What Are the Steps Involved in Electronic Circuit Design and Prototyping?

JUN 27, 2025 |

Electronic circuit design and prototyping is a fascinating process that transforms abstract ideas into tangible systems capable of performing complex tasks. Whether you're developing a simple LED blinking circuit or a sophisticated embedded system, understanding the steps involved can significantly enhance your efficiency and success in creating functional and innovative electronic solutions.

Understanding Requirements and Specifications

The first step in electronic circuit design is defining the requirements and specifications. This involves understanding what the circuit needs to do, its operational environment, and any constraints such as size, power consumption, and budget. It's essential to have a clear vision of the project's goals and limitations to guide the design process effectively.

Conceptual Design and Schematic Creation

Once the requirements are established, the next step is to conceptualize the circuit's design. This phase involves brainstorming and sketching out ideas that can meet the defined specifications. Using schematic software tools, designers can create detailed diagrams that visually represent the circuit components and their interconnected paths. This schematic acts as a blueprint for the project, helping to visualize the electrical relationships and ensuring all necessary components are considered.

Component Selection and Procurement

Choosing the right components is crucial for the success of your circuit. This involves selecting suitable resistors, capacitors, integrated circuits, transistors, and other parts based on factors like performance, cost, availability, and compatibility. Once the components are chosen, the procurement process follows, which often involves ordering parts from suppliers or checking inventory for availability.

Simulation and Testing

Before moving on to physical production, it's wise to simulate the circuit to predict its behavior under different conditions. Simulation tools allow designers to test the circuit virtually, identifying potential issues and verifying that it meets specifications. By simulating different scenarios, you can tweak the design, adjust component values, or even rethink certain aspects of your approach, ultimately saving time and resources.

Printed Circuit Board (PCB) Design

With a validated schematic, the next step is designing the PCB. This involves placing components on a board layout and routing traces to connect them electronically. PCB design software helps automate this process, ensuring optimal placement and routing to minimize interference and maximize performance. Proper PCB design is crucial for signal integrity, heat management, and compactness of the final product.

Prototyping and Assembly

Once the PCB design is complete, it's time to bring the circuit to life by assembling a prototype. This involves fabricating the PCB, soldering components, and connecting everything according to the design. Prototyping is where you first see your design in action, providing a tangible version that can be tested and iterated upon. During assembly, attention to detail is crucial to prevent errors that could affect functionality.

Testing and Debugging

After assembly, the prototype must be thoroughly tested to ensure it operates correctly and meets the initial design specifications. This step involves powering up the circuit, measuring voltages and currents, and using diagnostic tools to identify and rectify any issues. Debugging is an iterative process where faults are detected and corrected, often requiring modifications to the design or assembly.

Iterative Improvement and Finalization

Design and prototyping are inherently iterative processes. After initial tests and debugging, it’s common to refine and enhance the design based on findings, making improvements to both the PCB and the schematic as necessary. This cycle of testing and improvement continues until the circuit reliably fulfills its intended function.

Conclusion

Electronic circuit design and prototyping is a rewarding journey from conception to creation, requiring meticulous attention to detail, careful planning, and iterative refinement. By following these steps, designers can efficiently transform ideas into functional electronic systems, paving the way for innovation and technological advancement. Understanding this process not only aids in successful project completion but also fosters a deeper appreciation for the complexities and challenges involved in modern electronics.

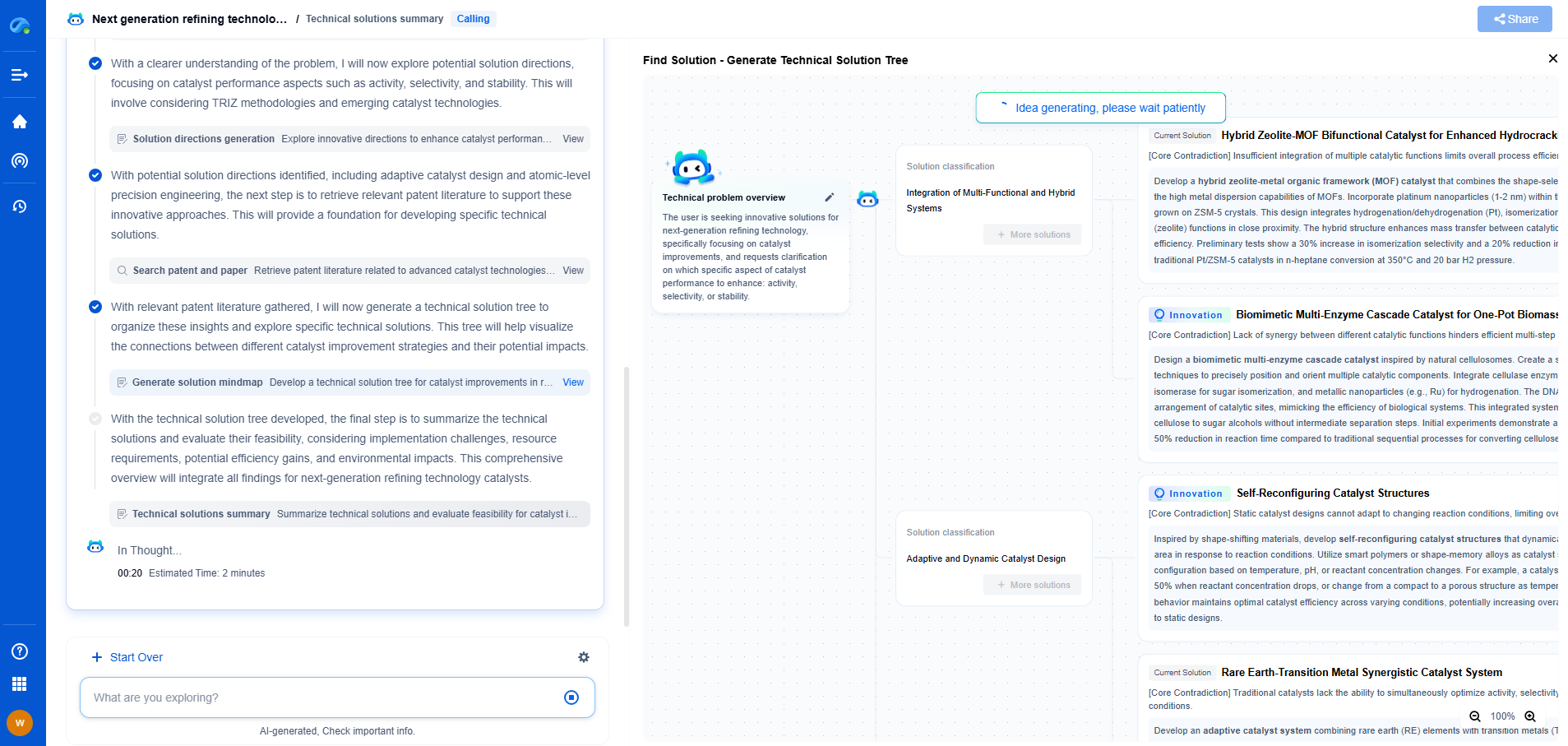

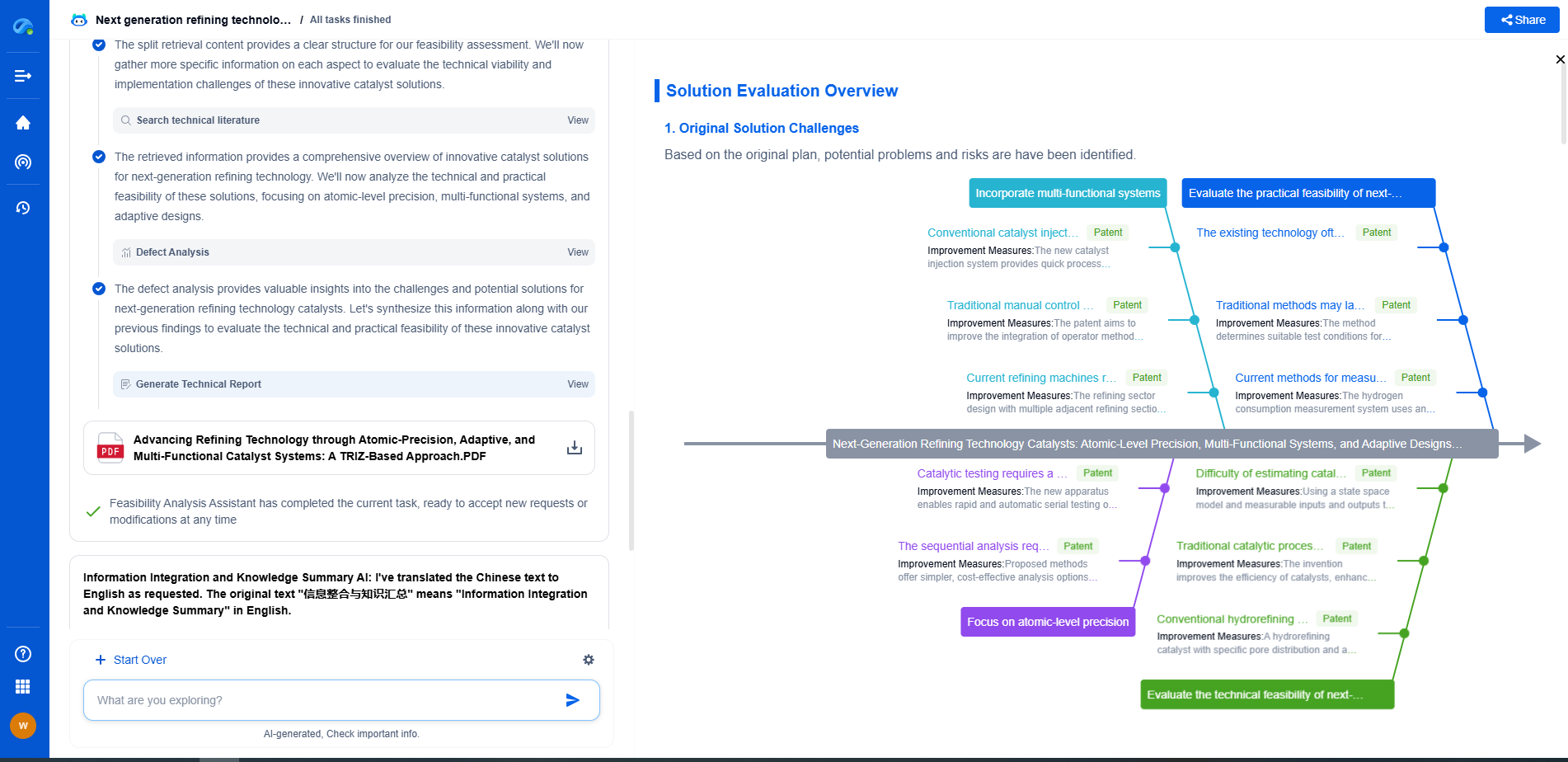

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com