Rotary and static UPS (Uninterruptible Power Supply) systems differ in design and application. Rotary UPS uses rotating machinery (typically flywheels and generators) to provide power, offering high fault tolerance, better performance in harsh environments, and longer life spans. Static UPS relies on electronic components (like inverters and batteries), is more compact, efficient at low loads, and ideal for data centers. Rotary systems suit industrial and mission-critical applications, while static systems are preferred for IT and office environments.

Reliability Considerations

Reliability is a fundamental factor when choosing between rotary and static UPS systems. Rotary UPS systems, which use a combination of mechanical and electrical components, are typically renowned for their robust and durable nature. Their design allows them to handle substantial power loads and offer protection against various power disturbances, such as sags, surges, and harmonics. The mechanical inertia of rotary systems provides a natural buffer during power transitions, reducing the risk of failure.

Static UPS systems, on the other hand, rely entirely on solid-state electronics. They are known for their quick response times and precision. Static systems are particularly effective in environments where power fluctuations are frequent, offering consistent performance and reduced risk of power interruptions. However, the reliance on electronic components means that static systems can be more susceptible to electronic failures, which could affect their reliability over time.

Maintenance Costs

Maintenance costs are another critical consideration for businesses weighing the options between rotary and static UPS systems. Rotary systems often require more extensive maintenance due to their mechanical components, such as bearings and brushes, which are subject to wear and tear. Regular inspections and part replacements are necessary to ensure optimal performance, which can lead to higher maintenance costs over the system's lifespan.

In contrast, static UPS systems generally have lower maintenance requirements. With fewer moving parts, the need for regular mechanical maintenance is minimized. However, they still require periodic checks of batteries and electronic components to maintain reliability. While upfront maintenance costs may be lower, static systems can incur significant expenses if electronic components fail and need replacement.

Energy Efficiency and Operating Costs

Energy efficiency is another factor that can influence the choice between rotary and static UPS systems. Rotary UPS systems are often less energy-efficient compared to their static counterparts. The mechanical elements in rotary systems typically consume more energy, leading to higher operating costs.

Static UPS systems are generally more energy-efficient, utilizing advanced technologies to minimize power losses. Their design allows for more efficient power conversion and distribution, resulting in lower energy consumption and reduced operating costs over time. This efficiency can translate into significant savings for businesses, particularly those with large-scale operations requiring extensive power protection.

Suitability for Different Applications

The suitability of UPS systems for different applications is influenced by the specific needs of a business. Rotary UPS systems are often preferred in environments where heavy industrial loads are common, given their ability to handle high power capacities and resist mechanical stress. They are ideal for data centers, manufacturing plants, and facilities with critical operations that must remain uninterrupted.

Static UPS systems are often chosen for environments where precision and quick response times are essential. They are well-suited for office settings, small to medium-sized businesses, and applications where space is a constraint. Their compact size and quiet operation make them an attractive option for these environments.

Conclusion

In the debate between rotary and static UPS systems, the choice ultimately depends on a business's specific needs and priorities. Rotary systems offer robust reliability and are suitable for handling heavy loads, but they come with higher maintenance and operating costs. Static systems provide excellent energy efficiency and lower maintenance requirements but may have limitations in handling substantial industrial loads.

When deciding between these two systems, businesses should consider factors such as reliability needs, maintenance budgets, energy efficiency goals, and the specific requirements of their operations. By carefully evaluating these factors, businesses can choose the UPS system that best aligns with their long-term operational and financial objectives.

Rotary vs Static UPS Systems: Reliability & Maintenance Costs

JUN 26, 2025 |

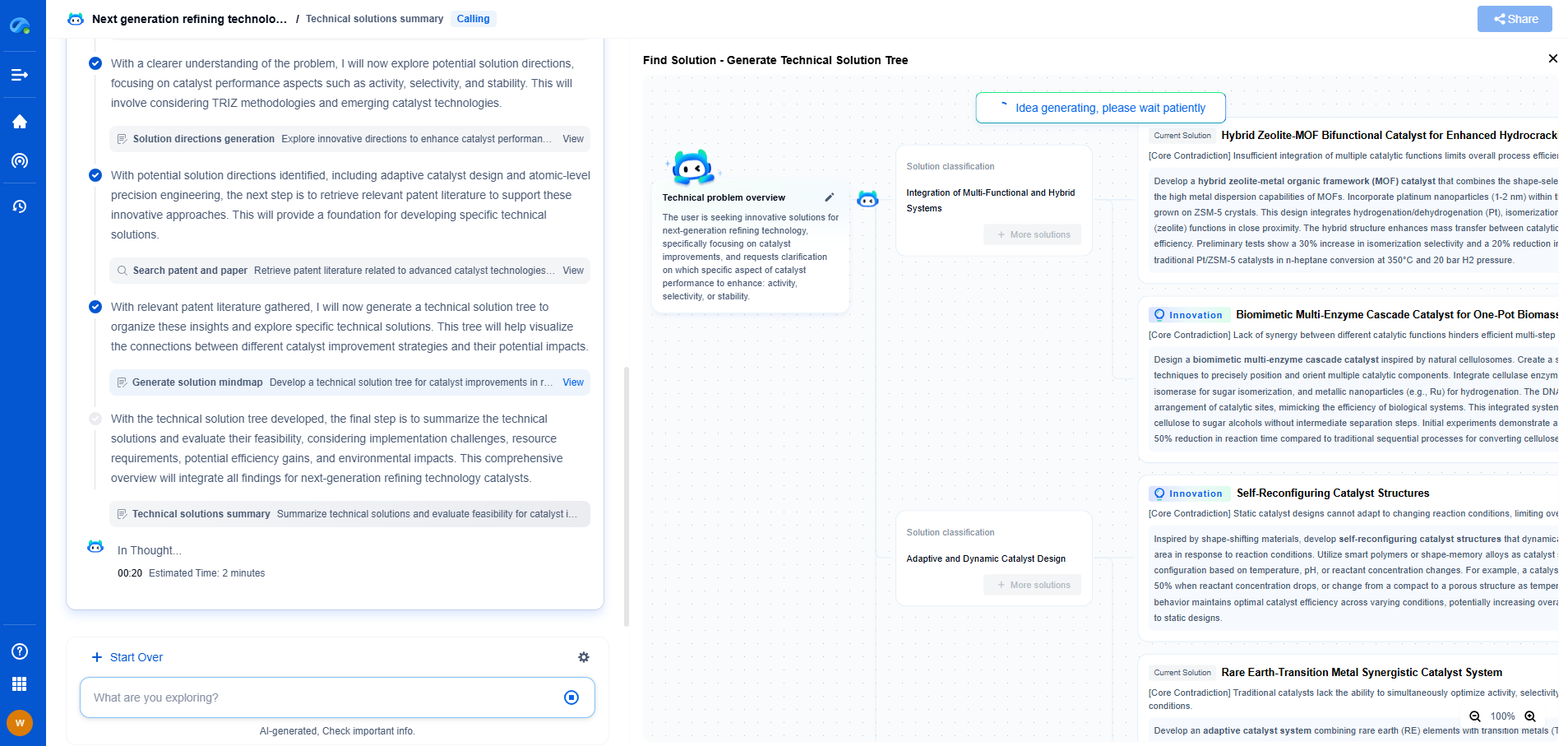

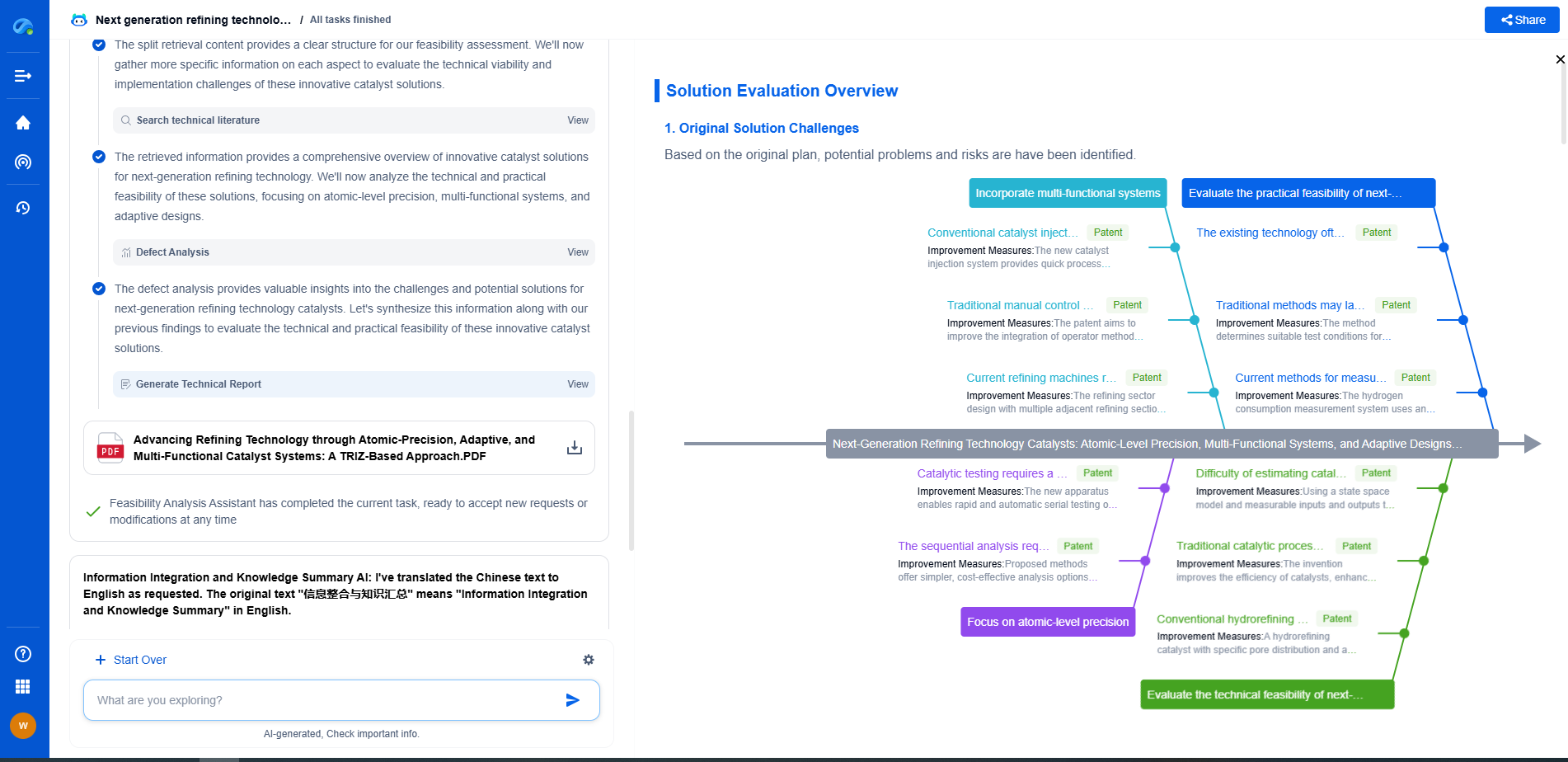

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com