Through-Hole vs. Surface Mount Devices: PCB Design Implications

JUN 27, 2025 |

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing the platform for mounting and connecting various electronic components. Two prominent mounting technologies utilized in PCB design are Through-Hole Technology (THT) and Surface Mount Technology (SMT). Each has distinct implications for design, functionality, and manufacturing, influencing how engineers approach the creation of electronic circuits.

Understanding Through-Hole Technology

Through-Hole Technology involves inserting component leads into pre-drilled holes on the PCB and soldering them to pads on the opposite side. Components used in THT are typically larger and include resistors, capacitors, inductors, and integrated circuits with leads. This method of mounting provides robust mechanical bonds, making it highly reliable for applications where stress or vibration is a concern, such as in automotive and industrial electronics.

Advantages of Through-Hole Technology

1. Mechanical Strength: The physical connection of components through the board offers greater durability and resistance to mechanical stress, making it suitable for high-power and high-voltage applications.

2. Ease of Prototyping: Through-hole components are easier to handle and replace, facilitating prototyping and testing phases where frequent changes may be needed.

3. Thermal Management: Through-hole components often provide better thermal performance due to their larger size and direct connection through the PCB.

Limitations of Through-Hole Technology

1. Space Inefficiency: Through-hole components require more space, limiting the density of the board and making it challenging to design compact devices.

2. Higher Production Costs: The drilling process and manual assembly involved in THT tend to increase manufacturing time and cost.

Surface Mount Technology Explained

Surface Mount Technology revolutionized PCB design by allowing components to be mounted directly onto the surface of the board. SMT components are typically smaller than their through-hole counterparts, enhancing design flexibility and enabling more intricate circuit layouts. This technology is prevalent in modern electronics, from smartphones to laptops, where compactness and weight are crucial.

Advantages of Surface Mount Technology

1. Space Efficiency: The small size of SMT components allows for higher component density, leading to more compact and lightweight devices.

2. Automated Manufacturing: SMT supports automated assembly processes, reducing labor costs and improving production speed.

3. Enhanced Performance: The shorter leads of SMT components reduce parasitic inductance and capacitance, enhancing signal integrity and enabling higher frequency operation.

Challenges of Surface Mount Technology

1. Mechanical Vulnerability: SMT components lack the mechanical strength of through-hole counterparts, making them less suitable for applications subject to high stress or vibration.

2. Difficult Prototyping: Due to their small size, SMT components can be challenging to handle and replace, complicating the prototyping process.

3. Thermal Considerations: SMT may pose thermal management challenges, requiring careful design to dissipate heat effectively, especially in high-power applications.

Design Implications in PCB Development

Choosing between THT and SMT involves careful consideration of the design requirements and application goals. Engineers must evaluate factors such as device size, power requirements, environmental conditions, and manufacturing capabilities.

Design Flexibility and Miniaturization

The choice of SMT enables greater design flexibility, allowing for miniaturization of devices without compromising functionality. This is crucial in consumer electronics, where compactness is a competitive advantage.

Cost and Time Efficiency

SMT's compatibility with automated processes translates to cost and time savings, making it ideal for large-scale production. In contrast, THT may be preferred for small batches or specialized applications where mechanical strength is paramount.

Reliability and Performance

Applications demanding high reliability and performance, such as aerospace and medical devices, may benefit from a hybrid approach combining THT and SMT. This allows designers to leverage the strengths of both technologies.

Conclusion

Through-Hole and Surface Mount Technologies each have unique advantages and challenges that significantly impact PCB design. Understanding these implications enables engineers to make informed decisions, tailoring designs to meet specific application requirements. Whether prioritizing mechanical strength or maximizing space efficiency, the choice of mounting technology plays a critical role in the success and functionality of electronic devices. As technology advances, the integration and evolution of these methods continue to shape the landscape of PCB design, driving innovation across industries.

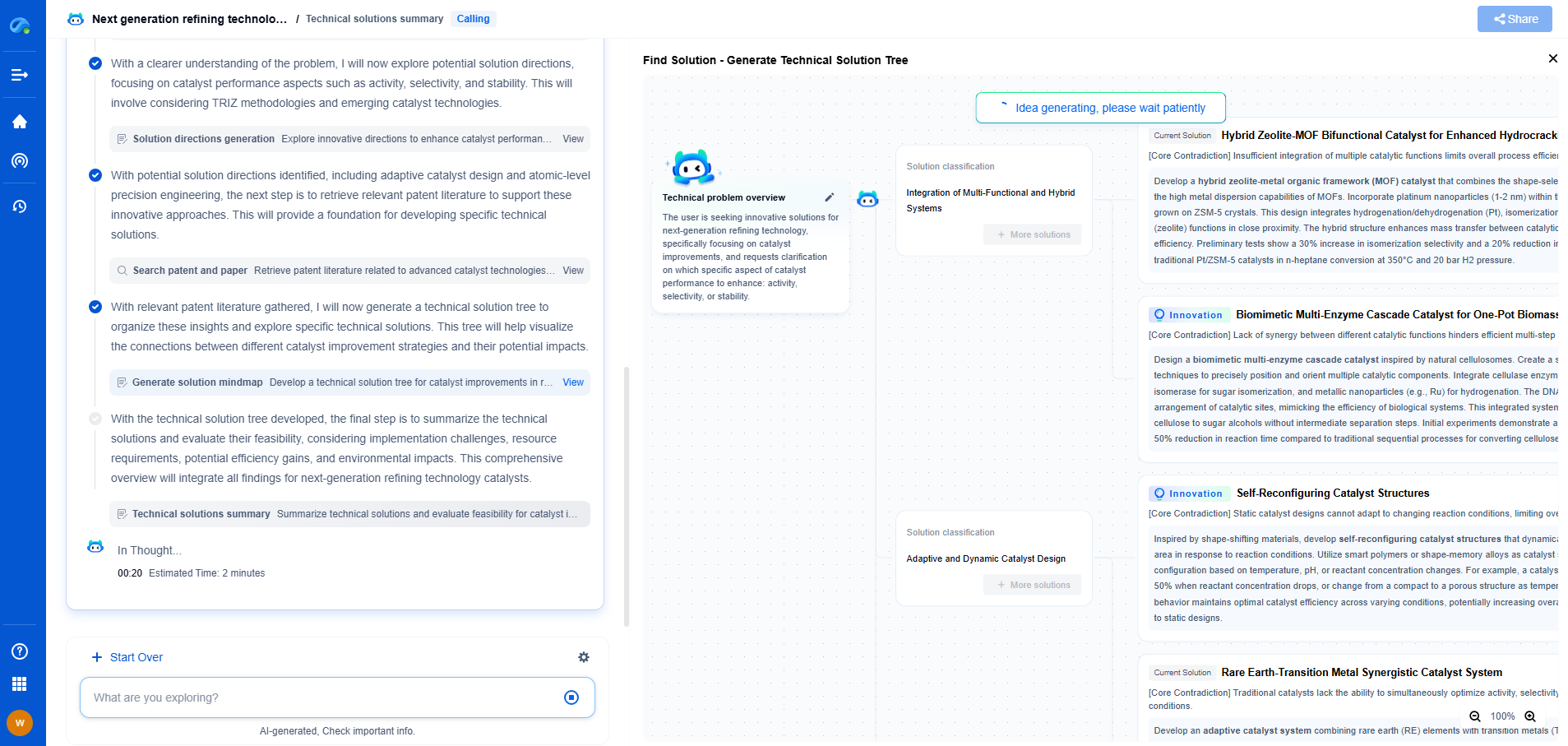

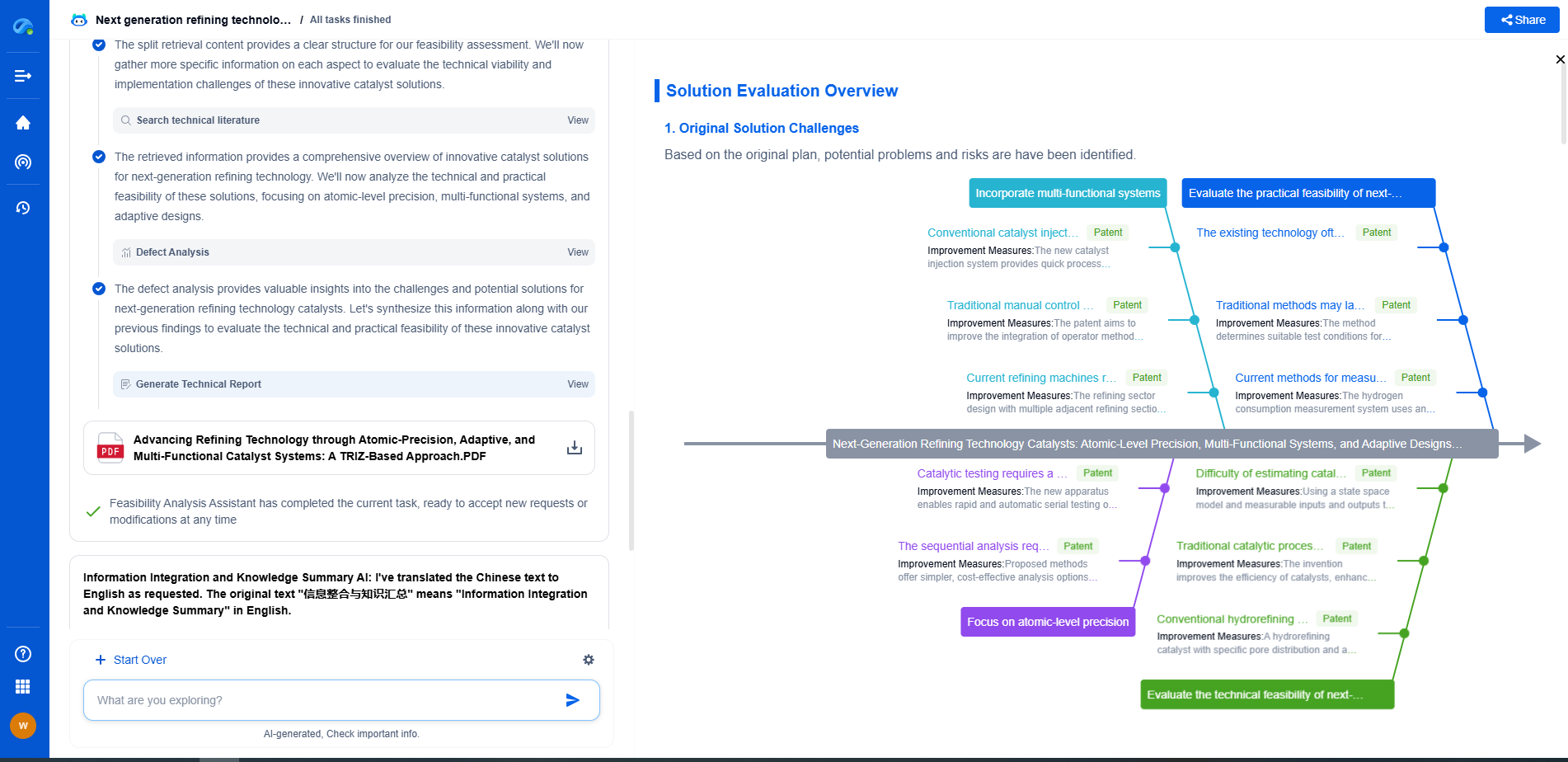

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com