Evaluate Chiller Efficiency Improvements with Retrofitting

JAN 23, 20269 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiller Technology Background and Efficiency Goals

Chiller systems have served as the backbone of commercial and industrial cooling infrastructure for over a century, with their evolution closely tied to advances in refrigeration science, compressor technology, and energy management systems. Early vapor-compression chillers emerged in the 1920s, utilizing ammonia and later chlorofluorocarbon refrigerants. The technology matured significantly through the latter half of the twentieth century, driven by demands for greater cooling capacity in expanding urban centers and manufacturing facilities. However, the energy crisis of the 1970s marked a pivotal shift, redirecting industry focus toward energy efficiency as operational costs became increasingly significant relative to capital expenditures.

The contemporary chiller landscape is characterized by stringent efficiency standards and environmental regulations. Modern chillers employ advanced refrigerants with low global warming potential, variable speed drives, magnetic bearing compressors, and sophisticated control algorithms. Despite these innovations, a substantial portion of the global installed base consists of legacy systems designed decades ago, operating at efficiency levels far below current standards. These aging systems represent both a challenge and an opportunity, as their continued operation contributes disproportionately to building energy consumption while offering significant potential for improvement through strategic retrofitting interventions.

The primary efficiency goals for chiller retrofitting center on reducing energy consumption per unit of cooling output, typically measured by coefficient of performance or kilowatts per ton. Industry benchmarks suggest that well-executed retrofits can achieve efficiency improvements ranging from fifteen to forty percent, depending on baseline conditions and intervention scope. Beyond energy metrics, contemporary efficiency goals encompass operational reliability, refrigerant environmental impact reduction, integration with building management systems, and adaptability to variable load conditions that characterize modern building usage patterns.

Achieving these efficiency targets requires a comprehensive understanding of thermodynamic principles, heat transfer mechanisms, and system-level interactions. The technical challenge lies not merely in component replacement but in optimizing the entire chiller plant ecosystem, including cooling towers, pumps, piping configurations, and control strategies. This holistic perspective forms the foundation for evaluating retrofit opportunities and establishing realistic performance improvement targets aligned with both economic constraints and sustainability imperatives.

The contemporary chiller landscape is characterized by stringent efficiency standards and environmental regulations. Modern chillers employ advanced refrigerants with low global warming potential, variable speed drives, magnetic bearing compressors, and sophisticated control algorithms. Despite these innovations, a substantial portion of the global installed base consists of legacy systems designed decades ago, operating at efficiency levels far below current standards. These aging systems represent both a challenge and an opportunity, as their continued operation contributes disproportionately to building energy consumption while offering significant potential for improvement through strategic retrofitting interventions.

The primary efficiency goals for chiller retrofitting center on reducing energy consumption per unit of cooling output, typically measured by coefficient of performance or kilowatts per ton. Industry benchmarks suggest that well-executed retrofits can achieve efficiency improvements ranging from fifteen to forty percent, depending on baseline conditions and intervention scope. Beyond energy metrics, contemporary efficiency goals encompass operational reliability, refrigerant environmental impact reduction, integration with building management systems, and adaptability to variable load conditions that characterize modern building usage patterns.

Achieving these efficiency targets requires a comprehensive understanding of thermodynamic principles, heat transfer mechanisms, and system-level interactions. The technical challenge lies not merely in component replacement but in optimizing the entire chiller plant ecosystem, including cooling towers, pumps, piping configurations, and control strategies. This holistic perspective forms the foundation for evaluating retrofit opportunities and establishing realistic performance improvement targets aligned with both economic constraints and sustainability imperatives.

Market Demand for Chiller Retrofitting Solutions

The global market for chiller retrofitting solutions has experienced substantial growth driven by escalating energy costs, stringent environmental regulations, and increasing awareness of operational efficiency among building owners and facility managers. Commercial and industrial sectors represent the primary demand sources, as aging HVAC infrastructure in office buildings, hospitals, data centers, and manufacturing facilities requires modernization to meet contemporary performance standards. The push toward carbon neutrality and net-zero emissions targets has further accelerated interest in retrofitting existing chillers rather than complete system replacements, offering a cost-effective pathway to significant energy savings.

Regulatory frameworks play a pivotal role in shaping market demand. Energy efficiency mandates such as ASHRAE standards in North America, the European Union's F-Gas Regulation, and various national building codes have established minimum performance thresholds that many legacy systems fail to meet. These compliance requirements compel facility operators to evaluate retrofitting options including variable speed drive installations, advanced control system upgrades, and refrigerant conversions. The phase-out of high global warming potential refrigerants has created additional urgency for system modifications.

Economic considerations strongly influence adoption patterns. Rising electricity prices combined with demonstrated payback periods typically ranging from two to five years make retrofitting financially attractive. Building owners increasingly recognize that efficiency improvements directly impact operational expenditures while enhancing asset value and tenant satisfaction. The availability of government incentives, utility rebate programs, and green financing mechanisms further reduces financial barriers to implementation.

Emerging market segments show particularly robust demand. Data centers with intensive cooling requirements seek continuous efficiency optimization to manage operational costs and meet sustainability commitments. Healthcare facilities prioritize reliability alongside efficiency, driving demand for comprehensive retrofitting solutions that minimize downtime risks. The industrial sector, especially in process cooling applications, represents significant untapped potential as manufacturers pursue operational excellence and cost reduction initiatives.

Technological advancements have expanded the scope and appeal of retrofitting solutions. Smart building integration, IoT-enabled monitoring systems, and predictive maintenance capabilities now complement traditional hardware upgrades, offering holistic performance improvements. This convergence of mechanical and digital solutions addresses diverse customer needs while creating new value propositions that extend beyond simple energy savings to encompass operational intelligence and system longevity.

Regulatory frameworks play a pivotal role in shaping market demand. Energy efficiency mandates such as ASHRAE standards in North America, the European Union's F-Gas Regulation, and various national building codes have established minimum performance thresholds that many legacy systems fail to meet. These compliance requirements compel facility operators to evaluate retrofitting options including variable speed drive installations, advanced control system upgrades, and refrigerant conversions. The phase-out of high global warming potential refrigerants has created additional urgency for system modifications.

Economic considerations strongly influence adoption patterns. Rising electricity prices combined with demonstrated payback periods typically ranging from two to five years make retrofitting financially attractive. Building owners increasingly recognize that efficiency improvements directly impact operational expenditures while enhancing asset value and tenant satisfaction. The availability of government incentives, utility rebate programs, and green financing mechanisms further reduces financial barriers to implementation.

Emerging market segments show particularly robust demand. Data centers with intensive cooling requirements seek continuous efficiency optimization to manage operational costs and meet sustainability commitments. Healthcare facilities prioritize reliability alongside efficiency, driving demand for comprehensive retrofitting solutions that minimize downtime risks. The industrial sector, especially in process cooling applications, represents significant untapped potential as manufacturers pursue operational excellence and cost reduction initiatives.

Technological advancements have expanded the scope and appeal of retrofitting solutions. Smart building integration, IoT-enabled monitoring systems, and predictive maintenance capabilities now complement traditional hardware upgrades, offering holistic performance improvements. This convergence of mechanical and digital solutions addresses diverse customer needs while creating new value propositions that extend beyond simple energy savings to encompass operational intelligence and system longevity.

Current Chiller Efficiency Status and Technical Challenges

The global chiller market faces mounting pressure to improve energy efficiency as cooling systems account for approximately 40% of total building energy consumption in commercial facilities. Existing chiller installations, many of which were commissioned 15-20 years ago, operate at efficiency levels significantly below current standards. The average coefficient of performance (COP) for legacy chillers ranges between 2.5 and 4.0, while modern high-efficiency units achieve COP values exceeding 6.0. This performance gap represents substantial energy waste and operational costs, creating urgent demand for efficiency enhancement solutions.

Current chiller efficiency is constrained by multiple technical factors. Aging compressor technology, particularly in reciprocating and older screw-type systems, suffers from mechanical wear and reduced volumetric efficiency. Heat exchanger fouling and scaling reduce thermal transfer effectiveness by 10-30% over operational lifespans. Outdated control systems lack variable speed drive capabilities and sophisticated load-matching algorithms, resulting in part-load inefficiencies. Additionally, refrigerant degradation and leakage in older systems using R-22 or R-134a compounds further compromise performance while raising environmental concerns.

Geographically, efficiency challenges vary significantly. North American and European installations predominantly feature centrifugal chillers in large commercial applications, where efficiency degradation stems primarily from control system limitations and heat exchanger deterioration. Asian markets, particularly in China and India, operate numerous air-cooled screw chillers in industrial settings, facing challenges related to ambient temperature sensitivity and inadequate maintenance practices. Middle Eastern facilities encounter unique difficulties with extreme ambient conditions accelerating component degradation and reducing operational efficiency.

The primary technical barriers to retrofitting include system integration complexity, refrigerant compatibility issues, and structural limitations of existing equipment. Many legacy chillers lack the physical space or structural capacity to accommodate advanced heat exchangers or variable speed drives. Control system retrofits face challenges interfacing with building management systems using outdated communication protocols. Furthermore, the economic justification for retrofitting versus replacement remains unclear in many scenarios, particularly when considering downtime costs and performance uncertainty. Regulatory pressures regarding refrigerant phase-outs add complexity, as retrofit solutions must address both efficiency improvements and environmental compliance simultaneously.

Current chiller efficiency is constrained by multiple technical factors. Aging compressor technology, particularly in reciprocating and older screw-type systems, suffers from mechanical wear and reduced volumetric efficiency. Heat exchanger fouling and scaling reduce thermal transfer effectiveness by 10-30% over operational lifespans. Outdated control systems lack variable speed drive capabilities and sophisticated load-matching algorithms, resulting in part-load inefficiencies. Additionally, refrigerant degradation and leakage in older systems using R-22 or R-134a compounds further compromise performance while raising environmental concerns.

Geographically, efficiency challenges vary significantly. North American and European installations predominantly feature centrifugal chillers in large commercial applications, where efficiency degradation stems primarily from control system limitations and heat exchanger deterioration. Asian markets, particularly in China and India, operate numerous air-cooled screw chillers in industrial settings, facing challenges related to ambient temperature sensitivity and inadequate maintenance practices. Middle Eastern facilities encounter unique difficulties with extreme ambient conditions accelerating component degradation and reducing operational efficiency.

The primary technical barriers to retrofitting include system integration complexity, refrigerant compatibility issues, and structural limitations of existing equipment. Many legacy chillers lack the physical space or structural capacity to accommodate advanced heat exchangers or variable speed drives. Control system retrofits face challenges interfacing with building management systems using outdated communication protocols. Furthermore, the economic justification for retrofitting versus replacement remains unclear in many scenarios, particularly when considering downtime costs and performance uncertainty. Regulatory pressures regarding refrigerant phase-outs add complexity, as retrofit solutions must address both efficiency improvements and environmental compliance simultaneously.

Mainstream Chiller Retrofitting Technical Solutions

01 Variable speed compressor control systems

Chiller efficiency can be improved through the implementation of variable speed drive systems for compressors. These systems allow the compressor to operate at optimal speeds based on cooling demand, reducing energy consumption during partial load conditions. Advanced control algorithms monitor system parameters and adjust compressor speed accordingly to maintain efficiency across varying load conditions. This approach significantly reduces energy waste compared to traditional fixed-speed compressor systems.- Variable speed compressor control systems: Chiller efficiency can be improved through the implementation of variable speed drive systems for compressors. These systems allow the compressor to operate at optimal speeds based on cooling demand, reducing energy consumption during partial load conditions. Advanced control algorithms monitor system parameters and adjust compressor speed accordingly to maintain efficiency across varying load conditions. This approach significantly reduces energy waste compared to traditional fixed-speed compressor systems.

- Heat exchanger optimization and design improvements: Enhanced heat exchanger designs contribute to improved chiller efficiency by maximizing heat transfer rates while minimizing pressure drops. This includes the use of advanced tube configurations, enhanced surface geometries, and optimized flow patterns. Improved heat exchanger performance allows for better thermal exchange between refrigerant and water circuits, resulting in reduced compressor work and lower energy consumption. Material selection and coating technologies also play a role in maintaining long-term efficiency.

- Refrigerant management and optimization: Efficient refrigerant management systems enhance chiller performance through proper refrigerant charge control, subcooling optimization, and advanced refrigerant circuit designs. These systems may include refrigerant quality sensors, charge optimization algorithms, and distribution management to ensure optimal refrigerant flow throughout the system. Proper refrigerant management reduces compressor load and improves overall system coefficient of performance. Advanced monitoring systems can detect and compensate for refrigerant degradation or leakage.

- Intelligent control and monitoring systems: Implementation of smart control systems with predictive algorithms and real-time monitoring capabilities significantly improves chiller efficiency. These systems utilize sensors throughout the chiller to collect operational data, which is analyzed to optimize performance parameters such as setpoints, staging, and sequencing. Machine learning algorithms can predict optimal operating conditions based on historical data and current demand patterns. Integration with building management systems allows for coordinated operation with other HVAC components to maximize overall system efficiency.

- Condenser water system optimization: Optimization of condenser water systems improves chiller efficiency by maintaining optimal condenser water temperatures and flow rates. This includes the use of variable speed condenser water pumps, cooling tower fan controls, and water treatment systems to maintain heat transfer efficiency. Advanced control strategies adjust condenser water parameters based on ambient conditions and cooling load to minimize compressor lift and energy consumption. Proper water quality management prevents fouling and scaling that can degrade heat transfer performance over time.

02 Heat exchanger optimization and design improvements

Enhanced heat exchanger designs contribute to improved chiller efficiency by maximizing heat transfer rates while minimizing pressure drops. This includes the use of advanced tube configurations, enhanced surface geometries, and optimized flow patterns. Improved heat exchanger performance allows for better thermal energy transfer between refrigerant and water circuits, resulting in reduced compressor work and overall energy consumption. Material selection and coating technologies also play a role in maintaining long-term heat transfer efficiency.Expand Specific Solutions03 Advanced refrigerant management and control

Efficient refrigerant management systems optimize chiller performance through precise control of refrigerant flow, pressure, and temperature. This includes the use of electronic expansion valves, subcooling and superheating control, and refrigerant charge optimization. Advanced monitoring systems detect and compensate for refrigerant leaks or charge imbalances. The implementation of environmentally friendly refrigerants with improved thermodynamic properties also contributes to enhanced system efficiency while meeting regulatory requirements.Expand Specific Solutions04 Integrated control and monitoring systems

Smart control systems integrate multiple chiller components and sensors to optimize overall system performance. These systems utilize real-time data collection, predictive algorithms, and machine learning to anticipate cooling demands and adjust operations proactively. Integration with building management systems enables coordinated control of multiple chillers and cooling towers for optimal plant-level efficiency. Remote monitoring capabilities allow for continuous performance tracking and early detection of efficiency degradation.Expand Specific Solutions05 Condenser and cooling tower optimization

Chiller efficiency is enhanced through optimization of condenser operation and cooling tower performance. This includes variable speed fan controls, water treatment systems to prevent fouling, and optimized water flow rates. Advanced condenser designs improve heat rejection efficiency, reducing the temperature lift required by the compressor. Integration of free cooling capabilities and waterside economizers allows systems to take advantage of favorable ambient conditions, further reducing compressor runtime and energy consumption.Expand Specific Solutions

Major Players in Chiller Retrofitting Market

The chiller efficiency retrofitting market is experiencing steady growth as building owners seek cost-effective solutions to reduce energy consumption and meet sustainability targets. The competitive landscape is dominated by established HVAC manufacturers including Haier Smart Home, Gree Electric Appliances, Carrier Corporation, and Daikin Applied Europe, alongside specialized technology providers like Mitsubishi Heavy Industries Thermal Systems and Trane International. The technology has reached a mature stage, with proven solutions ranging from variable speed drives to advanced control systems and IoT-enabled monitoring platforms. Companies like Schneider Electric IT and Honeywell International Technologies are integrating digital solutions with traditional mechanical improvements. The market shows strong activity in both developed regions, where aging infrastructure drives retrofit demand, and emerging markets where Midea and Envicool Technology are expanding. Competition centers on delivering measurable efficiency gains, minimizing installation disruption, and providing comprehensive energy management solutions that combine hardware upgrades with predictive maintenance capabilities.

Carrier Corp.

Technical Solution: Carrier implements comprehensive chiller retrofitting solutions focusing on compressor upgrades, variable speed drive (VSD) integration, and advanced control system modernization. Their retrofit packages typically include replacement of outdated fixed-speed compressors with high-efficiency centrifugal or screw compressors, installation of magnetic bearing technology to reduce friction losses, and integration of IoT-enabled building management systems for real-time performance optimization. The company's BluEdge platform enables predictive maintenance and continuous efficiency monitoring, achieving energy consumption reductions of 30-50% compared to legacy systems. Carrier also offers refrigerant conversion services to transition older chillers from high-GWP refrigerants to low-GWP alternatives like R-1233zd or R-515B, improving both environmental performance and operational efficiency.

Strengths: Comprehensive retrofit solutions with proven 30-50% energy savings, strong IoT integration and predictive analytics capabilities, extensive global service network. Weaknesses: Higher upfront investment costs, retrofit complexity may require extended downtime for older facilities.

Daikin Applied Europe SpA

Technical Solution: Daikin Applied focuses on intelligent retrofitting solutions combining hardware upgrades with advanced digital twin technology for performance simulation and optimization. Their retrofit packages feature oil-free magnetic bearing centrifugal compressor conversions that eliminate oil management systems and reduce maintenance requirements while improving efficiency by 25-35%. Daikin's Intelligent Equipment platform enables remote monitoring and diagnostics, utilizing AI-driven fault detection and optimization algorithms that continuously adjust operating parameters. The company specializes in low-lift chiller conversions for facilities with access to free cooling sources, achieving COP improvements from 5.0 to over 8.0. Their refrigerant retrofit services support transitions to R-32 and R-454B with minimal system modifications, and include comprehensive water-side economizer integration for hybrid cooling strategies in suitable climates.

Strengths: Oil-free magnetic bearing technology reduces maintenance, digital twin simulation enables precise performance prediction, exceptional low-lift chiller efficiency (COP >8.0). Weaknesses: Limited applicability of low-lift solutions to facilities without free cooling access, higher technology complexity requires specialized training.

Core Patents in Chiller Efficiency Enhancement

Method and system for evaluating the efficiency of an air conditioning apparatus

PatentInactiveUS20110218771A1

Innovation

- A system that allows for remote monitoring of chiller operating parameters through a computing device, which computes inefficiency measures and provides remedial actions to maintenance personnel, enabling real-time identification and correction of inefficiencies across multiple chiller units located at different sites.

Method to optimize chiller plant operation

PatentInactiveUS6718779B1

Innovation

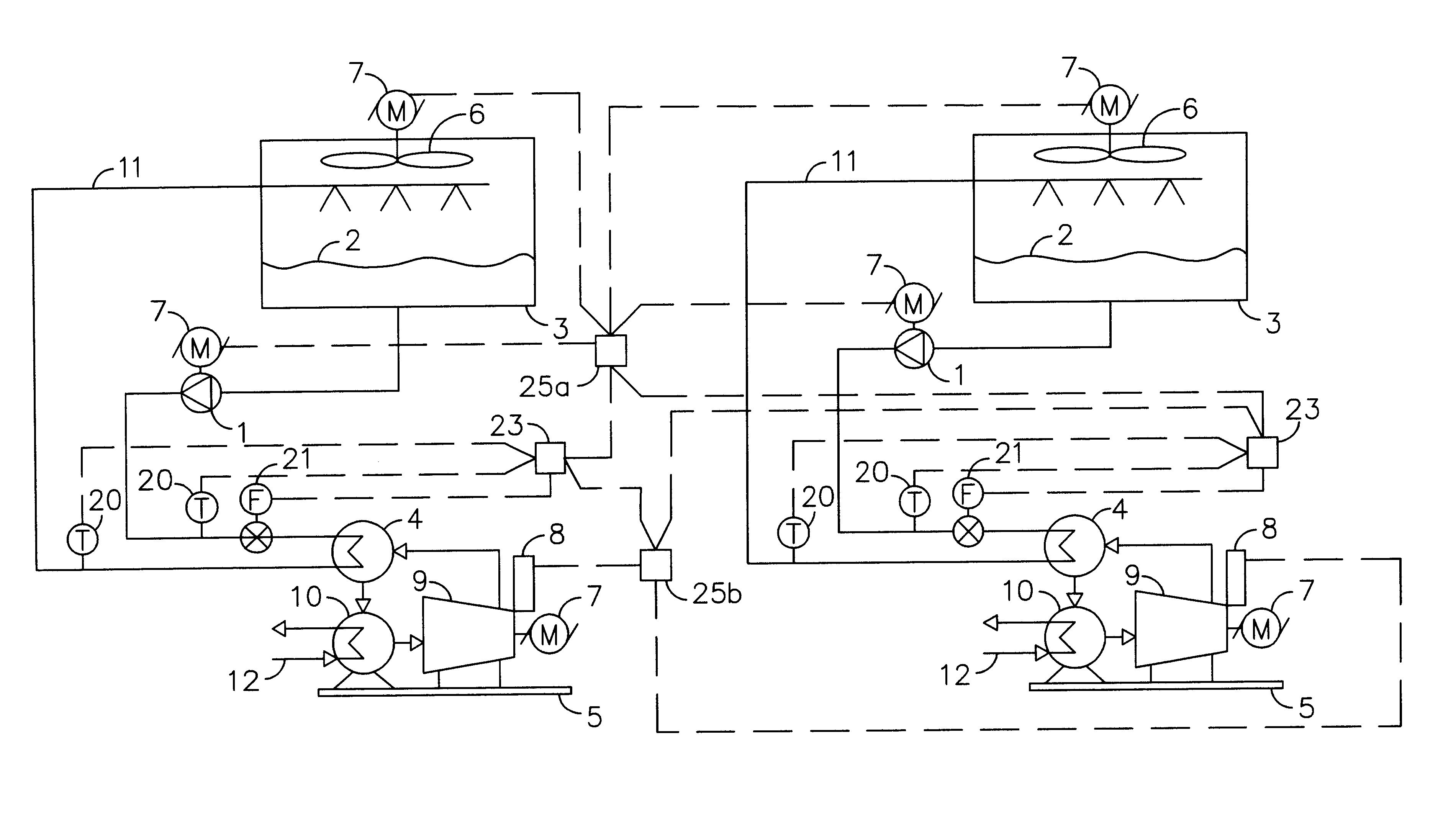

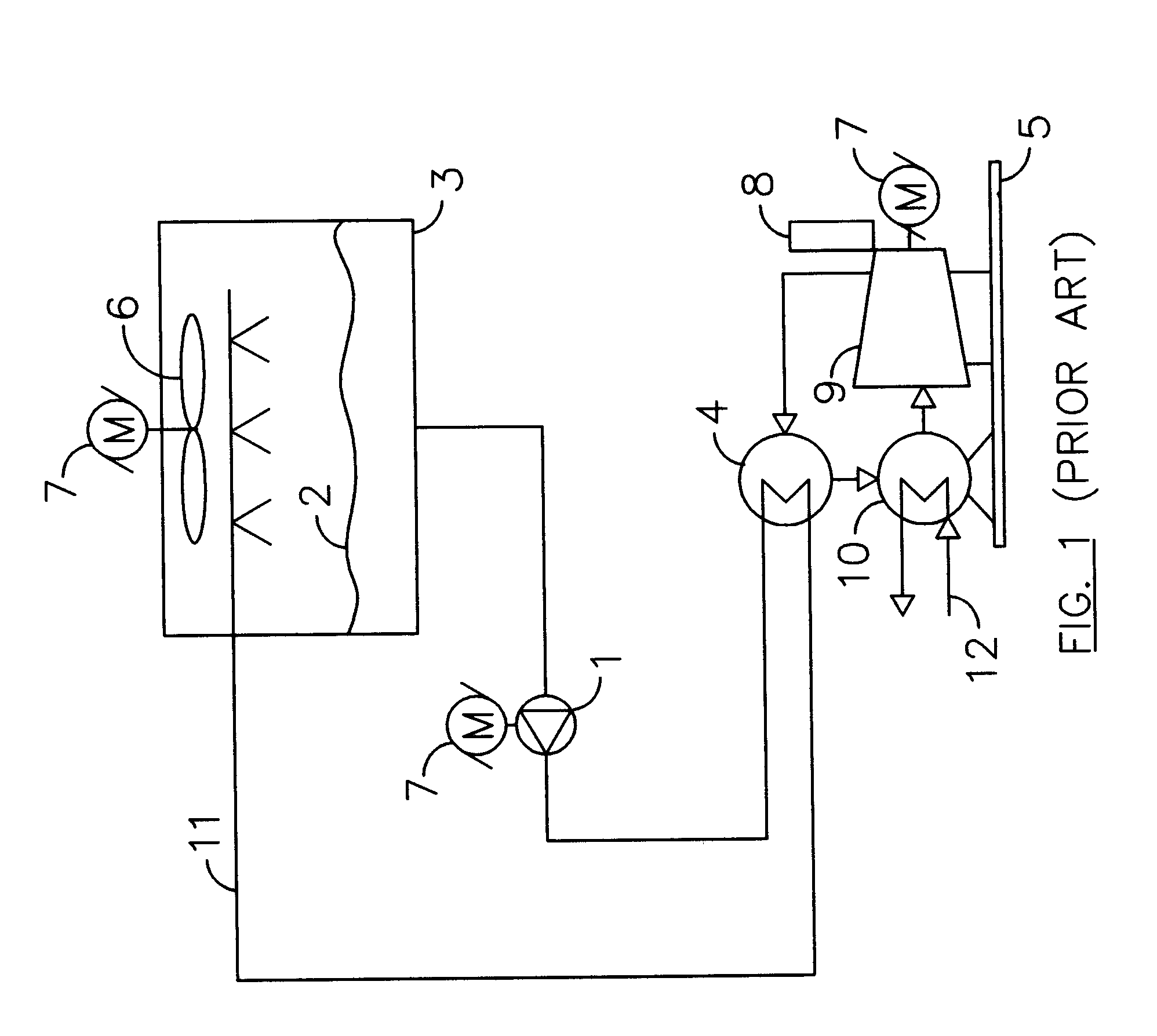

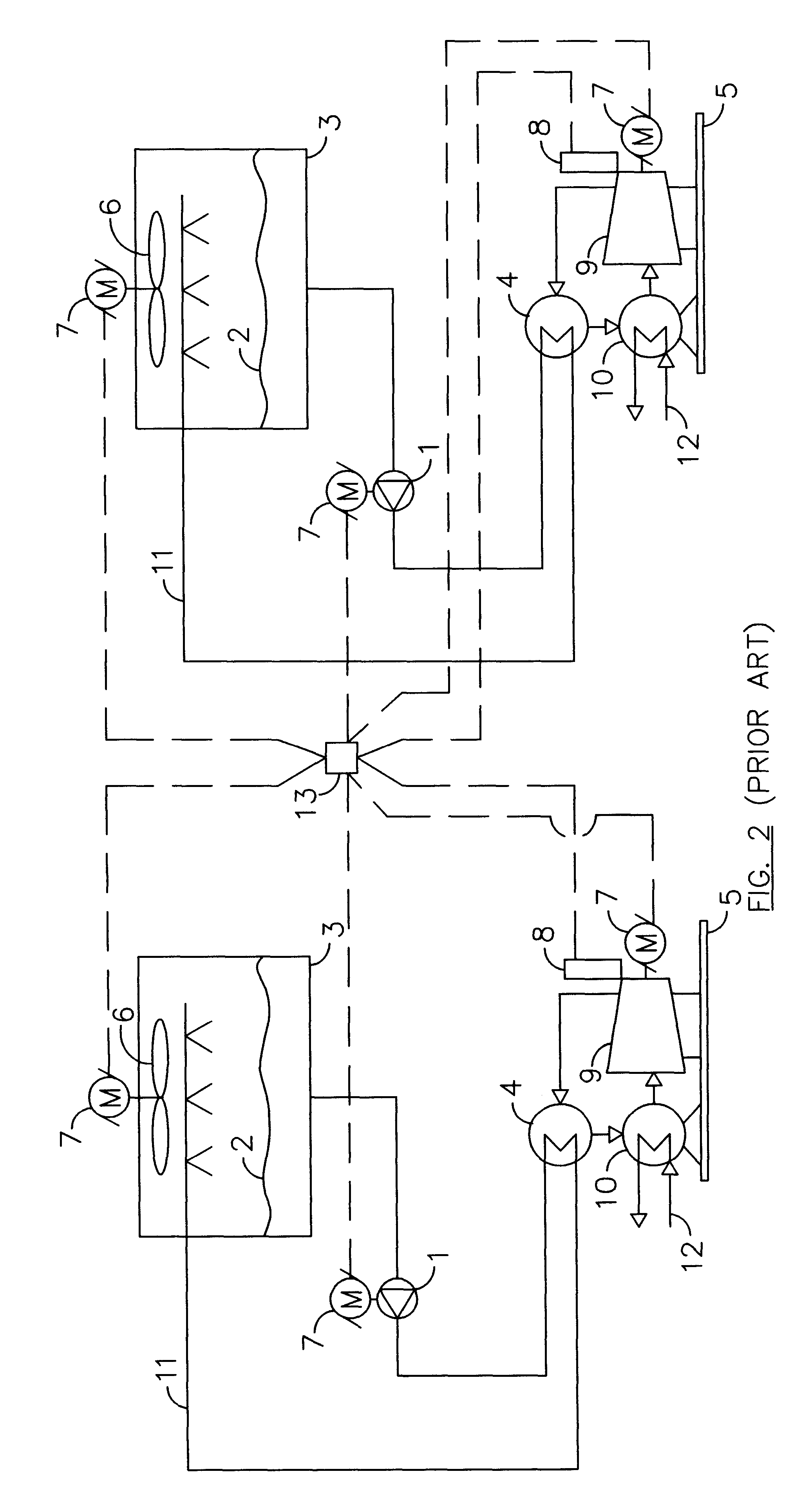

- A computerized controller system that uses temperature sensors and flow meters to maintain a constant temperature difference across the refrigerant condenser, controlling cooling fluid pump and cooling tower fan speeds based on measured parameters, allowing for flexible operation and integration with existing chiller plants without requiring proprietary access or complex setups.

Energy Efficiency Regulations and Standards

Energy efficiency regulations and standards form the foundational framework driving chiller retrofitting initiatives across global markets. These regulatory mechanisms establish minimum performance thresholds, measurement protocols, and compliance timelines that directly influence investment decisions in HVAC system upgrades. Understanding this regulatory landscape is essential for evaluating the economic viability and technical requirements of chiller efficiency improvement projects.

International standards such as ISO 50001 for energy management systems and ASHRAE Standard 90.1 for energy-efficient building design provide comprehensive guidelines for chiller performance evaluation. These frameworks define metrics including Energy Efficiency Ratio (EER), Integrated Part Load Value (IPLV), and Coefficient of Performance (COP) that serve as benchmarks for assessing retrofit effectiveness. Regional variations exist, with the European Union's Ecodesign Directive establishing stringent seasonal energy efficiency requirements, while the United States implements efficiency standards through the Department of Energy's appliance regulations.

Compliance mandates increasingly incorporate lifecycle assessment approaches, requiring facility operators to demonstrate continuous improvement rather than one-time upgrades. The European F-Gas Regulation phases down high global warming potential refrigerants, compelling retrofits that address both energy efficiency and environmental impact simultaneously. Similarly, China's GB 19577 standard for chiller efficiency has undergone multiple revisions, progressively tightening performance requirements and expanding coverage to smaller capacity units.

Emerging regulatory trends emphasize real-time monitoring and verification protocols. Smart building codes now mandate integration of building automation systems capable of tracking chiller performance against established baselines. California's Title 24 and similar progressive building codes require commissioning documentation and periodic retro-commissioning to maintain efficiency gains achieved through retrofitting. These evolving requirements transform compliance from a static target into a dynamic process requiring ongoing technical validation and performance optimization throughout the equipment lifecycle.

International standards such as ISO 50001 for energy management systems and ASHRAE Standard 90.1 for energy-efficient building design provide comprehensive guidelines for chiller performance evaluation. These frameworks define metrics including Energy Efficiency Ratio (EER), Integrated Part Load Value (IPLV), and Coefficient of Performance (COP) that serve as benchmarks for assessing retrofit effectiveness. Regional variations exist, with the European Union's Ecodesign Directive establishing stringent seasonal energy efficiency requirements, while the United States implements efficiency standards through the Department of Energy's appliance regulations.

Compliance mandates increasingly incorporate lifecycle assessment approaches, requiring facility operators to demonstrate continuous improvement rather than one-time upgrades. The European F-Gas Regulation phases down high global warming potential refrigerants, compelling retrofits that address both energy efficiency and environmental impact simultaneously. Similarly, China's GB 19577 standard for chiller efficiency has undergone multiple revisions, progressively tightening performance requirements and expanding coverage to smaller capacity units.

Emerging regulatory trends emphasize real-time monitoring and verification protocols. Smart building codes now mandate integration of building automation systems capable of tracking chiller performance against established baselines. California's Title 24 and similar progressive building codes require commissioning documentation and periodic retro-commissioning to maintain efficiency gains achieved through retrofitting. These evolving requirements transform compliance from a static target into a dynamic process requiring ongoing technical validation and performance optimization throughout the equipment lifecycle.

ROI Analysis for Chiller Retrofitting Projects

Evaluating the return on investment for chiller retrofitting projects requires a comprehensive financial framework that balances upfront capital expenditures against long-term operational savings. The economic viability of retrofitting initiatives depends on multiple variables including energy cost differentials, equipment lifespan extension, maintenance cost reductions, and potential utility incentives. A typical ROI calculation must account for both tangible benefits such as reduced electricity consumption and intangible advantages like improved system reliability and reduced environmental compliance risks.

The initial investment for chiller retrofitting varies significantly based on the scope of modifications, ranging from simple control system upgrades to comprehensive compressor replacements or heat exchanger enhancements. Baseline energy audits establish current performance metrics, enabling accurate projection of post-retrofit efficiency gains. Most commercial retrofitting projects demonstrate payback periods between three to seven years, with annual energy savings typically ranging from fifteen to forty percent depending on the existing system's age and condition. These savings translate directly to reduced operational expenses, creating positive cash flow that accelerates investment recovery.

Beyond direct energy savings, retrofitting projects generate additional financial benefits through extended equipment service life, often adding five to ten years of operational capacity. Reduced maintenance requirements and fewer emergency repairs contribute to lower lifecycle costs, while improved system performance may qualify facilities for green building certifications or preferential financing rates. Utility rebate programs and tax incentives for energy efficiency improvements can offset twenty to thirty-five percent of initial capital costs in many jurisdictions, substantially improving project economics.

Risk assessment forms a critical component of ROI analysis, considering factors such as energy price volatility, technological obsolescence, and regulatory changes affecting refrigerant usage. Sensitivity analysis helps identify break-even points under various scenarios, ensuring robust decision-making. Financial modeling should incorporate discount rates reflecting organizational cost of capital, inflation adjustments, and potential revenue impacts from improved cooling capacity or reduced downtime. Comprehensive ROI evaluation ultimately determines whether retrofitting represents a superior investment compared to complete system replacement or continued operation of existing equipment.

The initial investment for chiller retrofitting varies significantly based on the scope of modifications, ranging from simple control system upgrades to comprehensive compressor replacements or heat exchanger enhancements. Baseline energy audits establish current performance metrics, enabling accurate projection of post-retrofit efficiency gains. Most commercial retrofitting projects demonstrate payback periods between three to seven years, with annual energy savings typically ranging from fifteen to forty percent depending on the existing system's age and condition. These savings translate directly to reduced operational expenses, creating positive cash flow that accelerates investment recovery.

Beyond direct energy savings, retrofitting projects generate additional financial benefits through extended equipment service life, often adding five to ten years of operational capacity. Reduced maintenance requirements and fewer emergency repairs contribute to lower lifecycle costs, while improved system performance may qualify facilities for green building certifications or preferential financing rates. Utility rebate programs and tax incentives for energy efficiency improvements can offset twenty to thirty-five percent of initial capital costs in many jurisdictions, substantially improving project economics.

Risk assessment forms a critical component of ROI analysis, considering factors such as energy price volatility, technological obsolescence, and regulatory changes affecting refrigerant usage. Sensitivity analysis helps identify break-even points under various scenarios, ensuring robust decision-making. Financial modeling should incorporate discount rates reflecting organizational cost of capital, inflation adjustments, and potential revenue impacts from improved cooling capacity or reduced downtime. Comprehensive ROI evaluation ultimately determines whether retrofitting represents a superior investment compared to complete system replacement or continued operation of existing equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!