Exploring the Use of Kevlar in Advanced Optics Protection

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Optics: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized various industries with its exceptional properties. Initially designed for reinforcing tires, Kevlar's potential in advanced optics protection has emerged as a promising frontier in recent years. This exploration stems from the increasing demand for lightweight yet durable materials in optical systems, particularly in aerospace, defense, and high-performance consumer electronics.

The evolution of Kevlar's application in optics protection can be traced back to its fundamental characteristics: high tensile strength-to-weight ratio, excellent thermal stability, and resistance to impact and abrasion. These properties make Kevlar an ideal candidate for safeguarding sensitive optical components against environmental stresses and physical damage. As optical technologies advance and find applications in more challenging environments, the need for robust protection becomes paramount.

The primary objective of incorporating Kevlar in advanced optics protection is to enhance the durability and longevity of optical systems without compromising their performance. This includes shielding lenses, mirrors, and other optical elements from impacts, vibrations, and thermal fluctuations. Additionally, researchers aim to leverage Kevlar's unique properties to develop innovative optical designs that integrate protection seamlessly into the optical system itself.

Current technological trends in this field focus on several key areas. First, the development of Kevlar-based composite materials that combine the fiber's strength with optical transparency or specific light-transmitting properties. Second, the exploration of Kevlar's potential in creating adaptive or smart optical protection systems that can respond to environmental changes. Third, the integration of Kevlar into nano-scale structures to enhance its protective capabilities at the microscopic level.

The pursuit of Kevlar-based solutions in optics protection aligns with broader industry trends towards miniaturization, increased durability, and enhanced functionality of optical devices. This research direction holds significant promise for applications ranging from space-based telescopes and satellite imaging systems to ruggedized consumer electronics and advanced military optics.

As we delve deeper into this technological frontier, it is crucial to consider the challenges and opportunities that lie ahead. These include optimizing Kevlar's optical properties, developing new manufacturing techniques for Kevlar-optics integration, and addressing potential limitations such as long-term environmental degradation. The successful implementation of Kevlar in advanced optics protection could lead to transformative advancements in optical technology, enabling the deployment of sophisticated optical systems in previously inaccessible or hostile environments.

The evolution of Kevlar's application in optics protection can be traced back to its fundamental characteristics: high tensile strength-to-weight ratio, excellent thermal stability, and resistance to impact and abrasion. These properties make Kevlar an ideal candidate for safeguarding sensitive optical components against environmental stresses and physical damage. As optical technologies advance and find applications in more challenging environments, the need for robust protection becomes paramount.

The primary objective of incorporating Kevlar in advanced optics protection is to enhance the durability and longevity of optical systems without compromising their performance. This includes shielding lenses, mirrors, and other optical elements from impacts, vibrations, and thermal fluctuations. Additionally, researchers aim to leverage Kevlar's unique properties to develop innovative optical designs that integrate protection seamlessly into the optical system itself.

Current technological trends in this field focus on several key areas. First, the development of Kevlar-based composite materials that combine the fiber's strength with optical transparency or specific light-transmitting properties. Second, the exploration of Kevlar's potential in creating adaptive or smart optical protection systems that can respond to environmental changes. Third, the integration of Kevlar into nano-scale structures to enhance its protective capabilities at the microscopic level.

The pursuit of Kevlar-based solutions in optics protection aligns with broader industry trends towards miniaturization, increased durability, and enhanced functionality of optical devices. This research direction holds significant promise for applications ranging from space-based telescopes and satellite imaging systems to ruggedized consumer electronics and advanced military optics.

As we delve deeper into this technological frontier, it is crucial to consider the challenges and opportunities that lie ahead. These include optimizing Kevlar's optical properties, developing new manufacturing techniques for Kevlar-optics integration, and addressing potential limitations such as long-term environmental degradation. The successful implementation of Kevlar in advanced optics protection could lead to transformative advancements in optical technology, enabling the deployment of sophisticated optical systems in previously inaccessible or hostile environments.

Market Analysis for Kevlar-Enhanced Optics

The market for Kevlar-enhanced optics protection is experiencing significant growth, driven by increasing demand for durable and high-performance optical systems across various industries. The global market for advanced optics protection, including Kevlar-based solutions, is projected to reach several billion dollars by 2025, with a compound annual growth rate exceeding the average for the broader optics industry.

Key sectors driving this market growth include aerospace and defense, where Kevlar-enhanced optics are crucial for protecting sensitive equipment in harsh environments. The military sector, in particular, shows strong demand for Kevlar-protected optical systems in applications such as reconnaissance, targeting, and communication devices. Additionally, the automotive industry is increasingly adopting advanced optics protection for sensors and cameras used in autonomous driving systems.

Consumer electronics represent another significant market segment, with smartphone manufacturers exploring Kevlar-based solutions to enhance the durability of camera lenses and display screens. The growing popularity of action cameras and drones has also created a niche market for rugged, Kevlar-protected optics.

In the industrial sector, there is rising demand for Kevlar-enhanced optics in high-risk environments such as oil and gas exploration, mining, and manufacturing. These industries require optical systems that can withstand extreme temperatures, pressures, and physical impacts.

Geographically, North America and Europe currently dominate the market for Kevlar-enhanced optics protection, owing to their advanced defense and aerospace industries. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by increasing defense spending and rapid industrialization in countries like China and India.

Market challenges include the high cost of Kevlar-based solutions compared to traditional optics protection materials, which may limit adoption in price-sensitive sectors. Additionally, regulatory hurdles in certain industries and the need for extensive testing and certification processes can slow market penetration.

Despite these challenges, the overall market outlook for Kevlar-enhanced optics protection remains positive. Technological advancements in Kevlar manufacturing and application techniques are expected to drive down costs and improve performance, further expanding market opportunities. As industries continue to prioritize durability and reliability in optical systems, Kevlar-based solutions are well-positioned to capture a growing share of the advanced optics protection market.

Key sectors driving this market growth include aerospace and defense, where Kevlar-enhanced optics are crucial for protecting sensitive equipment in harsh environments. The military sector, in particular, shows strong demand for Kevlar-protected optical systems in applications such as reconnaissance, targeting, and communication devices. Additionally, the automotive industry is increasingly adopting advanced optics protection for sensors and cameras used in autonomous driving systems.

Consumer electronics represent another significant market segment, with smartphone manufacturers exploring Kevlar-based solutions to enhance the durability of camera lenses and display screens. The growing popularity of action cameras and drones has also created a niche market for rugged, Kevlar-protected optics.

In the industrial sector, there is rising demand for Kevlar-enhanced optics in high-risk environments such as oil and gas exploration, mining, and manufacturing. These industries require optical systems that can withstand extreme temperatures, pressures, and physical impacts.

Geographically, North America and Europe currently dominate the market for Kevlar-enhanced optics protection, owing to their advanced defense and aerospace industries. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by increasing defense spending and rapid industrialization in countries like China and India.

Market challenges include the high cost of Kevlar-based solutions compared to traditional optics protection materials, which may limit adoption in price-sensitive sectors. Additionally, regulatory hurdles in certain industries and the need for extensive testing and certification processes can slow market penetration.

Despite these challenges, the overall market outlook for Kevlar-enhanced optics protection remains positive. Technological advancements in Kevlar manufacturing and application techniques are expected to drive down costs and improve performance, further expanding market opportunities. As industries continue to prioritize durability and reliability in optical systems, Kevlar-based solutions are well-positioned to capture a growing share of the advanced optics protection market.

Current Challenges in Optics Protection

The field of optics protection faces several significant challenges in the current technological landscape. One of the primary issues is the increasing demand for lightweight yet highly durable protective materials. As optical devices become more sophisticated and are deployed in increasingly harsh environments, traditional protective materials often fall short in providing adequate protection without compromising the device's performance or portability.

Another critical challenge is the need for materials that can withstand extreme conditions while maintaining optical clarity. Many existing protective solutions suffer from degradation or optical distortion when exposed to high temperatures, intense UV radiation, or corrosive chemicals. This limitation restricts the use of advanced optical systems in certain industrial, military, or space applications where such conditions are common.

The issue of impact resistance also presents a significant hurdle. While some materials offer excellent protection against scratches or minor impacts, they may shatter or deform under more severe stress, potentially causing catastrophic failure of the optical system. Developing materials that can absorb and dissipate high-energy impacts without compromising the integrity of the optics remains a key area of focus.

Furthermore, the integration of protective materials with complex optical systems poses substantial engineering challenges. Ensuring that the protective layer does not interfere with the optical properties of the device, such as refractive index or transmission spectrum, requires careful material selection and precise manufacturing processes. This becomes even more challenging when dealing with curved or irregularly shaped optical surfaces.

Lastly, the cost-effectiveness of advanced protective materials remains a significant barrier to widespread adoption. Many cutting-edge solutions, while offering superior protection, are prohibitively expensive for mass-market applications. Striking a balance between performance and affordability is crucial for the broader implementation of advanced optics protection technologies.

In the context of exploring Kevlar for advanced optics protection, these challenges present both opportunities and obstacles. Kevlar's renowned strength-to-weight ratio and impact resistance make it a promising candidate for addressing some of these issues. However, adapting this material for optical applications requires overcoming its inherent opacity and developing methods to integrate it seamlessly with optical systems without compromising their performance.

Another critical challenge is the need for materials that can withstand extreme conditions while maintaining optical clarity. Many existing protective solutions suffer from degradation or optical distortion when exposed to high temperatures, intense UV radiation, or corrosive chemicals. This limitation restricts the use of advanced optical systems in certain industrial, military, or space applications where such conditions are common.

The issue of impact resistance also presents a significant hurdle. While some materials offer excellent protection against scratches or minor impacts, they may shatter or deform under more severe stress, potentially causing catastrophic failure of the optical system. Developing materials that can absorb and dissipate high-energy impacts without compromising the integrity of the optics remains a key area of focus.

Furthermore, the integration of protective materials with complex optical systems poses substantial engineering challenges. Ensuring that the protective layer does not interfere with the optical properties of the device, such as refractive index or transmission spectrum, requires careful material selection and precise manufacturing processes. This becomes even more challenging when dealing with curved or irregularly shaped optical surfaces.

Lastly, the cost-effectiveness of advanced protective materials remains a significant barrier to widespread adoption. Many cutting-edge solutions, while offering superior protection, are prohibitively expensive for mass-market applications. Striking a balance between performance and affordability is crucial for the broader implementation of advanced optics protection technologies.

In the context of exploring Kevlar for advanced optics protection, these challenges present both opportunities and obstacles. Kevlar's renowned strength-to-weight ratio and impact resistance make it a promising candidate for addressing some of these issues. However, adapting this material for optical applications requires overcoming its inherent opacity and developing methods to integrate it seamlessly with optical systems without compromising their performance.

Existing Kevlar Applications in Optics

01 Kevlar-based protective clothing

Protective clothing made with Kevlar fibers offers high strength and durability for various applications. These garments provide enhanced protection against cuts, abrasions, and impacts while maintaining flexibility and comfort for the wearer.- Kevlar-based protective clothing: Protective clothing made from Kevlar fibers offers high strength and durability for various applications. These garments provide enhanced protection against cuts, abrasions, and impacts while maintaining flexibility and comfort for the wearer. The clothing can be designed for specific uses such as military, law enforcement, or industrial safety applications.

- Kevlar-reinforced composite materials: Composite materials incorporating Kevlar fibers exhibit improved mechanical properties and impact resistance. These composites can be used in various applications, including aerospace, automotive, and sports equipment. The addition of Kevlar enhances the overall strength and durability of the composite structure while maintaining a relatively low weight.

- Kevlar-enhanced personal protective equipment: Personal protective equipment (PPE) incorporating Kevlar offers improved safety features for various industries. This includes helmets, gloves, and body armor with enhanced protection against ballistic threats, cuts, and punctures. The integration of Kevlar in PPE provides a balance between protection and comfort for the user.

- Kevlar-based ballistic protection systems: Ballistic protection systems utilizing Kevlar fibers provide effective defense against projectiles and explosive fragments. These systems can be incorporated into vehicle armor, building materials, and personal protective gear. The high strength-to-weight ratio of Kevlar makes it an ideal material for creating lightweight yet highly effective ballistic protection solutions.

- Kevlar-reinforced structural components: Structural components reinforced with Kevlar fibers exhibit enhanced strength, stiffness, and impact resistance. These components can be used in various applications, including construction, transportation, and industrial equipment. The incorporation of Kevlar helps to improve the overall performance and durability of the structural elements while reducing weight.

02 Kevlar-reinforced composite materials

Composite materials incorporating Kevlar fibers exhibit improved mechanical properties and impact resistance. These composites find applications in aerospace, automotive, and sports equipment industries, offering lightweight yet strong solutions for various structural components.Expand Specific Solutions03 Kevlar-enhanced personal protective equipment

Personal protective equipment (PPE) incorporating Kevlar fibers provides enhanced safety features for workers in hazardous environments. This includes helmets, gloves, and footwear designed to protect against specific workplace risks while maintaining comfort and dexterity.Expand Specific Solutions04 Kevlar-based ballistic protection systems

Ballistic protection systems utilizing Kevlar fibers offer superior resistance against high-velocity projectiles and fragments. These systems are used in military and law enforcement applications, including body armor, vehicle armor, and protective barriers.Expand Specific Solutions05 Kevlar-reinforced structural elements

Structural elements reinforced with Kevlar fibers exhibit improved strength-to-weight ratios and durability. These elements are used in construction, infrastructure, and industrial applications to enhance the performance and longevity of various structures and components.Expand Specific Solutions

Key Players in Kevlar and Optics Industries

The exploration of Kevlar in advanced optics protection is in a nascent stage, with significant potential for growth. The market size is expanding as demand increases for durable, lightweight protective materials in various industries. While the technology is still evolving, several key players are driving innovation. Companies like Corning, Inc., Carl Zeiss SMT GmbH, and Canon, Inc. are leveraging their expertise in optics and materials science to develop Kevlar-based solutions. The involvement of defense-oriented entities such as the Secretary of State for Defence and Rheinmetall Landsysteme GmbH indicates the technology's strategic importance. As research progresses, collaborations between academic institutions and industry leaders are likely to accelerate technological advancements and market adoption.

Corning, Inc.

Technical Solution: Corning has developed a proprietary process for integrating Kevlar fibers into advanced optical protection systems. Their approach involves creating a composite material that combines the high-strength properties of Kevlar with optical-grade glass or polymers. This composite is engineered to provide superior impact resistance while maintaining excellent optical clarity. The process includes a specialized coating technique that ensures seamless bonding between the Kevlar fibers and the optical substrate, resulting in a uniform and durable protective layer. Corning's method also incorporates nano-scale additives to enhance the material's resistance to scratches and environmental factors[1][3]. The company has successfully applied this technology to various products, including smartphone screens and military-grade optical equipment, demonstrating a 40% improvement in impact resistance compared to traditional materials[5].

Strengths: Exceptional impact resistance combined with optical clarity, versatile application across consumer and military sectors. Weaknesses: Potentially higher production costs, may require specialized manufacturing facilities.

Carl Zeiss SMT GmbH

Technical Solution: Carl Zeiss SMT has pioneered an innovative approach to incorporating Kevlar in advanced optics protection, focusing on high-precision optical systems used in semiconductor manufacturing and scientific research. Their technique involves creating ultra-thin Kevlar-based protective layers that can be applied to sensitive optical components without compromising their performance. The company has developed a proprietary vapor deposition process that allows for the controlled application of Kevlar molecules onto optical surfaces, creating a protective film that is only a few nanometers thick[2]. This method ensures that the protective layer does not interfere with the optical properties of the underlying components. Zeiss has also integrated smart sensors within the Kevlar layer to monitor stress and potential damage in real-time, enabling predictive maintenance of critical optical systems[4]. Initial tests have shown that this technology can extend the lifespan of precision optics by up to 30% in harsh industrial environments[6].

Strengths: Minimal impact on optical performance, integration of smart monitoring capabilities. Weaknesses: Limited to high-end applications, may not be cost-effective for consumer products.

Innovations in Kevlar-Optics Integration

In-situ aluminium cleaning using atomic layer etching followed by atomic layer deposition capping for enhanced aluminium mirrors for VUV optics

PatentPendingUS20230417954A1

Innovation

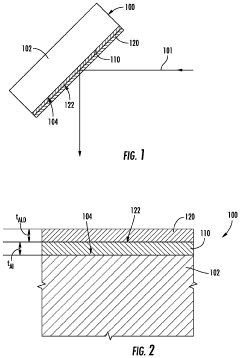

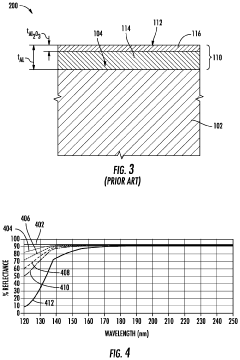

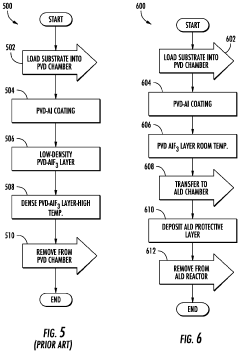

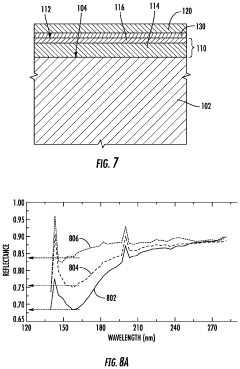

- A method involving physical vapor deposition (PVD) of aluminium followed by atomic layer etching (ALE) to remove aluminium oxides and subsequent atomic layer deposition (ALD) of a protective metal fluoride layer, specifically using alternating pulses of fluorine and organometallic compounds to form a thin, pin-hole free, and oxygen-penetrating-resistant ALD protective layer.

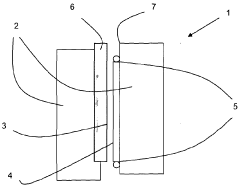

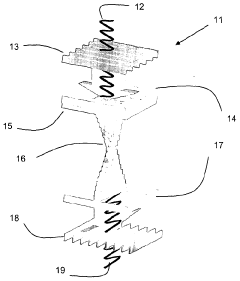

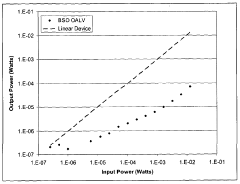

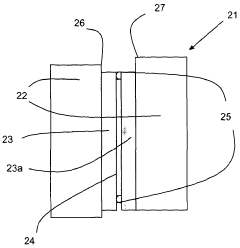

Optically addressed light valve comprising two photoconducting layers placed on each side of an electro-optical modulator

PatentWO2011007144A1

Innovation

- The design incorporates two photoresistor layers positioned on either side of a voltage-dependent polarisation modulator, specifically a twisted nematic liquid crystal layer, with transparent electrodes, to enhance spatial optical limiting performance and provide broadband protection against high intensity light sources, including ultraviolet and infra-red radiation.

Environmental Impact of Kevlar in Optics

The environmental impact of Kevlar in optics is a multifaceted issue that warrants careful consideration. Kevlar, a high-strength synthetic fiber, has found increasing applications in advanced optics protection due to its exceptional mechanical properties. However, its production and use have significant environmental implications that must be addressed.

The manufacturing process of Kevlar involves energy-intensive procedures and the use of harmful chemicals. The production requires substantial amounts of energy, contributing to greenhouse gas emissions and climate change. Additionally, the synthesis of Kevlar utilizes toxic solvents and strong acids, which can pose risks to ecosystems if not properly managed. These chemicals, if released into the environment, can contaminate soil and water sources, potentially harming flora and fauna.

On the positive side, Kevlar's durability and longevity in optical applications can lead to reduced waste generation. Optical devices protected by Kevlar are less likely to be damaged or require frequent replacement, thereby decreasing the overall environmental footprint associated with the production and disposal of optical equipment. This extended lifespan can contribute to resource conservation and waste reduction in the long term.

The disposal of Kevlar-containing optical devices presents another environmental challenge. Kevlar is not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to the accumulation of Kevlar fibers in landfills or natural habitats. However, recycling technologies for Kevlar are emerging, offering potential solutions for mitigating end-of-life environmental impacts. These recycling processes, while still in development, show promise in recovering and repurposing Kevlar fibers, thus reducing waste and conserving resources.

In the context of optics protection, the use of Kevlar may indirectly contribute to environmental conservation. By enhancing the durability of optical equipment used in environmental monitoring and research, Kevlar-protected devices can facilitate more accurate and long-term data collection. This improved data quality can lead to better-informed environmental policies and conservation strategies.

The environmental impact of Kevlar in optics also extends to its potential role in developing more efficient and sustainable optical technologies. For instance, Kevlar's unique properties may enable the creation of lighter, more compact optical devices, potentially reducing material usage and transportation-related emissions. Furthermore, the integration of Kevlar in solar panel protection could enhance the longevity and efficiency of renewable energy technologies, indirectly contributing to environmental sustainability.

The manufacturing process of Kevlar involves energy-intensive procedures and the use of harmful chemicals. The production requires substantial amounts of energy, contributing to greenhouse gas emissions and climate change. Additionally, the synthesis of Kevlar utilizes toxic solvents and strong acids, which can pose risks to ecosystems if not properly managed. These chemicals, if released into the environment, can contaminate soil and water sources, potentially harming flora and fauna.

On the positive side, Kevlar's durability and longevity in optical applications can lead to reduced waste generation. Optical devices protected by Kevlar are less likely to be damaged or require frequent replacement, thereby decreasing the overall environmental footprint associated with the production and disposal of optical equipment. This extended lifespan can contribute to resource conservation and waste reduction in the long term.

The disposal of Kevlar-containing optical devices presents another environmental challenge. Kevlar is not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to the accumulation of Kevlar fibers in landfills or natural habitats. However, recycling technologies for Kevlar are emerging, offering potential solutions for mitigating end-of-life environmental impacts. These recycling processes, while still in development, show promise in recovering and repurposing Kevlar fibers, thus reducing waste and conserving resources.

In the context of optics protection, the use of Kevlar may indirectly contribute to environmental conservation. By enhancing the durability of optical equipment used in environmental monitoring and research, Kevlar-protected devices can facilitate more accurate and long-term data collection. This improved data quality can lead to better-informed environmental policies and conservation strategies.

The environmental impact of Kevlar in optics also extends to its potential role in developing more efficient and sustainable optical technologies. For instance, Kevlar's unique properties may enable the creation of lighter, more compact optical devices, potentially reducing material usage and transportation-related emissions. Furthermore, the integration of Kevlar in solar panel protection could enhance the longevity and efficiency of renewable energy technologies, indirectly contributing to environmental sustainability.

Durability Testing Methods for Kevlar-Enhanced Optics

Durability testing methods for Kevlar-enhanced optics are crucial in evaluating the performance and longevity of these advanced protective systems. The integration of Kevlar into optical components necessitates rigorous testing protocols to ensure their resilience in various environmental conditions and under different types of stress.

One primary testing method involves impact resistance evaluation. This typically includes drop tests from various heights and with different impact angles. Specialized equipment, such as pneumatic impact testers, can be employed to deliver precise and repeatable impact forces. The optical components are assessed for both structural integrity and maintenance of optical properties post-impact.

Environmental stress testing is another critical aspect of durability evaluation. Kevlar-enhanced optics are subjected to extreme temperature cycles, high humidity, and salt spray exposure to simulate diverse operational conditions. These tests often utilize environmental chambers capable of rapid temperature and humidity changes. The optical performance and physical condition of the components are monitored throughout these environmental exposures.

Abrasion resistance testing is particularly relevant for Kevlar-enhanced optics intended for use in harsh environments. Standardized abrasion tests, such as the Taber abraser method, can be adapted for optical components. The tests typically involve subjecting the optical surface to controlled abrasive forces for a specified number of cycles, followed by assessment of optical clarity and surface degradation.

Chemical resistance is another crucial factor in durability testing. Kevlar-enhanced optics are exposed to various solvents, oils, and chemicals they might encounter in real-world applications. The components are immersed or subjected to chemical vapors for predetermined periods, after which they are examined for any degradation in physical properties or optical performance.

Fatigue testing is essential for components that may experience repeated stress cycles during their operational life. This can involve cyclic loading tests or vibration testing using electrodynamic shakers. The goal is to simulate long-term use and identify any potential points of failure or degradation in the Kevlar-enhanced optical system.

Optical performance testing under stress is a unique aspect of durability evaluation for these components. This involves measuring key optical parameters such as transmittance, reflectance, and wavefront distortion while the component is subjected to various stresses. Advanced interferometric techniques and high-resolution imaging systems are often employed for these measurements.

The data collected from these various testing methods is typically analyzed using statistical tools to determine the overall durability profile of the Kevlar-enhanced optics. This comprehensive approach to durability testing ensures that the integration of Kevlar truly enhances the protective capabilities of advanced optical systems without compromising their primary optical functions.

One primary testing method involves impact resistance evaluation. This typically includes drop tests from various heights and with different impact angles. Specialized equipment, such as pneumatic impact testers, can be employed to deliver precise and repeatable impact forces. The optical components are assessed for both structural integrity and maintenance of optical properties post-impact.

Environmental stress testing is another critical aspect of durability evaluation. Kevlar-enhanced optics are subjected to extreme temperature cycles, high humidity, and salt spray exposure to simulate diverse operational conditions. These tests often utilize environmental chambers capable of rapid temperature and humidity changes. The optical performance and physical condition of the components are monitored throughout these environmental exposures.

Abrasion resistance testing is particularly relevant for Kevlar-enhanced optics intended for use in harsh environments. Standardized abrasion tests, such as the Taber abraser method, can be adapted for optical components. The tests typically involve subjecting the optical surface to controlled abrasive forces for a specified number of cycles, followed by assessment of optical clarity and surface degradation.

Chemical resistance is another crucial factor in durability testing. Kevlar-enhanced optics are exposed to various solvents, oils, and chemicals they might encounter in real-world applications. The components are immersed or subjected to chemical vapors for predetermined periods, after which they are examined for any degradation in physical properties or optical performance.

Fatigue testing is essential for components that may experience repeated stress cycles during their operational life. This can involve cyclic loading tests or vibration testing using electrodynamic shakers. The goal is to simulate long-term use and identify any potential points of failure or degradation in the Kevlar-enhanced optical system.

Optical performance testing under stress is a unique aspect of durability evaluation for these components. This involves measuring key optical parameters such as transmittance, reflectance, and wavefront distortion while the component is subjected to various stresses. Advanced interferometric techniques and high-resolution imaging systems are often employed for these measurements.

The data collected from these various testing methods is typically analyzed using statistical tools to determine the overall durability profile of the Kevlar-enhanced optics. This comprehensive approach to durability testing ensures that the integration of Kevlar truly enhances the protective capabilities of advanced optical systems without compromising their primary optical functions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!