Semiconductor Fabrication Process: From Wafer to Chip

JUN 27, 2025 |

The semiconductor fabrication process is a fascinating journey that transforms a simple silicon wafer into a sophisticated microchip. This highly intricate procedure involves numerous steps, each critical to ensuring that the final product performs its intended functions with precision. Let's delve deeper into this process and explore how wafers become the chips powering modern technology.

Starting with the Silicon Wafer

The journey begins with the creation of a silicon wafer. Silicon, which is abundant and has excellent semiconductor properties, is the preferred material. The process starts with the growth of a large crystal of silicon, known as an ingot. This is achieved through a method called the Czochralski process, where a seed crystal is dipped into molten silicon and slowly pulled upwards while rotating, forming a cylindrical ingot.

The ingot is then sliced into thin discs, known as wafers, using a diamond saw. These wafers are polished to create a smooth, defect-free surface ideal for the subsequent photolithography and etching processes. The typical thickness of a wafer is about 0.75mm, although this can vary depending on the specific application and technology node.

Photolithography: The Art of Patterning

Photolithography is the cornerstone of semiconductor manufacturing, a process that allows for creating intricate circuit patterns on the wafer. It begins with the application of a light-sensitive material called photoresist onto the wafer. The wafer is then exposed to ultraviolet light through a mask that contains the desired circuit pattern. This exposure causes the photoresist to harden in the exposed areas.

The next step is to develop the wafer, which removes the unexposed photoresist, leaving behind the hardened pattern. This pattern will guide subsequent processes that define the chip's architecture. As technology advances, the industry continually pushes the limits of photolithography to produce smaller and more complex patterns, enabling the creation of increasingly powerful chips.

Etching: Carving the Pathways

Following photolithography, the wafer undergoes etching, a process that removes material from the wafer to create the necessary circuit pathways. There are two main types of etching: wet etching, which uses chemical solutions to dissolve unwanted material, and dry etching, which employs gases or plasma to achieve the same goal.

Etching is a highly precise process, as it must only remove material from specific areas defined by the photoresist pattern. This step is crucial for forming the intricate network of transistors and interconnections that define a chip's functionality. Any errors at this stage can severely impact the chip's performance or render it unusable.

Doping: Tailoring Electrical Properties

To tailor the electrical properties of the silicon, the wafer undergoes a process known as doping. This involves introducing impurities into the silicon to modify its conductivity. Common dopants include boron, phosphorous, and arsenic.

Doping can be done using ion implantation, where ions of the dopant are accelerated and embedded into the wafer, or diffusion, where the wafer is exposed to a dopant gas at high temperatures. The choice of dopant and concentration levels is carefully controlled to ensure that the transistors function correctly, enabling the chip to perform various logical operations.

Interconnects and Metallization

Once the transistors are formed, they need to be connected to create functional circuits. This is achieved through a process called metallization, where layers of metal are deposited on the wafer to form interconnects. These interconnects are essential for allowing electrical signals to travel across the chip.

Copper and aluminum are commonly used metals for interconnects, chosen for their conductivity and reliability. The metal layers are added through a process known as physical vapor deposition or chemical vapor deposition, followed by another round of photolithography and etching to define the precise pathways.

Final Steps: Testing and Packaging

After the circuit formation is complete, the wafer undergoes a series of rigorous tests to ensure that each chip performs as expected. These tests include electrical and functional checks to identify any defects or failures at an early stage. Once the chips pass these tests, the wafer is cut into individual dies.

The final step is packaging, where each die is encased in a protective housing and provided with connectors. This packaging is crucial for protecting the chip from physical damage and environmental factors while enabling it to be easily integrated into electronic devices.

Conclusion

The semiconductor fabrication process is a marvel of modern engineering, requiring precision, expertise, and cutting-edge technology. From a humble silicon wafer to a complex microchip, each step in this process is essential to realizing the powerful and efficient electronics we rely on every day. As technology continues to advance, the methods and materials involved in semiconductor fabrication will undoubtedly evolve, paving the way for even more remarkable innovations.

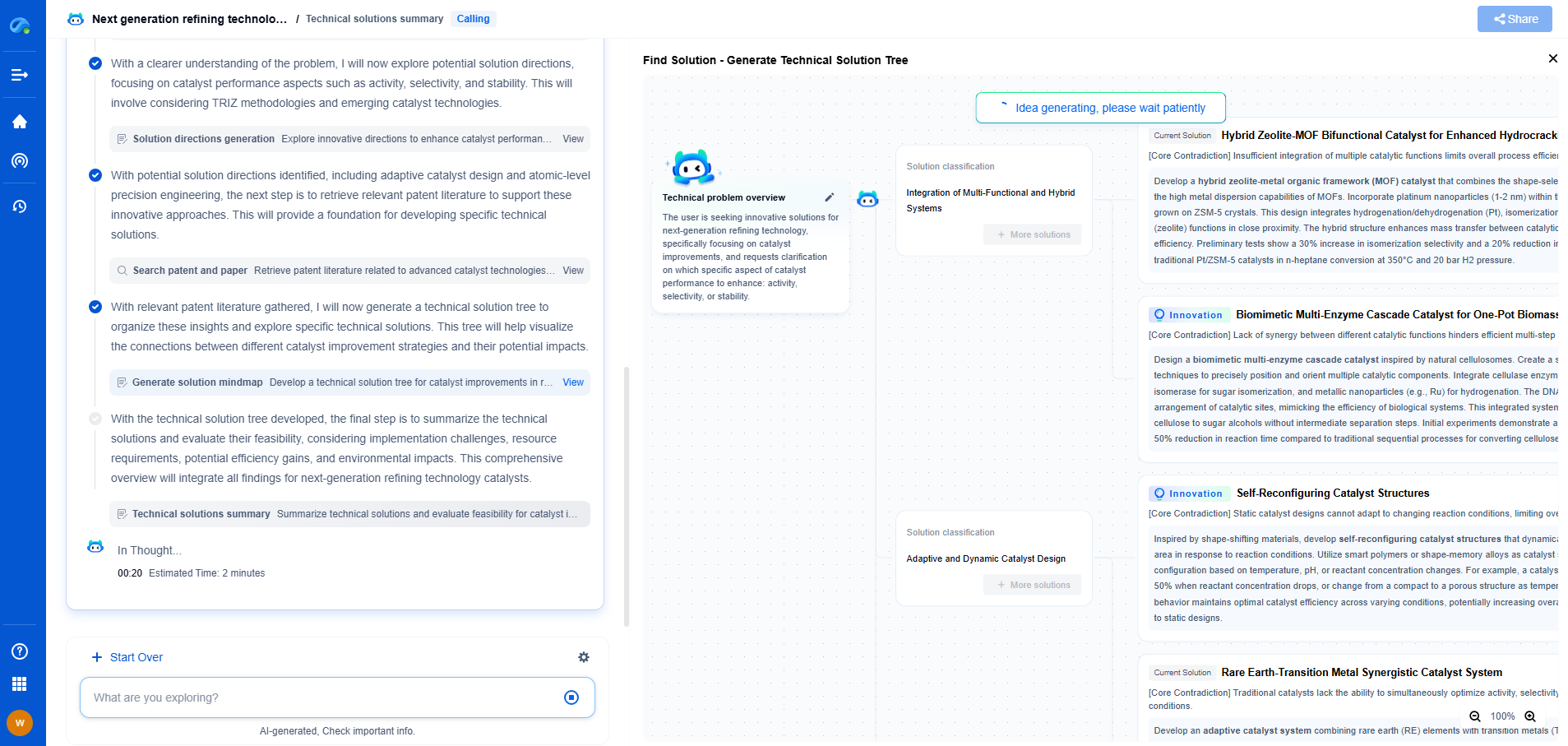

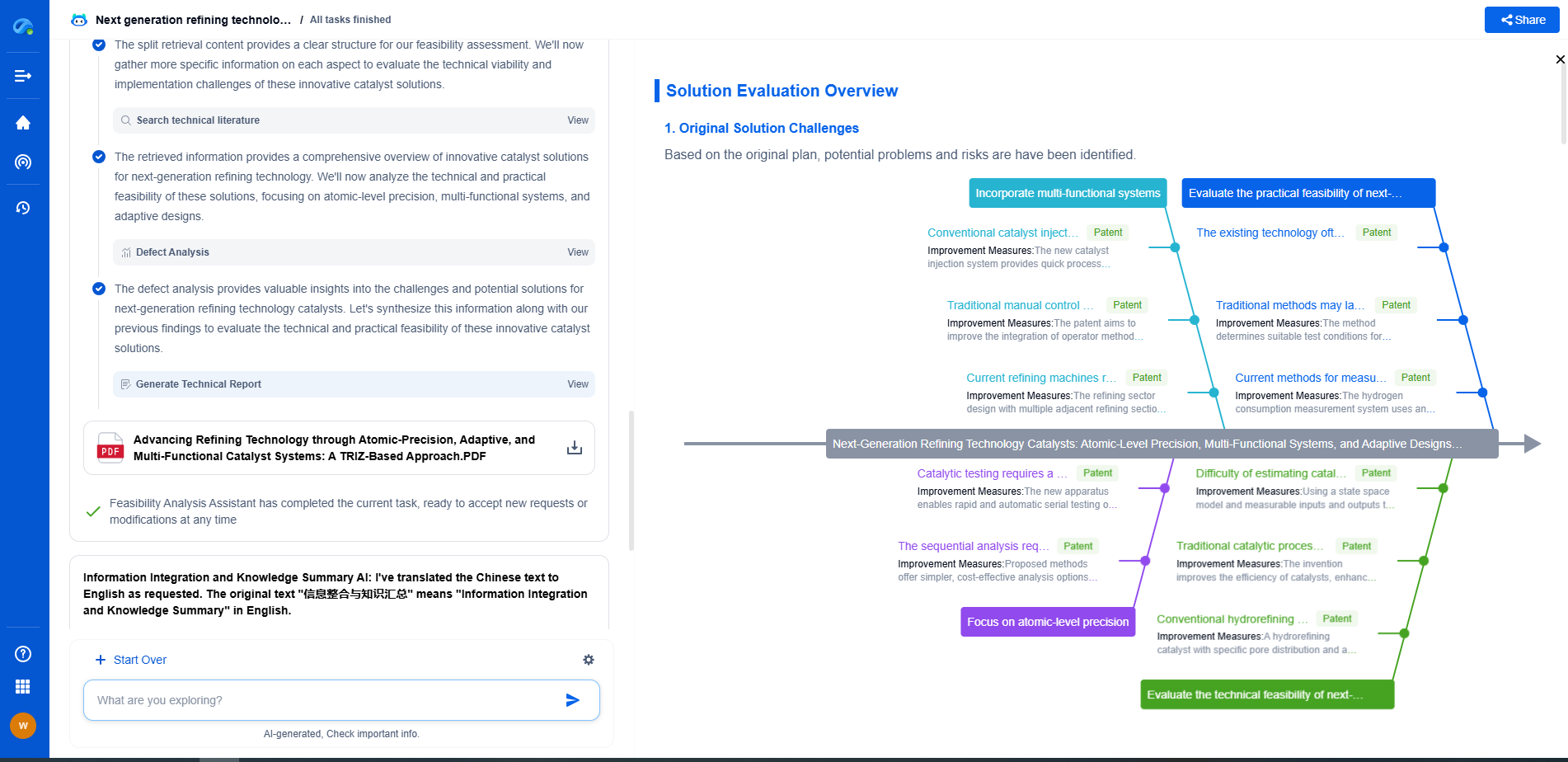

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com