Compare Chiller Energy Usage in Differing Geographies

JAN 23, 20269 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiller Technology Background and Energy Efficiency Goals

Chiller systems have evolved significantly since their inception in the early 20th century, transitioning from inefficient absorption-based units to today's sophisticated vapor-compression technologies. The fundamental principle remains consistent: removing heat from a liquid through a refrigeration cycle to provide cooling for commercial, industrial, and residential applications. However, the technological sophistication has advanced dramatically, incorporating variable speed drives, magnetic bearing compressors, and intelligent control systems that optimize performance based on real-time conditions.

The geographical context introduces critical variables that fundamentally impact chiller energy consumption patterns. Climate zones ranging from tropical to temperate regions present vastly different cooling loads, ambient temperatures, and humidity levels. These environmental factors directly influence compressor work, condenser efficiency, and overall system coefficient of performance. Additionally, regional infrastructure variations, including electrical grid characteristics, water availability for cooling towers, and local energy costs, create distinct operational parameters that must be considered when evaluating chiller performance across different locations.

Energy efficiency goals for chiller systems have become increasingly stringent as global sustainability initiatives gain momentum. International standards such as ASHRAE 90.1, European Union's Ecodesign Directive, and China's GB standards establish minimum efficiency requirements that vary by region. The industry has witnessed a progressive shift toward integrated part load value metrics rather than full-load efficiency alone, recognizing that chillers operate at partial capacity for the majority of their operational hours. This paradigm shift reflects a more realistic assessment of actual energy consumption patterns.

Contemporary energy efficiency targets emphasize achieving seasonal energy efficiency ratios exceeding 18 for air-cooled systems and 25 for water-cooled configurations in optimal conditions. However, these benchmarks must be contextualized within geographical realities, as a high-efficiency chiller in a moderate climate may consume more total energy than a standard-efficiency unit in a cooler region due to extended operating hours and higher ambient temperatures. The ultimate objective extends beyond equipment efficiency ratings to encompass total system energy optimization, considering factors such as free cooling opportunities, thermal storage integration, and demand response capabilities that vary significantly across different geographical contexts.

The geographical context introduces critical variables that fundamentally impact chiller energy consumption patterns. Climate zones ranging from tropical to temperate regions present vastly different cooling loads, ambient temperatures, and humidity levels. These environmental factors directly influence compressor work, condenser efficiency, and overall system coefficient of performance. Additionally, regional infrastructure variations, including electrical grid characteristics, water availability for cooling towers, and local energy costs, create distinct operational parameters that must be considered when evaluating chiller performance across different locations.

Energy efficiency goals for chiller systems have become increasingly stringent as global sustainability initiatives gain momentum. International standards such as ASHRAE 90.1, European Union's Ecodesign Directive, and China's GB standards establish minimum efficiency requirements that vary by region. The industry has witnessed a progressive shift toward integrated part load value metrics rather than full-load efficiency alone, recognizing that chillers operate at partial capacity for the majority of their operational hours. This paradigm shift reflects a more realistic assessment of actual energy consumption patterns.

Contemporary energy efficiency targets emphasize achieving seasonal energy efficiency ratios exceeding 18 for air-cooled systems and 25 for water-cooled configurations in optimal conditions. However, these benchmarks must be contextualized within geographical realities, as a high-efficiency chiller in a moderate climate may consume more total energy than a standard-efficiency unit in a cooler region due to extended operating hours and higher ambient temperatures. The ultimate objective extends beyond equipment efficiency ratings to encompass total system energy optimization, considering factors such as free cooling opportunities, thermal storage integration, and demand response capabilities that vary significantly across different geographical contexts.

Market Demand for Climate-Adaptive Chiller Systems

The global market for climate-adaptive chiller systems is experiencing robust expansion driven by escalating energy costs, stringent environmental regulations, and the growing recognition that cooling demands vary dramatically across geographical regions. Traditional chiller systems designed with uniform specifications fail to optimize performance when deployed in diverse climatic zones, resulting in significant energy waste and operational inefficiencies. This gap between standardized equipment and localized climate requirements has created substantial demand for intelligent, geography-aware cooling solutions.

Commercial and industrial sectors represent the primary demand drivers, particularly in regions experiencing rapid urbanization and infrastructure development. Data centers, healthcare facilities, manufacturing plants, and large-scale commercial complexes in tropical, arid, and temperate zones are increasingly seeking chiller systems capable of adapting operational parameters to local temperature ranges, humidity levels, and seasonal variations. The imperative to reduce carbon footprints while maintaining operational reliability has elevated climate-adaptive technologies from optional enhancements to strategic necessities.

Regulatory frameworks worldwide are accelerating market adoption. Energy efficiency standards in Europe, North America, and Asia-Pacific regions now mandate performance benchmarks that account for regional climate characteristics. Building certification programs increasingly reward installations that demonstrate measurable energy savings through climate-responsive technologies. These policy mechanisms are transforming procurement criteria, with facility managers prioritizing lifecycle cost optimization over initial capital expenditure.

Emerging markets in Southeast Asia, the Middle East, and Africa present particularly strong growth trajectories. These regions face extreme cooling loads combined with energy infrastructure constraints, making efficient chiller operation economically critical. The convergence of rising temperatures due to climate change and expanding middle-class populations is intensifying cooling demand while simultaneously increasing sensitivity to energy costs.

Technology integration trends further amplify market potential. The proliferation of IoT sensors, cloud-based analytics platforms, and machine learning algorithms enables real-time climate data integration into chiller control systems. This technological convergence allows predictive adjustments based on weather forecasts, occupancy patterns, and grid conditions, creating differentiated value propositions that resonate with sophisticated facility operators seeking competitive advantages through operational excellence.

Commercial and industrial sectors represent the primary demand drivers, particularly in regions experiencing rapid urbanization and infrastructure development. Data centers, healthcare facilities, manufacturing plants, and large-scale commercial complexes in tropical, arid, and temperate zones are increasingly seeking chiller systems capable of adapting operational parameters to local temperature ranges, humidity levels, and seasonal variations. The imperative to reduce carbon footprints while maintaining operational reliability has elevated climate-adaptive technologies from optional enhancements to strategic necessities.

Regulatory frameworks worldwide are accelerating market adoption. Energy efficiency standards in Europe, North America, and Asia-Pacific regions now mandate performance benchmarks that account for regional climate characteristics. Building certification programs increasingly reward installations that demonstrate measurable energy savings through climate-responsive technologies. These policy mechanisms are transforming procurement criteria, with facility managers prioritizing lifecycle cost optimization over initial capital expenditure.

Emerging markets in Southeast Asia, the Middle East, and Africa present particularly strong growth trajectories. These regions face extreme cooling loads combined with energy infrastructure constraints, making efficient chiller operation economically critical. The convergence of rising temperatures due to climate change and expanding middle-class populations is intensifying cooling demand while simultaneously increasing sensitivity to energy costs.

Technology integration trends further amplify market potential. The proliferation of IoT sensors, cloud-based analytics platforms, and machine learning algorithms enables real-time climate data integration into chiller control systems. This technological convergence allows predictive adjustments based on weather forecasts, occupancy patterns, and grid conditions, creating differentiated value propositions that resonate with sophisticated facility operators seeking competitive advantages through operational excellence.

Current Chiller Performance Across Geographic Regions

Chiller systems demonstrate significant performance variations across different geographic regions, primarily driven by climatic conditions, infrastructure maturity, and operational practices. In tropical and subtropical regions such as Southeast Asia and the Middle East, chillers operate under extreme ambient temperatures often exceeding 40°C, resulting in substantially higher energy consumption. These systems typically experience coefficient of performance degradation of 15-25% compared to temperate climate operations, with cooling loads remaining consistently high throughout the year.

European and North American facilities in temperate zones benefit from seasonal temperature variations that allow for natural cooling integration and reduced compressor loads during cooler months. Data from commercial buildings in these regions shows average annual energy efficiency ratios ranging from 0.55 to 0.75 kW/ton, representing moderate performance levels. However, aging infrastructure in certain urban centers continues to limit optimization potential, with many systems operating 20-30% below theoretical efficiency benchmarks.

Emerging markets in South Asia and Africa face unique challenges related to power quality and maintenance capabilities. Voltage fluctuations and inconsistent electrical supply contribute to premature equipment degradation and suboptimal performance. Field studies indicate that chillers in these regions often operate at 40-60% of their rated efficiency due to inadequate preventive maintenance and limited access to qualified technical personnel.

Advanced economies in East Asia, particularly Japan and South Korea, demonstrate superior chiller performance through stringent energy codes and widespread adoption of variable speed drive technology. These markets achieve energy efficiency ratios approaching 0.45 kW/ton in optimized installations, supported by robust monitoring systems and predictive maintenance protocols. The integration of district cooling networks in urban developments further enhances overall system efficiency.

Coastal regions worldwide encounter accelerated corrosion issues affecting heat exchanger performance, while high-altitude locations benefit from reduced condensing temperatures but face challenges with reduced air density affecting air-cooled systems. These geographic-specific factors create a complex performance landscape requiring tailored solutions for optimal energy management across different operational environments.

European and North American facilities in temperate zones benefit from seasonal temperature variations that allow for natural cooling integration and reduced compressor loads during cooler months. Data from commercial buildings in these regions shows average annual energy efficiency ratios ranging from 0.55 to 0.75 kW/ton, representing moderate performance levels. However, aging infrastructure in certain urban centers continues to limit optimization potential, with many systems operating 20-30% below theoretical efficiency benchmarks.

Emerging markets in South Asia and Africa face unique challenges related to power quality and maintenance capabilities. Voltage fluctuations and inconsistent electrical supply contribute to premature equipment degradation and suboptimal performance. Field studies indicate that chillers in these regions often operate at 40-60% of their rated efficiency due to inadequate preventive maintenance and limited access to qualified technical personnel.

Advanced economies in East Asia, particularly Japan and South Korea, demonstrate superior chiller performance through stringent energy codes and widespread adoption of variable speed drive technology. These markets achieve energy efficiency ratios approaching 0.45 kW/ton in optimized installations, supported by robust monitoring systems and predictive maintenance protocols. The integration of district cooling networks in urban developments further enhances overall system efficiency.

Coastal regions worldwide encounter accelerated corrosion issues affecting heat exchanger performance, while high-altitude locations benefit from reduced condensing temperatures but face challenges with reduced air density affecting air-cooled systems. These geographic-specific factors create a complex performance landscape requiring tailored solutions for optimal energy management across different operational environments.

Existing Geographic-Specific Chiller Solutions

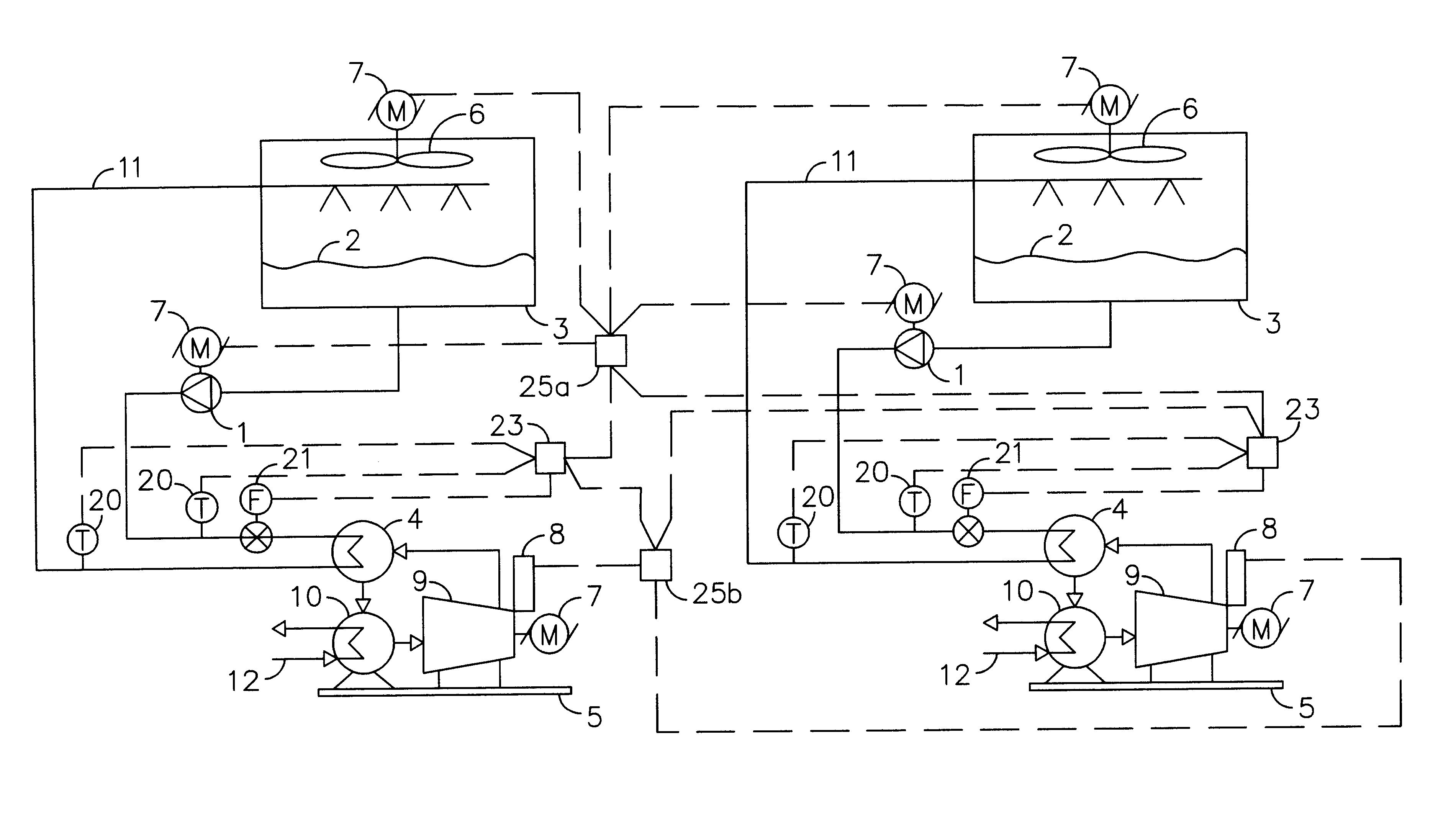

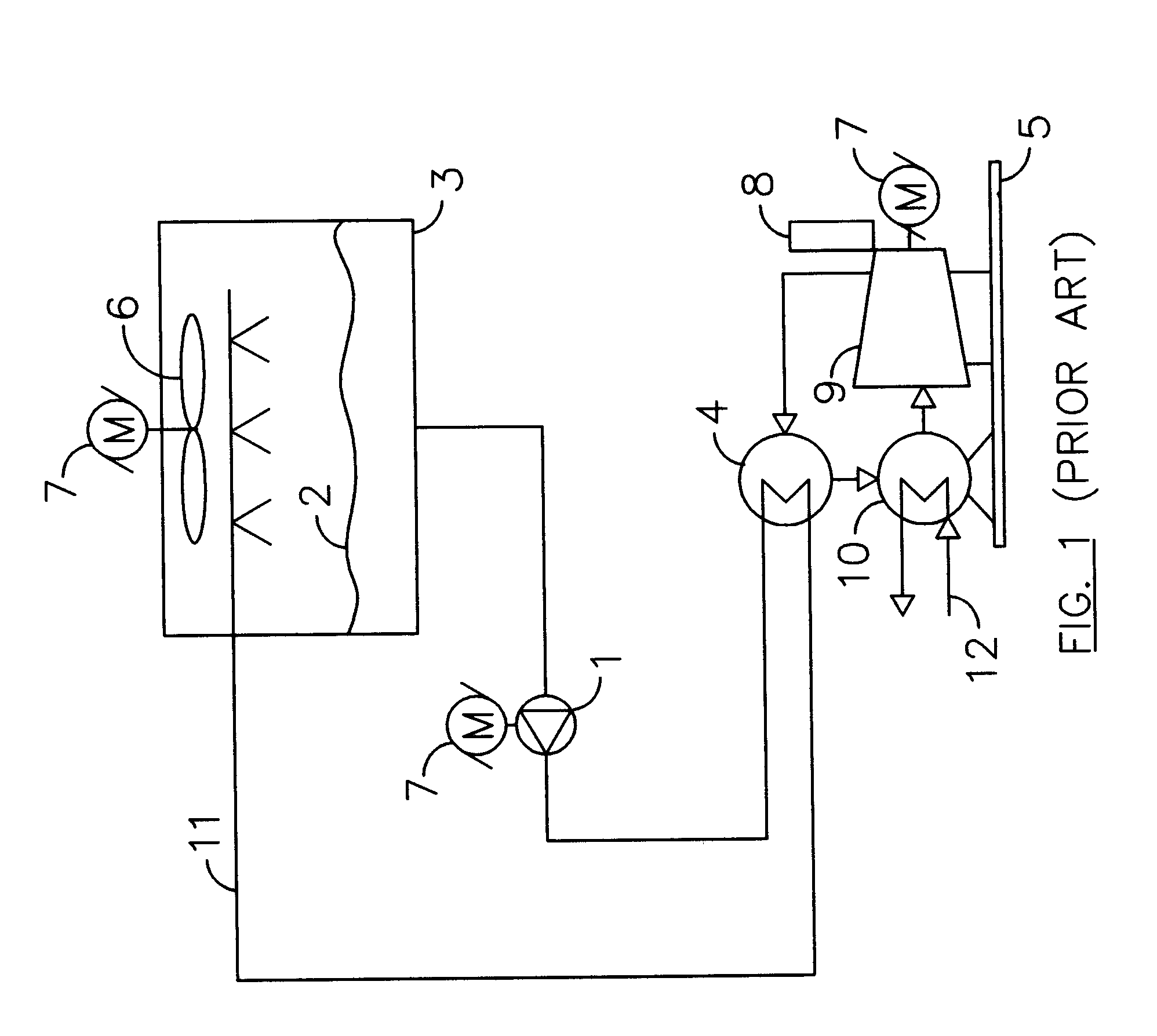

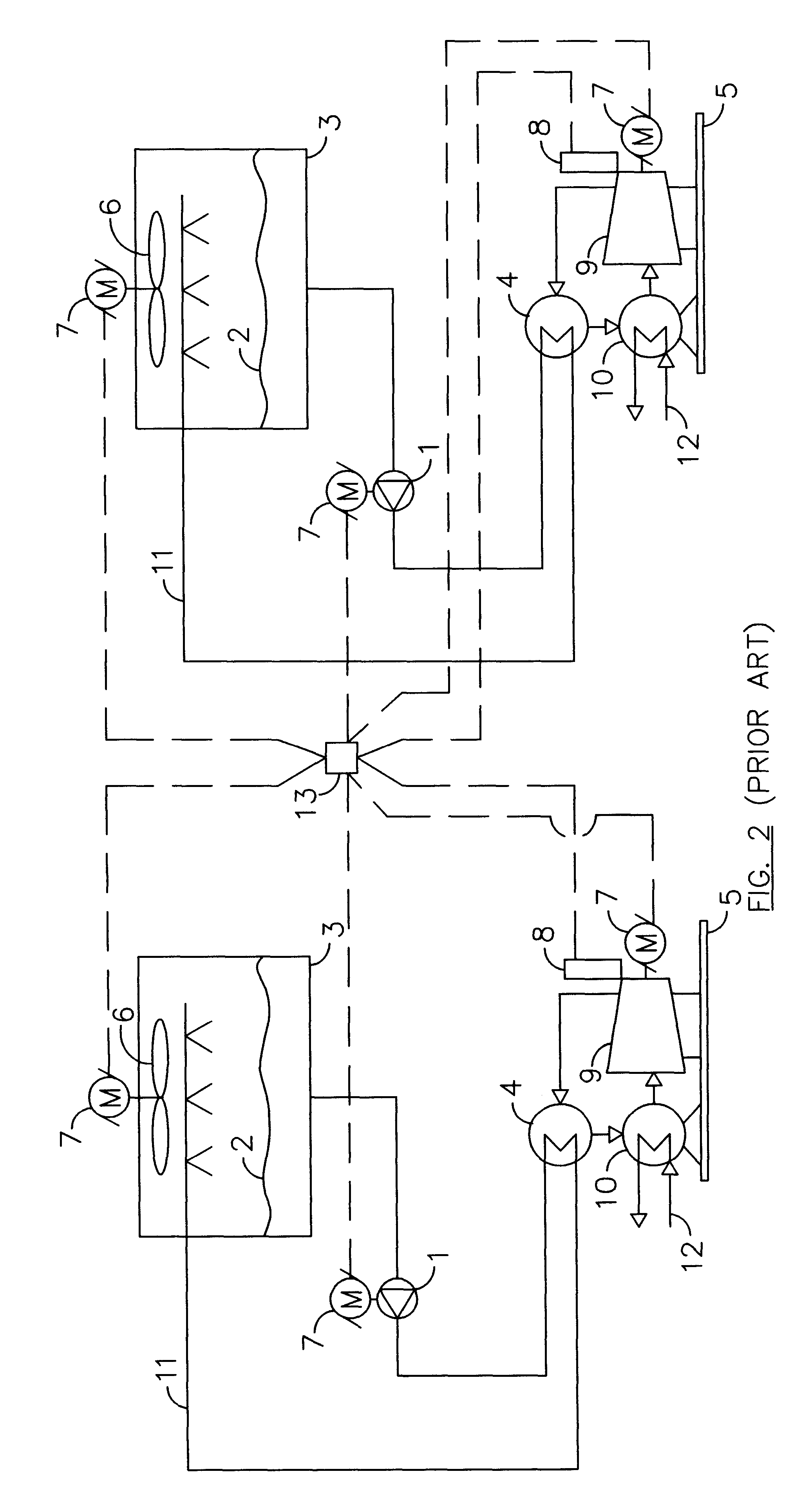

01 Optimization of chiller control systems for energy efficiency

Advanced control systems and algorithms can be implemented to optimize chiller operation and reduce energy consumption. These systems monitor various parameters such as load conditions, ambient temperature, and cooling demand to adjust chiller performance dynamically. Smart control strategies include variable speed drives, load balancing, and predictive control methods that anticipate cooling needs and adjust operations accordingly to minimize energy usage while maintaining desired cooling capacity.- Optimization of chiller control systems for energy efficiency: Advanced control systems and algorithms can be implemented to optimize chiller operation and reduce energy consumption. These systems monitor various parameters such as load conditions, ambient temperature, and cooling demand to adjust chiller performance dynamically. By utilizing predictive control strategies, variable speed drives, and intelligent scheduling, the energy usage of chillers can be significantly reduced while maintaining desired cooling capacity. Smart control systems can also coordinate multiple chillers to operate at optimal efficiency points.

- Use of variable speed compressors and drives: Variable speed technology allows compressors to adjust their operating speed based on cooling demand rather than running at constant full capacity. This approach enables chillers to match their output to actual load requirements, resulting in substantial energy savings during partial load conditions. The implementation of variable frequency drives and inverter-controlled compressors provides precise capacity modulation and improves overall system efficiency across different operating conditions.

- Heat recovery and waste heat utilization systems: Chiller systems can be designed to capture and utilize waste heat generated during the cooling process for other applications such as water heating or space heating. Heat recovery systems extract thermal energy that would otherwise be rejected to the environment and redirect it for productive use. This dual-purpose approach improves overall system efficiency and reduces total energy consumption by offsetting heating loads in buildings or industrial processes.

- Advanced refrigerant management and low-GWP alternatives: The selection and management of refrigerants significantly impacts chiller energy efficiency and environmental performance. Modern systems utilize advanced refrigerants with improved thermodynamic properties and lower global warming potential. Proper refrigerant charge optimization, leak detection systems, and the use of next-generation refrigerants can enhance heat transfer efficiency and reduce energy consumption while meeting environmental regulations.

- Integration with building management and monitoring systems: Connecting chillers to comprehensive building management systems enables real-time monitoring, data analytics, and coordinated operation with other HVAC components. These integrated systems collect operational data to identify inefficiencies, predict maintenance needs, and optimize energy usage patterns. Advanced monitoring capabilities allow for continuous performance assessment, fault detection, and automated adjustments to maintain peak efficiency throughout the chiller lifecycle.

02 Integration of thermal energy storage systems

Thermal energy storage systems can be integrated with chillers to shift cooling loads to off-peak hours when energy costs are lower. These systems store cooling energy during periods of low demand or when electricity rates are reduced, then release it during peak demand periods. This approach reduces overall energy consumption and operational costs by taking advantage of time-of-use electricity pricing and reducing the peak load on chillers.Expand Specific Solutions03 Use of variable refrigerant flow and modular chiller designs

Variable refrigerant flow technology and modular chiller configurations allow for more flexible and efficient cooling operations. These designs enable chillers to operate at partial loads more efficiently by adjusting refrigerant flow rates and activating only the necessary modules based on actual cooling demand. This modularity prevents energy waste from operating oversized equipment at low loads and improves overall system efficiency across varying operational conditions.Expand Specific Solutions04 Implementation of heat recovery systems

Heat recovery systems capture waste heat from chiller operations and repurpose it for other heating applications within a facility. By recovering and utilizing heat that would otherwise be rejected to the environment, these systems improve overall energy efficiency and reduce the total energy consumption of the facility. Applications include preheating water, space heating, or process heating, thereby offsetting energy that would be required from other sources.Expand Specific Solutions05 Monitoring and diagnostic systems for performance optimization

Advanced monitoring and diagnostic systems continuously track chiller performance metrics and identify opportunities for energy savings. These systems use sensors, data analytics, and machine learning algorithms to detect inefficiencies, predict maintenance needs, and provide actionable insights for optimization. Real-time monitoring enables operators to make informed decisions about chiller operation, identify degradation in performance, and implement corrective measures before significant energy waste occurs.Expand Specific Solutions

Major Chiller Manufacturers and Regional Market Leaders

The chiller energy optimization landscape represents a mature yet evolving market driven by sustainability imperatives and geographic climate variations. The industry spans established HVAC giants like Johnson Controls, Carrier Corp., and Gree Electric alongside specialized innovators such as Green Revolution Cooling and Optimum Energy. Market dynamics reflect regional diversification, with Asian manufacturers (LG Electronics, SMC Corp.) competing against Western leaders (Honeywell, Trane) across varying climate zones. Technology maturity varies significantly: traditional vapor-compression systems dominate commercially, while emerging solutions like Green Revolution Cooling's immersion technology and Nostromo's thermal storage represent next-generation approaches. Research institutions including King Abdullah University, Nanyang Technological University, and National University of Singapore drive innovation in climate-adaptive optimization algorithms. The competitive landscape indicates consolidation among major players while niche providers target specific geographic challenges, suggesting a transitional phase toward AI-driven, geography-specific energy management solutions.

Carrier Corp.

Technical Solution: Carrier Corporation offers advanced chiller systems with integrated energy monitoring capabilities designed to optimize performance across varying geographic conditions. Their AquaEdge and AquaForce chiller lines incorporate variable-speed compressors and advanced controls that automatically adjust to local climate conditions, from hot-humid tropical environments to cold-dry continental climates. The company's Abound connected building platform aggregates energy usage data from chiller installations worldwide, enabling facility managers to benchmark performance across different geographies. The system accounts for geographic variables including ambient temperature ranges, humidity levels, water quality affecting condenser performance, and altitude impacts on refrigerant behavior. Carrier's analytics tools normalize energy consumption data using cooling degree days (CDD) specific to each location, allowing meaningful comparisons between facilities in Dubai versus Stockholm. Their geographic comparison reports identify efficiency gaps attributable to operational practices versus environmental factors, with typical findings showing 15-25% energy variance between well-managed and poorly-managed facilities in similar climate zones.

Strengths: Hardware-software integration provides accurate field data; extensive global installation base enables robust benchmarking; climate-adaptive equipment design. Weaknesses: Proprietary platform may limit integration with third-party systems; geographic comparison features require subscription to cloud services.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell delivers chiller energy comparison solutions through their Forge Energy Optimization platform, which leverages artificial intelligence to analyze performance across geographically dispersed facilities. The system ingests data from chiller plants in different climate zones and applies machine learning models trained on millions of operational hours to identify geography-specific efficiency patterns. Their approach incorporates local weather data feeds, including temperature, humidity, and solar radiation, to contextualize energy consumption within environmental constraints. For geographic comparisons, Honeywell's platform calculates climate-normalized energy metrics that adjust for local conditions—accounting for factors like higher condensing temperatures in hot climates requiring more compressor work, or reduced lift requirements in cooler regions. The system generates comparative dashboards showing energy usage per ton-hour of cooling delivered, adjusted for geographic variables, enabling portfolio managers to identify underperforming sites. Honeywell's analytics distinguish between unavoidable geographic penalties (climate-driven) and addressable operational inefficiencies, with case studies demonstrating identification of 20-40% efficiency improvement opportunities through cross-geographic benchmarking.

Strengths: AI-driven analytics provide deep insights into geographic performance drivers; strong weather data integration; scalable across large facility portfolios. Weaknesses: Requires substantial historical data for accurate modeling; AI recommendations may need local expertise validation for implementation.

Core Technologies in Climate-Responsive Chiller Design

Method to optimize chiller plant operation

PatentInactiveUS6718779B1

Innovation

- A computerized controller system that uses temperature sensors and flow meters to maintain a constant temperature difference across the refrigerant condenser, controlling cooling fluid pump and cooling tower fan speeds based on measured parameters, allowing for flexible operation and integration with existing chiller plants without requiring proprietary access or complex setups.

Hybrid air-conditioning system for decoupled sensible and latent heat removal and method

PatentWO2022248976A1

Innovation

- A hybrid air-conditioning system combining mechanical vapor compression (MVC) and indirect evaporative cooling (IEC) units, where MVC handles latent heat removal and IEC decouples sensible heat removal through direct heat exchange between wet and dry channels, optimizing energy efficiency and reducing energy consumption.

Regional Energy Standards and Efficiency Regulations

Regional energy standards and efficiency regulations constitute a critical framework that directly influences chiller system design, operation, and performance benchmarking across different geographical markets. These regulatory mechanisms establish minimum efficiency thresholds, testing protocols, and compliance requirements that manufacturers and facility operators must adhere to, thereby creating significant variations in equipment specifications and operational practices worldwide.

In North America, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) standards, combined with the U.S. Department of Energy (DOE) efficiency mandates, define Integrated Part Load Value (IPLV) and Energy Efficiency Ratio (EER) as primary metrics for chiller performance evaluation. The ASHRAE 90.1 standard provides progressive efficiency baselines that are periodically updated, with recent revisions imposing stricter requirements on both water-cooled and air-cooled chillers. Canadian provinces implement additional provincial regulations that sometimes exceed federal standards, creating sub-regional compliance complexity.

European markets operate under the Ecodesign Directive and the Energy Efficiency Directive, which mandate Seasonal Energy Efficiency Ratio (SEER) and European Seasonal Energy Efficiency Ratio (ESEER) as evaluation criteria. The F-Gas Regulation further restricts refrigerant choices based on Global Warming Potential (GWP), indirectly affecting chiller design and efficiency characteristics. Member states retain authority to implement supplementary national requirements, resulting in varied enforcement stringency across the European Union.

Asia-Pacific regions demonstrate the most diverse regulatory landscape. China's GB standards have rapidly evolved to match international efficiency levels, with tiered energy labeling systems incentivizing high-efficiency equipment adoption. Japan's Top Runner Program establishes dynamic efficiency targets based on leading market performance, continuously raising the efficiency bar. Southeast Asian nations are progressively developing their own standards, often referencing ISO 5151 and AHRI protocols while adapting requirements to tropical climate conditions.

Middle Eastern countries increasingly adopt efficiency standards influenced by both European and American frameworks, with the Gulf Cooperation Council (GCC) developing unified standards to address extreme ambient conditions. These regulations typically incorporate climate-specific testing conditions that recognize the performance challenges of operating chillers in high-temperature environments, affecting comparative energy consumption assessments across regions.

In North America, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) standards, combined with the U.S. Department of Energy (DOE) efficiency mandates, define Integrated Part Load Value (IPLV) and Energy Efficiency Ratio (EER) as primary metrics for chiller performance evaluation. The ASHRAE 90.1 standard provides progressive efficiency baselines that are periodically updated, with recent revisions imposing stricter requirements on both water-cooled and air-cooled chillers. Canadian provinces implement additional provincial regulations that sometimes exceed federal standards, creating sub-regional compliance complexity.

European markets operate under the Ecodesign Directive and the Energy Efficiency Directive, which mandate Seasonal Energy Efficiency Ratio (SEER) and European Seasonal Energy Efficiency Ratio (ESEER) as evaluation criteria. The F-Gas Regulation further restricts refrigerant choices based on Global Warming Potential (GWP), indirectly affecting chiller design and efficiency characteristics. Member states retain authority to implement supplementary national requirements, resulting in varied enforcement stringency across the European Union.

Asia-Pacific regions demonstrate the most diverse regulatory landscape. China's GB standards have rapidly evolved to match international efficiency levels, with tiered energy labeling systems incentivizing high-efficiency equipment adoption. Japan's Top Runner Program establishes dynamic efficiency targets based on leading market performance, continuously raising the efficiency bar. Southeast Asian nations are progressively developing their own standards, often referencing ISO 5151 and AHRI protocols while adapting requirements to tropical climate conditions.

Middle Eastern countries increasingly adopt efficiency standards influenced by both European and American frameworks, with the Gulf Cooperation Council (GCC) developing unified standards to address extreme ambient conditions. These regulations typically incorporate climate-specific testing conditions that recognize the performance challenges of operating chillers in high-temperature environments, affecting comparative energy consumption assessments across regions.

Climate Impact on Chiller Lifecycle Assessment

Climate conditions fundamentally shape the environmental footprint of chiller systems throughout their operational lifespan. Geographic variations in temperature, humidity, and seasonal patterns directly influence energy consumption profiles, which constitute the dominant environmental impact factor in lifecycle assessments. In tropical and subtropical regions, chillers operate under sustained high ambient temperatures and elevated humidity levels, resulting in extended operational hours and increased compressor workload. This continuous demand amplifies electricity consumption and consequently magnifies carbon emissions associated with power generation. Conversely, temperate climates with distinct seasonal variations allow for reduced cooling loads during cooler months, creating opportunities for natural cooling strategies and operational optimization that lower overall environmental burdens.

The carbon intensity of regional electricity grids introduces another critical dimension to climate-related lifecycle impacts. Chillers deployed in geographies relying heavily on coal-fired power generation exhibit substantially higher carbon footprints compared to identical systems operating in regions with cleaner energy portfolios dominated by renewable sources or natural gas. This grid dependency means that two identical chiller installations can demonstrate vastly different environmental performance profiles based solely on their geographic location and associated energy infrastructure.

Manufacturing and end-of-life phases also experience climate-influenced variations in lifecycle assessments. Transportation distances from manufacturing facilities to installation sites contribute differently to embodied carbon depending on geographic proximity to production centers. Additionally, regional regulations governing refrigerant management and equipment disposal create disparate environmental outcomes across different jurisdictions. Coastal and high-humidity environments accelerate corrosion and material degradation, potentially shortening equipment lifespan and increasing replacement frequency, thereby elevating the manufacturing impact allocation per operational year.

Water consumption patterns in chiller systems present geography-specific environmental considerations. Water-cooled chillers in arid regions face heightened environmental scrutiny due to freshwater scarcity, while similar systems in water-abundant areas may demonstrate more favorable lifecycle profiles. Climate-driven maintenance requirements further differentiate environmental impacts, as extreme weather conditions necessitate more frequent servicing, replacement parts, and associated resource consumption. These multifaceted climate interactions underscore the necessity of geography-specific lifecycle assessment methodologies when evaluating chiller environmental performance across diverse operational contexts.

The carbon intensity of regional electricity grids introduces another critical dimension to climate-related lifecycle impacts. Chillers deployed in geographies relying heavily on coal-fired power generation exhibit substantially higher carbon footprints compared to identical systems operating in regions with cleaner energy portfolios dominated by renewable sources or natural gas. This grid dependency means that two identical chiller installations can demonstrate vastly different environmental performance profiles based solely on their geographic location and associated energy infrastructure.

Manufacturing and end-of-life phases also experience climate-influenced variations in lifecycle assessments. Transportation distances from manufacturing facilities to installation sites contribute differently to embodied carbon depending on geographic proximity to production centers. Additionally, regional regulations governing refrigerant management and equipment disposal create disparate environmental outcomes across different jurisdictions. Coastal and high-humidity environments accelerate corrosion and material degradation, potentially shortening equipment lifespan and increasing replacement frequency, thereby elevating the manufacturing impact allocation per operational year.

Water consumption patterns in chiller systems present geography-specific environmental considerations. Water-cooled chillers in arid regions face heightened environmental scrutiny due to freshwater scarcity, while similar systems in water-abundant areas may demonstrate more favorable lifecycle profiles. Climate-driven maintenance requirements further differentiate environmental impacts, as extreme weather conditions necessitate more frequent servicing, replacement parts, and associated resource consumption. These multifaceted climate interactions underscore the necessity of geography-specific lifecycle assessment methodologies when evaluating chiller environmental performance across diverse operational contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!