Wafer Testing and Probing: Ensuring Device Quality

JUN 27, 2025 |

In the fast-paced world of semiconductor manufacturing, wafer testing and probing play a crucial role in ensuring device quality. As electronic devices become more sophisticated and complex, the process of testing and probing wafers before they are packaged becomes increasingly vital. This stage of production is essential for identifying defects early, ensuring functionality, and maintaining the high standards expected from today's technology.

The Basics of Wafer Testing

Wafer testing involves the evaluation of semiconductor wafers to detect any defects or malfunctions before they are cut into individual chips. This process is fundamental in the semiconductor industry, as it ensures that only high-quality, functional devices make it to the market. Wafer testing typically uses automated test equipment (ATE) to apply electrical signals to the wafer and measure the responses. By analyzing these responses, manufacturers can determine whether the wafer's components function as intended.

Types of Wafer Testing

There are several types of wafer testing, each designed to assess different aspects of the semiconductor's performance. Parametric testing involves measuring electrical parameters such as resistance, capacitance, and current leakage to ensure the device meets its specifications. Functional testing, on the other hand, assesses the operational capabilities of the wafer's circuits to ensure they perform their intended tasks. Finally, burn-in testing subjects the wafer to elevated temperatures and voltages to gauge its reliability and longevity under stress.

The Role of Probing in Wafer Testing

Probing is an integral part of the wafer testing process, as it facilitates the connection between test equipment and the wafer. This is achieved using probe cards, which are intricate devices that establish hundreds of microscopic contacts with the wafer's surface. The precision of these probe cards is paramount, as they must accurately align with tiny contact pads on the wafer to ensure effective testing. The quality of the probe card can significantly impact the results of the test, making them crucial for maintaining device standards.

Advancements in Probing Technology

With the demand for smaller, faster, and more reliable devices, probing technology has evolved significantly. Modern probe cards are equipped with advanced features such as MEMS (Micro-Electromechanical Systems) technology, which allows for greater precision and reduced wear. Additionally, advancements in materials and manufacturing techniques have led to the development of probe cards that can accommodate the increasingly complex designs of modern semiconductors. These innovations ensure that wafer probing remains reliable and effective, even as devices become more intricate.

Challenges in Wafer Testing and Probing

Despite technological advancements, wafer testing and probing still present several challenges. As semiconductor devices become smaller and more densely packed, aligning probe cards with contact pads requires increased precision, leading to higher manufacturing costs and complexity. Additionally, the delicate nature of wafers means that excessive probing pressure can result in damage, necessitating careful calibration of probe card parameters. These challenges underscore the importance of continuous innovation and improvement in wafer testing techniques.

Ensuring Device Quality Through Testing and Probing

The ultimate goal of wafer testing and probing is to ensure the quality and reliability of semiconductor devices. By identifying defects early in the manufacturing process, companies can avoid costly recalls and maintain consumer trust. Furthermore, rigorous testing and probing can lead to improved device performance, as only the best-performing components are selected for packaging. This commitment to quality is essential in an industry where technological advancements are rapid and consumer expectations are high.

Conclusion

Wafer testing and probing are indispensable in the semiconductor manufacturing process, ensuring that only high-quality devices reach the market. As technology continues to evolve, these practices will become even more critical in maintaining device reliability and performance standards. By understanding the intricacies of wafer testing and probing, manufacturers can navigate the challenges and continue to deliver cutting-edge devices that meet the demands of modern consumers.

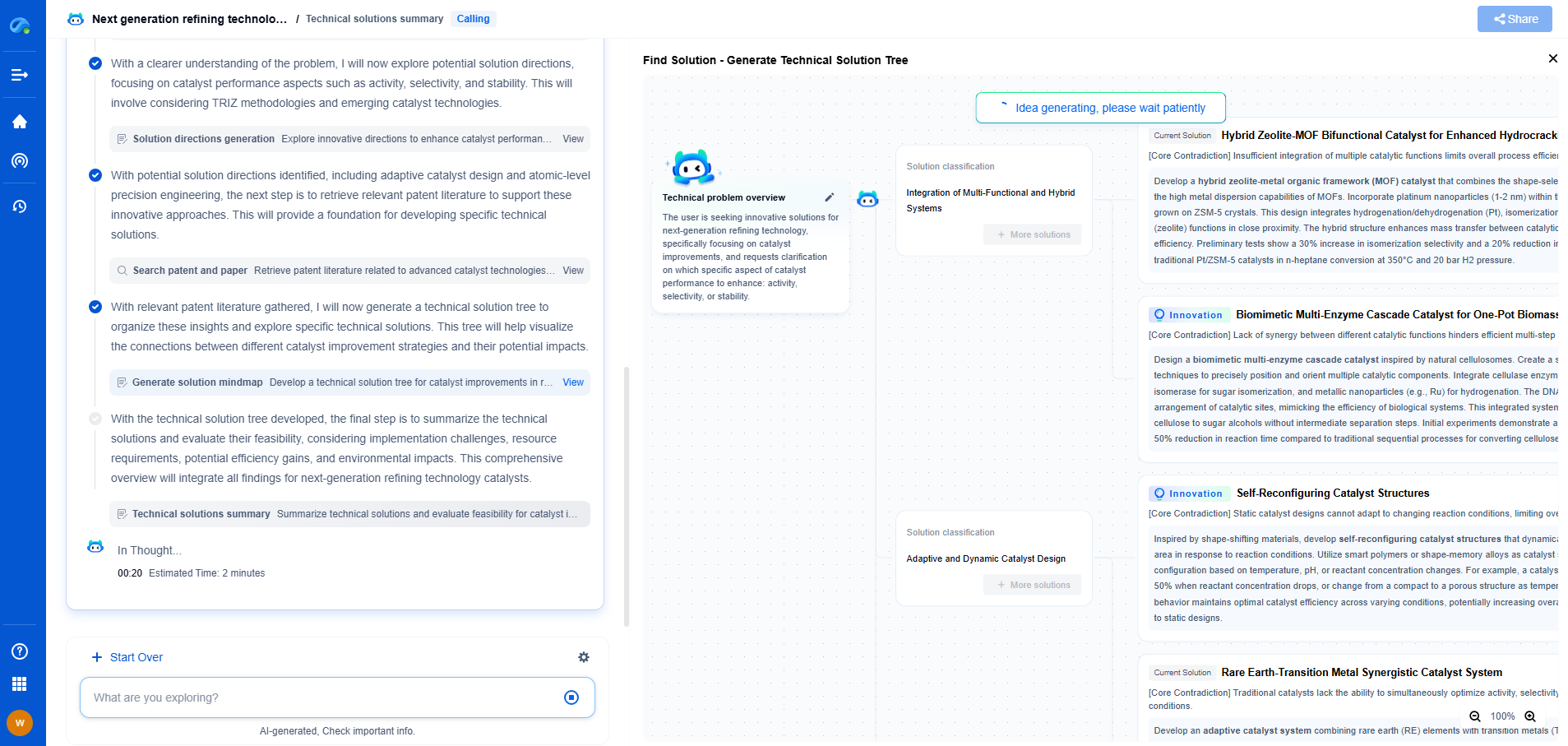

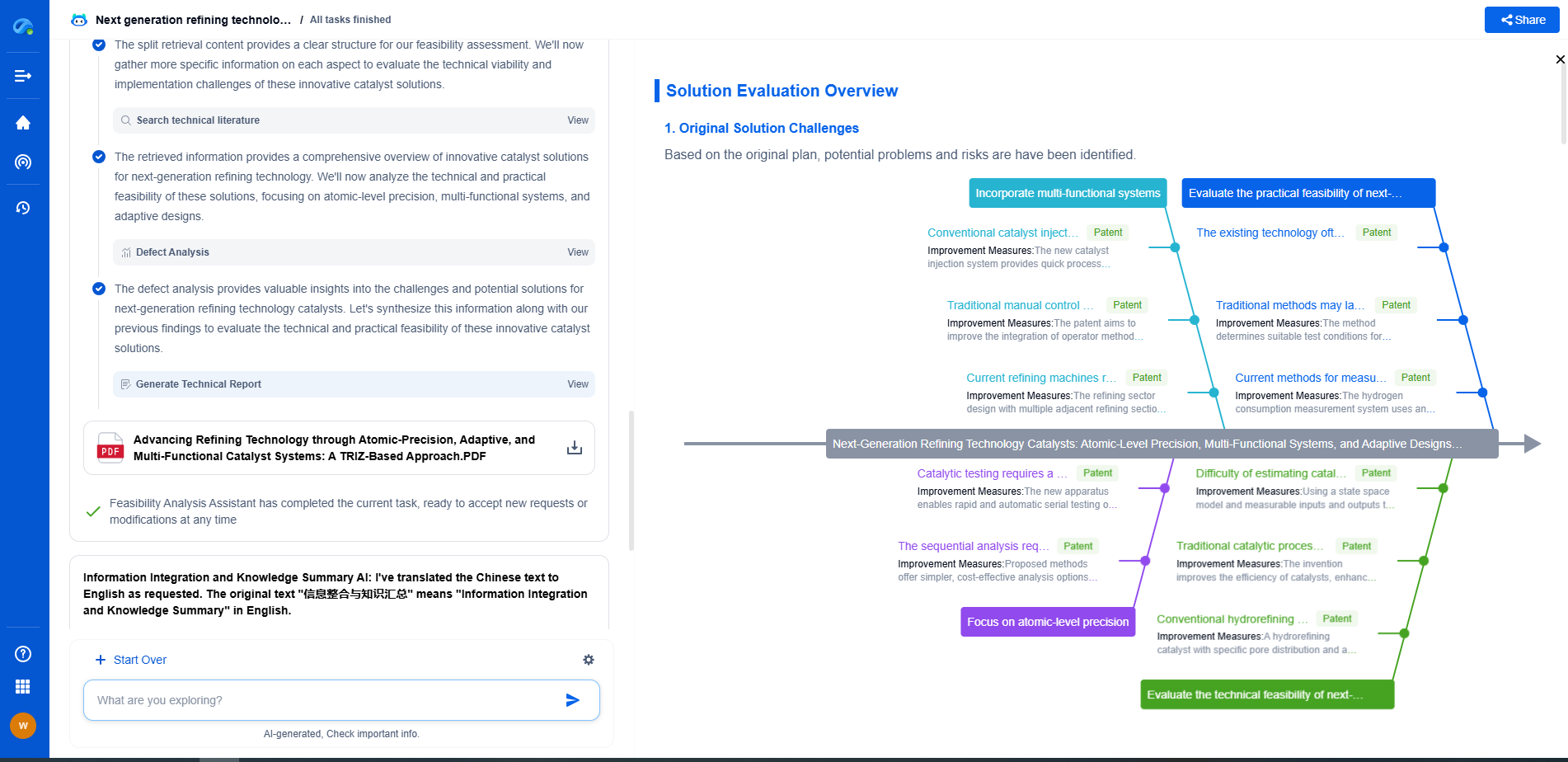

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com