What Type of Coating Is Best for Preventing UV and Moisture Degradation?

JUL 22, 2025 |

In the quest to protect surfaces from the damaging effects of UV radiation and moisture, selecting the right type of coating is crucial. Ultraviolet (UV) rays can break down the chemical bonds in materials, causing them to weaken and fade. Similarly, moisture can lead to rust, mold, and structural degradation. Therefore, choosing a coating that effectively combats these elements is essential for prolonging the life and appearance of your assets.

Types of Coatings for UV and Moisture Protection

A variety of coatings are available on the market, each with unique properties that make them suitable for different environments and materials. Here are some of the most effective types:

1. Polyurethane Coatings

Polyurethane coatings are renowned for their durability and resistance to UV rays and moisture. They form a hard, protective layer that is particularly effective for outdoor applications, such as on vehicles, outdoor furniture, and building exteriors. Polyurethane coatings come in two varieties: aliphatic and aromatic. Aliphatic polyurethanes provide superior UV resistance, making them ideal for surfaces exposed to direct sunlight.

2. Epoxy Coatings

Epoxy coatings are another popular choice for moisture protection due to their excellent water resistance. While they are primarily used indoors because of their tendency to yellow under UV exposure, newer formulations have improved their UV resistance. Epoxy coatings are commonly applied to garage floors, countertops, and other surfaces needing robust protection from water.

3. Acrylic Coatings

Acrylic coatings are valued for their flexibility and ease of application. They offer good UV resistance, which helps prevent fading and degradation. These coatings are often used on walls, roofs, and floors. Acrylic coatings are particularly advantageous where breathability is important since they allow moisture to escape, reducing the risk of blistering and peeling.

4. Silicone Coatings

Silicone coatings excel in extreme weather conditions due to their high UV resistance and waterproofing capabilities. These coatings are often used on roofs and in situations where prolonged exposure to harsh environmental factors is expected. Silicone's elasticity also allows it to expand and contract with temperature fluctuations, minimizing cracking and peeling.

5. Fluoropolymer Coatings

Fluoropolymer coatings provide exceptional UV resistance and durability. They are often used in high-performance applications, such as on aircraft, skyscrapers, and bridges. These coatings maintain their color and gloss over time, even under intense sunlight and harsh weather conditions. Although they can be more expensive, their long-term benefits often justify the cost.

Factors to Consider When Choosing a Coating

When selecting a coating, it’s important to consider the specific environmental conditions and material type. Here are key factors to keep in mind:

- Exposure: Assess how much UV and moisture exposure the surface will encounter. Higher exposure levels may require coatings with enhanced protective properties.

- Material Compatibility: Ensure the coating is suitable for the material you are protecting. Some coatings may adhere better to certain surfaces than others.

- Application Method: Consider the ease of application and whether professional installation is required. Some coatings may require specialized equipment or expertise.

- Longevity and Maintenance: Evaluate the coating’s expected lifespan and maintenance needs. Longer-lasting coatings might require less frequent reapplication and upkeep.

- Budget: Balance the initial cost of the coating with its longevity and protective benefits. Investing in a high-quality coating can offer cost savings over time by reducing repair and replacement expenses.

Conclusion

Selecting the best coating for preventing UV and moisture degradation involves understanding the specific needs of your project and the properties of available coatings. Polyurethane, epoxy, acrylic, silicone, and fluoropolymer coatings all offer distinct advantages, and choosing the right one will depend on factors such as environmental conditions, material compatibility, and budget constraints. By making an informed choice, you can ensure long-lasting protection and preserve the integrity and appearance of your surfaces.

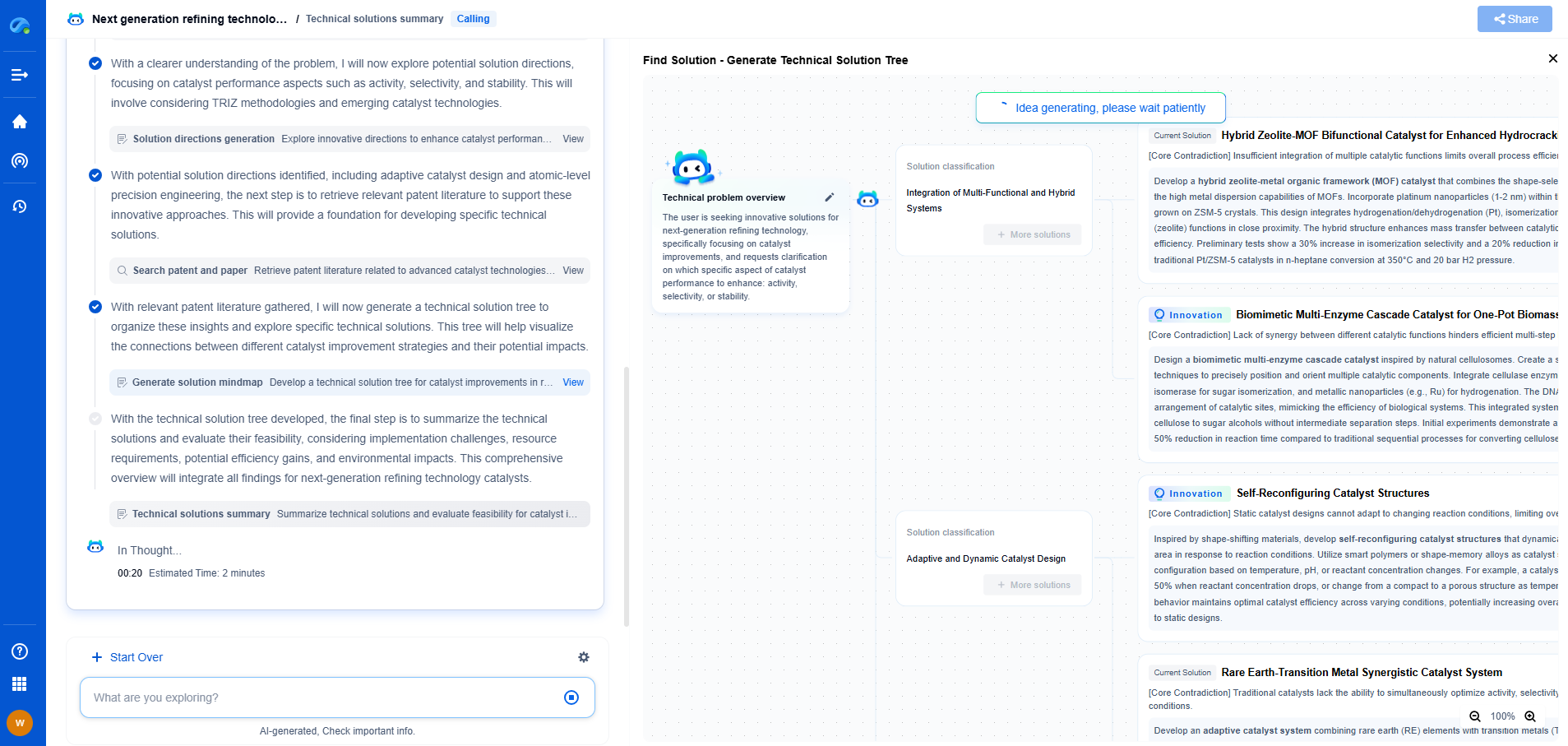

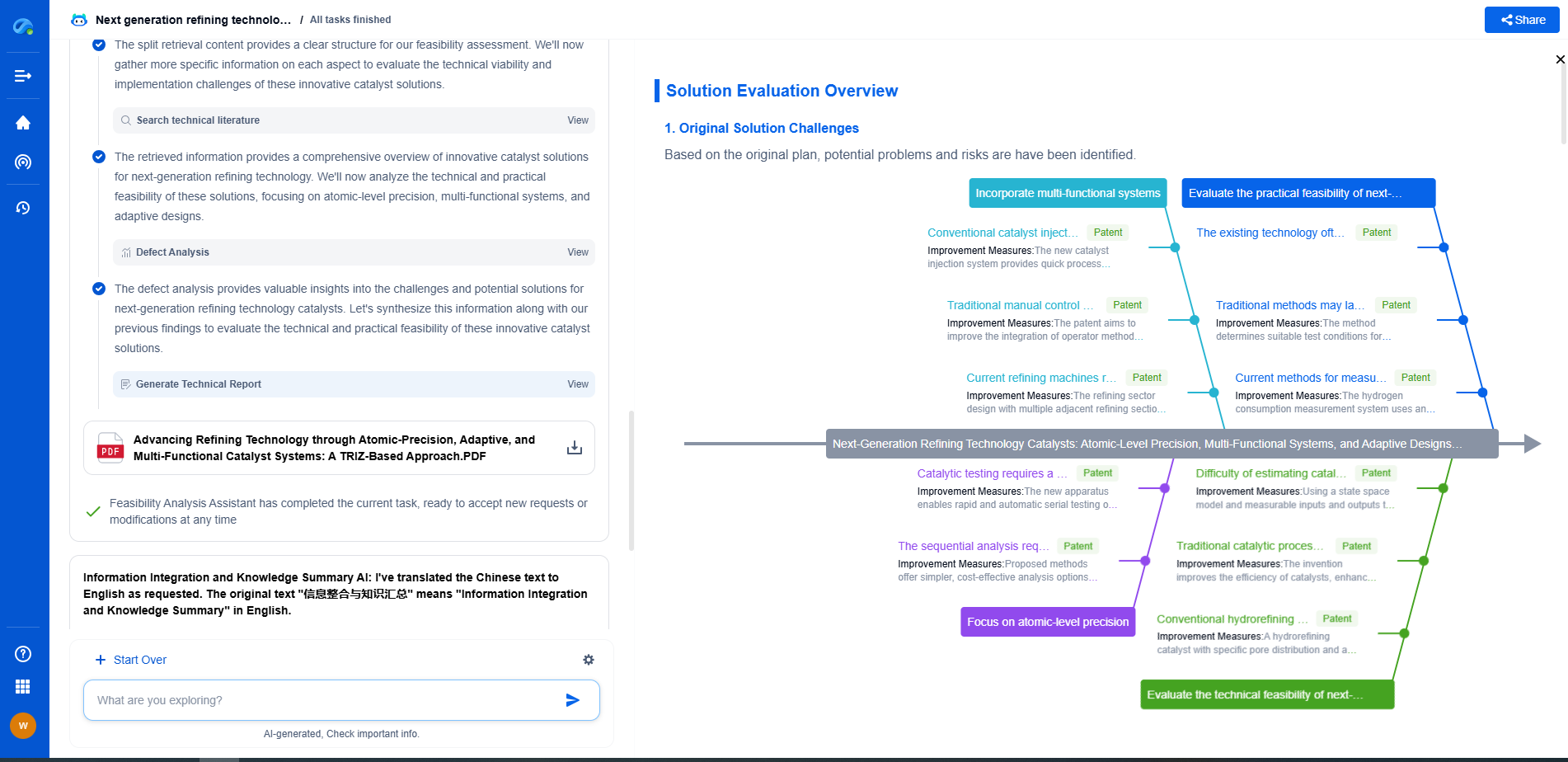

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com