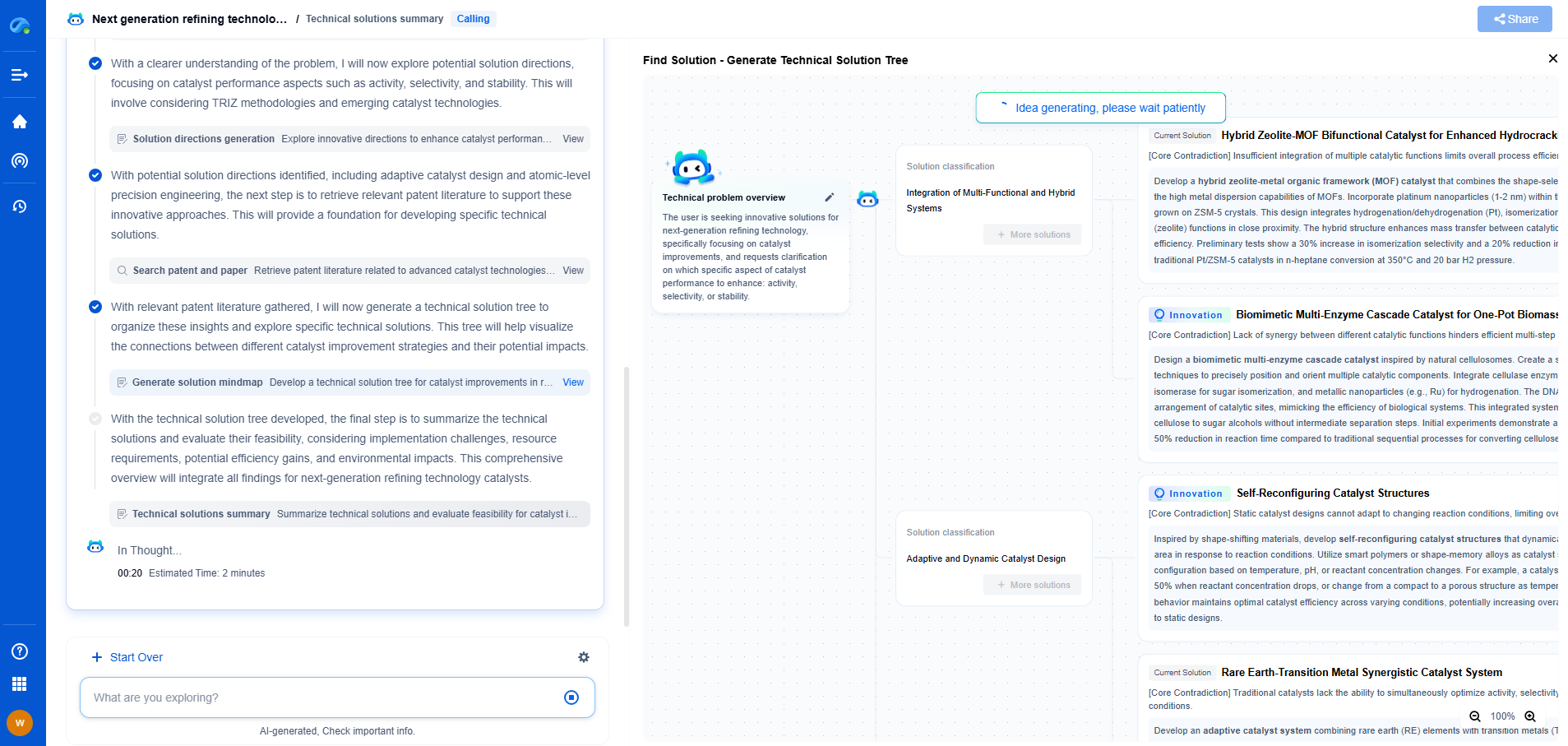

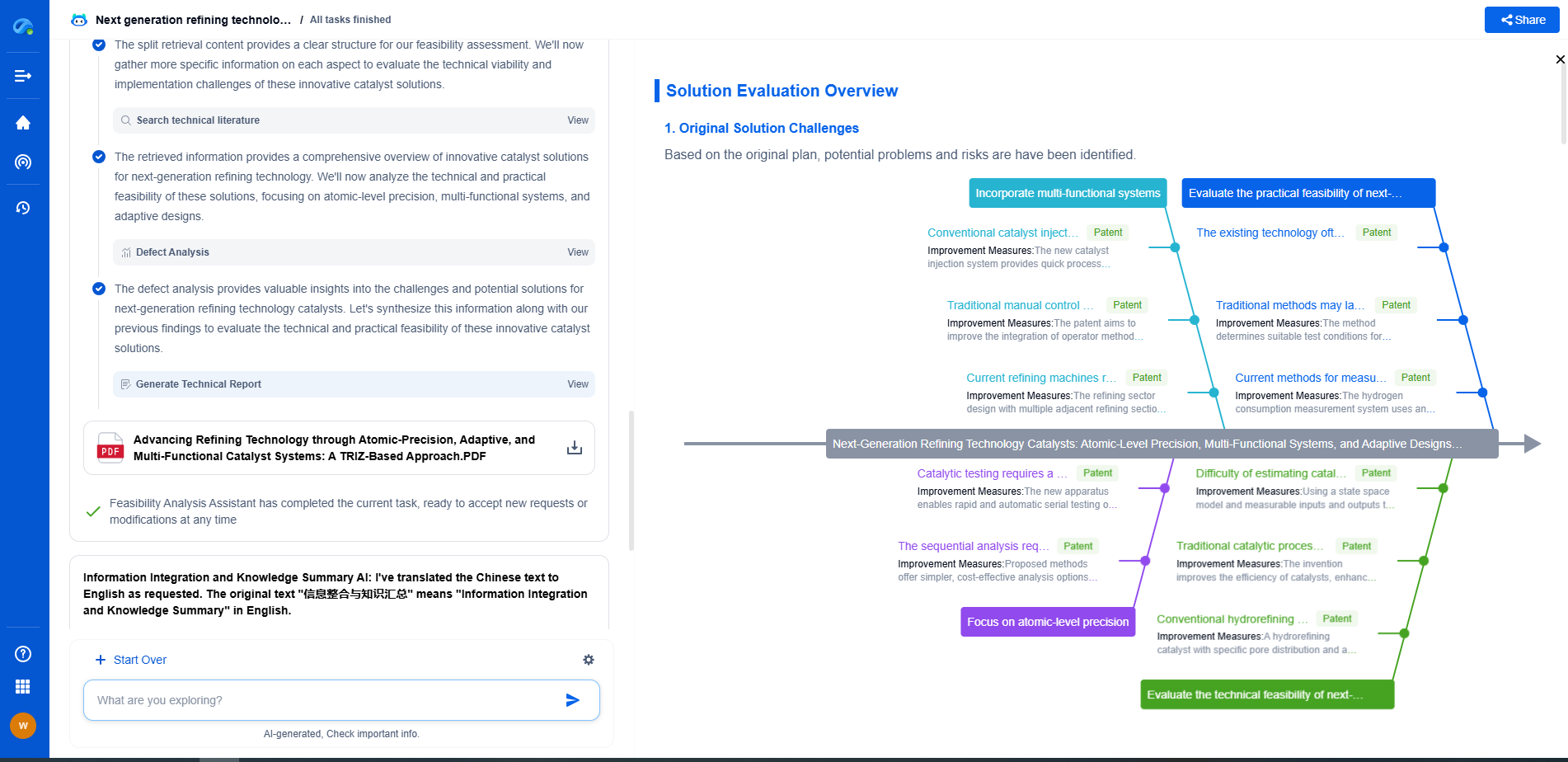

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com