Shoot-Through Current in H-Bridges: Prevention Methods

JUN 27, 2025 |

To grasp the importance of preventing shoot-through current in H-bridges, it's essential to first understand what it is and why it poses a significant problem in electrical circuits. H-bridges are fundamental components used in motor control and power conversion applications. They consist of four switches arranged in an H-like configuration to control the direction of current flow through a load. However, if two switches in the same leg of the bridge conduct simultaneously, this results in a short circuit, known as shoot-through current, which can damage components and reduce efficiency.

Causes of Shoot-Through Current

Shoot-through current typically occurs due to timing errors in the control signals of the switches, often caused by simultaneous activation or inadequate dead-time settings. Dead-time refers to the intentional delay introduced between the switching off of one transistor and the switching on of another, crucial for preventing shoot-through. Without adequate dead-time, both transistors might conduct simultaneously, leading to a direct path for current flow from the power supply to ground, bypassing the load entirely.

Impacts on Circuit Performance

The presence of shoot-through current can have devastating impacts on circuit performance. It leads to overheating, increased power losses, and potential damage to the semiconductor devices within the bridge. Moreover, it can cause erratic behavior in motor control applications, reducing the precision and reliability of the system. Understanding and mitigating shoot-through is crucial for maintaining the integrity and efficiency of H-bridge circuits.

Prevention Methods

Dead-Time Insertion

One effective method for preventing shoot-through current is the insertion of dead-time in the control signal timing. This involves programming a delay between the turn-off of one switch and the turn-on of the next. Dead-time is crucial in ensuring that no two switches in the same leg are conducting simultaneously. The correct amount of dead-time depends on the specific characteristics of the transistors used and the overall speed requirements of the application.

Gate Driver Design

The design of gate drivers plays a critical role in preventing shoot-through current. A well-designed gate driver can manage the timing and sequencing of switch activation to ensure that there is no overlap in conduction periods. High-performance gate drivers can rapidly charge and discharge the gate capacitance, allowing for precise control over switch timings. Additionally, integrating protection features like desaturation detection can further enhance reliability.

Current Sensing and Feedback

Implementing current sensing mechanisms can aid in detecting shoot-through conditions early. By continuously monitoring the current flow through the H-bridge, systems can be designed to take corrective action should shoot-through occur. Feedback loops can automatically adjust control signals to reduce the risk of shoot-through, enhancing the robustness of the system.

Switching Speed and Component Selection

The choice of switching components also significantly impacts the likelihood of shoot-through. Using transistors with fast switching speeds can help reduce the risk of overlap in conduction times. Furthermore, selecting components that can withstand higher current levels can mitigate damage should shoot-through occur unexpectedly.

Conclusion

Preventing shoot-through current in H-bridges is vital to ensuring the longevity and efficacy of electronic circuits used in motor control and power conversion applications. By understanding the causes and impacts of this phenomenon, and by employing prevention methods such as dead-time insertion, thoughtful gate driver design, current sensing, and careful component selection, engineers can safeguard their systems against the detrimental effects of shoot-through. These strategies not only enhance the performance and reliability of H-bridges but also contribute to the broader goal of efficient and sustainable electronic design.

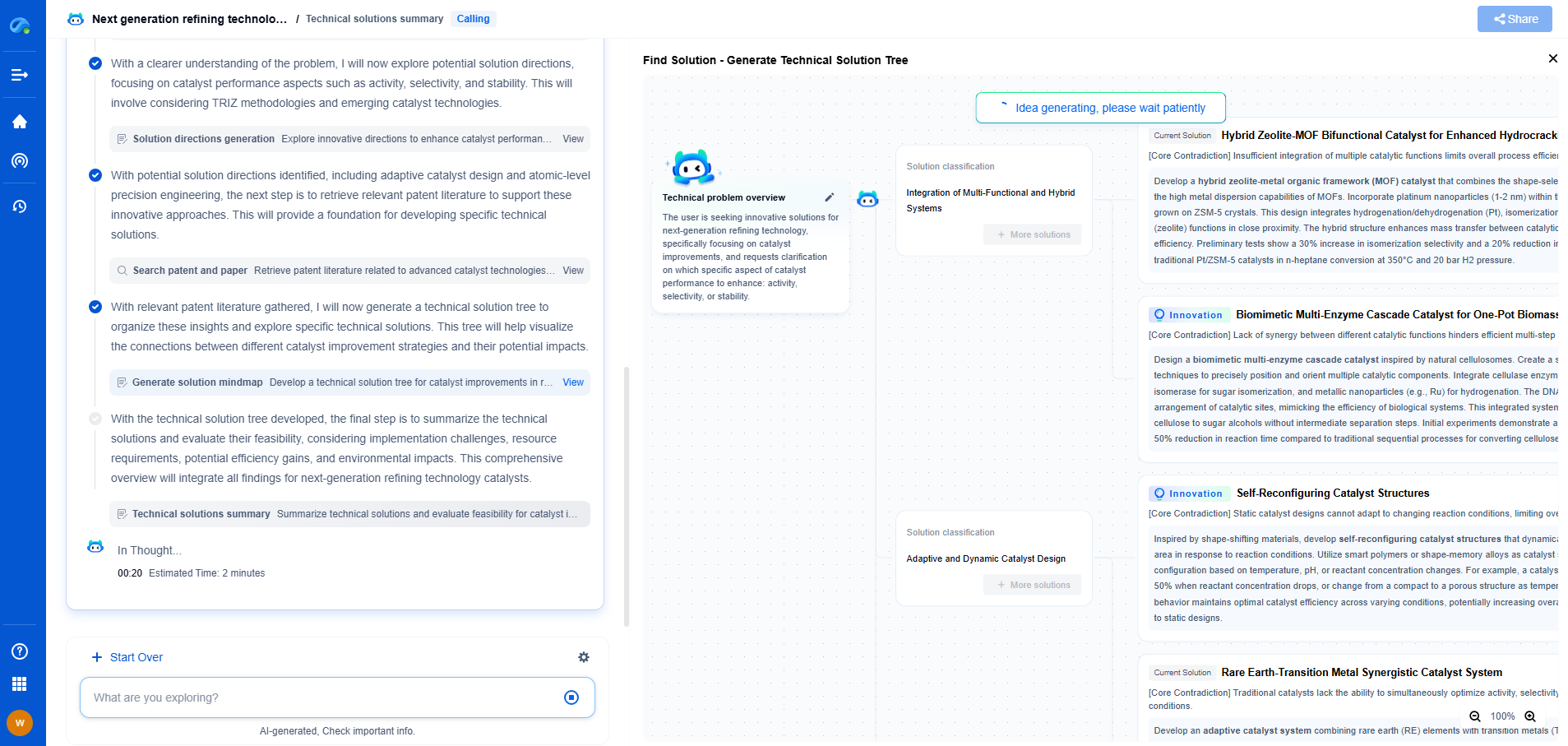

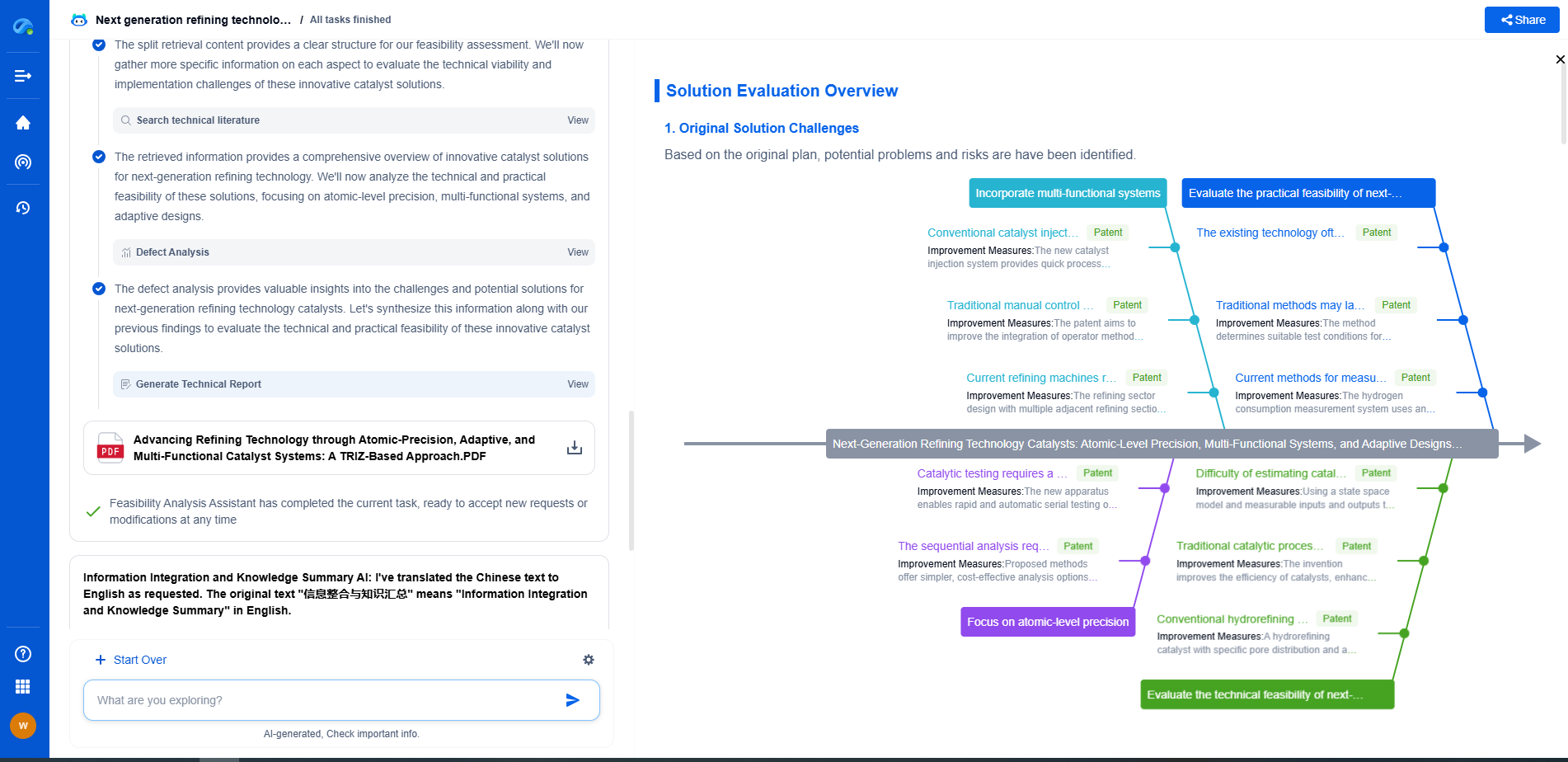

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com