As semiconductor manufacturing processes approach their physical limits, extreme ultraviolet (EUV) lithography has become a key technology for enabling nanoscale chip fabrication. However, while EUV offers high resolution, it also faces numerous challenges arising from quantum effects.

Compared with traditional deep ultraviolet (DUV) lithography, EUV photons have higher energy but significantly lower photon density, leading to increased randomness in photon absorption and enhanced electron migration effects, which ultimately affect pattern fidelity. At sub-10 nm nodes, where the size of photoresist molecules approaches the feature dimensions, the impact of quantum fluctuations can no longer be ignored.

Fundamentals of EUV Lithography and Origins of Quantum Effects

EUV lithography employs 13.5 nm wavelength light (photon energy ~92 eV) generated by laser-induced plasma emission from molten tin. The light is collected and focused via a mirror system and projected onto a silicon wafer to form nanoscale patterns in the photoresist. Because EUV light is strongly absorbed by air, the process must be conducted in a vacuum. Compared with 193 nm DUV lithography, EUV photons have ~14× higher energy, capable of ionizing core electrons (not just valence electrons), triggering complex electron cascade reactions.

The physical mechanisms of quantum effects can be summarized as:

·Randomness of photon absorption: EUV photon density is significantly lower than DUV (for the same dose, photon count is 14× lower), resulting in discrete absorption events.

·Electron migration effect: Ionization by a single EUV photon releases high-energy photoelectrons (~80 eV), which generate secondary electrons via inelastic scattering. These electrons can migrate >10 nm—far beyond the ~2 nm molecular size—meaning a single photon absorption can affect surrounding molecules, increasing stochastic noise.

·Molecular scale limitations: At sub-10 nm half-pitch, the photoresist molecular size (~2 nm) becomes comparable to the feature size, making quantum fluctuations unavoidable.

Impact of Quantum Effects on Lithographic Quality

Quantum effects in EUV lithography primarily manifest as dose stochasticity and edge placement errors (EPE). Data show that in DUV lithography at a 30 mJ/cm² dose, each 50 nm pixel absorbs ~500,000 photons with dose variation <0.5%. In contrast, EUV lithography at 60 mJ/cm² yields only ~3,400 photons per 50 nm pixel, with dose variation exceeding 50%.

Such >50% dose fluctuation causes severe EPE, including line edge roughness (LER), critical dimension non-uniformity (CDU), and feature placement deviation. Aggravating factors include:

·Low photon density: Higher EUV photon energy means 1/14 the photon count of DUV at the same dose.

·Photoresist thinning: Required for high resolution to avoid high aspect ratio issues, further reducing absorption.

·Reduced molecular size: Smaller photoresist molecules reduce the effective photon capture area.

Modeling Challenges of Quantum Effects

To address quantum effects, a multi-stage modeling approach is required.

In the first stage, photon absorption probability must be simulated at the molecular scale (around 2 nm), taking into account variations in ionization cross-sections among different elements (e.g., tin, carbon, oxygen).

In the second stage, electron transport effects should be modeled, including the scattering paths of photoelectrons and secondary electrons, as well as their energy deposition range (which can extend up to 10 nm).

In the third stage, the spatial correlation of photoresist chemical reactions (such as acid diffusion) must be simulated, as it is influenced by the electron energy distribution.

Since both photon absorption and electron scattering are stochastic events, low photon densities can lead to stochastic defects—such as microbridges or voids. These defects directly constrain EUV lithography yield and reliability, making modeling a key step in mitigating quantum effects.

Solutions and Technology Comparisons

Dose Increase (Limited Effectiveness):

Increasing the dose raises photon density, reducing statistical fluctuations (variance ∝ 1/√photon count). However, doubling EUV dose from 60 mJ/cm² to 120 mJ/cm² only reduces variance to about 35%. Higher doses can cause photoresist heating, outgassing, and contamination of optical components. In addition, increased electron density may induce electron blur, potentially worsening stochastic defects.

Double Patterning Technology:

This technique divides a single high-density design into two sub-patterns, combining them through two EUV exposures and an intermediate thin-film deposition. The advantage lies in bypassing EUV resolution limits, doubling feature density, and significantly reducing quantum noise in each exposure. However, process complexity doubles, and costs (masks, time, energy consumption) increase by more than 30%.

High-NA EUV:

ASML’s High-NA EUV (NA = 0.55) achieved first exposure in 2024, improving resolution to 8 nm. Higher resolution reduces reliance on electron transport effects, while the adoption of metal oxide resists (e.g., HfO₂) enhances electron capture efficiency and reduces LER, helping mitigate quantum effects. Nevertheless, each system costs over USD 400 million, reduced field size increases stitching error risk, and ultra-thin resists required may exacerbate absorption insufficiency.

Photoresist Material Innovations:

Metal–Organic Frameworks (MOFs) with high-absorption elements (e.g., tin, hafnium) can improve EUV absorption and control electron transport distances. However, while higher sensitivity can be achieved, defect rates may also rise. Lowering molecular weight can reduce line-edge roughness but weakens etch resistance; rigid molecular structures can suppress electron diffusion but are more complex to synthesize.

Comparison of Quantum Effects in DUV vs. EUV

Photon Energy: DUV photons (6.4 eV) mainly drive photolithography via valence electron excitation; EUV photons (92 eV) can directly ionize core electrons and trigger secondary electron cascades.

Photon Density & Dose Variability: DUV provides high photon density (≈ 500,000 photons per 50 nm pixel) with dose variation below 0.5%; EUV has low photon density (≈ 3,400 photons per 50 nm pixel) with dose variation exceeding 50%.

Molecular Scale Effects: In DUV, feature sizes are much larger than molecular dimensions, making quantum effects negligible. In EUV, feature sizes are comparable to molecular dimensions, making quantum effects significant.

Conclusion

For sub-10 nm nodes, the core challenges of EUV lithography are insufficient photon density and uncontrolled electron transport, both contributing to non-negligible stochastic defects.

In the short term, double patterning remains the most cost-effective solution, particularly for the 5–7 nm nodes.

In the long term, High-NA EUV must overcome photoresist material bottlenecks (e.g., adoption of dry development processes) and cost constraints.

Future research directions may include Hyper-NA technology to address atomic-scale quantum tunneling effects, as well as the application of machine learning to optimize secondary electron cascade pathways through real-time monitoring and dynamic adjustment of exposure parameters.

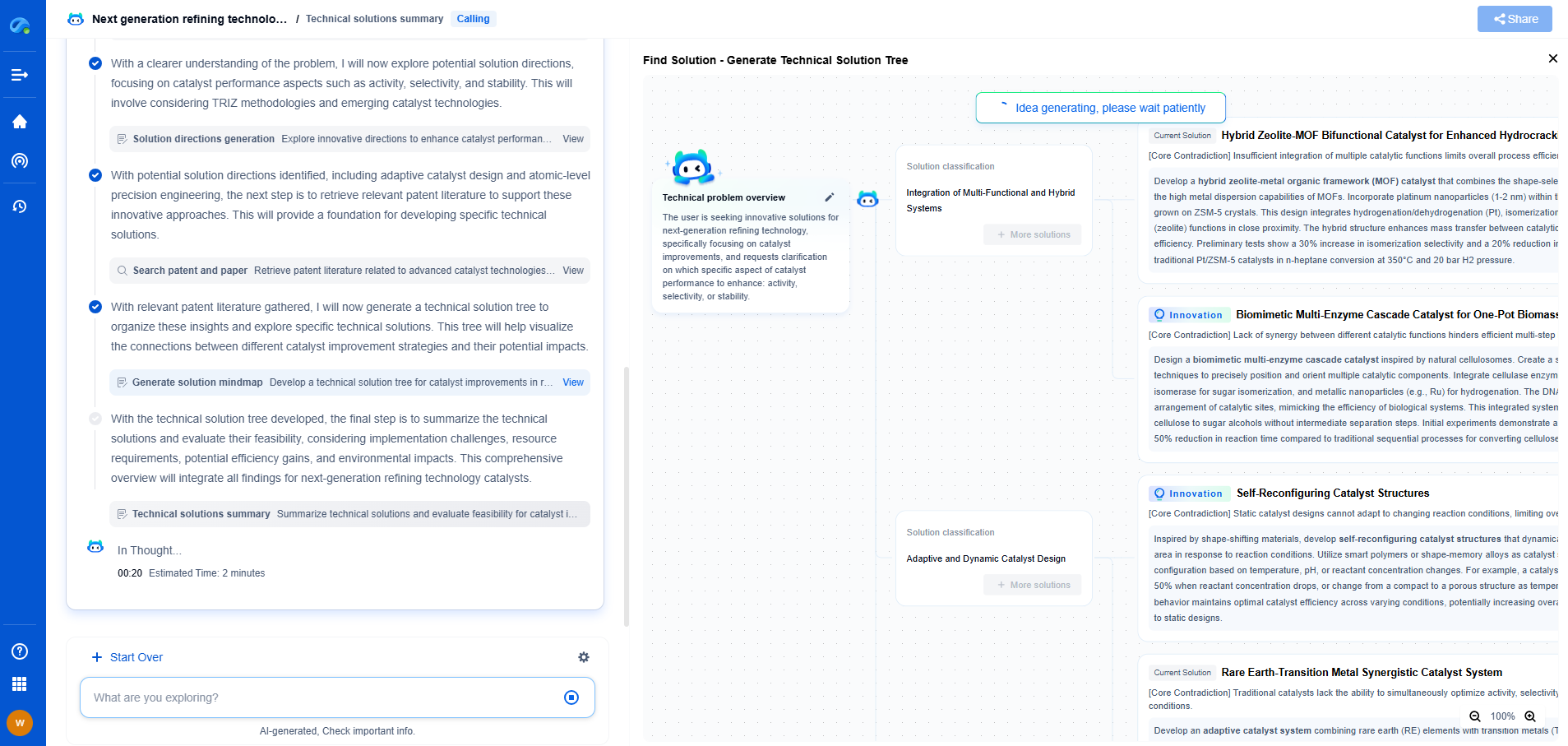

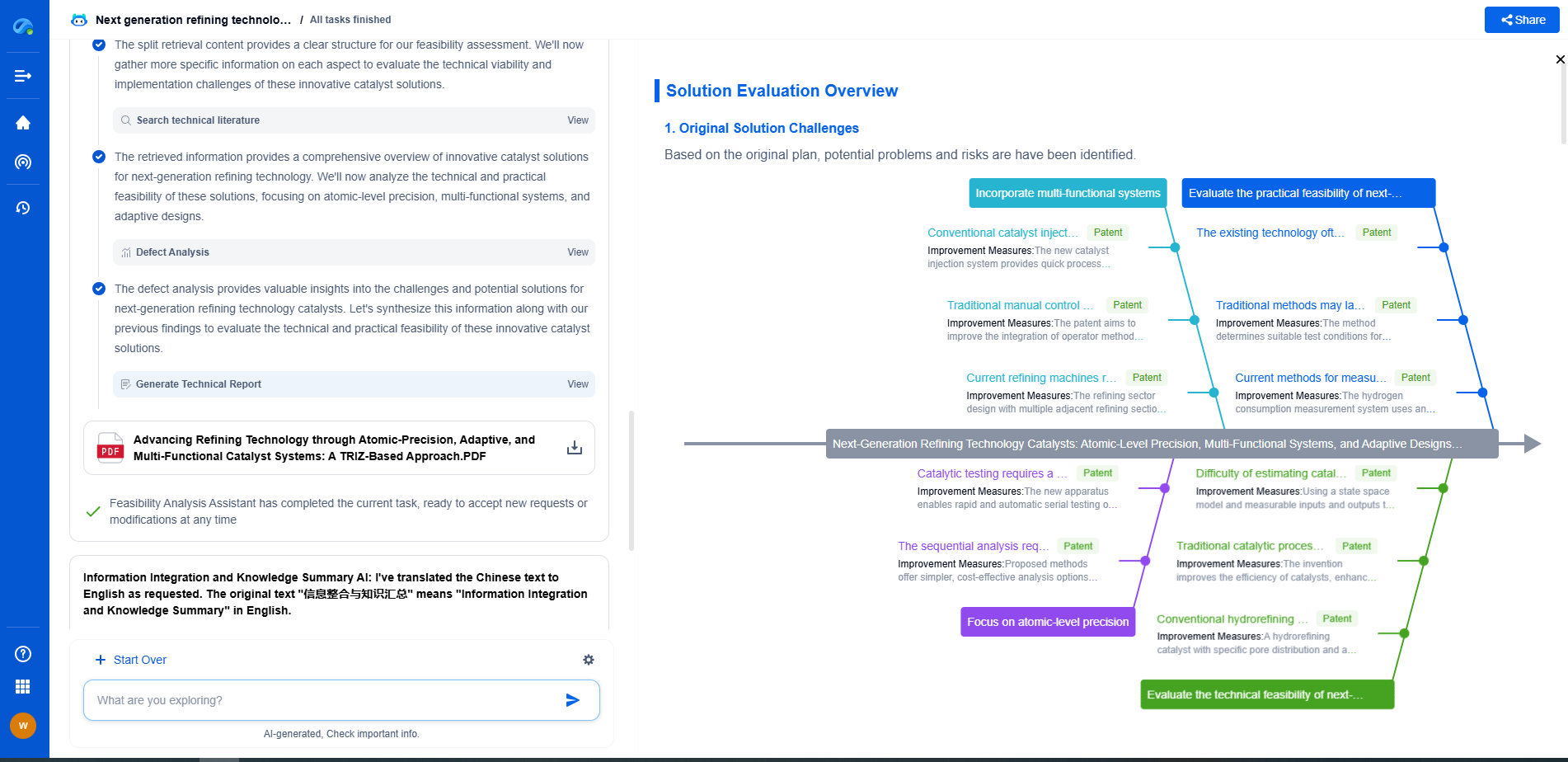

Infuse Insights into Chip R&D with PatSnap Eureka

Whether you're exploring novel transistor architectures, monitoring global IP filings in advanced packaging, or optimizing your semiconductor innovation roadmap—Patsnap Eureka empowers you with AI-driven insights tailored to the pace and complexity of modern chip development.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Join the new era of semiconductor R&D. Try Patsnap Eureka today and experience the future of innovation intelligence.