Background and Objectives

Background

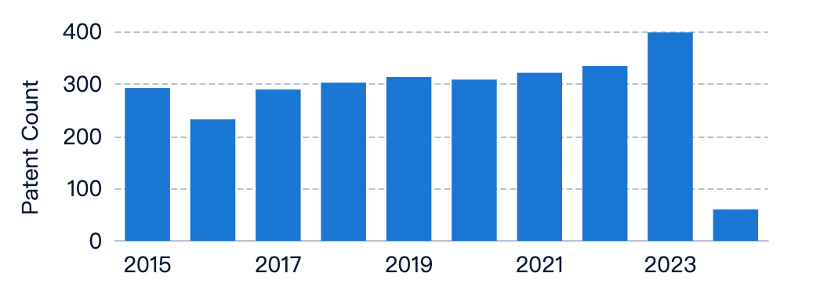

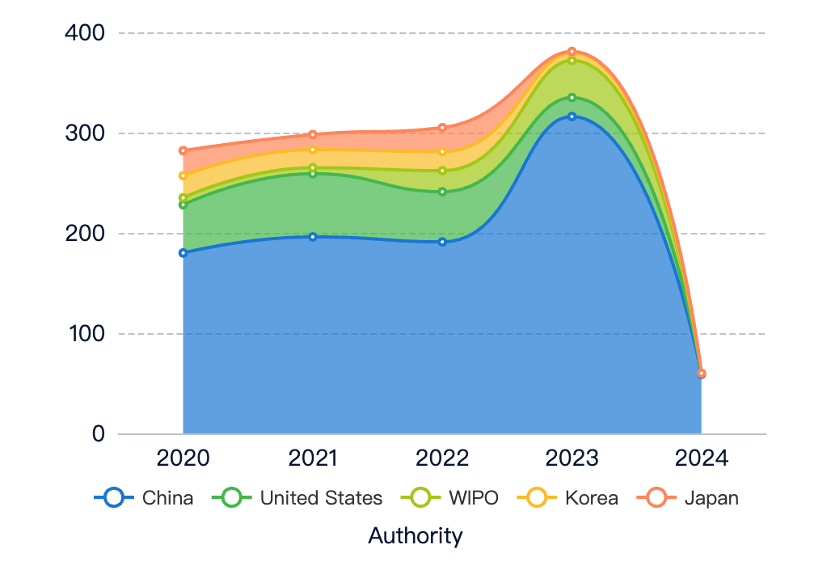

Patent data shows an increasing trend in applications related to thermite production, reflecting growing interest and innovation in commercial and industrial applications. In contrast, literature on thermite fluctuates without a clear trend, indicating steady but less pronounced academic research compared to patents.

Objectives

The primary goals are to optimize thermite formulations and synthesis methods, investigate large-scale manufacturing techniques, explore novel applications in welding, demolition, and military operations, and ensure comprehensive risk assessments and safety protocols are developed and followed.

To get a detailed scientific explanations of Thermite, try Eureka.

Current Status

Thermite Composition

Thermite is a pyrotechnic composition consisting of a metal powder and a metal oxide that undergoes an exothermic redox reaction when ignited, producing intense heat and molten metal. The most common thermite composition is a mixture of aluminum metal powder and iron oxide. When ignited, the aluminum reduces the iron oxide, producing molten iron and aluminum oxide as a byproduct.

Applications

Thermite has a wide range of applications due to its ability to generate extremely high temperatures, typically in excess of 2500°C (4532°F). Some of its major applications include:

- Welding and Metal Joining: Thermite is used in welding and metal joining processes, particularly in the railway industry for welding rail tracks. The intense heat generated by the thermite reaction melts the metal, allowing for a strong and durable weld.

- Incendiary Devices: Thermite has been used in incendiary devices and weapons due to its ability to generate intense heat and molten metal. However, its use in such applications is highly regulated and restricted.

- Emergency Rescue Operations: Thermite can be used in emergency rescue operations to cut through metal structures such as vehicle wreckage or reinforced doors when other cutting methods are ineffective or unavailable.

- Pyrotechnics and Special Effects: Thermite is sometimes used in pyrotechnic displays and special effects in the entertainment industry due to the intense light and heat it produces.

- Mining and Demolition: Thermite can be used in mining and demolition applications to cut through rock or metal structures.

While thermite has various practical applications, its production and use are subject to strict regulations and safety protocols due to the potential hazards associated with handling and igniting such a highly exothermic and reactive mixture.

Technical Challenges

The production and use of thermite present several technical characteristics and challenges:

- Composition and Stoichiometry: Precise control of the composition and stoichiometric ratio of the metal powder and metal oxide is crucial for achieving the desired thermite reaction and performance. Deviations from the optimal ratio can lead to incomplete reactions or reduced heat generation.

- Particle Size and Homogeneity: The particle size and homogeneity of the metal powder and metal oxide play a significant role in the reaction kinetics and propagation of the thermite reaction. Finer particle sizes and better mixing can enhance the reactivity and combustion rate.

- Ignition and Initiation: Thermite mixtures require a high-temperature ignition source, typically in the range of 800°C to 1000°C, to initiate the exothermic reaction. Proper ignition techniques and safety measures are essential to ensure controlled and safe initiation.

- Containment and Heat Management: The intense heat generated by the thermite reaction necessitates the use of suitable refractory materials and containment systems to prevent damage or uncontrolled reactions. Effective heat management and cooling mechanisms are crucial for safe handling and application.

- Environmental and Safety Considerations: The production and use of thermite involve potential environmental and safety hazards, such as the generation of toxic fumes, molten metal splatter, and the risk of uncontrolled reactions. Strict adherence to safety protocols, personal protective equipment, and environmental regulations is mandatory.

To address these technical challenges and promote the safe and efficient production and use of thermite, the following technological paths can be explored:

- Advanced Material Characterization and Synthesis: Develop techniques for precise control and optimization of the composition, particle size, and homogeneity of the metal powder and metal oxide components. This may involve advanced material synthesis methods such as sol-gel processes, mechanical alloying, or chemical vapor deposition.

- Ignition and Initiation Systems: Develop reliable and safe ignition systems that can consistently provide the required high-temperature initiation source for the thermite reaction. This may involve the use of specialized pyrotechnic igniters, electrical ignition systems, or laser-assisted ignition techniques.

- Refractory Materials and Containment Systems: Explore the development of advanced refractory materials and containment systems that can withstand the extreme temperatures generated by the thermite reaction while ensuring structural integrity and thermal management.

- Reaction Modeling and Simulation: Utilize computational modeling and simulation techniques to study the thermite reaction kinetics, heat transfer, and fluid dynamics. This can aid in optimizing the reaction parameters, predicting potential hazards, and designing effective containment and cooling systems.

- Safety and Environmental Management: Implement rigorous safety protocols, personal protective equipment, and environmental management practices to mitigate the risks associated with thermite production and use. This may involve the development of specialized ventilation systems, waste management strategies, and emergency response plans.

- Automation and Process Control: Explore the implementation of automated systems and process control mechanisms to enhance the consistency, reproducibility, and safety of thermite production and application processes, minimizing the need for manual intervention and reducing the risk of human error.

Research Content

Research Objectives

The primary objective of this research project is to develop a comprehensive understanding of the production and application of thermite, a pyrotechnic composition renowned for its ability to generate intense heat and molten slag. By delving into the intricate chemical reactions, manufacturing processes, and potential applications, we aim to unlock the full potential of this versatile material. The research endeavors to address the following key objectives:

a) Optimize the formulation and synthesis of thermite compositions, exploring various fuel-oxidizer combinations and additives to enhance performance characteristics such as reaction temperature, burn rate, and slag fluidity.

b) Investigate advanced manufacturing techniques and equipment for large-scale production of thermite, ensuring consistent quality, safety, and cost-effectiveness.

c) Explore novel applications of thermite in industries such as welding, demolition, and specialized military operations, leveraging its exceptional exothermic properties.

d) Conduct comprehensive risk assessments and develop robust safety protocols for the handling, storage, and transportation of thermite, ensuring compliance with relevant regulations and minimizing potential hazards.

Research Direction and Focus

To achieve the stated objectives, the research will encompass a multidisciplinary approach integrating expertise from chemistry, materials science, engineering, and safety disciplines. The primary focus areas are as follows:

Thermite Composition and Synthesis

- Systematic evaluation of various fuel-oxidizer combinations, including aluminum and iron oxides, to optimize thermite formulations.

- Exploration of additives and binders to enhance reaction kinetics, slag fluidity, and overall performance.

- Development of efficient synthesis methods, such as sol-gel techniques or mechanical alloying, for producing high-quality thermite compositions.

Manufacturing and Scale-up

- Design and optimization of specialized equipment for large-scale thermite production, ensuring consistent quality and safety.

- Implementation of advanced process control and monitoring systems for real-time adjustments and quality assurance.

- Exploration of continuous or semi-continuous manufacturing processes to improve efficiency and reduce costs.

Applications and Safety

- Comprehensive evaluation of thermite’s potential applications in industries such as welding, demolition, and specialized military operations.

- Development of application-specific formulations and delivery systems tailored to specific use cases.

- Rigorous risk assessments and the establishment of robust safety protocols for handling, storage, and transportation of thermite compositions.

- Collaboration with regulatory bodies and industry partners to ensure compliance with relevant standards and regulations.

This research endeavor will leverage state-of-the-art analytical techniques, computational modeling, and experimental methods to generate comprehensive data and insights. The findings will contribute to the advancement of thermite technology, enabling safer and more efficient production and application while fostering innovation in related industries.

Technical Development Roadmap

Key Areas of Advancement

Significant advancements have been made in three primary areas:

- Composition and Formulation: Development of nano-thermite compositions, exploration of environmentally friendly mixtures, and optimization of reaction kinetics.

- Ignition and Combustion Control: Advanced ignition systems, controlled combustion mechanisms, and reaction quenching techniques have been developed to enhance safety and reliability.

- Applications and Integration: Progress in thermite-based welding technologies, pyrotechnics, and propellants, as well as integration in demolition and mining operations.

Main Player Analysis

Key Players and Focus

Research institutions and companies are significantly contributing to thermite research and application:

- Russian Academy of Sciences: Focus on self-propagating high-temperature synthesis (SHS) and autowave synthesis for ceramics, alloys, and composites.

- Tokyo Institute of Technology: Research on microgravity combustion synthesis and centrifugal-thermite processes.

- NIPPON STEEL CORP.: Optimizing thermite compositions for efficient steel production.

- Halliburton Energy Services Inc.: Development of thermite applications for downhole operations in the oil and gas industry.

- Pangang Group Panzhihua Iron & Steel Research Institute Co., Ltd.: Focus on iron and steel production applications.

Current Technical Solution Overview

Thermite composition and preparation

Various thermite compositions and methods for their preparation are disclosed. These include thermite compositions with specific components such as aluminum and metal oxides, as well as additives like carbon or binders. The compositions can be tailored for different applications and properties.

Thermite compositions with core-shell structure: These thermite compositions feature a core-shell structure where the fuel and oxidizer components are arranged in a core-shell configuration. This structure can enhance reactivity, energy density, and control over the reaction. Various materials and preparation methods are used to create these core-shell thermites.

Nanoscale and micron-sized thermite compositions: Thermite compositions can be prepared at the nanoscale or micron-scale where the fuel and oxidizer particles are reduced to very small sizes. This can improve reactivity, energy density, and combustion characteristics. Different synthesis methods such as low-temperature impact milling or electrochemical deposition are employed.

Thermite compositions with tailored properties: Thermite compositions can be designed and formulated to exhibit specific properties such as high or low reaction temperatures, gas generation, or alloying capabilities. This can be achieved by selecting appropriate fuel and oxidizer components as well as incorporating additives or modifiers.

Thermite compositions for welding and joining applications: Thermite compositions can be used for welding and joining applications such as rail welding or pipe joining. These compositions are formulated to generate high temperatures and molten metal for melting and fusing the materials being joined.

Thermite reaction and product formation

The thermite reaction involves the exothermic reduction of metal oxides by a metal, typically aluminum, to produce the corresponding metal. Methods for initiating and controlling the thermite reaction as well as producing various products like alloys, composites, or melts are described.

Thermite reaction for producing metals and alloys: The thermite reaction involves the exothermic reduction of a metal oxide by a reactive metal, typically aluminum. This reaction can be utilized to produce various metals and alloys such as ferroalloys, copper, and magnesium by carefully selecting the reactants and controlling the reaction conditions.

Thermite reaction for welding and joining: The intense heat generated by the thermite reaction can be harnessed for welding and joining applications such as welding railway rails, pipelines, or electrochemical protection wires. The molten metal produced by the reaction can be used to fuse the materials being joined.

Thermite reaction for synthesis of composite materials: The thermite reaction can be employed to synthesize composite materials such as aluminum oxide-reinforced metal matrix composites or core-shell structured thermite materials. The high temperatures and rapid reaction rates facilitate the formation of unique microstructures and material properties.

Thermite reaction for educational and demonstration purposes: The thermite reaction is often used in educational settings and demonstrations to illustrate the principles of exothermic reactions, heat generation, and the formation of molten products. Various devices and apparatus have been developed to safely conduct and observe the thermite reaction for instructional purposes.

Thermite reaction for pyrotechnic and destructive applications: Due to the intense heat and rapid reaction rate, thermite compositions can be utilized in pyrotechnic and destructive applications such as incendiary devices, cutting tools, or thermite charges. These applications leverage the exothermic nature and high temperatures of the thermite reaction.

Thermite devices and apparatus

Various devices and apparatus related to thermite reactions are disclosed. These include thermite reaction experimental setups for teaching or demonstration purposes as well as devices for igniting, containing, or controlling the thermite reaction for specific applications.

Thermite ignition and initiation devices: Various devices and apparatuses are designed to ignite or initiate thermite reactions. These include ignition devices that use electrical or chemical means to trigger the thermite reaction as well as devices that facilitate the controlled initiation of the thermite reaction for specific applications.

Thermite welding and joining devices: Thermite welding and joining devices utilize the intense heat generated by thermite reactions to join or weld metal components together. These devices are commonly used in applications such as welding railway tracks, pipelines, and other metal structures.

Thermite cutting and penetration devices: Thermite cutting and penetration devices harness the exothermic thermite reaction to cut through or penetrate various materials, including metals and other solid structures. These devices find applications in fields such as demolition, military operations, and industrial cutting processes.

Thermite compositions and formulations: Thermite compositions and formulations involve the development and preparation of thermite mixtures with specific properties and characteristics tailored for various applications. These formulations may include additives, binders, or other components to enhance performance or modify reaction characteristics.

Thermite reaction demonstration and experimental devices: Devices and apparatuses are designed for demonstrating and studying thermite reactions in educational or research settings. These devices allow for the controlled and safe observation of thermite reactions, often incorporating safety features and visualization components.

Nanostructured and core-shell thermite

Thermite compositions with nanostructured or core-shell architectures are described. These structures can enhance the reactivity, energy density, or other properties of the thermite material. Methods for synthesizing and applying these advanced thermite materials are also provided.

Core-shell nanostructured thermite materials: These materials consist of a core and a shell layer with nanoscale dimensions where the core and shell are composed of different materials that can undergo an exothermic thermite reaction. The nanostructured design allows for enhanced reactivity and energy release compared to conventional thermite compositions.

Preparation methods for core-shell thermite nanostructures: Various techniques are employed to synthesize core-shell thermite nanostructures such as spray co-precipitation, sol-gel processes, and layer-by-layer deposition. These methods allow for precise control over the composition, size, and morphology of the core and shell layers.

Applications of core-shell thermite nanostructures: Core-shell thermite nanostructures find applications in areas such as energetic materials, propellants, welding, and biomass blasting devices. Their high energy density and tailored reactivity make them suitable for various applications requiring controlled energy release.

Multi-layered and hybrid core-shell thermite structures: In addition to conventional core-shell designs, researchers have explored multi-layered and hybrid structures incorporating additional layers or materials. These advanced designs aim to further enhance the performance and functionality of thermite nanostructures.

Characterization and properties of core-shell thermite nanostructures: Various analytical techniques are employed to characterize the structural, morphological, and thermal properties of core-shell thermite nanostructures. Understanding these properties is crucial for optimizing their performance and tailoring them for specific applications.

Thermite applications and specialized compositions

Thermite compositions and methods tailored for specific applications are discussed. These include thermite compositions for welding, cutting, destructive devices, or other specialized uses as well as compositions with tailored properties like high or low temperature stability, gas generation, or corrosivity.

Thermite compositions with tailored properties: Thermite compositions can be formulated with specific properties such as low-temperature ignition, controlled reaction rates, or enhanced energy output. These tailored compositions can be achieved through various techniques, including the use of additives, nanostructured materials, or specialized manufacturing processes.

Thermite compositions for welding and cutting applications: Thermite compositions can be utilized for welding and cutting applications, particularly in the field of pipeline construction and maintenance. These compositions generate intense heat and molten metal, enabling processes like thermite welding, cutting, and joining of metal structures.

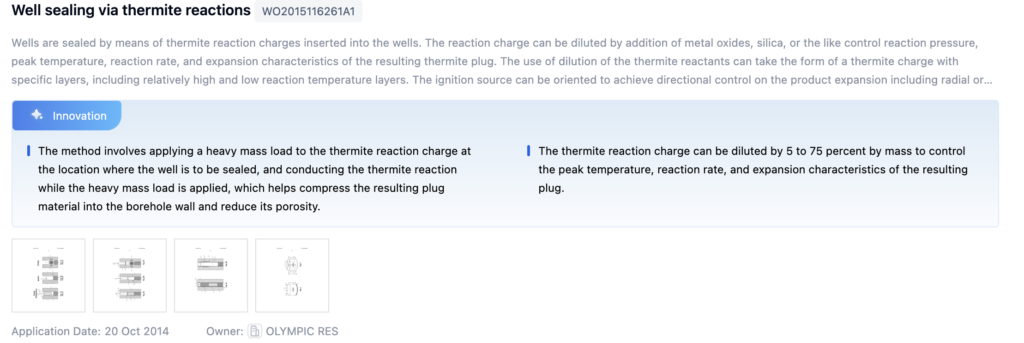

Thermite compositions for downhole and well applications: Thermite compositions can be employed in downhole and well applications, such as well sealing, plugging, and abandonment. The exothermic reaction of thermite can generate high temperatures and pressures, making it suitable for melting and fusing materials in these challenging environments.

Thermite compositions with enhanced reactivity and energy output: Researchers have developed thermite compositions with improved reactivity and higher energy output. These compositions may incorporate nanostructured materials, novel fuel-oxidizer combinations, or specialized manufacturing techniques to achieve enhanced performance characteristics.

Thermite compositions for specialized applications: Thermite compositions can be tailored for specific applications such as pyrotechnics, demolition, or munitions. These compositions may incorporate specialized additives, binders, or configurations to meet the unique requirements of the intended application.

Key Patent Interpretation

Patent Highlights

Patent 1: Well Sealing via Thermite Reactions

- Applying a heavy mass load to the thermite reaction charge compresses the resulting plug material into the borehole wall.

- The thermite reaction charge can be diluted to control peak temperature, reaction rate, and expansion characteristics.

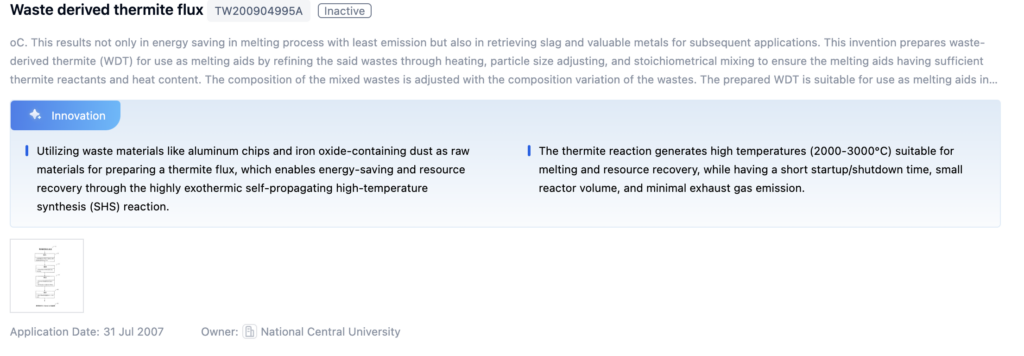

Patent 2: Waste Derived Thermite Flux

- Utilizing waste materials for thermite flux enables energy-saving and resource recovery.

- The thermite reaction is suitable for melting and resource recovery with minimal emissions.

Patent 3: Sheathed Thermite Rod

- Sheathed within an aluminum tube for rigidity and burn continuity.

- The sheathing reduces the drying period, increasing production speed.

Possible Research Directions

- Thermite Composition and Preparation Methods: Various thermite compositions and their preparation methods are disclosed. These include thermites with specific compositions such as Al/Fe2O3, Al/CuO, and nanoscale or core-shell structured thermites. The methods involve mixing the appropriate metal and metal oxide components in desired ratios and forms.

- Thermite Reaction Devices and Apparatus: Several devices and apparatus are described for facilitating or demonstrating the thermite reaction. These include ignition devices, reaction chambers, and experimental setups for educational or research purposes related to the thermite reaction.

- Applications of Thermite Reactions: The thermite reaction is utilized for various applications such as welding, cutting, producing alloys or composite materials, and destructive devices. The intense heat and molten metal produced by the thermite reaction are harnessed for these purposes.

- Thermite Ignition and Initiation Methods: Different methods and compositions are described for initiating or igniting the thermite reaction. These include ignition mixtures, electric igniters, and techniques for reliably and safely triggering the exothermic thermite reaction.

- Specialized Thermite Compositions and Structures: Thermite compositions with tailored properties or specialized structures are described, such as thermites with porous or hollow structures, fluorine-based thermites, and thermites designed for specific applications like composite copper pipe production or electrochemical protection wire welding.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!