Understanding the Optical Properties of Anti-Reflective Coatings

JUL 22, 2025 |

The Basics of Anti-Reflective Coatings

Anti-reflective (AR) coatings are thin film layers applied to the surface of optical elements, such as lenses and screens, to reduce reflection. When light hits any glass or plastic surface, a portion of it is reflected. This reflection can lead to glare, reduced contrast, and less light transmission, which can significantly affect the performance of optical devices.

The primary aim of an anti-reflective coating is to minimize these reflections by manipulating the way light waves interact with the surface. By minimizing reflection, AR coatings increase the amount of light that passes through the optical device, improving clarity and visibility.

How Do Anti-Reflective Coatings Work?

The effectiveness of AR coatings lies in the principle of interference. Light travels in waves, and when these waves hit a surface, they can be reflected or transmitted. AR coatings are designed to cause destructive interference with the reflected light waves.

Typically, an AR coating consists of a layer of material with a refractive index that is intermediate between air and the lens material. The thickness of this layer is carefully controlled to be a quarter of the wavelength of light intended to be minimized. When light waves of this specific wavelength reflect off both the top and bottom surfaces of the coating, they are out of phase—meaning they cancel each other out. This cancellation reduces the intensity of the reflected light, thereby enhancing light transmission and reducing glare.

Materials Used in Anti-Reflective Coatings

Selecting appropriate materials for AR coatings is crucial for their performance. Common materials include magnesium fluoride, silicon dioxide, and titanium dioxide. Each of these materials has different refractive indices, and when layered appropriately, they can target specific wavelengths for reflection reduction.

Manufacturers often tailor AR coatings to specific applications, selecting materials that will optimize the performance for the intended use. For example, coatings for camera lenses might be different from those used on eyeglasses or computer screens, as the requirements for reflection reduction and light transmission can vary.

Applications of Anti-Reflective Coatings

Anti-reflective coatings are ubiquitous in modern technology and everyday life. In photography and cinematography, AR coatings on camera and projector lenses enhance image clarity and brightness, crucial for capturing high-quality visuals. In the realm of eyewear, AR coatings improve vision clarity, especially in low-light conditions, and reduce eye strain by minimizing glare from lights and screens.

In telecommunications, AR coatings are employed in optical fibers to maximize signal transmission. Flat-panel displays, such as those on televisions, smartphones, and computer monitors, often incorporate AR coatings to improve visibility and reduce glare from ambient light.

Furthermore, solar panels use AR coatings to maximize the amount of light absorbed, enhancing the efficiency of energy conversion. In the automotive industry, AR coatings improve the performance of headlights and other optical components, contributing to safer driving conditions.

The Future of Anti-Reflective Coatings

The development of AR coatings continues to advance, driven by the demand for better optical performance and energy efficiency. Researchers are exploring new materials and methods to produce coatings that can self-clean, provide additional scratch resistance, or adapt dynamically to changes in lighting conditions.

Nanotechnology plays a significant role in the future of AR coatings, with the ability to create ultra-thin, multi-layered structures that can target multiple wavelengths simultaneously. This advancement could lead to AR coatings that are even more effective across a broader range of applications.

In conclusion, the optical properties of anti-reflective coatings are a testament to the power of physics in enhancing our interaction with light. By reducing reflections and improving light transmission, these coatings significantly improve the functionality and efficiency of optical devices. As technology progresses, we can expect to see even more innovative applications and improvements in the performance of anti-reflective coatings.

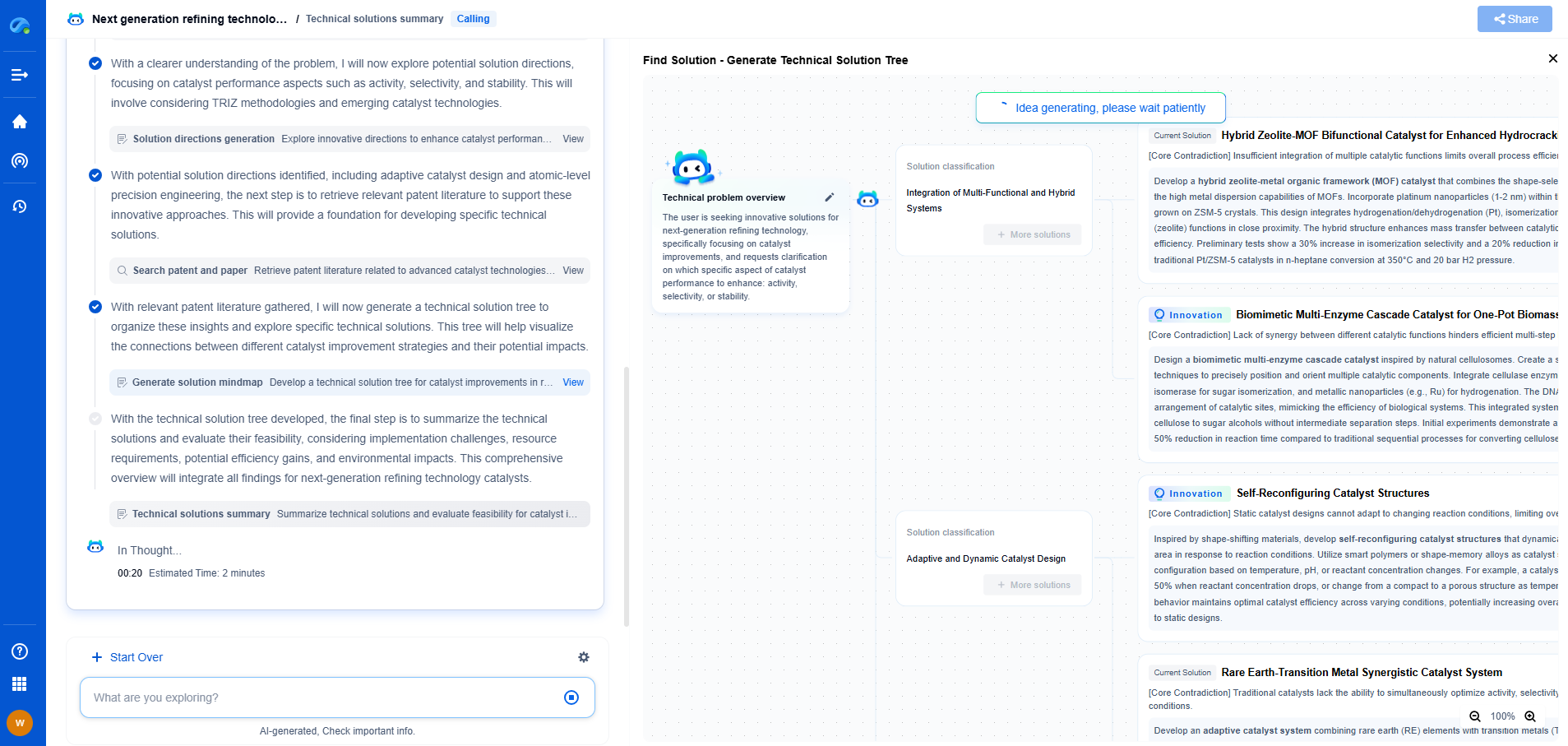

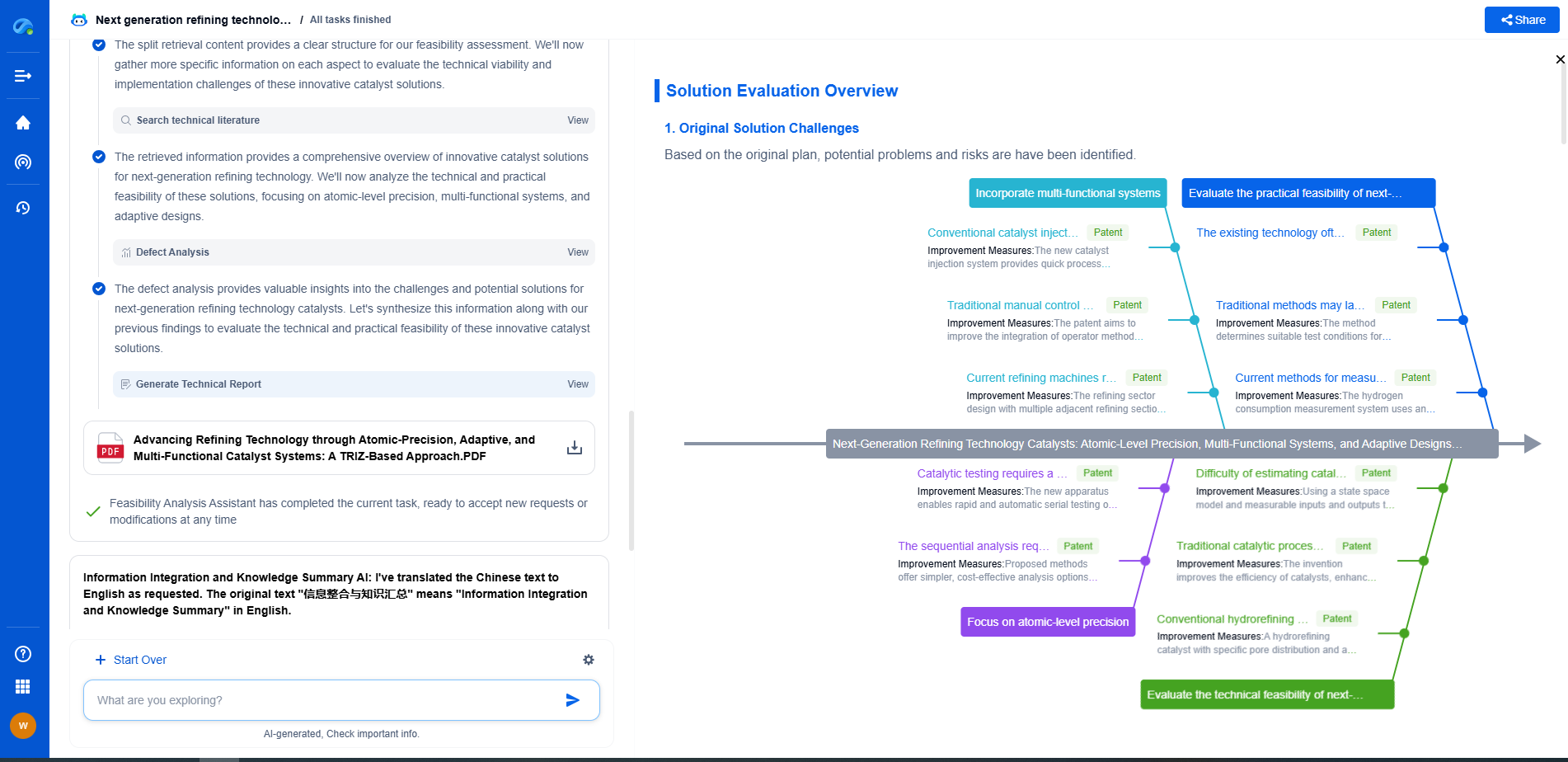

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com