Glass Transition In Amorphous vs Semi-Crystalline Polymers: Dual Events And Interpretation

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Glass Transition Background and Research Objectives

The glass transition phenomenon in polymers has been a subject of extensive research since the early 20th century, evolving from rudimentary observations to sophisticated theoretical frameworks. This transition represents a fundamental property where polymeric materials transform from a rigid, glassy state to a more flexible, rubbery state as temperature increases. The distinction between glass transition behaviors in amorphous versus semi-crystalline polymers presents particularly intriguing scientific challenges that have significant implications for material applications across industries.

Historically, the concept of glass transition was first systematically studied in the 1930s, with significant theoretical advancements occurring in the 1950s through the work of researchers like Gibbs, DiMarzio, and Williams-Landel-Ferry. The development of thermal analysis techniques, particularly Differential Scanning Calorimetry (DSC) in the 1960s, revolutionized the experimental approach to studying these transitions, allowing for more precise measurements of thermal events in polymeric materials.

Recent technological advances have revealed that glass transitions in semi-crystalline polymers exhibit substantially more complex behavior than their amorphous counterparts. While amorphous polymers typically display a single, well-defined glass transition temperature (Tg), semi-crystalline polymers often manifest dual or multiple transition events that have been subject to varied interpretations in the scientific community. These multiple transitions may represent distinct molecular mobility changes in different regions of the polymer structure.

The current technological landscape demands a deeper understanding of these phenomena as industries increasingly require polymeric materials with precisely tailored properties. From automotive components requiring specific impact resistance at varying temperatures to biomedical implants needing controlled degradation profiles, the practical applications driving this research are diverse and economically significant.

Our research objectives focus on elucidating the fundamental mechanisms underlying the dual glass transition events observed in semi-crystalline polymers. Specifically, we aim to: (1) characterize the molecular dynamics associated with each transition event using advanced spectroscopic and thermal analysis techniques; (2) develop predictive models that correlate polymer structure with transition behavior; (3) establish a unified theoretical framework that reconciles competing interpretations of these phenomena; and (4) translate these insights into practical guidelines for material design and processing.

The technological trajectory suggests that mastering these complex transitions will enable the development of next-generation polymeric materials with unprecedented property combinations and performance characteristics. As computational modeling capabilities advance alongside experimental techniques, we anticipate significant breakthroughs in this field within the next five years, potentially revolutionizing how we design and utilize polymeric materials across industries.

Historically, the concept of glass transition was first systematically studied in the 1930s, with significant theoretical advancements occurring in the 1950s through the work of researchers like Gibbs, DiMarzio, and Williams-Landel-Ferry. The development of thermal analysis techniques, particularly Differential Scanning Calorimetry (DSC) in the 1960s, revolutionized the experimental approach to studying these transitions, allowing for more precise measurements of thermal events in polymeric materials.

Recent technological advances have revealed that glass transitions in semi-crystalline polymers exhibit substantially more complex behavior than their amorphous counterparts. While amorphous polymers typically display a single, well-defined glass transition temperature (Tg), semi-crystalline polymers often manifest dual or multiple transition events that have been subject to varied interpretations in the scientific community. These multiple transitions may represent distinct molecular mobility changes in different regions of the polymer structure.

The current technological landscape demands a deeper understanding of these phenomena as industries increasingly require polymeric materials with precisely tailored properties. From automotive components requiring specific impact resistance at varying temperatures to biomedical implants needing controlled degradation profiles, the practical applications driving this research are diverse and economically significant.

Our research objectives focus on elucidating the fundamental mechanisms underlying the dual glass transition events observed in semi-crystalline polymers. Specifically, we aim to: (1) characterize the molecular dynamics associated with each transition event using advanced spectroscopic and thermal analysis techniques; (2) develop predictive models that correlate polymer structure with transition behavior; (3) establish a unified theoretical framework that reconciles competing interpretations of these phenomena; and (4) translate these insights into practical guidelines for material design and processing.

The technological trajectory suggests that mastering these complex transitions will enable the development of next-generation polymeric materials with unprecedented property combinations and performance characteristics. As computational modeling capabilities advance alongside experimental techniques, we anticipate significant breakthroughs in this field within the next five years, potentially revolutionizing how we design and utilize polymeric materials across industries.

Market Applications of Amorphous and Semi-Crystalline Polymers

The market for polymeric materials is significantly influenced by their glass transition properties, with amorphous and semi-crystalline polymers occupying distinct application spaces based on their thermal behavior. Amorphous polymers, characterized by their lack of crystalline regions, find extensive applications in optical components due to their transparency and uniform refractive properties. The eyewear industry heavily relies on amorphous polymers like polycarbonate and PMMA (acrylic) for prescription lenses and sunglasses, where clarity and impact resistance are paramount.

In the packaging sector, amorphous PET dominates the beverage bottle market, valued at approximately $44 billion globally. The material's clarity, barrier properties, and processability make it ideal for containing carbonated beverages and food products. Similarly, polystyrene's amorphous nature enables its use in food packaging where transparency is desired, though environmental concerns have begun to limit its application.

Semi-crystalline polymers command premium positions in engineering applications due to their superior mechanical properties and chemical resistance. Polyamides (nylons) represent a $26 billion market, with applications spanning automotive components, electronic housings, and industrial machinery parts. Their ability to maintain dimensional stability across temperature ranges makes them particularly valuable in under-hood automotive applications.

The medical device industry leverages both polymer types strategically. Amorphous polymers like PEEK and PSU are preferred for implantable devices requiring biocompatibility and transparency, while semi-crystalline polymers like UHMWPE dominate in orthopedic implants where wear resistance is critical. This sector's growth is projected at 8% annually through 2028.

Electronics manufacturing represents another significant market, with amorphous polymers used in display technologies and semi-crystalline polymers in circuit boards and connectors. The thermal management capabilities of semi-crystalline polymers make them essential in high-performance computing applications where heat dissipation is crucial.

The textile industry differentiates applications based on crystallinity as well. Semi-crystalline polyesters and polyamides dominate performance apparel and industrial textiles, while amorphous variants find use in specialized applications requiring specific optical or thermal properties.

Emerging applications include 3D printing materials, where understanding glass transition behavior is essential for process optimization. Amorphous polymers generally offer better dimensional accuracy in printing, while semi-crystalline materials provide superior mechanical properties in finished parts. This sector is experiencing rapid growth at approximately 20% annually, driven by both industrial and consumer applications.

In the packaging sector, amorphous PET dominates the beverage bottle market, valued at approximately $44 billion globally. The material's clarity, barrier properties, and processability make it ideal for containing carbonated beverages and food products. Similarly, polystyrene's amorphous nature enables its use in food packaging where transparency is desired, though environmental concerns have begun to limit its application.

Semi-crystalline polymers command premium positions in engineering applications due to their superior mechanical properties and chemical resistance. Polyamides (nylons) represent a $26 billion market, with applications spanning automotive components, electronic housings, and industrial machinery parts. Their ability to maintain dimensional stability across temperature ranges makes them particularly valuable in under-hood automotive applications.

The medical device industry leverages both polymer types strategically. Amorphous polymers like PEEK and PSU are preferred for implantable devices requiring biocompatibility and transparency, while semi-crystalline polymers like UHMWPE dominate in orthopedic implants where wear resistance is critical. This sector's growth is projected at 8% annually through 2028.

Electronics manufacturing represents another significant market, with amorphous polymers used in display technologies and semi-crystalline polymers in circuit boards and connectors. The thermal management capabilities of semi-crystalline polymers make them essential in high-performance computing applications where heat dissipation is crucial.

The textile industry differentiates applications based on crystallinity as well. Semi-crystalline polyesters and polyamides dominate performance apparel and industrial textiles, while amorphous variants find use in specialized applications requiring specific optical or thermal properties.

Emerging applications include 3D printing materials, where understanding glass transition behavior is essential for process optimization. Amorphous polymers generally offer better dimensional accuracy in printing, while semi-crystalline materials provide superior mechanical properties in finished parts. This sector is experiencing rapid growth at approximately 20% annually, driven by both industrial and consumer applications.

Current Understanding and Challenges in Dual Glass Transition Events

The current understanding of dual glass transition events in polymers has evolved significantly over the past decades, yet several challenges remain in fully interpreting these phenomena. Glass transition temperature (Tg) represents a critical parameter in polymer science, marking the reversible transition from a hard, glassy state to a soft, rubbery state. In amorphous polymers, this transition is typically observed as a single event. However, semi-crystalline polymers often exhibit dual or multiple glass transition events, complicating the traditional understanding of this phenomenon.

Research has established that these dual events in semi-crystalline polymers are associated with different molecular mobility regions within the polymer structure. The primary glass transition corresponds to the amorphous regions, while secondary transitions are attributed to the restricted mobility of chain segments at the crystal-amorphous interface or within partially ordered domains. Differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) have been instrumental in identifying these multiple transitions, revealing distinct relaxation processes occurring at different temperatures.

Recent advances in analytical techniques, particularly modulated temperature DSC and solid-state NMR spectroscopy, have enhanced our ability to characterize these transitions with greater precision. These methods have demonstrated that the rigid amorphous fraction (RAF) at the crystal-amorphous interface exhibits distinct thermal behavior from the mobile amorphous fraction (MAF), contributing to the observation of dual glass transitions.

Despite these advances, significant challenges persist in the comprehensive interpretation of dual glass transition events. One major difficulty lies in distinguishing between true thermodynamic transitions and kinetic phenomena that mimic glass transitions. The complex interplay between crystallization kinetics, thermal history, and molecular weight distribution further complicates the analysis of these transitions.

Another challenge involves the quantitative correlation between polymer microstructure and observed thermal transitions. While qualitative relationships have been established, precise mathematical models that predict dual glass transition behavior based on crystallinity, lamellar thickness, and interfacial properties remain elusive. This gap limits our ability to design polymers with tailored thermal properties for specific applications.

Furthermore, the influence of processing conditions on dual glass transition events presents a significant challenge. Different cooling rates, annealing protocols, and processing methods can dramatically alter the crystalline morphology and consequently the observed thermal transitions. This variability makes it difficult to establish standardized characterization protocols and complicates the comparison of results across different studies.

The molecular mechanisms underlying the restricted mobility in semi-crystalline regions also remain incompletely understood. While various models have been proposed, including the three-phase model and the continuous mobility gradient model, definitive experimental validation of these theoretical frameworks continues to be challenging due to limitations in spatial resolution of current analytical techniques.

Research has established that these dual events in semi-crystalline polymers are associated with different molecular mobility regions within the polymer structure. The primary glass transition corresponds to the amorphous regions, while secondary transitions are attributed to the restricted mobility of chain segments at the crystal-amorphous interface or within partially ordered domains. Differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) have been instrumental in identifying these multiple transitions, revealing distinct relaxation processes occurring at different temperatures.

Recent advances in analytical techniques, particularly modulated temperature DSC and solid-state NMR spectroscopy, have enhanced our ability to characterize these transitions with greater precision. These methods have demonstrated that the rigid amorphous fraction (RAF) at the crystal-amorphous interface exhibits distinct thermal behavior from the mobile amorphous fraction (MAF), contributing to the observation of dual glass transitions.

Despite these advances, significant challenges persist in the comprehensive interpretation of dual glass transition events. One major difficulty lies in distinguishing between true thermodynamic transitions and kinetic phenomena that mimic glass transitions. The complex interplay between crystallization kinetics, thermal history, and molecular weight distribution further complicates the analysis of these transitions.

Another challenge involves the quantitative correlation between polymer microstructure and observed thermal transitions. While qualitative relationships have been established, precise mathematical models that predict dual glass transition behavior based on crystallinity, lamellar thickness, and interfacial properties remain elusive. This gap limits our ability to design polymers with tailored thermal properties for specific applications.

Furthermore, the influence of processing conditions on dual glass transition events presents a significant challenge. Different cooling rates, annealing protocols, and processing methods can dramatically alter the crystalline morphology and consequently the observed thermal transitions. This variability makes it difficult to establish standardized characterization protocols and complicates the comparison of results across different studies.

The molecular mechanisms underlying the restricted mobility in semi-crystalline regions also remain incompletely understood. While various models have been proposed, including the three-phase model and the continuous mobility gradient model, definitive experimental validation of these theoretical frameworks continues to be challenging due to limitations in spatial resolution of current analytical techniques.

Established Methodologies for Glass Transition Characterization

01 Glass transition temperature in polymer processing

The glass transition temperature (Tg) is a critical parameter in polymer processing that affects the mechanical properties and behavior of polymers. During processing, amorphous and semi-crystalline polymers transition from a rigid, glassy state to a more flexible, rubbery state as they exceed their Tg. Understanding and controlling this transition is essential for various manufacturing techniques such as injection molding, extrusion, and thermoforming. The processing temperature relative to Tg determines flow characteristics, crystallization behavior, and ultimately the physical properties of the final product.- Glass transition temperature in polymer processing: The glass transition temperature (Tg) is a critical parameter in polymer processing that affects the physical properties of both amorphous and semi-crystalline polymers. During processing, polymers must be heated above their Tg to achieve sufficient molecular mobility for shaping. For semi-crystalline polymers, processing typically occurs above both the Tg and melting temperature to ensure complete melting of crystalline regions. Understanding and controlling the glass transition temperature is essential for optimizing processing conditions and achieving desired material properties in the final product.

- Relationship between polymer structure and glass transition: The molecular structure of polymers significantly influences their glass transition behavior. Amorphous polymers exhibit a single glass transition, while semi-crystalline polymers show both a glass transition (for the amorphous regions) and a melting point (for crystalline domains). Factors affecting Tg include molecular weight, chain flexibility, side groups, and intermolecular forces. Rigid polymer backbones, bulky side groups, and strong intermolecular interactions typically result in higher glass transition temperatures. Understanding these structure-property relationships enables the design of polymers with specific thermal behavior for targeted applications.

- Measurement and characterization of glass transition: Various analytical techniques are employed to measure and characterize the glass transition in polymers. Differential Scanning Calorimetry (DSC) is commonly used to detect the change in heat capacity associated with the glass transition. Dynamic Mechanical Analysis (DMA) measures changes in mechanical properties as polymers transition from glassy to rubbery states. Other methods include dilatometry, which tracks volume changes, and thermomechanical analysis. For semi-crystalline polymers, these techniques can distinguish between the glass transition of amorphous regions and the melting of crystalline domains, providing comprehensive thermal characterization.

- Modification of glass transition temperature: The glass transition temperature of polymers can be modified through various approaches to meet specific application requirements. Plasticizers are commonly added to lower Tg by increasing free volume and chain mobility. Conversely, crosslinking and the addition of fillers or reinforcements can increase Tg by restricting chain movement. Copolymerization allows for precise tuning of Tg by combining monomers with different thermal properties. For semi-crystalline polymers, controlling the degree of crystallinity also affects the glass transition behavior of the amorphous regions, providing another avenue for property modification.

- Applications leveraging glass transition properties: The glass transition behavior of polymers is exploited in numerous applications across various industries. Shape memory polymers utilize the dramatic property changes at Tg to enable controlled deformation and recovery. In drug delivery systems, the glass transition of polymer matrices controls drug release rates. For packaging materials, Tg determines barrier properties and mechanical performance under different temperature conditions. In 3D printing, understanding the glass transition is crucial for proper filament extrusion and layer adhesion. Semi-crystalline polymers with well-defined glass transitions and crystalline melting points are particularly valuable in applications requiring both toughness and dimensional stability.

02 Effect of additives on glass transition temperature

Various additives can significantly influence the glass transition temperature of polymers. Plasticizers typically lower the Tg by increasing free volume and chain mobility, while fillers and reinforcing agents may either increase or decrease Tg depending on their interaction with the polymer matrix. Nucleating agents can affect crystallization behavior in semi-crystalline polymers, indirectly impacting the glass transition region. Compatibilizers and coupling agents used in polymer blends and composites can alter interfacial properties and consequently modify the glass transition behavior of the overall system.Expand Specific Solutions03 Measurement and characterization of glass transition

Various analytical techniques are employed to measure and characterize the glass transition in amorphous and semi-crystalline polymers. Differential Scanning Calorimetry (DSC) is commonly used to detect the step change in heat capacity associated with glass transition. Dynamic Mechanical Analysis (DMA) measures changes in viscoelastic properties through the transition region. Dielectric analysis, thermomechanical analysis, and rheological measurements provide complementary information about molecular mobility and relaxation processes. These techniques help in understanding the breadth of the transition, which is often influenced by polymer structure, molecular weight distribution, and thermal history.Expand Specific Solutions04 Relationship between crystallinity and glass transition

In semi-crystalline polymers, a complex relationship exists between crystallinity and glass transition behavior. The amorphous regions undergo glass transition while crystalline domains remain ordered until reaching the melting temperature. Higher crystallinity typically constrains the mobility of amorphous chains, often resulting in a broader and less pronounced glass transition. The degree of crystallinity, crystal size, and morphology significantly influence the glass transition temperature and the breadth of the transition region. Annealing and thermal treatments can modify the crystalline structure and consequently alter the glass transition characteristics of semi-crystalline polymers.Expand Specific Solutions05 Applications leveraging glass transition properties

The glass transition phenomenon in polymers enables various technological applications across industries. Shape memory polymers utilize the dramatic property changes at Tg to achieve programmable shape changes. Drug delivery systems exploit the diffusion characteristics above and below Tg to control release rates. In biomedical applications, the glass transition temperature can be tailored to match body temperature for specific therapeutic functions. Electronic and optical devices leverage the changes in electrical, thermal, and optical properties through the glass transition region. Understanding and controlling glass transition behavior is also crucial in developing high-performance materials for aerospace, automotive, and packaging applications.Expand Specific Solutions

Leading Research Institutions and Industry Players in Polymer Science

The glass transition phenomenon in amorphous and semi-crystalline polymers represents a maturing research field with significant industrial applications. The market is experiencing steady growth, estimated at $8-10 billion annually, driven by demands in electronics, automotive, and medical sectors. Technologically, the field has reached moderate maturity with ongoing innovation in understanding dual transition events and their interpretation. Key players demonstrate varying specialization levels: Corning, SCHOTT AG, and 3M lead in fundamental glass transition research; Eastman Chemical and Solvay Specialty Polymers focus on polymer applications; while academic institutions like Vrije Universiteit Brussel and Dalian University of Technology contribute theoretical advancements. Companies like Toyota and L'Oréal represent end-users implementing these materials in commercial applications, creating a diverse ecosystem spanning research, manufacturing, and application domains.

Corning, Inc.

Technical Solution: Corning has developed advanced characterization techniques to study glass transition phenomena in both amorphous and semi-crystalline polymers. Their approach utilizes dynamic mechanical analysis (DMA) and modulated differential scanning calorimetry (MDSC) to distinguish between the rigid amorphous fraction (RAF) and mobile amorphous fraction (MAF) in semi-crystalline polymers[1]. Corning's technology enables precise measurement of the dual glass transition events that occur in semi-crystalline polymers - one associated with the MAF and another with the RAF. Their proprietary analysis software can deconvolute these overlapping transitions, providing quantitative data on the relative proportions and mobility constraints of different amorphous regions[3]. This technology has been particularly valuable in developing glass-polymer composites with tailored thermal and mechanical properties for applications in display technologies and optical components.

Strengths: Superior precision in characterizing complex glass transitions in multi-phase polymer systems; ability to correlate molecular mobility with macroscopic properties; extensive materials database enabling predictive modeling. Weaknesses: Requires sophisticated and expensive analytical equipment; analysis is time-consuming and requires significant expertise; models may not fully account for processing history effects on transition behavior.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered a comprehensive approach to understanding glass transition phenomena through their "Dual Network Theory" for polymer-glass interfaces. Their research focuses on the interplay between crystalline domains and amorphous regions in semi-crystalline polymers, particularly how these interactions affect the glass transition temperature (Tg) and mechanical properties[2]. SCHOTT's methodology combines temperature-modulated DSC with advanced solid-state NMR spectroscopy to map molecular mobility gradients extending from crystalline boundaries into amorphous domains. Their proprietary analysis identifies multiple relaxation processes occurring at different temperature ranges, corresponding to distinct amorphous fractions with varying degrees of mobility restriction[4]. This understanding has enabled SCHOTT to develop specialized polymer-glass composites with precisely engineered interfacial properties for applications in pharmaceutical packaging, electronic components, and optical systems where thermal stability and dimensional precision are critical.

Strengths: Exceptional capability to engineer interfaces between crystalline and amorphous domains; proprietary characterization techniques that reveal mobility gradients; successful commercial applications demonstrating practical value of their theoretical framework. Weaknesses: Models work best for specific polymer families and may require recalibration for novel materials; limited ability to predict behavior under extreme processing conditions or during aging.

Key Scientific Advances in Interpreting Dual Transition Phenomena

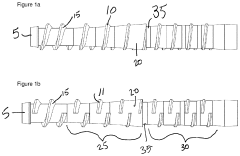

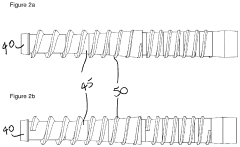

Improved Oil-Bearing Material Extraction Device And System

PatentPendingUS20240042718A1

Innovation

- A novel configuration of the barrel and screw for a commercial oil press with temperature-controlled zones allows for efficient oil extraction in a single pass at temperatures not exceeding 70°C, optimizing oil yield and reducing residual oil content in the press cake, suitable for commercial-scale processing.

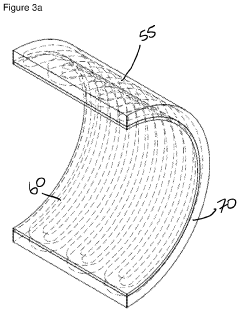

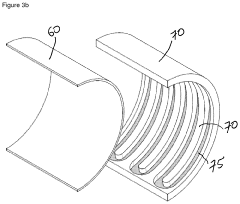

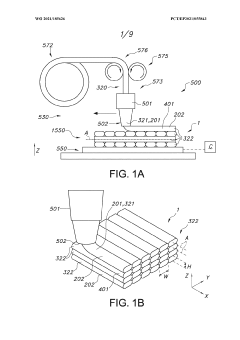

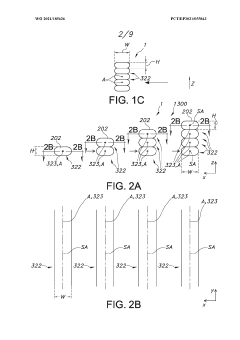

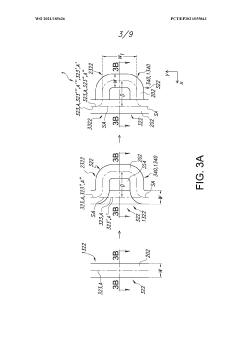

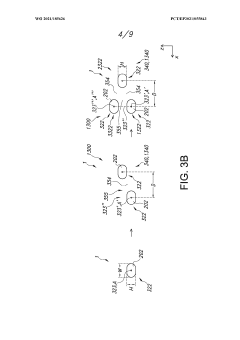

3D printed item with surface with a woven appearance

PatentWO2021185626A1

Innovation

- A method employing fused deposition modeling with continuous printer head movements and oscillations in the xy-plane to create layers with print path deviations, producing a woven or fabric-like appearance while maintaining structural stability and controlled light transmission.

Material Processing Implications of Glass Transition Behavior

Understanding the glass transition behavior in polymers is crucial for optimizing material processing techniques. The distinct differences between amorphous and semi-crystalline polymers significantly impact manufacturing parameters and end-product properties. For amorphous polymers, processing typically occurs above the glass transition temperature (Tg) where the material exhibits rubber-like behavior with sufficient chain mobility. This temperature window must be carefully controlled to prevent thermal degradation while ensuring adequate flow characteristics.

Semi-crystalline polymers present more complex processing considerations due to their dual-phase nature. The amorphous regions undergo glass transition while crystalline domains maintain structural integrity until reaching melting temperature. This creates a processing window between Tg and melting point where selective manipulation of the amorphous phase is possible without disrupting crystalline structures. Manufacturers leverage this phenomenon for processes like annealing and stress relaxation.

The rate of cooling during processing critically affects the final material properties. Rapid cooling from above Tg can freeze amorphous polymers in non-equilibrium states, resulting in physical aging over time. For semi-crystalline polymers, cooling rates determine the degree of crystallinity, with slower cooling generally promoting higher crystallization and consequently altering mechanical properties, transparency, and chemical resistance.

Dual glass transition events observed in some semi-crystalline polymers—attributed to rigid amorphous fractions (RAF) and mobile amorphous fractions (MAF)—necessitate specialized processing approaches. The RAF, constrained by proximity to crystalline regions, requires higher processing temperatures to mobilize, while the MAF behaves similarly to conventional amorphous phases. This distinction demands precise thermal management during manufacturing.

Processing techniques like injection molding, extrusion, and thermoforming must account for these glass transition behaviors. For instance, mold temperatures in injection molding are often set relative to the material's Tg to control crystallization kinetics and internal stress development. Similarly, in film extrusion, the temperature profile along the extruder barrel must accommodate the different mobility requirements of various polymer regions.

Advanced processing technologies increasingly incorporate real-time monitoring of glass transition behavior through techniques like dielectric analysis or ultrasonic measurements. These methods allow for adaptive processing parameters that respond to batch variations or environmental conditions, ensuring consistent product quality despite the complex thermal behavior of polymeric materials.

Semi-crystalline polymers present more complex processing considerations due to their dual-phase nature. The amorphous regions undergo glass transition while crystalline domains maintain structural integrity until reaching melting temperature. This creates a processing window between Tg and melting point where selective manipulation of the amorphous phase is possible without disrupting crystalline structures. Manufacturers leverage this phenomenon for processes like annealing and stress relaxation.

The rate of cooling during processing critically affects the final material properties. Rapid cooling from above Tg can freeze amorphous polymers in non-equilibrium states, resulting in physical aging over time. For semi-crystalline polymers, cooling rates determine the degree of crystallinity, with slower cooling generally promoting higher crystallization and consequently altering mechanical properties, transparency, and chemical resistance.

Dual glass transition events observed in some semi-crystalline polymers—attributed to rigid amorphous fractions (RAF) and mobile amorphous fractions (MAF)—necessitate specialized processing approaches. The RAF, constrained by proximity to crystalline regions, requires higher processing temperatures to mobilize, while the MAF behaves similarly to conventional amorphous phases. This distinction demands precise thermal management during manufacturing.

Processing techniques like injection molding, extrusion, and thermoforming must account for these glass transition behaviors. For instance, mold temperatures in injection molding are often set relative to the material's Tg to control crystallization kinetics and internal stress development. Similarly, in film extrusion, the temperature profile along the extruder barrel must accommodate the different mobility requirements of various polymer regions.

Advanced processing technologies increasingly incorporate real-time monitoring of glass transition behavior through techniques like dielectric analysis or ultrasonic measurements. These methods allow for adaptive processing parameters that respond to batch variations or environmental conditions, ensuring consistent product quality despite the complex thermal behavior of polymeric materials.

Structure-Property Relationships in Complex Polymer Systems

The intricate relationship between polymer structure and resulting properties forms the cornerstone of modern polymer science and engineering. In complex polymer systems, particularly when comparing amorphous and semi-crystalline polymers, these structure-property relationships become even more nuanced and critical to understand.

The glass transition phenomenon represents one of the most fundamental property manifestations directly linked to polymer structure. In amorphous polymers, the glass transition occurs as a single, relatively well-defined event where chain mobility increases significantly above the glass transition temperature (Tg). However, semi-crystalline polymers exhibit a more complex behavior characterized by dual glass transition events.

This duality stems from the coexistence of crystalline and amorphous regions within semi-crystalline polymers. The rigid crystalline domains act as physical crosslinks, restricting the mobility of adjacent amorphous chains. This creates what polymer scientists term the "rigid amorphous fraction" (RAF), which exhibits different thermal behavior than the "mobile amorphous fraction" (MAF) located further from crystalline interfaces.

The interpretation of these dual glass transitions provides valuable insights into polymer morphology. The lower-temperature transition corresponds to the MAF, while the higher-temperature event reflects the RAF requiring more thermal energy to achieve similar mobility. This structural heterogeneity directly influences mechanical properties, with the RAF contributing to enhanced stiffness while the MAF provides flexibility and impact resistance.

Processing conditions significantly affect these structure-property relationships. Cooling rates, annealing treatments, and processing temperatures can dramatically alter the crystalline/amorphous ratio and the nature of the interfaces between these regions. Consequently, the same polymer can exhibit vastly different mechanical, thermal, and optical properties depending on its processing history.

Advanced characterization techniques such as modulated differential scanning calorimetry (MDSC), dynamic mechanical analysis (DMA), and solid-state NMR have been instrumental in elucidating these complex structure-property relationships. These methods allow researchers to quantify the relative proportions of crystalline regions, RAF, and MAF, providing a more complete understanding of how molecular architecture translates to macroscopic properties.

The practical implications of these structure-property relationships extend across numerous applications. For instance, in packaging materials, controlling crystallinity can optimize barrier properties while maintaining processability. In biomedical applications, the dual nature of glass transitions in semi-crystalline polymers can be exploited to create materials with tailored degradation profiles and mechanical responses.

The glass transition phenomenon represents one of the most fundamental property manifestations directly linked to polymer structure. In amorphous polymers, the glass transition occurs as a single, relatively well-defined event where chain mobility increases significantly above the glass transition temperature (Tg). However, semi-crystalline polymers exhibit a more complex behavior characterized by dual glass transition events.

This duality stems from the coexistence of crystalline and amorphous regions within semi-crystalline polymers. The rigid crystalline domains act as physical crosslinks, restricting the mobility of adjacent amorphous chains. This creates what polymer scientists term the "rigid amorphous fraction" (RAF), which exhibits different thermal behavior than the "mobile amorphous fraction" (MAF) located further from crystalline interfaces.

The interpretation of these dual glass transitions provides valuable insights into polymer morphology. The lower-temperature transition corresponds to the MAF, while the higher-temperature event reflects the RAF requiring more thermal energy to achieve similar mobility. This structural heterogeneity directly influences mechanical properties, with the RAF contributing to enhanced stiffness while the MAF provides flexibility and impact resistance.

Processing conditions significantly affect these structure-property relationships. Cooling rates, annealing treatments, and processing temperatures can dramatically alter the crystalline/amorphous ratio and the nature of the interfaces between these regions. Consequently, the same polymer can exhibit vastly different mechanical, thermal, and optical properties depending on its processing history.

Advanced characterization techniques such as modulated differential scanning calorimetry (MDSC), dynamic mechanical analysis (DMA), and solid-state NMR have been instrumental in elucidating these complex structure-property relationships. These methods allow researchers to quantify the relative proportions of crystalline regions, RAF, and MAF, providing a more complete understanding of how molecular architecture translates to macroscopic properties.

The practical implications of these structure-property relationships extend across numerous applications. For instance, in packaging materials, controlling crystallinity can optimize barrier properties while maintaining processability. In biomedical applications, the dual nature of glass transitions in semi-crystalline polymers can be exploited to create materials with tailored degradation profiles and mechanical responses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!