Background and Objectives

Background

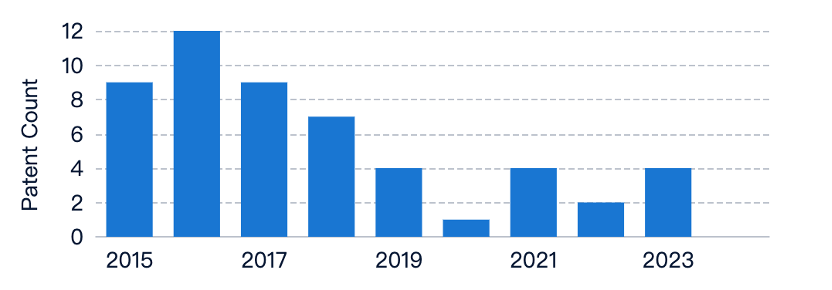

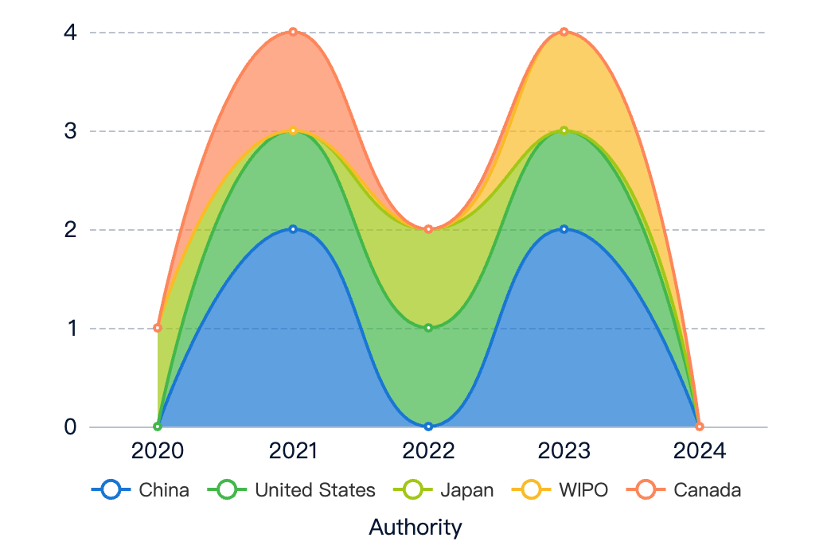

The Toyota ammonia engine is a new technology aiming to utilize ammonia as a fuel source for internal combustion engines. Patent data shows a fluctuating trend with a peak in the early years and a gradual decline recently. This suggests initial interest and research activity around this technology have tapered off.

Regarding the impact on electric vehicles (EVs), data indicates a low level of patent activity with a small spike recently, hinting at potential renewed interest. However, patent activity alone does not provide a comprehensive picture. Factors such as research priorities, funding, or technological challenges may influence these trends. More in-depth analysis is required to assess the true potential and implications of this technology on the EV industry.

Objectives

The study aims to assess the technical feasibility, economic viability, and environmental implications of integrating ammonia-powered engines into EVs. It seeks to provide insights and recommendations for strategic decision-making in the automotive industry.

To get a detailed scientific explanations of Toyota Ammonia Engine, try Eureka.

Technical Current Status Analysis

💡 Looking into the technical development of the Toyota Ammonia Engine? Eureka Technical Q&A provides detailed insights into its design, innovations, and future potential, offering a comprehensive understanding of how this cutting-edge engine could revolutionize sustainable energy in the automotive industry.

Electric Vehicles (EVs)

EVs have gained momentum due to their environmental benefits and push towards sustainable transportation. However, challenges such as limited driving range, long charging times, and infrastructure availability hinder their widespread adoption.

Ammonia-Powered Engines

Toyota’s development of ammonia-powered engines could impact the EV market by offering a potential alternative for sectors like long-haul trucking and maritime transportation, where battery technology limitations are significant.

Technical Characteristics:

- Ammonia as a Fuel: Carbon-free and potentially sustainable when produced from renewable sources.

- Energy Density: Higher than hydrogen, possibly leading to longer driving ranges.

- Refueling Infrastructure: Easier storage and transport compared to hydrogen.

Challenges:

- Engine Development: Adapting engines for ammonia combustion presents technical challenges.

- Safety Considerations: Ammonia is toxic and corrosive, requiring robust safety measures.

- Production and Distribution: Establishing a reliable and cost-effective supply chain is challenging.

- Infrastructure Development: Significant investment and coordination are needed.

- Competition with EVs: Ammonia engines may compete with battery EVs, potentially slowing EV adoption.

Research Content

Research Objectives

The research aims to comprehensively investigate the potential impact of Toyota’s ammonia engine technology on the EV industry, assessing technical feasibility, economic viability, and environmental implications.

Research Direction and Focus

The research will adopt a multidisciplinary approach, focusing on:

Technical Feasibility Assessment

Analyzing the engine’s design, efficiency, power output, and compatibility with EV architectures, and addressing challenges like infrastructure, safety, and manufacturing complexities.

Economic and Market Analysis

Conducting cost-benefit analyses, assessing production costs, market demand, and consumer acceptance, and exploring potential cost savings from reduced reliance on lithium-ion batteries.

Environmental Impact Assessment

Evaluating lifecycle emissions, carbon footprint, and potential for reducing greenhouse gas emissions compared to traditional engines and lithium-ion battery-powered EVs.

Regulatory and Policy Considerations

Examining regulatory frameworks, emissions standards, fuel economy regulations, and identifying barriers or opportunities for adopting ammonia engine technology in the EV market.

Technical Development Roadmap

Key Areas of Advancement

Toyota’s technological roadmap for ammonia engines focuses on:

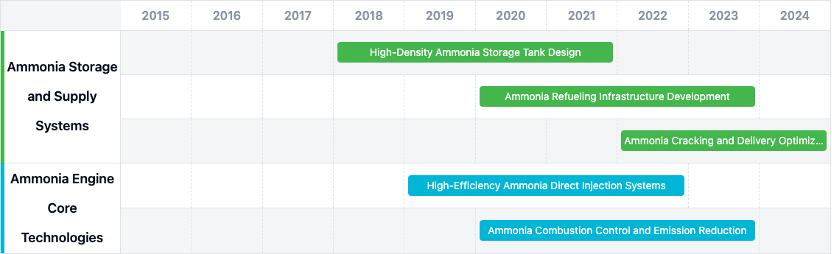

Ammonia Engine Core Technologies

Developing high-efficiency ammonia direct injection systems, optimizing combustion control, and exploring dual-fuel engine configurations to enhance efficiency and performance.

Ammonia Storage and Supply Systems

Designing high-density ammonia storage tanks, developing refueling infrastructure, and optimizing ammonia cracking and delivery processes for efficient supply chain integration.

Main Player Analysis

Key Players and Focus

- Toyota Central R&D Labs Inc.: Focus on optimizing combustion processes, improving efficiency, and reducing emissions.

- Toyota Motor Corp.: Extensive research on ammonia storage and delivery systems, combustion optimization, and hybrid systems.

- Toyota Industries Corp.: Exploring ammonia as a fuel source for materials handling equipment and power generation systems.

Current Technical Solution Overview

Ammonia-Fueled Internal Combustion Engines

Ammonia-Fueled Internal Combustion Engines: Designed to burn ammonia directly or crack it into hydrogen and nitrogen for combustion, potentially reducing carbon emissions compared to fossil fuels.

Ammonia-Fueled Engines for Vehicles: Integration into vehicles with components like storage tanks, fuel delivery, and exhaust treatment systems to reduce carbon footprint and transition to sustainable transportation.

Hybrid Systems Combining Ammonia Engines and Fuel Cells: Combining ammonia-fueled engines with fuel cells for improved efficiency and reduced emissions.

Emission Control and Exhaust Treatment Systems: Systems like selective catalytic reduction (SCR) and ammonia slip catalysts to reduce nitrogen oxides (NOx) and other pollutants.

Impact on Electric Vehicles: Ammonia engines could compete with or complement EVs, especially in long-haul transportation or marine applications, depending on costs, infrastructure, and regulations.

Ammonia-Electric Hybrid Vehicles

Ammonia-Powered Electric Vehicles: Using ammonia to generate hydrogen for fuel cells, combining ammonia’s storage advantages with electric vehicles’ efficiency.

Hybrid Electric Vehicles with Ammonia Systems: Incorporating ammonia as a fuel source for engines or hydrogen carriers for fuel cells in hybrid propulsion systems.

Ammonia Cracking and Hydrogen Generation: Efficient systems for cracking ammonia to produce hydrogen for fuel cells in electric vehicles.

Thermal Management and Energy Storage: Addressing thermal management and energy storage challenges in ammonia-electric hybrid vehicles.

Ammonia Storage and Delivery Systems

Ammonia Storage Systems for Electric Vehicles: Systems for storing and delivering ammonia, including solid or liquid storage materials and heating mechanisms.

Ammonia Delivery and Injection Systems: Systems for delivering and injecting ammonia into vehicle systems like exhaust treatment or engines.

Ammonia Storage Materials and Regeneration: Development of materials and methods for regenerating or resaturating ammonia storage materials.

Hybrid Energy Storage Systems: Incorporating ammonia as an energy source in hybrid systems with batteries or hydrogen.

Ammonia Engine Control and After treatment

Ammonia Engine Control Strategies: Optimizing performance and emissions with control strategies for air-fuel ratio, injection timing, and ignition.

Ammonia Engine Aftertreatment Systems: Reducing emissions with systems like SCR and ammonia slip catalysts.

Ammonia Engine Integration with Electric Vehicles: Using ammonia engines to generate electricity or charge energy storage systems in EVs.

Ammonia Engine Fuel Supply and Pretreatment: Effective systems for fuel supply, metering, injection, and heating of ammonia for engines.

Impact of Ammonia Engines on Electric Vehicles

Ammonia-Powered Electric Vehicles: Using ammonia to generate electricity for EVs, combining ammonia’s storage benefits with electric propulsion.

Conversion of Internal Combustion Engine Vehicles to EVs: Methods for converting conventional vehicles to electric, replacing engines with electric motors and batteries.

Ammonia Injection Systems for Emission Control: Using ammonia in exhaust systems for NOx reduction in diesel engines.

Hybrid Electric Vehicles with Internal Combustion Engines: Combining engines with electric motors and batteries for hybrid propulsion.

Electric Vehicle Charging and Infrastructure: Developing charging stations, grid integration, and management strategies for EVs.

Key Patent Interpretation

Patent Highlights

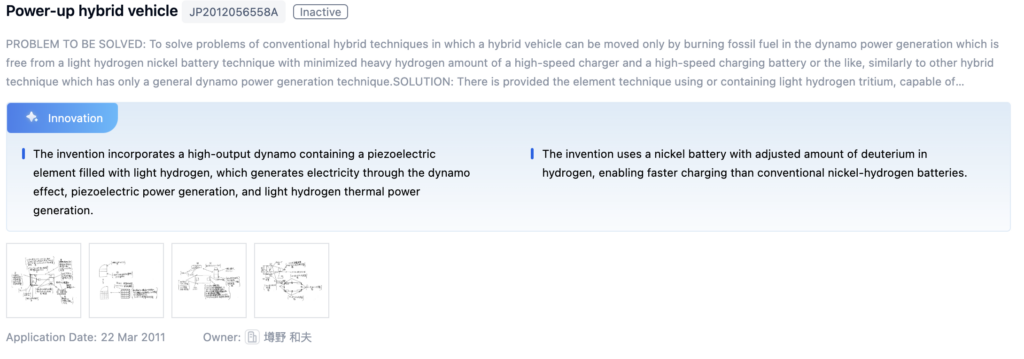

Patent 1: Power-Up Hybrid Vehicle

- High-output dynamo containing a piezoelectric element with light hydrogen for electricity generation.

- Nickel battery with adjusted deuterium for faster charging than conventional batteries.

Patent 2: Combustion Emission-Reducing Method

- Fuel mixture with an ammonia-like component for reducing NOx emissions.

- Fuel-reductant composition for hydrogen storage and reduced exhaust emissions.

Patent 3: Method and System for Determining Fuel Consumption

- Method for determining actual fuel consumption, energy use, and emissions in everyday vehicle operation.

- Accounts for real driving behavior, traffic conditions, and usage patterns.

Possible Research Directions

- Ammonia Combustion Engines for Vehicles: Using ammonia as a fuel for internal combustion engines, either directly or by cracking it into hydrogen and nitrogen.

- Ammonia-Powered Electric Vehicles: Electric vehicles using ammonia-powered systems to generate electricity for propulsion.

- Ammonia Engine Control and Management Systems: Regulating injection, combustion, and aftertreatment of ammonia in vehicle engines.

- Impact of Ammonia Engines on Electric Vehicles: Exploring how ammonia engines could provide an alternative to traditional engines, reducing emissions and fossil fuel dependence while offering performance advantages over current EVs.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!