Standardization vs Customization in Industrial PSUs

JUN 26, 2025 |

In today's rapidly evolving industrial landscape, public sector undertakings (PSUs) face the challenging task of balancing standardization and customization. As these organizations strive to enhance efficiency, reduce costs, and meet diverse customer needs, it is crucial to understand the merits and drawbacks of each approach and find a harmonious equilibrium that leverages both strategies.

The Case for Standardization

Standardization refers to the establishment of common standards and practices across processes, products, and services. In industrial PSUs, this approach offers several advantages:

1. **Cost Efficiency**: By standardizing processes and components, PSUs can achieve economies of scale, reducing production costs and minimizing waste. Bulk purchasing of standardized materials often leads to discounts, further lowering operational expenses.

2. **Quality Consistency**: Standardization ensures uniformity in product quality. With set protocols and guidelines, PSUs can maintain a consistent level of quality across their offerings, fostering customer trust and satisfaction.

3. **Simplified Training**: When processes are standardized, training new employees becomes more straightforward and time-efficient. This uniformity ensures that workers across different regions or units have the same knowledge base and skill set.

4. **Regulatory Compliance**: In industries with stringent regulatory requirements, standardization helps ensure compliance with laws and regulations, reducing the risk of legal issues and penalties.

However, standardization is not a one-size-fits-all solution. It can hinder innovation, limit flexibility, and, at times, fail to meet specific customer demands.

The Need for Customization

Customization involves tailoring products and services to meet the unique needs of individual customers or market segments. This approach is essential for PSUs operating in diverse and dynamic environments:

1. **Enhanced Customer Satisfaction**: By offering customized solutions, PSUs can address specific customer preferences and requirements, leading to higher satisfaction and loyalty.

2. **Competitive Advantage**: In a competitive market, the ability to provide bespoke solutions can differentiate a PSU from its competitors, attracting new clients and retaining existing ones.

3. **Adaptability to Market Changes**: Customization allows PSUs to quickly adapt to shifts in market demands and technological advancements, ensuring they remain relevant and competitive.

4. **Innovation Encouragement**: A focus on customization encourages creativity and innovation within the organization as employees strive to develop unique solutions for customer challenges.

However, customization can lead to increased complexity and higher costs, potentially impacting the organization's efficiency and profitability.

Striking the Right Balance

For industrial PSUs, the key to success lies in finding the right balance between standardization and customization. This involves a strategic approach that leverages the strengths of both methodologies while mitigating their weaknesses.

1. **Segmentation Strategy**: PSUs can adopt a segmentation strategy, identifying which aspects of their operations benefit from standardization and which require customization. For instance, core components and processes can be standardized to ensure efficiency and quality, while customer-facing elements can be customized to enhance satisfaction.

2. **Modular Approach**: By implementing a modular approach, PSUs can standardize certain parts of their products or services, allowing for easy customization of other elements. This provides the flexibility to cater to diverse customer needs without sacrificing efficiency.

3. **Technology Integration**: Leveraging advanced technologies, such as data analytics and artificial intelligence, can help PSUs predict market trends and customer preferences, enabling them to tailor their offerings effectively while maintaining standardized processes.

4. **Continuous Feedback Loop**: Establishing a continuous feedback loop with customers allows PSUs to gather insights into their needs and preferences, ensuring that the balance between standardization and customization evolves with market demands.

Conclusion: A Dynamic Equilibrium

In the realm of industrial PSUs, both standardization and customization play vital roles. A dynamic equilibrium between the two can unlock significant value, driving efficiency, quality, and customer satisfaction. By carefully assessing their unique needs and leveraging strategic approaches, PSUs can harness the full potential of both standardization and customization, ensuring sustainable growth and competitiveness in an ever-changing industrial landscape.

Stay Ahead in Power Systems Innovation

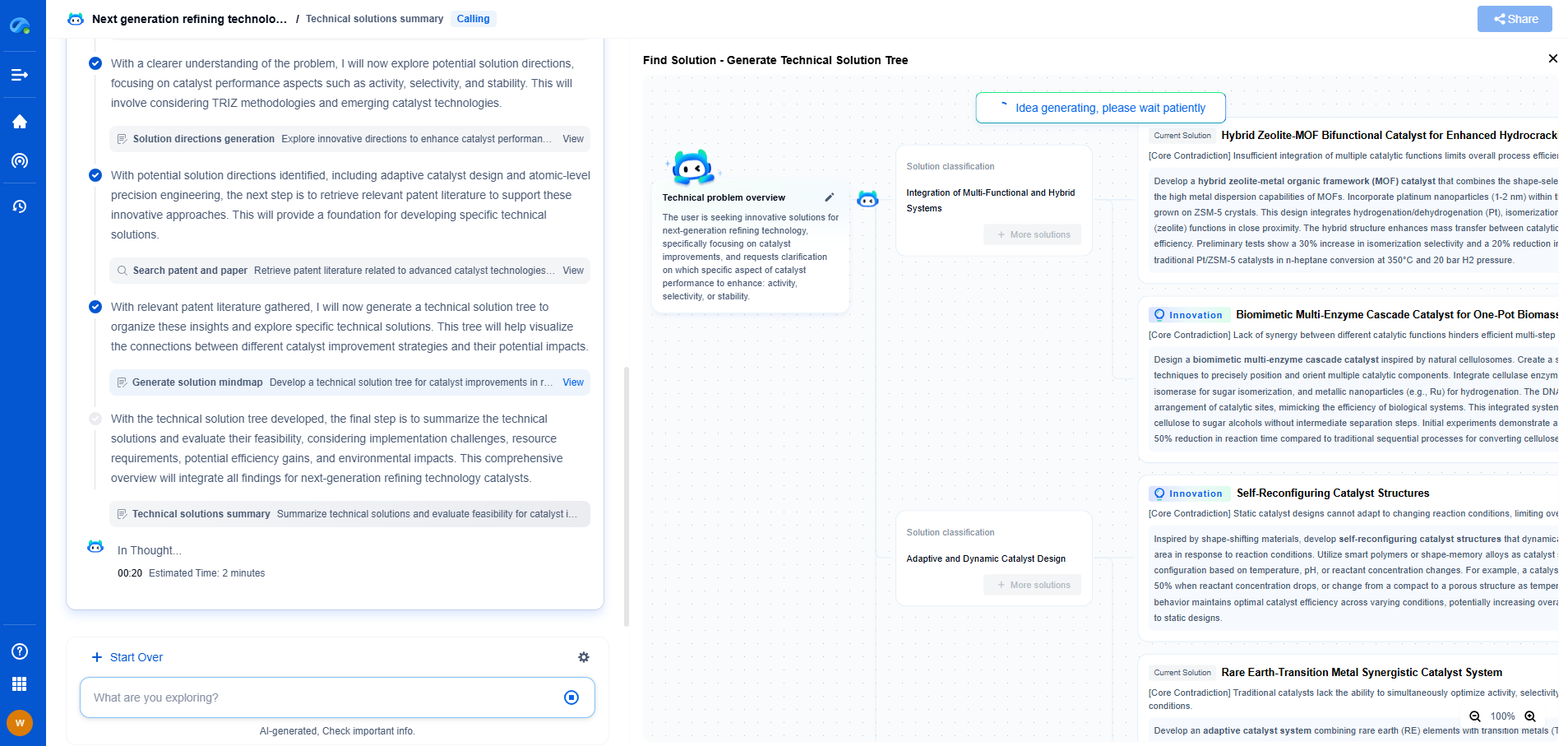

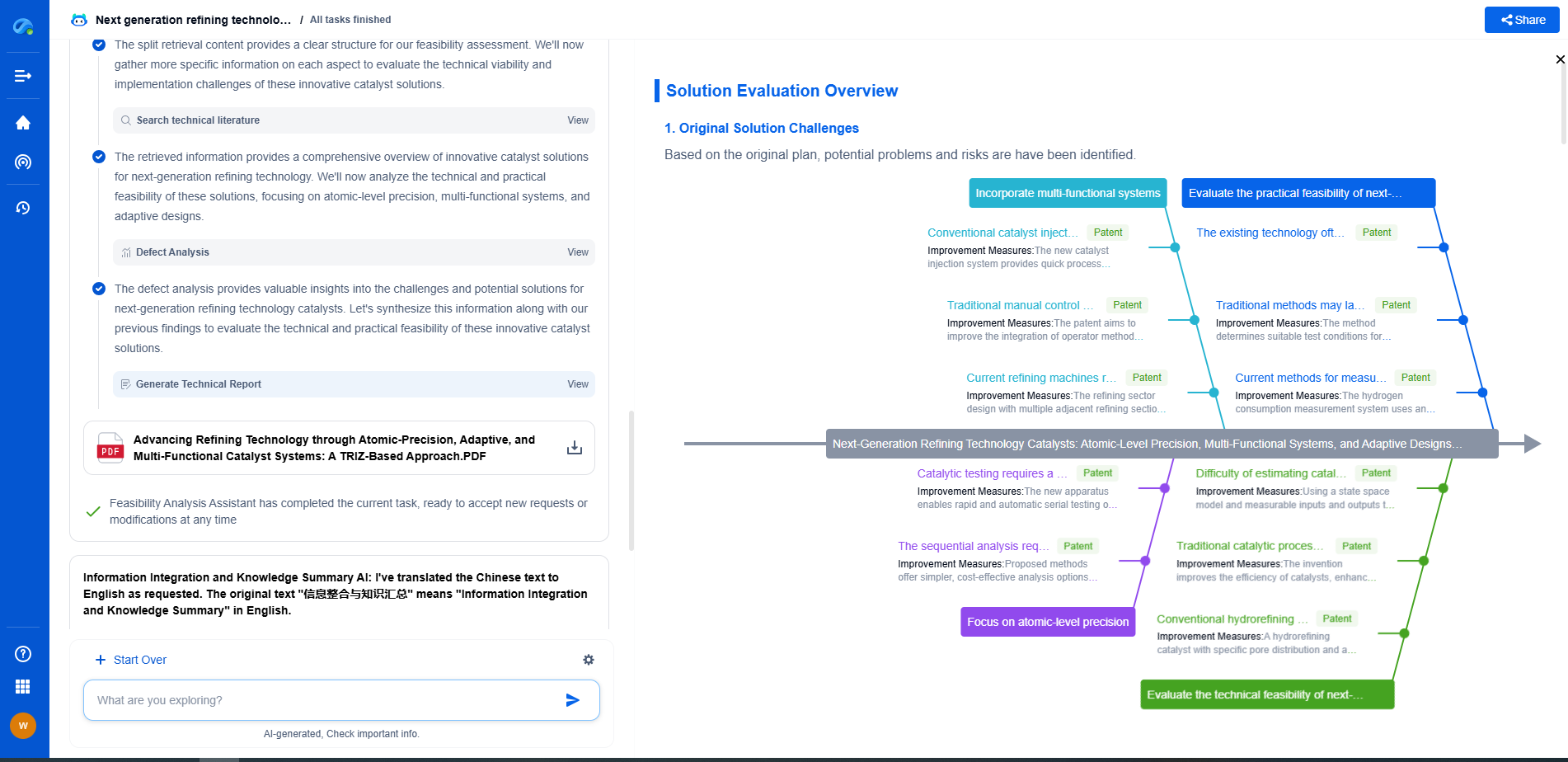

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com