What Is I–V Curve Tracing in Solar Power Systems?

JUL 22, 2025 |

I–V curve tracing is a critical process in the analysis and performance assessment of solar power systems. It involves measuring the current output (I) and the voltage (V) of a solar panel, giving insight into its operational efficiency and health. The I–V curve is a graphical representation that depicts how the current flowing through a solar module changes with varying voltage levels. This curve is vital for diagnosing issues, optimizing performance, and ensuring the long-term viability of a solar power system.

Importance of I–V Curve Tracing

The importance of I–V curve tracing cannot be overstated in the context of solar power systems. It serves as a diagnostic tool that helps in identifying defects, degradation, and potential failures in solar panels. By understanding the I–V curve, operators can detect issues such as shading, soiling, and electrical mismatches that may be hampering the system's output. Furthermore, regular I–V curve tracing can help in maintaining system efficiency and maximizing energy yield, thereby ensuring that the investment in solar technology is justified and returns are optimized.

Components of an I–V Curve

An I–V curve consists of several key components that need to be understood for effective analysis:

1. Short Circuit Current (Isc): This is the maximum current that a solar panel can produce when the output terminals are shorted. It represents the point on the curve where the voltage is zero.

2. Open Circuit Voltage (Voc): This is the maximum voltage available from a solar panel when the circuit is open and no current is flowing. It is the point on the curve where the current is zero.

3. Maximum Power Point (MPP): This is the point on the curve where the product of current and voltage (I x V) is at its maximum. It represents the optimal operating condition of the solar panel where it can produce maximum power.

4. Fill Factor (FF): This is a parameter that indicates the quality of the solar panel. It is defined as the ratio of the maximum power point to the product of the open circuit voltage and the short circuit current. A higher fill factor signifies a better-quality solar module.

Methods of I–V Curve Tracing

There are several methods for conducting I–V curve tracing in solar power systems:

1. Manual I–V Tracing: This involves using a multimeter to manually measure current and voltage at various points. While accurate, it is labor-intensive and time-consuming, making it suitable only for small-scale systems or preliminary testing.

2. Automated I–V Tracers: These are specialized devices that can automatically measure and record I–V curves. They are much faster and more efficient than manual methods and can handle larger systems with greater precision.

3. Drone-Based I–V Curve Tracing: In recent years, drone technology has been incorporated into solar panel inspections. Drones equipped with I–V tracers can analyze large solar farms quickly and efficiently, reducing the time and labor required for ground-based inspections.

Benefits of Regular I–V Curve Tracing

Regular I–V curve tracing offers several benefits to solar power system operators:

1. Early Detection of Issues: By regularly tracing I–V curves, operators can identify potential issues before they escalate into major problems, thus minimizing downtime and maintenance costs.

2. Performance Optimization: Continuous monitoring and analysis enable operators to optimize the performance of solar panels, ensuring they operate at maximum efficiency.

3. Longevity of Equipment: Regular inspections help in maintaining the health of solar modules, thereby extending their lifespan and protecting the investment.

4. Enhanced ROI: By maximizing energy output and minimizing operational inefficiencies, regular I–V curve tracing contributes to a better return on investment.

Conclusion

I–V curve tracing is an indispensable tool in the maintenance and optimization of solar power systems. By understanding the intricacies of the I–V curve, operators can ensure their systems are functioning at peak performance, thereby maximizing energy production and investment returns. With advancements in technology, such as automated tracers and drone-based inspections, the process has become more efficient, making it easier for operators to maintain the health and efficiency of their solar installations. Regular I–V curve tracing is a small investment that yields significant benefits in the form of improved system performance and longevity.

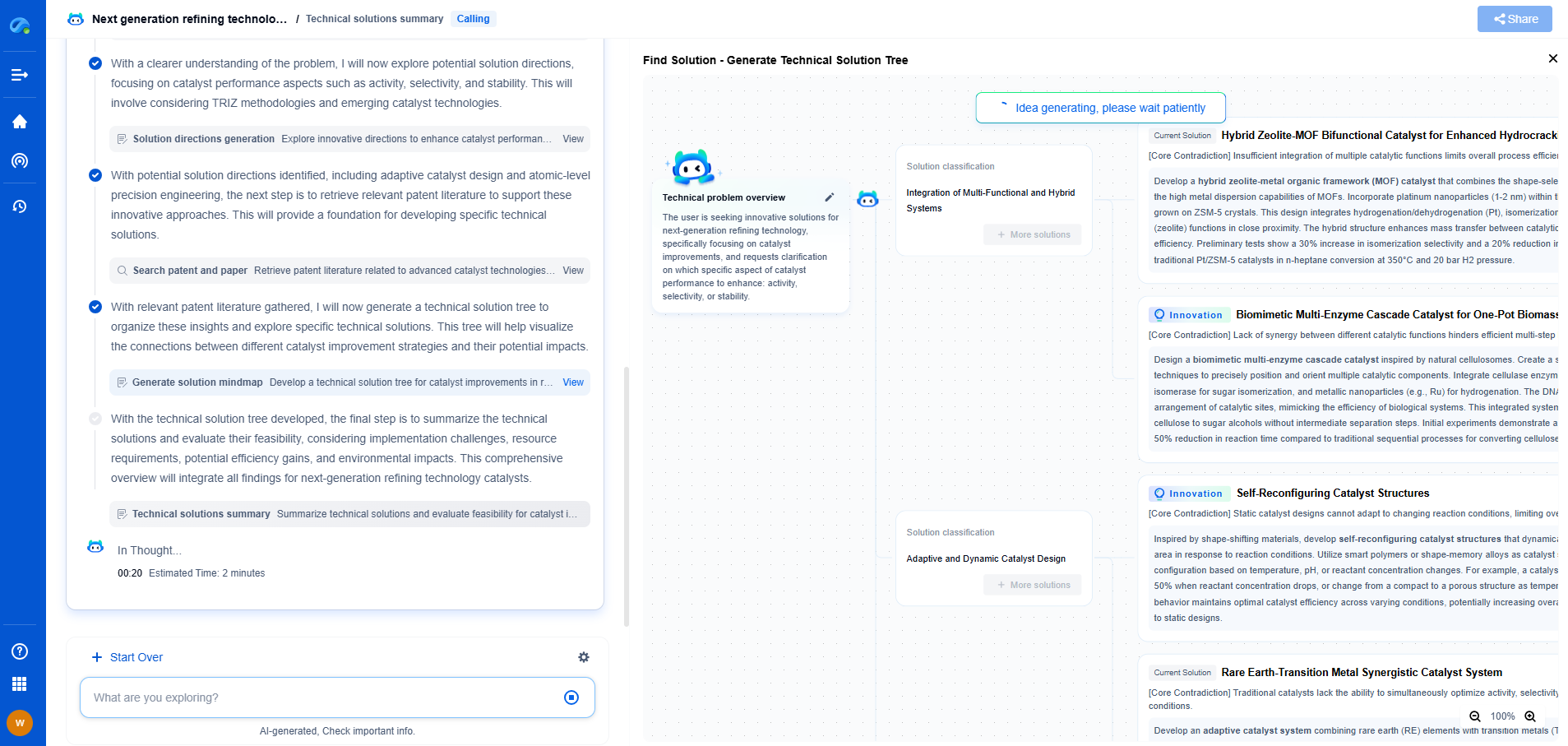

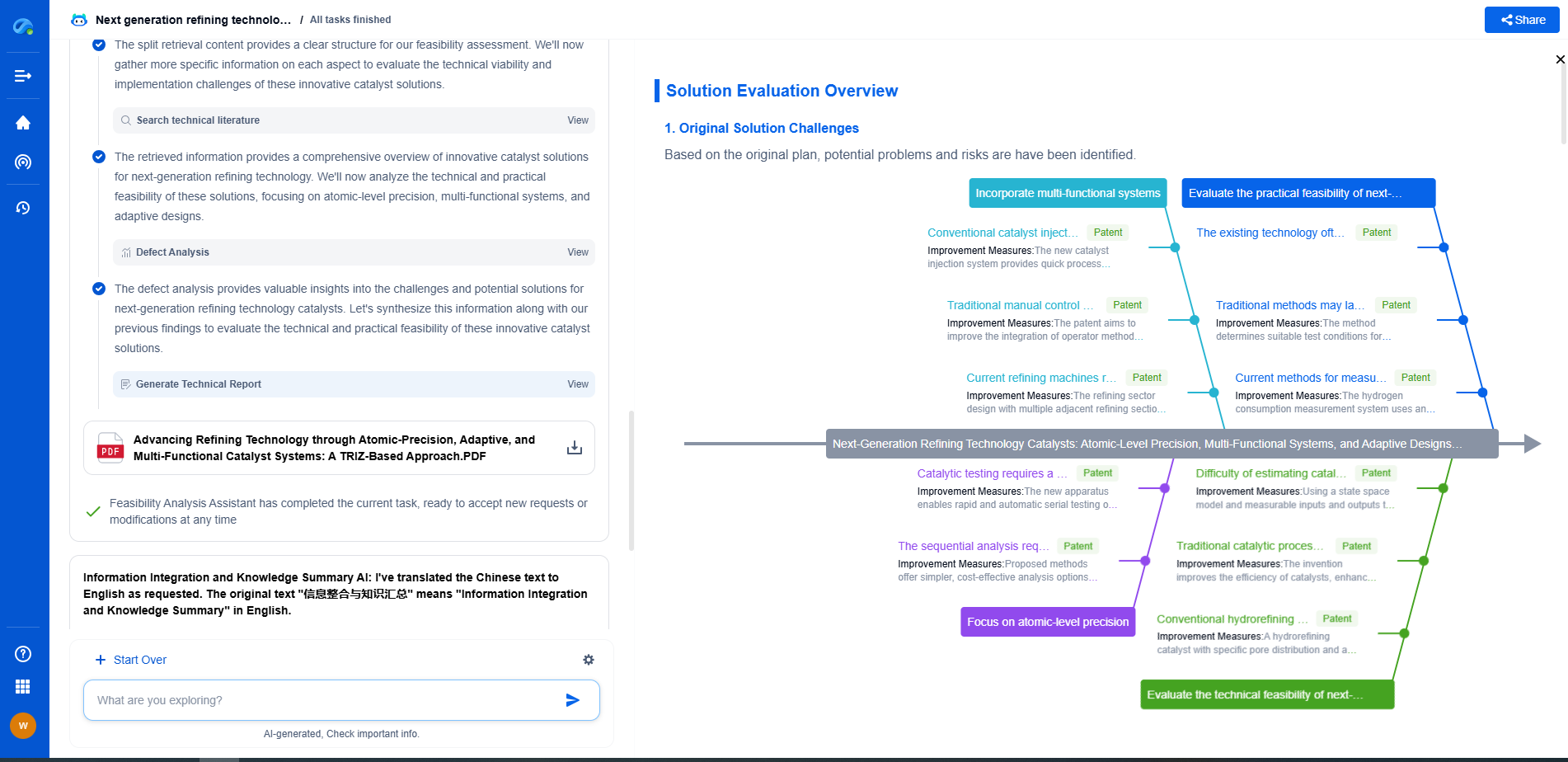

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com