Technical Background and Objectives

Background

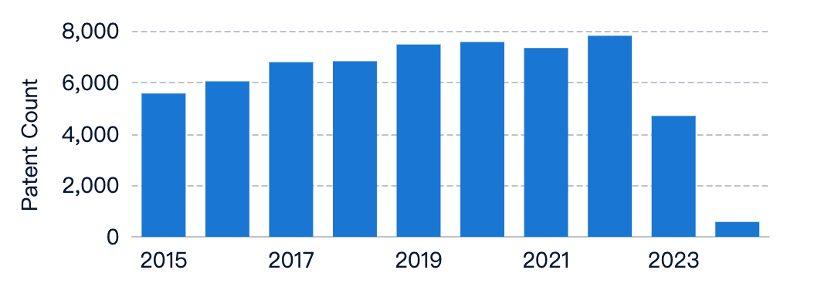

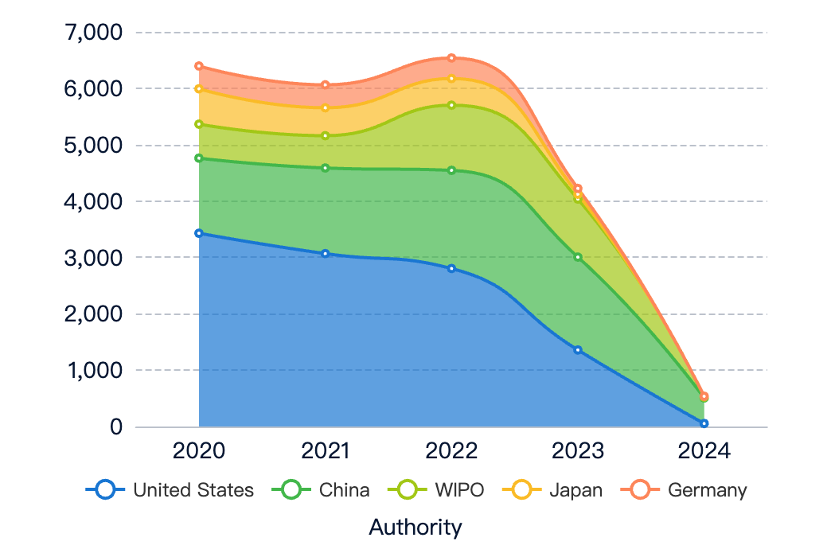

The field of ‘engine brake reduce weight’ shows an interesting trend with a steady increase in patent applications, indicating growing interest and research activities. This suggests that reducing the weight of engine brakes is a focus of innovation. In contrast, literature publications do not show a clear trend, fluctuating over the years. This divergence indicates that the industry is driving the development, possibly due to market demands or regulatory requirements.

Objectives

The primary objective is to explore innovative solutions to reduce the weight of engine brakes, enhancing fuel efficiency and vehicle performance. This research aims to develop a lightweight engine brake system that maintains or exceeds conventional braking performance, promoting sustainable transportation and reducing environmental impact.

To get a detailed scientific explanations of engine brake reduce weight, try Eureka.

Technical Current Status Analysis

Engine Brakes

Engine brakes, also known as compression release engine brakes or Jake brakes, are auxiliary braking devices used in heavy-duty vehicles to slow down the vehicle and reduce wear on service brakes. By releasing compressed air from the engine cylinders during the compression stroke, engine brakes convert the engine’s compression into a retarding force.

Applications and Impact:

- Trucking Industry: Reducing vehicle weight improves fuel efficiency, operating costs, and environmental impact.

- Construction and Mining: Essential for maintaining control and safety in challenging terrains.

- Public Roads: Enhances safety by providing additional braking power for heavily loaded vehicles.

Technical Characteristics and Challenges:

- Noise and Vibration: Can be disruptive and uncomfortable.

- Engine Wear and Durability: Repeated compression release cycles can accelerate wear.

- Integration with Emission Control Systems: Modern engines have advanced emission control systems.

- Control and Calibration: Precise control is essential for optimal performance.

- Weight Reduction Opportunities: Using lightweight materials and advanced manufacturing techniques.

Technological Paths:

- Advanced Noise and Vibration Control: Implement active noise cancellation and optimized valve timing.

- Durable Components: Develop advanced materials and surface treatments.

- Integrated Emission Control: Develop control algorithms and calibration strategies.

- Intelligent Control and Calibration: Use advanced algorithms and machine learning.

- Lightweight Design and Materials: Use advanced alloys, composites, and additive manufacturing.

- System Integration and Optimization: Optimize interaction between engine brake and vehicle subsystems.

Research Content

Research Objectives

The primary objective is to develop innovative solutions to reduce the weight of engine brakes, enhancing fuel efficiency and vehicle performance. This aligns with the goal of promoting sustainable transportation and reducing environmental impact.

Research Direction and Focus

Materials Selection and Characterization

- Evaluate lightweight materials like advanced alloys, composites, and ceramics.

- Assess mechanical properties, thermal characteristics, and durability.

Design Optimization and Simulation

- Use CAD and FEA tools to optimize component design.

- Analyze stress distribution, thermal management, and vibration characteristics.

Manufacturing Processes and Prototyping

- Investigate advanced manufacturing processes like 3D printing and precision casting.

- Prototype and test components under real-world conditions.

System Integration and Testing

- Integrate lightweight components into a complete system.

- Evaluate braking performance, energy efficiency, and compatibility with vehicle architectures.

- Conduct field trials and simulated driving scenarios.

Collaboration with industry partners, regulatory bodies, and academic institutions is essential to ensure alignment with industry standards, safety regulations, and technological advancements.

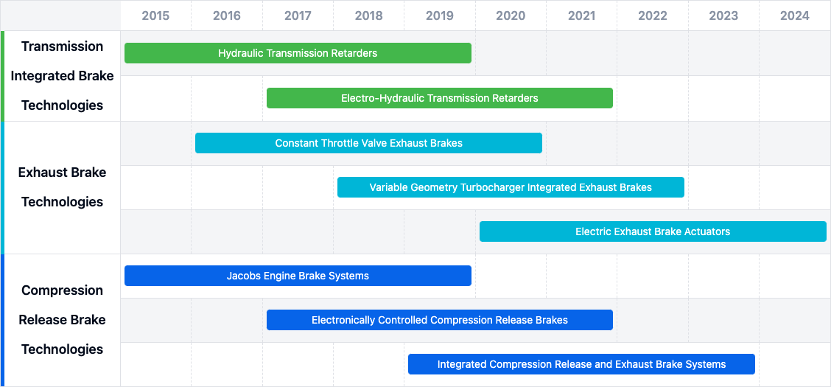

Technical Development Roadmap

Key Areas of Advancement

- Exhaust Brake Technologies: From constant throttle valve exhaust brakes to electric exhaust brake actuators.

- Compression Release Brake Technologies: From traditional Jacobs systems to integrated compression release and exhaust brake systems.

- Transmission Integrated Brake Technologies: From hydraulic to electric motor-assisted transmission retarders.

These advancements aim to improve vehicle safety, fuel efficiency, and reduce emissions. The integration of electronic control systems and electric motors enables precise and responsive braking, enhancing overall performance.

Main Player Analysis

Key Players and Focus

- Toyota Motor Corp.: Extensive R&D in conventional and advanced engine braking systems.

- LG Electronics Inc.: Expertise in control systems, electronics integration, and advanced sensing technologies.

- University of Malaya: Research on biodiesel production, engine performance optimization, and alternative fuels.

- Missouri University of Science & Technology: Focus on waste heat recovery, regenerative braking, and alternative fuel performance.

- Honda Motor Co. Ltd.: Innovations in regenerative braking and hybrid architectures.

Current Technical Solution Overview

Compression Release Engine Brake

Mechanism: Utilizes the compression stroke to generate braking force by releasing compressed air, reducing engine output power.

System Integration: Integrated into overall engine design for weight reduction by eliminating separate braking components.

Lightweight Materials: Use advanced alloys or composites for valves, camshafts, and actuators.

Control Strategies: Advanced algorithms and software solutions to manage the braking process efficiently.

Integration with Exhaust Systems: Utilize exhaust components for compression release braking.

Engine Exhaust Brake

Noise Reduction: Techniques to reduce noise during braking operations.

Control Systems: Regulate exhaust brake operation for optimal performance.

Integration with Engine Components: Improve efficiency by leveraging existing engine architecture.

Heavy-Duty Vehicles: Engineered for higher braking demands and loads.

Engine Brake Control Systems

Weight Reduction: Incorporate lightweight components or optimized designs.

Braking Force Management: Control based on vehicle weight, speed, and road conditions.

Transmission Integration: Seamless operation with optimized braking performance.

Compression Release Mechanisms: Enhance braking effect by releasing compressed air.

Brake Force Estimation and Control: Monitor parameters to optimize performance.

Engine Brake Safety Systems

Safety Features: Automatic control, monitoring devices, or failsafe mechanisms.

Noise Reduction: Techniques to minimize noise during engine braking.

Integration with Vehicle Systems: Coordinate with service brakes and energy storage.

Engine Brake Integration with Transmission and Vehicle Systems

Automatic Transmission Integration: Effective braking during deceleration.

Control Strategies: Algorithms for optimized braking performance.

System Integration: Ensure proper coordination with vehicle components.

Specific Vehicle Types: Designs for heavy-duty, off-road, or hybrid vehicles.

Key Patent Interpretation

Patent Highlights

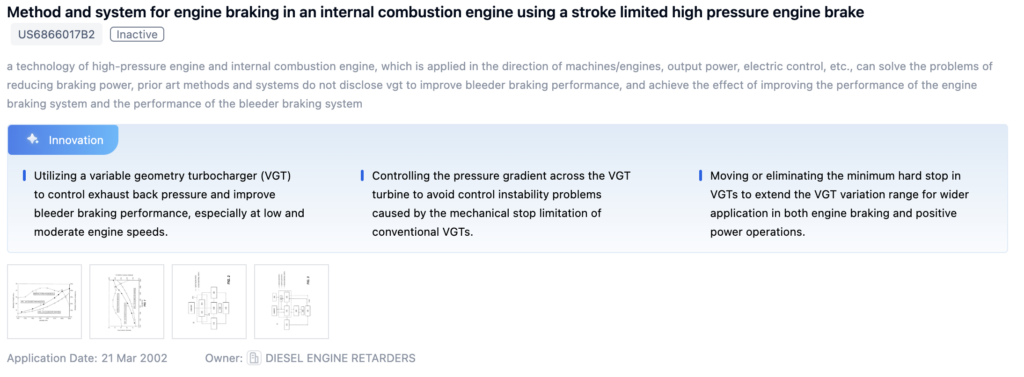

Patent 1: Method and System for Engine Braking

- Utilizes a variable geometry turbocharger (VGT) to control exhaust back pressure and improve performance.

Patent 2: Control of a Combustion Engine in a Vehicle

- Simulates future speed profiles for coasting and evaluates engine shutdown during coasting to improve fuel efficiency.

Patent 3: Autonomous Vehicle Control Method

- Uses a nonlinear model predictive control algorithm to prevent motion sickness while ensuring safety and efficiency.

Possible Research Directions

- Engine Brake Systems for Reducing Vehicle Weight: Lightweight materials and optimized designs to improve fuel efficiency and performance.

- Engine Brake Systems with Improved Braking Performance: Advanced valve timing and airflow paths to increase braking force.

- Engine Brake Control Systems for Improved Vehicle Dynamics: Integrate with vehicle systems to enhance stability and control.

- Noise Reduction Techniques for Engine Brake Systems: Optimize exhaust designs and noise-canceling technologies to improve noise characteristics.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!