What’s the Difference Between Standalone and Hybrid Supply Systems?

JUN 26, 2025 |

In the complex world of supply systems, businesses often face the decision of choosing between standalone and hybrid systems. Understanding the differences between these two types of supply systems is crucial for making informed decisions that align with a company’s operational goals, cost efficiency, and scalability needs. This article delves into the distinctive features of standalone and hybrid supply systems, highlighting their advantages, disadvantages, and potential applications.

Defining Standalone Supply Systems

Standalone supply systems refer to a single, independent system designed to manage specific supply chain functions without the need for integration with other systems. These systems are typically customized to meet the unique needs of a particular area within the supply chain, such as inventory management, warehousing, or procurement. Because they operate independently, standalone systems are often easier to implement and can be tailored to address specific operational challenges.

Advantages of Standalone Systems

One of the key advantages of standalone supply systems is their simplicity. Because they are designed to operate independently, they are less complex and easier to manage. This simplicity often leads to faster implementation times and reduced costs, as there is no need for extensive system integration. Additionally, standalone systems can be highly customizable, allowing businesses to create tailored solutions that address their unique operational needs.

Disadvantages of Standalone Systems

Despite their simplicity, standalone systems have some drawbacks. The primary concern is the lack of integration with other systems, which can lead to data silos and inefficiencies. Without seamless communication between different parts of the supply chain, businesses may struggle to gain a comprehensive view of their operations. This can result in duplicated efforts, increased error rates, and missed opportunities for optimization.

Exploring Hybrid Supply Systems

Hybrid supply systems, on the other hand, are designed to integrate multiple systems or technologies to provide a cohesive and unified supply chain management solution. By combining the strengths of different systems, hybrid models aim to offer a more holistic approach to managing supply chain activities. Hybrid systems often involve a combination of on-premise and cloud-based solutions, integrating various functions such as inventory management, demand forecasting, and logistics.

Advantages of Hybrid Systems

One of the main benefits of hybrid supply systems is their ability to provide a comprehensive view of the entire supply chain. By integrating multiple systems, businesses can achieve better coordination, improved data visibility, and enhanced decision-making capabilities. This integration allows for real-time data sharing, which can lead to more accurate demand forecasting, efficient resource allocation, and optimized production planning.

Another advantage is flexibility. Hybrid systems can adapt to changing business needs and incorporate new technologies as they emerge. This scalability is particularly beneficial for growing businesses that need to expand their operations without overhauling their entire supply chain infrastructure.

Disadvantages of Hybrid Systems

While hybrid systems offer significant benefits, they also come with challenges. The complexity of integrating various systems can lead to higher implementation costs and longer deployment times. Ensuring compatibility between different technologies and maintaining system integrity requires ongoing investment and expertise. Furthermore, hybrid systems may require more extensive training for staff to effectively manage and operate the integrated solutions.

Choosing the Right System for Your Business

Deciding between a standalone or hybrid supply system depends on several factors, including the size of the business, budget constraints, and specific operational needs. Small businesses or those with limited resources might prefer standalone systems due to their lower cost and ease of implementation. However, larger organizations with complex supply chains may benefit more from the comprehensive capabilities of hybrid systems, despite the higher initial investment and complexity.

Conclusion

Understanding the difference between standalone and hybrid supply systems is crucial for businesses looking to optimize their supply chain management. Each system has its unique advantages and challenges, and choosing the right one depends on the specific needs and goals of your organization. By carefully evaluating your requirements and considering both the short-term and long-term implications, you can select a supply system that enhances operational efficiency, supports growth, and drives success in an increasingly competitive market.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

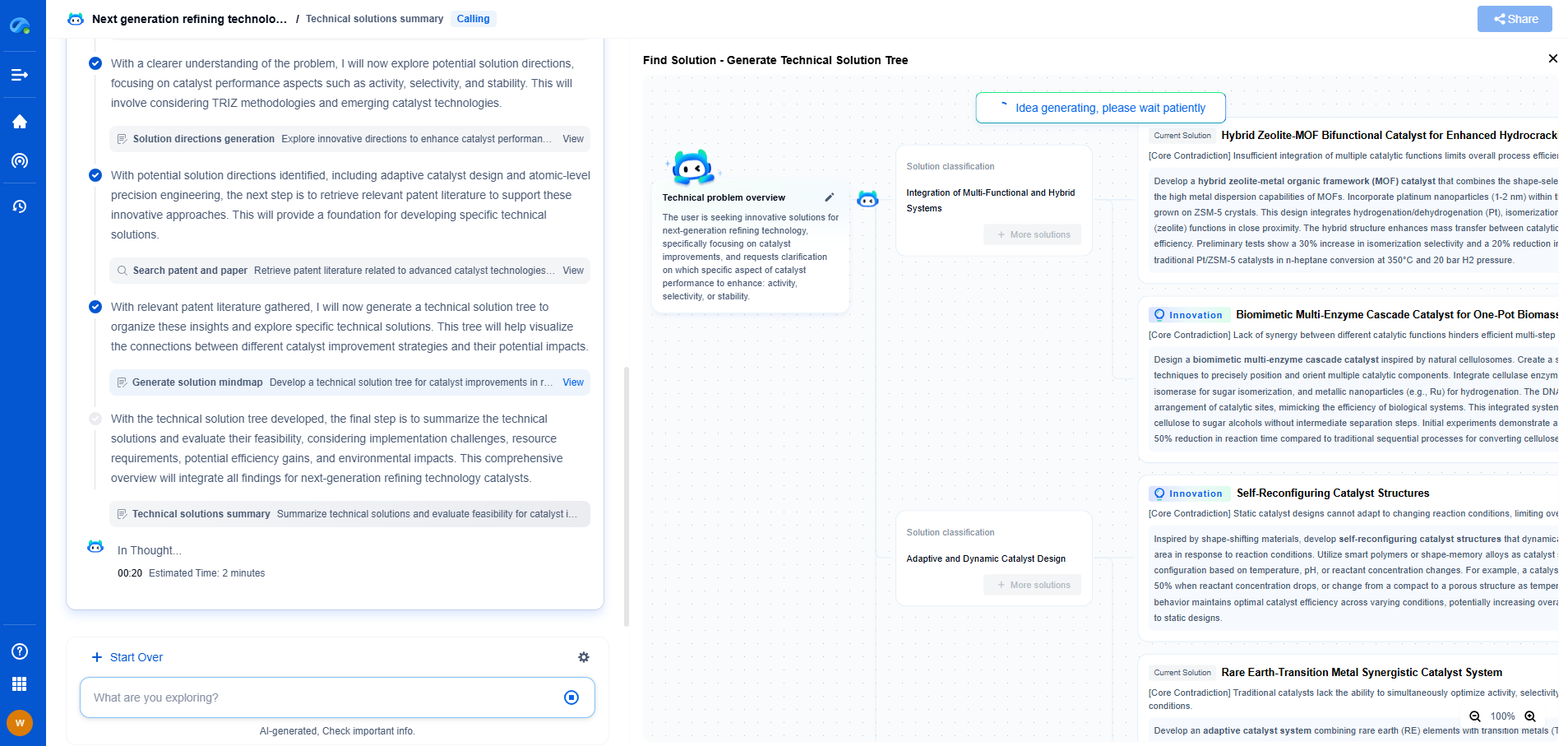

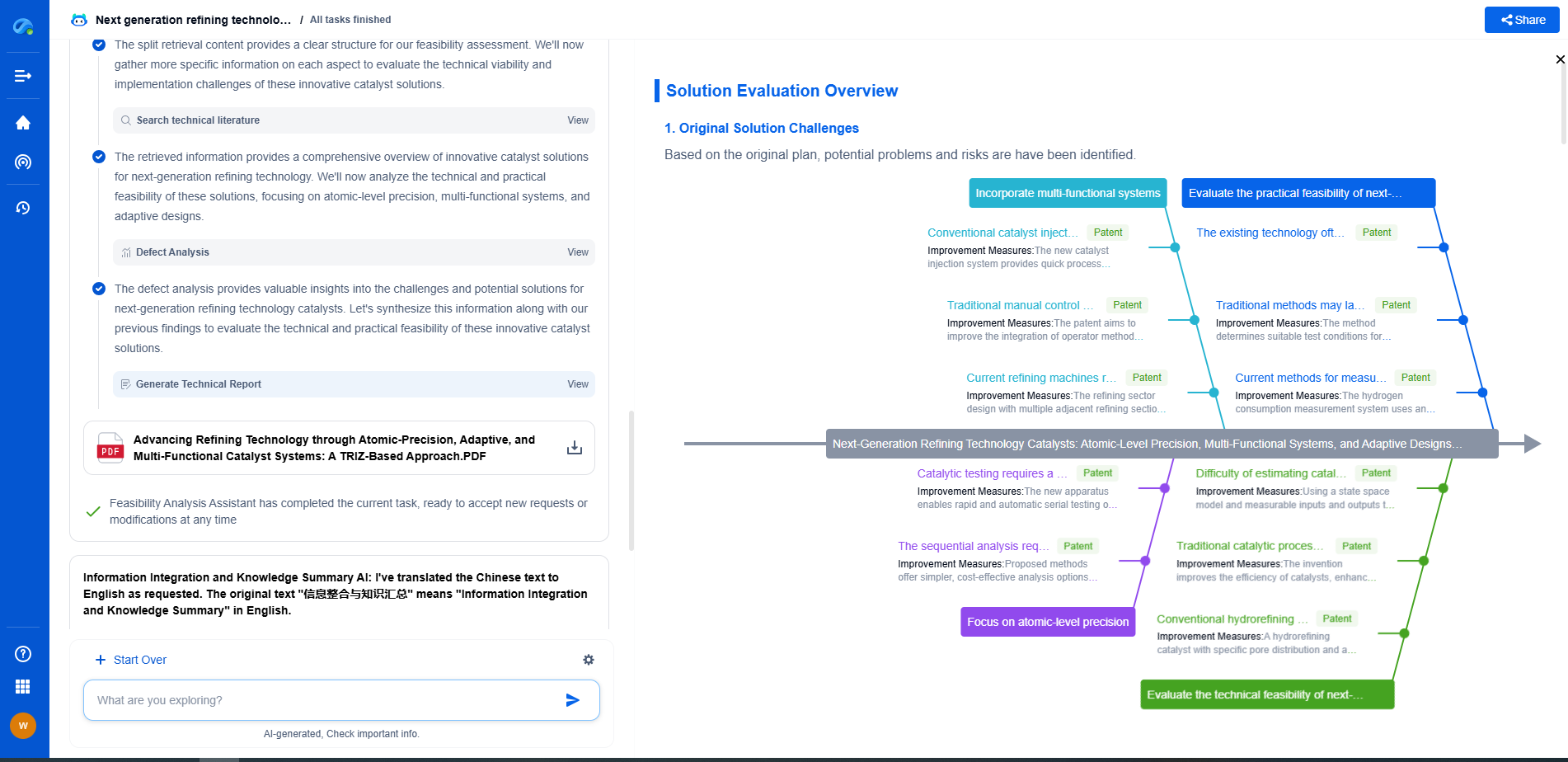

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com