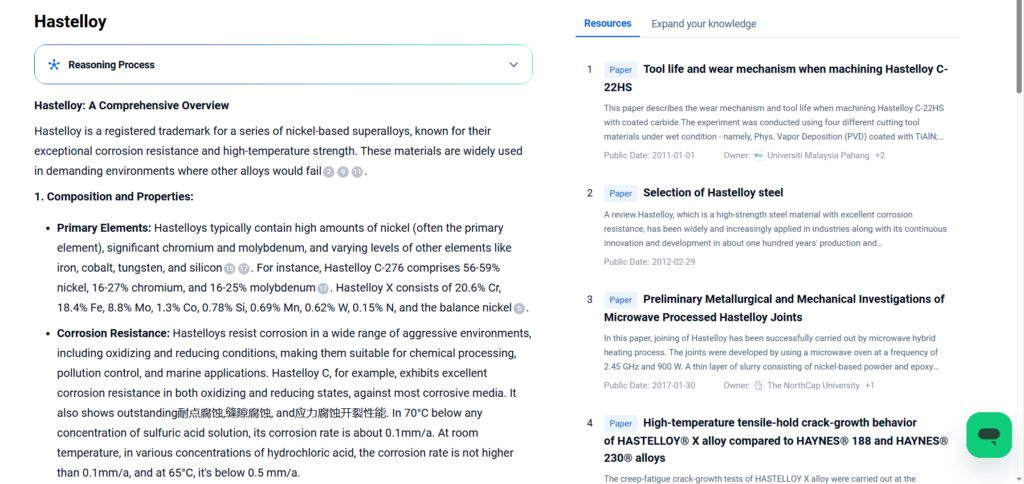

Hastelloy is a trademarked family of corrosion-resistant metal alloys primarily made of nickel, with varying amounts of molybdenum, iron, cobalt, and chromium. Known for their exceptional performance in harsh chemical environments, Hastelloy alloys are widely used in aerospace, marine, chemical processing, and energy sectors. This blog explores its composition, grades, properties, industrial applications, innovations, and sustainability impact—while showcasing how PatSnap Eureka AI Agent enables insights into related patents and material advancements.

What is Hastelloy?

Iis not a single alloy but a group of superalloys manufactured by Haynes International. Common variants include Hastelloy C-22, C-276, X, and B-2, each designed for specific environments and corrosion challenges. These alloys maintain strength and formability under high temperature and pressure conditions, making them ideal for aggressive chemical and marine settings.

Composition & Properties / Performance

Chemical Composition

- Base Element: Nickel (Ni)

- Alloying Elements: Molybdenum (Mo), Chromium (Cr), Iron (Fe), Cobalt (Co), Tungsten (W)

- CAS Numbers: Varies by grade (e.g., 7440-02-0 for Nickel)

Physical & Mechanical Properties

- Density: ~8.89 g/cm³

- Melting Point: 1325–1370°C depending on grade

- Tensile Strength: 690 MPa to 760 MPa

- Hardness: Rockwell B85 to C30

- Thermal Conductivity: ~10 W/m·K

- Electrical Resistivity: 1.29 Ω·mm^2/m

Functional Properties

- Excellent resistance to oxidizing and reducing agents

- High temperature stability

- Outstanding weldability

- Resistance to pitting, stress-corrosion cracking, and crevice corrosion

Material Grades & Designations

Common Hastelloy Grades

- C-276: Most versatile; resistant to a wide range of chemicals

- C-22: Enhanced corrosion resistance in oxidizing environments

- X: Superior high-temperature strength

- B-2: Specialized for hydrochloric acid and reducing agents

Cross-Reference Table

| Grade | ASTM Equivalent | ISO | Application Focus |

|---|---|---|---|

| C-276 | UNS N10276 | ISO NW 0276 | Chemical Processing |

| C-22 | UNS N06022 | ISO NW 6022 | Pollution Control Equipment |

| Hastelloy X | UNS N06002 | ISO NW 6002 | Aerospace Combustion Chambers |

Application Landscape

Core Industries

- Chemical Processing: Vessels, reactors, and piping for acids and chlorides

- Aerospace: Combustion liners, transition ducts, and afterburners

- Marine: Subsea components and seawater cooling systems

- Power Generation: Heat exchangers and scrubbers

- Pharmaceuticals: Equipment exposed to cleaning agents and biofluids

Real-World Applications

- Hastelloy C-276 is used in chlorine dioxide scrubbers.

- C-22 helps fabricate flue gas scrubbers in incineration plants.

- Hastelloy X is employed in jet engine combustors and nuclear reactor components.

Emerging Trends

- Hastelloy membranes in hydrogen separation and CO2 capture

- Biocompatible Hastelloy stents in experimental cardiovascular implants

- Additive manufacturing of its parts using laser powder bed fusion

Hastelloy vs Other Similar Materials

| Feature | Hastelloy C-22 | Inconel 625 | Stainless Steel 316L |

|---|---|---|---|

| Corrosion Resistance | Excellent | Very Good | Moderate |

| Max Temperature | ~1250°C | ~1000°C | ~870°C |

| Strength | High | High | Medium |

| Weldability | High | Moderate | High |

Advantages

- Exceptional corrosion resistance: Performs reliably in oxidizing and reducing media including sulfuric, hydrochloric, and phosphoric acids.

- Thermal endurance: Withstands temperatures exceeding 1000°C, making it ideal for aerospace and nuclear applications.

- Mechanical strength: Maintains high tensile and yield strength under stress and in aggressive environments.

- Versatile fabrication: Readily formed and machined into complex geometries for custom applications.

- Excellent weldability: Requires no post-weld heat treatment, reducing downtime and fabrication costs.

- Extended lifespan: Reduces maintenance cycles and total lifecycle cost, especially in chemical or marine settings.

- High availability: Supplied in various standardized forms including plates, tubes, bars, and wires.

- Safe for bioprocessing: Resistant to contamination and suitable for pharmaceutical-grade equipment.

Innovations & Technology

Latest Developments

- Hastelloy Membranes: Researchers have developed Hastelloy-based membranes capable of selectively separating hydrogen and carbon dioxide gases. These membranes enhance efficiency in hydrogen purification and carbon capture technologies.

- Biomedical Devices: Nanoscale coatings of Hastelloy C-22 have been engineered to reduce bacterial adhesion, opening pathways for safe, long-term implants and catheters.

- 3D Printing & Aerospace: Additive manufacturing with Hastelloy X has advanced to produce high-performance parts for turbine engines. These components maintain integrity under high thermal gradients and oxidizing atmospheres.

- Catalytic Coatings: Surface-engineered Hastelloy substrates are now being used in chemical reactors to improve catalyst longevity and reactivity under extreme pH and temperature.

- Fuel Cell Components: Novel Hastelloy alloys are under development for use as plates in PEM fuel cells due to their durability in acidic environments.

Sustainability & Environmental Impact

- Durability: Long life span reduces replacement and waste

- Recyclability: Nickel-based alloys are fully recyclable

- Toxicity: Generally non-toxic but high nickel content requires handling compliance

- Certifications: Complies with RoHS, REACH, and ISO 14001 standards

PatSnap Eureka AI Agent Capabilities

- Tracks global patent trends for high-performance alloys

- Identifies leaders and emerging startups in applications

- Maps technology clusters in aerospace and chemical sectors

- Detects innovation white spaces and competitor filing patterns

Conclusion

Hastelloy alloys are indispensable in industries where extreme environments demand exceptional material performance. Their resistance to corrosion, high strength, and adaptability to complex manufacturing methods make them vital to modern engineering. By leveraging PatSnap Eureka AI Agent, R&D teams can stay ahead of innovation trends, monitor key patents, and uncover new opportunities in the specialty alloy space.

FAQs

Its exceptional corrosion resistance and high-temperature strength make it suitable for harsh industrial environments.

Most of them grades are non-magnetic or only slightly magnetic.

Yes. It offers excellent weldability without requiring post-weld heat treatment.

It’s heavily used in chemical plants, jet engines, marine structures, and nuclear facilities.

In aggressive environments, especially with acids or high temperatures, Hastelloy significantly outperforms stainless steel.

For more scientific explanations ofHastelloy, try PatSnap Eureka AI Agent.