Why Do Diodes Fail? Common Failure Modes and Prevention

JUN 27, 2025 |

Diodes are essential components in electronic circuits, serving as one-way valves that allow current to flow in one direction while blocking it in the opposite direction. Despite their reliability, diodes can fail, leading to malfunctioning circuits or damaged components. Understanding why diodes fail and how to prevent such failures can save time and resources in electronic design and maintenance.

Thermal Overload

One of the most common reasons for diode failure is thermal overload. Diodes are designed to operate within specific temperature ranges. When they exceed these limits, their performance can degrade, leading to failure. Thermal overload occurs when a diode is subjected to excessive current, which causes it to heat up beyond its maximum rated temperature. If the heat isn't dissipated effectively, the diode’s junction can overheat, leading to a breakdown.

Preventing thermal overload involves ensuring that the diode is properly rated for the current it will carry. Designers can use heat sinks, thermal pads, or appropriate circuit design to help disperse heat. Implementing thermal management strategies, such as proper ventilation and cooling, can further help in mitigating the risks associated with thermal overload.

Electrical Overstress (EOS)

Electrical overstress is another primary cause of diode failure. This occurs when a diode is exposed to a voltage or current that exceeds its specified limits, even if only for a brief moment. EOS can cause permanent damage to the diode's junction, leading to catastrophic failure.

To prevent EOS, it is crucial to ensure that circuit designs stay within the specified voltage and current limits of the diodes used. Incorporating protection mechanisms such as fuses, circuit breakers, or transient voltage suppressors can help manage unexpected surges. Additionally, regularly testing and maintaining equipment can help identify potential issues before they lead to failure.

Reverse Bias Breakdown

Diodes are designed to block current in the reverse direction, but when the reverse voltage exceeds a certain threshold, known as the breakdown voltage, it can cause the diode to fail. This is particularly problematic in scenarios where reverse voltage spikes occur, such as during power surges or lightning strikes.

To prevent reverse bias breakdown, ensure that the diode's reverse voltage rating is appropriate for the application. Using components like Zener diodes, which are designed to handle reverse breakdown by safely conducting reverse current, can also provide protection against such failures.

Physical Damage

Diodes can also fail due to physical damage, which can occur during manufacturing, handling, or operation. Mechanical stress, such as bending or vibration, can lead to cracked packages or damaged leads. Additionally, exposure to harsh environmental conditions, such as moisture or corrosive chemicals, can degrade the diode’s materials, leading to failure.

Preventing physical damage involves careful handling and installation of diodes. Ensuring that the devices are stored correctly and protected from mechanical stress and harsh environments can extend their lifespan. Using conformal coatings or encapsulation can provide additional protection in challenging environments.

Aging and Wear-Out

Like all electronic components, diodes can succumb to aging and wear-out over time. Continuous operation, especially under suboptimal conditions, can cause gradual degradation of the diode's materials, eventually leading to failure. This is often observed in applications with high-frequency switching, where the repeated thermal and electrical stresses take their toll.

To combat aging and wear-out, it's important to select diodes with appropriate life expectancy ratings for the intended application. Regular maintenance and replacement schedules can also help ensure long-term reliability of the circuits in which the diodes operate.

Conclusion

Diode failures can disrupt electronic circuits and lead to significant downtime or damage. By understanding common failure modes such as thermal overload, electrical overstress, reverse bias breakdown, physical damage, and aging, engineers and technicians can implement strategies to prevent these failures. Proper design, selection, handling, and maintenance of diodes are crucial in ensuring their reliability and longevity in various applications.

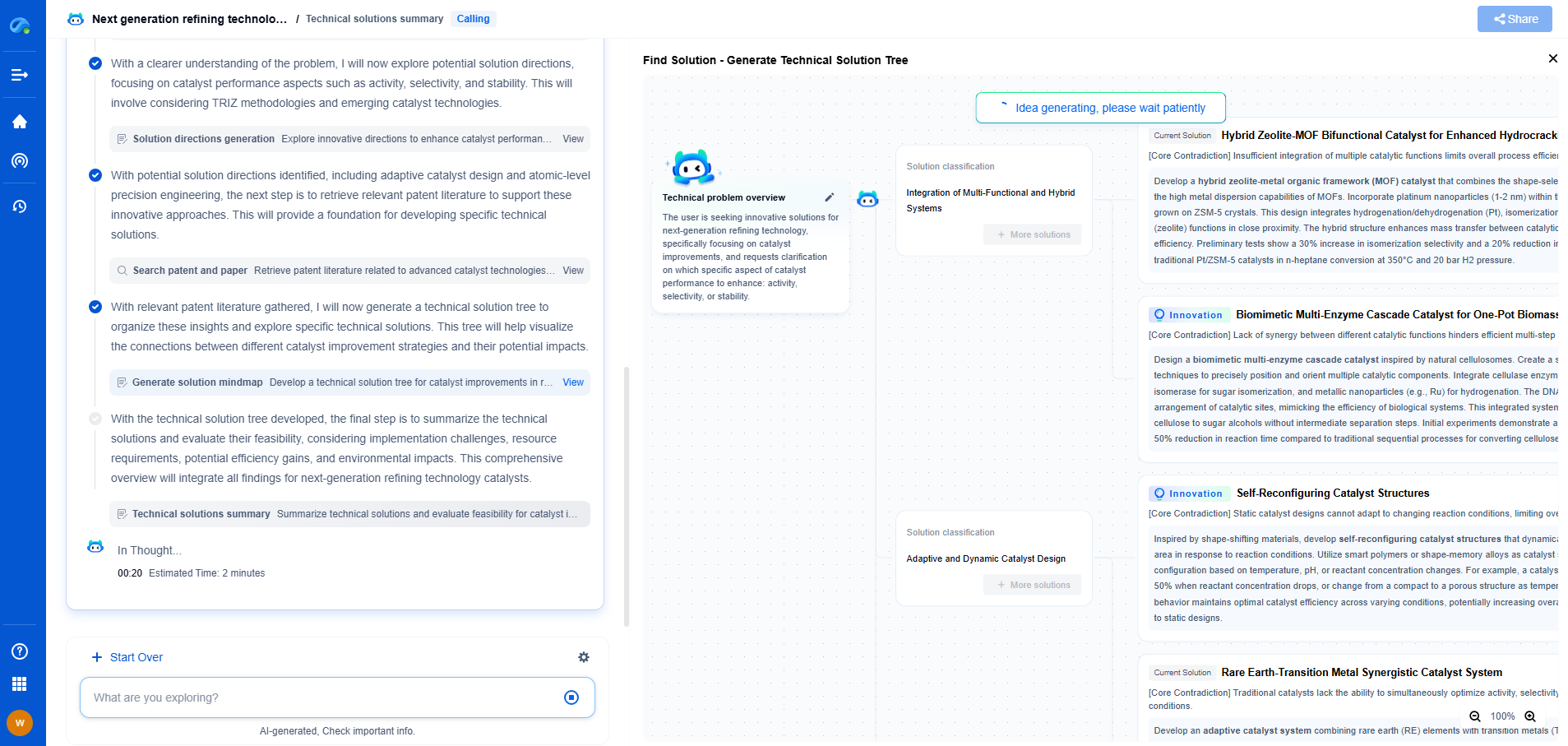

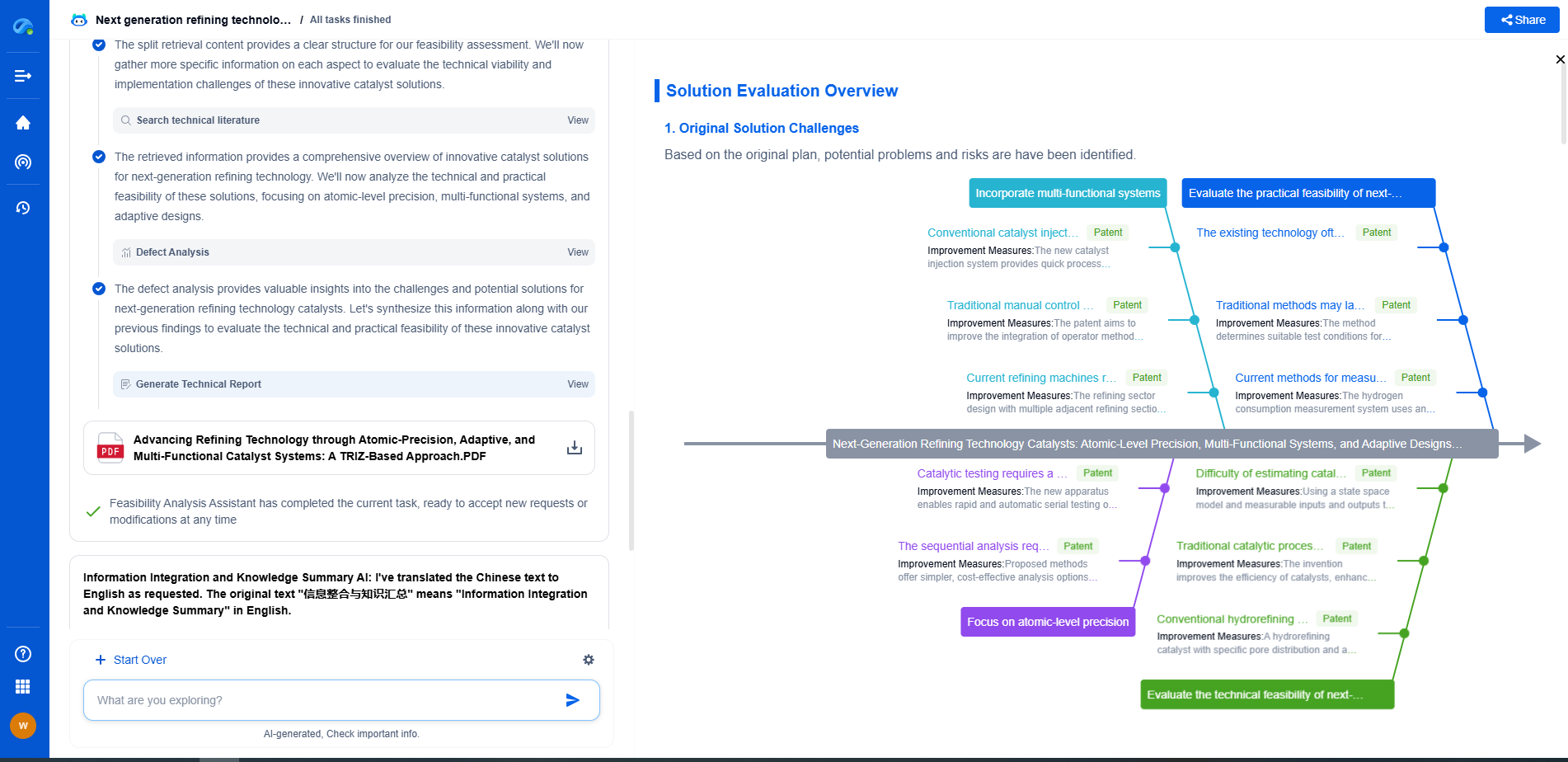

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com