What Is Modbus-Based Control in Power Supply Systems?

JUN 26, 2025 |

In the ever-evolving landscape of power supply systems, efficient and reliable communication protocols are essential. Modbus, a robust and versatile communication protocol, has become a cornerstone in the realm of industrial automation. Originally developed in the late 1970s, Modbus has stood the test of time, adapting to various technological advancements. This blog explores the relevance and application of Modbus-based control in power supply systems, highlighting its features, benefits, and role in modern energy management.

Understanding Modbus Protocol

Modbus is a serial communication protocol that facilitates interaction between multiple devices over a network. It operates on a master-slave architecture, wherein a master device communicates with one or more slave devices. This simplicity in design is one of Modbus's strongest attributes, as it allows for easy implementation and reliable data exchange.

There are several versions of Modbus, including Modbus RTU (Remote Terminal Unit), Modbus ASCII, and Modbus TCP/IP. Modbus RTU is known for its compact, binary-based format, making it ideal for communication over serial lines. Modbus TCP/IP, on the other hand, facilitates communication over Ethernet networks, allowing for integration with modern IT infrastructures.

Advantages of Modbus-Based Control

1. Interoperability: One of the key advantages of Modbus is its interoperability. It is an open protocol, meaning it is not tied to any specific manufacturer. This ensures that devices from different vendors can communicate seamlessly, eliminating compatibility issues in power supply systems.

2. Flexibility: Modbus can be deployed in various network topologies, including point-to-point, multi-drop, and client-server configurations. This flexibility enables it to cater to diverse power supply architectures, making it suitable for a wide range of applications.

3. Scalability: As power supply systems expand, there is a need for scalable communication solutions. Modbus excels in this regard, allowing for easy integration of new devices without disrupting existing operations. This scalability is invaluable for growing industrial environments.

4. Reliability: Modbus has a proven track record of reliability, even in harsh industrial environments. Its simple, efficient design minimizes the risk of communication errors, ensuring accurate data transfer and system stability.

Applications in Power Supply Systems

1. Monitoring and Control: Modbus is instrumental in monitoring and controlling various aspects of power supply systems. It allows operators to gather real-time data on voltage, current, power factor, and other critical parameters. This data is crucial for optimizing system performance and preventing potential issues.

2. Energy Management: In the context of energy management, Modbus facilitates the integration of smart meters and energy management systems. By enabling precise data exchange, it empowers businesses to implement effective energy-saving strategies, reduce operational costs, and enhance sustainability.

3. Fault Detection and Diagnostics: Modbus-based systems are equipped with diagnostic capabilities that enable early detection of faults and anomalies. By identifying issues promptly, operators can perform preventive maintenance, thereby reducing downtime and improving overall system reliability.

4. Remote Access and Control: With the advent of the Industrial Internet of Things (IIoT), remote access and control have become paramount. Modbus, especially in its TCP/IP variant, supports remote monitoring and control, allowing operators to manage power supply systems from anywhere with an internet connection.

Challenges and Considerations

While Modbus offers numerous benefits, there are some challenges to consider. Its simplicity, while advantageous, means it may lack some features present in more complex protocols. Additionally, network security can be a concern, particularly when using Modbus TCP/IP. Implementing robust security measures, such as encryption and authentication, is essential to safeguard data integrity.

Conclusion

Modbus-based control in power supply systems is integral to modern industrial automation and energy management. Its interoperability, flexibility, scalability, and reliability make it a preferred choice for engineers and operators worldwide. By facilitating seamless communication between devices, Modbus plays a vital role in optimizing the performance, efficiency, and sustainability of power supply systems. As technology continues to evolve, Modbus remains a relevant and valuable tool in the ever-changing landscape of industrial automation.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

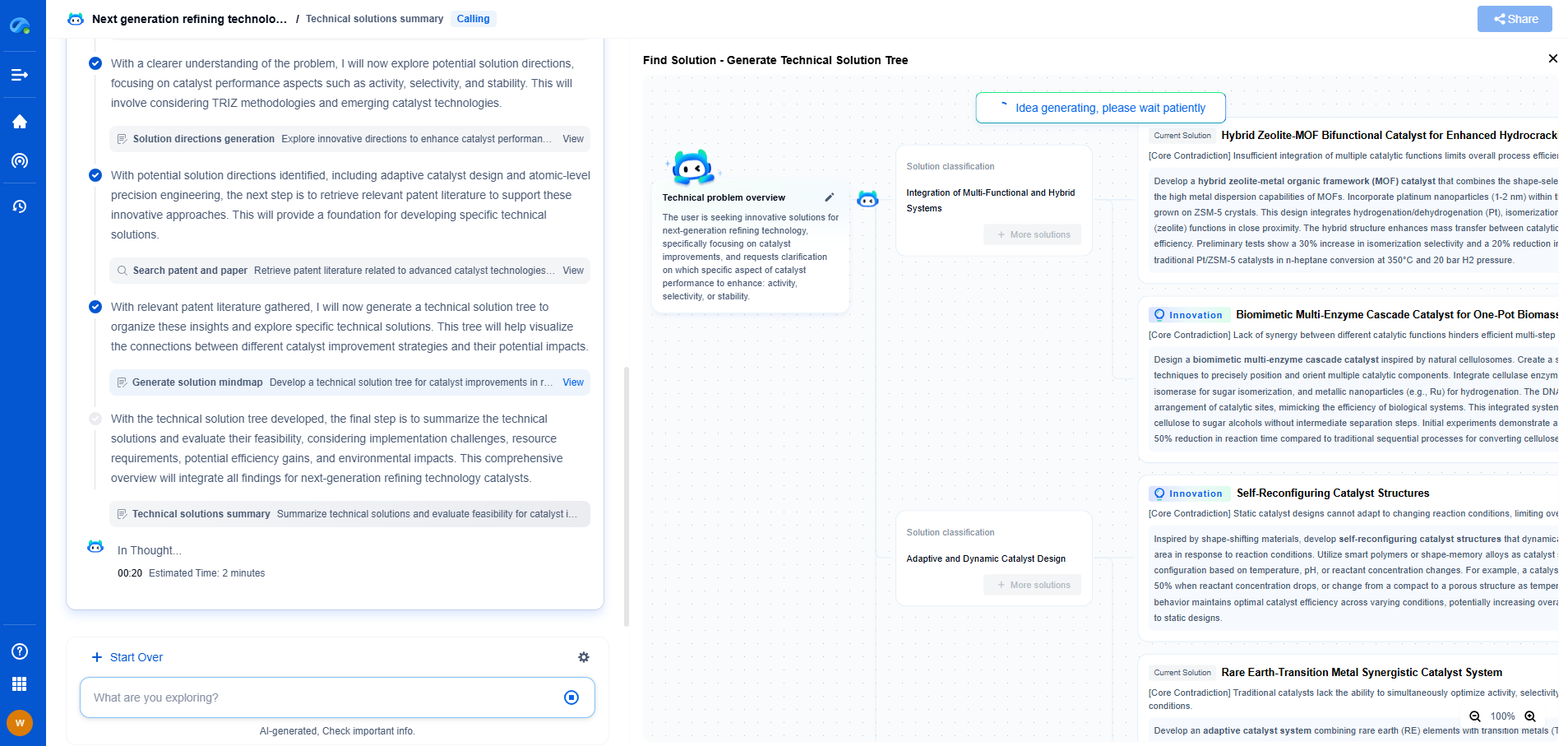

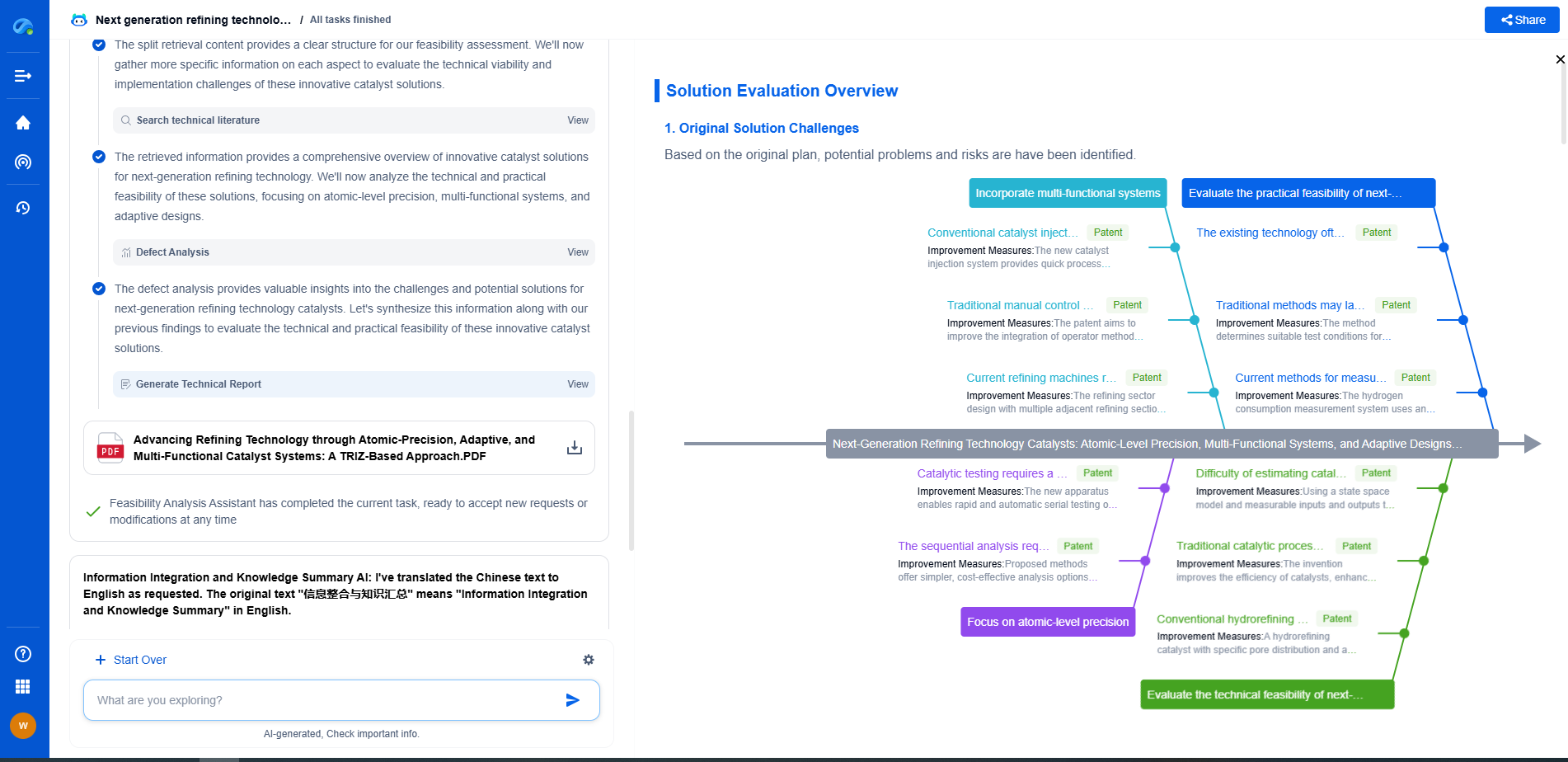

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com