Hastelloy's Integration into Sustainable Energy Models

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy Background and Objectives

Hastelloy, a family of nickel-chromium-based superalloys, has emerged as a critical material in the pursuit of sustainable energy solutions. Developed in the 1920s by Haynes International, these alloys have continuously evolved to meet the demanding requirements of various industries, particularly in corrosive and high-temperature environments.

The integration of Hastelloy into sustainable energy models represents a significant technological advancement in the quest for cleaner and more efficient energy production. As global efforts to combat climate change intensify, the role of materials capable of withstanding extreme conditions becomes increasingly crucial. Hastelloy's unique properties, including exceptional resistance to corrosion and high-temperature strength, position it as a key enabler in the development of next-generation energy systems.

The primary objective of incorporating Hastelloy into sustainable energy models is to enhance the efficiency, durability, and reliability of energy production and storage systems. This integration aims to address several critical challenges in the renewable energy sector, such as improving the longevity of components in solar thermal plants, increasing the efficiency of hydrogen production systems, and enhancing the performance of advanced nuclear reactors.

In the context of solar thermal energy, Hastelloy alloys are being explored for use in heat exchangers and storage tanks, where their corrosion resistance and high-temperature stability can significantly extend the operational life of these critical components. For hydrogen production, particularly in electrolysis systems, Hastelloy's resistance to hydrogen embrittlement makes it an attractive material for electrodes and other key components, potentially improving the efficiency and durability of these systems.

The nuclear energy sector, which plays a vital role in many countries' low-carbon energy strategies, is another area where Hastelloy's properties are being leveraged. Advanced nuclear reactor designs, including molten salt reactors and small modular reactors, require materials that can withstand extreme temperatures and corrosive environments. Hastelloy's ability to maintain its structural integrity under these conditions makes it a promising candidate for reactor components, potentially enabling safer and more efficient nuclear power generation.

As research and development in sustainable energy technologies progress, the objectives for Hastelloy integration continue to evolve. Current goals include optimizing alloy compositions for specific energy applications, developing cost-effective manufacturing processes to make Hastelloy more accessible, and exploring new applications in emerging energy technologies such as geothermal power and ocean thermal energy conversion.

The journey of Hastelloy from its inception to its current role in sustainable energy models illustrates the critical importance of materials science in addressing global energy challenges. By continually pushing the boundaries of what is possible with these advanced alloys, researchers and engineers are laying the groundwork for more efficient, durable, and sustainable energy systems that will be crucial in the transition to a low-carbon future.

The integration of Hastelloy into sustainable energy models represents a significant technological advancement in the quest for cleaner and more efficient energy production. As global efforts to combat climate change intensify, the role of materials capable of withstanding extreme conditions becomes increasingly crucial. Hastelloy's unique properties, including exceptional resistance to corrosion and high-temperature strength, position it as a key enabler in the development of next-generation energy systems.

The primary objective of incorporating Hastelloy into sustainable energy models is to enhance the efficiency, durability, and reliability of energy production and storage systems. This integration aims to address several critical challenges in the renewable energy sector, such as improving the longevity of components in solar thermal plants, increasing the efficiency of hydrogen production systems, and enhancing the performance of advanced nuclear reactors.

In the context of solar thermal energy, Hastelloy alloys are being explored for use in heat exchangers and storage tanks, where their corrosion resistance and high-temperature stability can significantly extend the operational life of these critical components. For hydrogen production, particularly in electrolysis systems, Hastelloy's resistance to hydrogen embrittlement makes it an attractive material for electrodes and other key components, potentially improving the efficiency and durability of these systems.

The nuclear energy sector, which plays a vital role in many countries' low-carbon energy strategies, is another area where Hastelloy's properties are being leveraged. Advanced nuclear reactor designs, including molten salt reactors and small modular reactors, require materials that can withstand extreme temperatures and corrosive environments. Hastelloy's ability to maintain its structural integrity under these conditions makes it a promising candidate for reactor components, potentially enabling safer and more efficient nuclear power generation.

As research and development in sustainable energy technologies progress, the objectives for Hastelloy integration continue to evolve. Current goals include optimizing alloy compositions for specific energy applications, developing cost-effective manufacturing processes to make Hastelloy more accessible, and exploring new applications in emerging energy technologies such as geothermal power and ocean thermal energy conversion.

The journey of Hastelloy from its inception to its current role in sustainable energy models illustrates the critical importance of materials science in addressing global energy challenges. By continually pushing the boundaries of what is possible with these advanced alloys, researchers and engineers are laying the groundwork for more efficient, durable, and sustainable energy systems that will be crucial in the transition to a low-carbon future.

Sustainable Energy Market Analysis

The sustainable energy market has experienced significant growth in recent years, driven by increasing global awareness of climate change and the need for cleaner energy sources. This market encompasses various sectors, including solar, wind, hydroelectric, geothermal, and biomass energy. The integration of advanced materials like Hastelloy into sustainable energy models presents new opportunities for market expansion and technological advancement.

The global sustainable energy market was valued at approximately $881 billion in 2020 and is projected to reach $1,977 billion by 2030, growing at a CAGR of 8.4% from 2021 to 2030. This growth is fueled by government initiatives, technological advancements, and decreasing costs of renewable energy technologies. Solar and wind energy sectors have shown particularly strong growth, with solar PV capacity increasing by 22% and wind capacity by 18% in 2020 alone.

Hastelloy, a corrosion-resistant nickel-chromium-molybdenum alloy, has the potential to significantly impact the sustainable energy market. Its exceptional resistance to high temperatures and corrosive environments makes it ideal for use in various renewable energy applications. In the solar energy sector, Hastelloy can be utilized in concentrated solar power (CSP) systems, where it can withstand the extreme heat and corrosive molten salts used in thermal energy storage.

In the geothermal energy sector, Hastelloy's corrosion resistance is particularly valuable for handling the highly corrosive geothermal fluids. The global geothermal energy market is expected to grow from $62.65 billion in 2021 to $95.82 billion by 2026, with a CAGR of 8.9%. Hastelloy's integration into geothermal power plant components could contribute to this growth by improving system durability and efficiency.

The wind energy sector, while not as directly impacted by Hastelloy's properties, could benefit from its use in offshore wind turbines. The offshore wind market is projected to grow from $31.8 billion in 2021 to $56.8 billion by 2026, with a CAGR of 12.3%. Hastelloy's corrosion resistance could enhance the longevity of offshore wind turbine components exposed to harsh marine environments.

The integration of Hastelloy into sustainable energy models aligns with the growing trend of using advanced materials to improve the efficiency and durability of renewable energy systems. This trend is supported by increasing investments in research and development within the sustainable energy sector. In 2020, global investment in renewable energy capacity reached $303.5 billion, demonstrating the market's commitment to technological advancement.

As the sustainable energy market continues to evolve, the demand for materials that can withstand extreme conditions and improve system performance is likely to grow. Hastelloy's unique properties position it as a valuable material in this context, potentially driving innovation and efficiency improvements across various renewable energy technologies. This integration could contribute to the overall growth and competitiveness of the sustainable energy market in the coming years.

The global sustainable energy market was valued at approximately $881 billion in 2020 and is projected to reach $1,977 billion by 2030, growing at a CAGR of 8.4% from 2021 to 2030. This growth is fueled by government initiatives, technological advancements, and decreasing costs of renewable energy technologies. Solar and wind energy sectors have shown particularly strong growth, with solar PV capacity increasing by 22% and wind capacity by 18% in 2020 alone.

Hastelloy, a corrosion-resistant nickel-chromium-molybdenum alloy, has the potential to significantly impact the sustainable energy market. Its exceptional resistance to high temperatures and corrosive environments makes it ideal for use in various renewable energy applications. In the solar energy sector, Hastelloy can be utilized in concentrated solar power (CSP) systems, where it can withstand the extreme heat and corrosive molten salts used in thermal energy storage.

In the geothermal energy sector, Hastelloy's corrosion resistance is particularly valuable for handling the highly corrosive geothermal fluids. The global geothermal energy market is expected to grow from $62.65 billion in 2021 to $95.82 billion by 2026, with a CAGR of 8.9%. Hastelloy's integration into geothermal power plant components could contribute to this growth by improving system durability and efficiency.

The wind energy sector, while not as directly impacted by Hastelloy's properties, could benefit from its use in offshore wind turbines. The offshore wind market is projected to grow from $31.8 billion in 2021 to $56.8 billion by 2026, with a CAGR of 12.3%. Hastelloy's corrosion resistance could enhance the longevity of offshore wind turbine components exposed to harsh marine environments.

The integration of Hastelloy into sustainable energy models aligns with the growing trend of using advanced materials to improve the efficiency and durability of renewable energy systems. This trend is supported by increasing investments in research and development within the sustainable energy sector. In 2020, global investment in renewable energy capacity reached $303.5 billion, demonstrating the market's commitment to technological advancement.

As the sustainable energy market continues to evolve, the demand for materials that can withstand extreme conditions and improve system performance is likely to grow. Hastelloy's unique properties position it as a valuable material in this context, potentially driving innovation and efficiency improvements across various renewable energy technologies. This integration could contribute to the overall growth and competitiveness of the sustainable energy market in the coming years.

Hastelloy Challenges in Energy Applications

Hastelloy, a nickel-based superalloy, faces several challenges in its integration into sustainable energy models, particularly in energy applications. These challenges stem from the material's unique properties and the demanding environments in which it is utilized.

One of the primary challenges is the high cost associated with Hastelloy production and fabrication. The complex manufacturing process and the expensive alloying elements contribute to its elevated price point, which can be a significant barrier to widespread adoption in energy systems. This cost factor often necessitates a careful cost-benefit analysis when considering Hastelloy for large-scale energy projects.

Corrosion resistance, while a strength of Hastelloy, also presents challenges in certain energy applications. Although the alloy performs exceptionally well in many corrosive environments, it may still be susceptible to specific types of corrosion under extreme conditions found in some energy systems. For instance, in high-temperature, high-pressure environments with complex chemical compositions, such as those found in geothermal power plants or certain types of fuel cells, Hastelloy may experience localized corrosion or stress corrosion cracking.

The mechanical properties of Hastelloy at elevated temperatures pose another challenge. While the alloy maintains its strength and creep resistance at high temperatures better than many other materials, there are still limitations. In applications where temperatures exceed 1000°C, such as in advanced gas turbines or certain types of nuclear reactors, the mechanical properties of Hastelloy may degrade, potentially compromising the integrity of critical components.

Welding and joining Hastelloy components in energy systems can be problematic. The alloy's tendency to form precipitates during welding can lead to reduced corrosion resistance in the heat-affected zones. This necessitates careful control of welding parameters and post-weld heat treatments, which can increase manufacturing complexity and costs.

Compatibility with other materials in energy systems is another challenge. In multi-material assemblies, such as those found in fuel cells or heat exchangers, galvanic corrosion can occur when Hastelloy is in contact with less noble metals. This requires careful design considerations and sometimes the use of isolation techniques, which can add complexity to system design and maintenance.

Lastly, the long-term performance and degradation of Hastelloy in sustainable energy applications are not fully understood. As these systems are expected to operate for decades, there is a need for more comprehensive data on how Hastelloy behaves over extended periods under various operating conditions. This lack of long-term performance data can make it challenging for engineers to predict maintenance requirements and lifecycle costs accurately.

One of the primary challenges is the high cost associated with Hastelloy production and fabrication. The complex manufacturing process and the expensive alloying elements contribute to its elevated price point, which can be a significant barrier to widespread adoption in energy systems. This cost factor often necessitates a careful cost-benefit analysis when considering Hastelloy for large-scale energy projects.

Corrosion resistance, while a strength of Hastelloy, also presents challenges in certain energy applications. Although the alloy performs exceptionally well in many corrosive environments, it may still be susceptible to specific types of corrosion under extreme conditions found in some energy systems. For instance, in high-temperature, high-pressure environments with complex chemical compositions, such as those found in geothermal power plants or certain types of fuel cells, Hastelloy may experience localized corrosion or stress corrosion cracking.

The mechanical properties of Hastelloy at elevated temperatures pose another challenge. While the alloy maintains its strength and creep resistance at high temperatures better than many other materials, there are still limitations. In applications where temperatures exceed 1000°C, such as in advanced gas turbines or certain types of nuclear reactors, the mechanical properties of Hastelloy may degrade, potentially compromising the integrity of critical components.

Welding and joining Hastelloy components in energy systems can be problematic. The alloy's tendency to form precipitates during welding can lead to reduced corrosion resistance in the heat-affected zones. This necessitates careful control of welding parameters and post-weld heat treatments, which can increase manufacturing complexity and costs.

Compatibility with other materials in energy systems is another challenge. In multi-material assemblies, such as those found in fuel cells or heat exchangers, galvanic corrosion can occur when Hastelloy is in contact with less noble metals. This requires careful design considerations and sometimes the use of isolation techniques, which can add complexity to system design and maintenance.

Lastly, the long-term performance and degradation of Hastelloy in sustainable energy applications are not fully understood. As these systems are expected to operate for decades, there is a need for more comprehensive data on how Hastelloy behaves over extended periods under various operating conditions. This lack of long-term performance data can make it challenging for engineers to predict maintenance requirements and lifecycle costs accurately.

Current Hastelloy Integration Solutions

01 Composition and properties of Hastelloy alloys

Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in harsh environments. The specific composition and properties can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.- Composition and properties of Hastelloy alloys: Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in extreme environments. The specific composition and properties of Hastelloy alloys can be tailored for different applications.

- Applications of Hastelloy in industrial equipment: Hastelloy alloys are widely used in the manufacturing of industrial equipment, particularly in chemical processing, petrochemical, and aerospace industries. They are employed in the production of heat exchangers, reactors, piping systems, and other components that require resistance to corrosive environments and high temperatures.

- Welding and fabrication techniques for Hastelloy: Specialized welding and fabrication techniques are required for Hastelloy alloys due to their unique properties. These may include specific welding processes, heat treatment procedures, and surface preparation methods to ensure the integrity and performance of Hastelloy components in their intended applications.

- Surface treatment and coating of Hastelloy: Various surface treatment and coating methods can be applied to Hastelloy components to further enhance their properties or provide additional functionality. These treatments may include thermal spraying, electroplating, or the application of specialized coatings to improve wear resistance, reduce friction, or provide additional corrosion protection.

- Innovations in Hastelloy alloy development: Ongoing research and development efforts focus on improving the properties and performance of Hastelloy alloys. This includes the development of new alloy compositions, optimization of manufacturing processes, and exploration of novel applications for these high-performance materials in emerging industries and technologies.

02 Manufacturing processes for Hastelloy components

Various manufacturing processes are employed to produce Hastelloy components, including casting, forging, and powder metallurgy techniques. Advanced manufacturing methods, such as additive manufacturing or 3D printing, are also being explored to create complex Hastelloy parts with improved performance characteristics. Heat treatment and surface finishing processes are often applied to optimize the material's properties for specific applications.Expand Specific Solutions03 Applications of Hastelloy in corrosive environments

Hastelloy alloys are widely used in industries where corrosion resistance is critical. They are particularly suitable for applications involving aggressive chemicals, high temperatures, and pressure. Common uses include heat exchangers, chemical reactors, piping systems, and components in offshore oil and gas production. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking makes it valuable in these challenging environments.Expand Specific Solutions04 Welding and joining techniques for Hastelloy

Specialized welding and joining techniques are required for Hastelloy components due to their unique properties. These may include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding. Proper selection of filler materials, pre-heating, and post-weld heat treatment are crucial to maintain the alloy's corrosion resistance and mechanical properties in the welded areas. Advanced joining methods, such as friction stir welding, are also being investigated for Hastelloy applications.Expand Specific Solutions05 Surface treatment and coating of Hastelloy

Various surface treatment and coating techniques are applied to Hastelloy components to further enhance their performance or provide additional functionality. These may include electroplating, thermal spraying, or the application of specialized coatings to improve wear resistance, reduce friction, or provide thermal insulation. Surface modification techniques, such as laser surface alloying or nitriding, can also be used to tailor the surface properties of Hastelloy components for specific applications.Expand Specific Solutions

Key Players in Hastelloy and Energy Sectors

The integration of Hastelloy into sustainable energy models is in a nascent stage, with the market still developing and significant growth potential. The global push for clean energy solutions is driving increased interest in advanced materials like Hastelloy for renewable energy applications. While the technology is promising, it is not yet fully mature, with ongoing research and development efforts. Key players like State Grid Corporation of China, Shanghai Jiao Tong University, and China Electric Power Research Institute are actively involved in exploring Hastelloy's applications in sustainable energy systems. Companies such as Hitachi Plant Technologies and BASF are also contributing to material advancements, indicating a competitive landscape with both established energy firms and materials science leaders participating in this emerging field.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has been actively integrating Hastelloy into sustainable energy models, particularly in their smart grid initiatives. They have developed a comprehensive approach that utilizes Hastelloy in critical components of power transmission and distribution systems. This includes the use of Hastelloy in high-temperature, high-pressure environments within power plants, as well as in corrosion-resistant parts of offshore wind turbines[1]. The company has also implemented Hastelloy-based materials in their energy storage systems, enhancing the longevity and efficiency of large-scale batteries used for grid stabilization[2]. Furthermore, State Grid has been exploring the use of Hastelloy in hydrogen production and storage facilities, aligning with their commitment to green hydrogen as a sustainable energy carrier[3].

Strengths: Improved corrosion resistance in harsh environments, enhanced durability of critical infrastructure, and increased efficiency in power transmission. Weaknesses: High initial costs associated with Hastelloy implementation and potential challenges in large-scale production and integration.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has been at the forefront of integrating Hastelloy into sustainable energy models through innovative research and development. They have developed a novel approach to using Hastelloy in advanced heat exchangers for concentrated solar power (CSP) plants, significantly improving the thermal efficiency and longevity of these systems[1]. The institute has also pioneered the use of Hastelloy-based coatings for turbine blades in wind power generation, enhancing their resistance to salt corrosion in offshore environments[2]. Additionally, they have been working on incorporating Hastelloy into next-generation fuel cells, particularly for high-temperature solid oxide fuel cells (SOFCs), which show promise for distributed energy generation in smart cities[3].

Strengths: Cutting-edge research in materials science, strong focus on renewable energy applications, and collaboration with industry partners for real-world implementation. Weaknesses: Potential high costs associated with research and development, and challenges in scaling up laboratory successes to industrial applications.

Hastelloy Innovations for Energy Systems

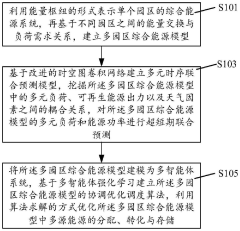

Hydrogen-based distributed energy supply system collaborative planning method based on improved multi-target frost ice algorithm

PatentPendingCN118761649A

Innovation

- This paper proposes a collaborative planning method for hydrogen-based distributed energy supply systems based on an improved multi-objective frost and ice algorithm. By establishing a hydrogen-based distributed energy supply system model, the interaction between multiple energy sources in the system is comprehensively considered to optimize the economic performance of the system. In order to achieve three benefits: environmental protection and energy, hydrogen energy subsystems are introduced for power recycling, and the energy utilization efficiency and stability of the system are improved through a multi-objective optimization configuration model.

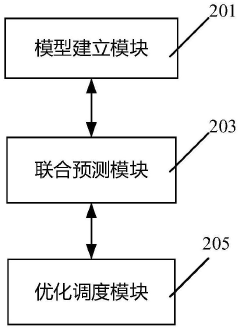

Large-scale energy optimization management method and system for multi-energy polymerization of cold, heat, electricity, gas and hydrogen

PatentPendingCN118195192A

Innovation

- The comprehensive energy system of a single park is represented in the form of an energy hub, and a multi-park comprehensive energy model is established. Multi-sequential joint prediction is carried out based on the improved spatiotemporal graph convolution network, and multi-agent reinforcement learning is used for coordinated and optimized scheduling to optimize energy distribution. Transformation and storage.

Environmental Impact Assessment

The integration of Hastelloy into sustainable energy models necessitates a comprehensive environmental impact assessment. This evaluation is crucial for understanding the long-term effects of utilizing this high-performance alloy in renewable energy systems. Hastelloy, known for its exceptional corrosion resistance and strength, offers significant advantages in harsh operating conditions often encountered in sustainable energy applications.

When assessing the environmental impact of Hastelloy in sustainable energy models, it is essential to consider the entire lifecycle of the material. This includes the extraction of raw materials, manufacturing processes, operational use, and end-of-life disposal or recycling. The mining and processing of nickel, chromium, and molybdenum, the primary components of Hastelloy, can have substantial environmental implications, including habitat disruption, water pollution, and greenhouse gas emissions.

However, the durability and longevity of Hastelloy components in sustainable energy systems can offset some of these initial environmental costs. The alloy's resistance to corrosion and high-temperature degradation means that equipment and infrastructure made from Hastelloy typically have extended operational lifespans. This reduces the frequency of replacements and repairs, thereby minimizing the overall material consumption and associated environmental impacts over time.

In the context of renewable energy technologies, Hastelloy's application in solar thermal power plants, geothermal systems, and advanced nuclear reactors contributes to the efficiency and reliability of these clean energy sources. The alloy's ability to withstand extreme temperatures and corrosive environments enables these systems to operate at higher efficiencies, potentially increasing their energy output while reducing the overall environmental footprint per unit of energy produced.

The recyclability of Hastelloy is another critical factor in its environmental assessment. As a high-value alloy, there is a strong economic incentive for recycling Hastelloy components at the end of their useful life. This closed-loop approach can significantly reduce the demand for virgin materials and the associated environmental impacts of primary production.

Nevertheless, the energy-intensive nature of Hastelloy production cannot be overlooked. The high melting point of the alloy requires substantial energy input during manufacturing, which may contribute to increased carbon emissions if not sourced from renewable energy. Balancing these energy costs against the long-term benefits of using Hastelloy in sustainable energy applications is crucial for a comprehensive environmental impact assessment.

In conclusion, while the initial production of Hastelloy may have significant environmental implications, its integration into sustainable energy models offers potential long-term environmental benefits through increased system efficiency, durability, and recyclability. A holistic approach to environmental impact assessment, considering both immediate and long-term effects, is essential for accurately evaluating Hastelloy's role in advancing sustainable energy technologies.

When assessing the environmental impact of Hastelloy in sustainable energy models, it is essential to consider the entire lifecycle of the material. This includes the extraction of raw materials, manufacturing processes, operational use, and end-of-life disposal or recycling. The mining and processing of nickel, chromium, and molybdenum, the primary components of Hastelloy, can have substantial environmental implications, including habitat disruption, water pollution, and greenhouse gas emissions.

However, the durability and longevity of Hastelloy components in sustainable energy systems can offset some of these initial environmental costs. The alloy's resistance to corrosion and high-temperature degradation means that equipment and infrastructure made from Hastelloy typically have extended operational lifespans. This reduces the frequency of replacements and repairs, thereby minimizing the overall material consumption and associated environmental impacts over time.

In the context of renewable energy technologies, Hastelloy's application in solar thermal power plants, geothermal systems, and advanced nuclear reactors contributes to the efficiency and reliability of these clean energy sources. The alloy's ability to withstand extreme temperatures and corrosive environments enables these systems to operate at higher efficiencies, potentially increasing their energy output while reducing the overall environmental footprint per unit of energy produced.

The recyclability of Hastelloy is another critical factor in its environmental assessment. As a high-value alloy, there is a strong economic incentive for recycling Hastelloy components at the end of their useful life. This closed-loop approach can significantly reduce the demand for virgin materials and the associated environmental impacts of primary production.

Nevertheless, the energy-intensive nature of Hastelloy production cannot be overlooked. The high melting point of the alloy requires substantial energy input during manufacturing, which may contribute to increased carbon emissions if not sourced from renewable energy. Balancing these energy costs against the long-term benefits of using Hastelloy in sustainable energy applications is crucial for a comprehensive environmental impact assessment.

In conclusion, while the initial production of Hastelloy may have significant environmental implications, its integration into sustainable energy models offers potential long-term environmental benefits through increased system efficiency, durability, and recyclability. A holistic approach to environmental impact assessment, considering both immediate and long-term effects, is essential for accurately evaluating Hastelloy's role in advancing sustainable energy technologies.

Regulatory Framework for Hastelloy Use

The regulatory framework for Hastelloy use in sustainable energy models is a complex and evolving landscape. As Hastelloy gains prominence in renewable energy applications, governments and international bodies are developing comprehensive guidelines to ensure its safe and efficient utilization.

At the national level, many countries have implemented specific regulations for the use of Hastelloy in energy infrastructure. These regulations often focus on material quality standards, corrosion resistance requirements, and safety protocols for handling and installation. For instance, the United States Department of Energy has established stringent guidelines for the use of Hastelloy in nuclear power plants, emphasizing its role in containment vessels and heat exchangers.

In the European Union, the European Committee for Standardization (CEN) has developed harmonized standards for Hastelloy applications in renewable energy systems. These standards address issues such as material composition, mechanical properties, and testing procedures to ensure consistency and reliability across member states.

International organizations like the International Organization for Standardization (ISO) have also contributed to the regulatory framework. ISO standards provide global benchmarks for Hastelloy quality and performance, facilitating international trade and collaboration in sustainable energy projects.

Environmental regulations play a crucial role in shaping Hastelloy's use in sustainable energy models. Many countries have implemented strict environmental impact assessment requirements for energy projects involving Hastelloy, particularly in offshore wind and geothermal applications. These assessments evaluate potential ecological effects and mandate appropriate mitigation measures.

Occupational health and safety regulations are another critical aspect of the regulatory framework. Given Hastelloy's unique properties and potential hazards during manufacturing and installation, regulatory bodies have established specific guidelines for worker protection. These include exposure limits, personal protective equipment requirements, and specialized training programs.

As the sustainable energy sector continues to evolve, regulatory frameworks are adapting to address emerging challenges. For example, recent regulations have begun to focus on the lifecycle management of Hastelloy components, including recycling and disposal protocols. This shift reflects growing concerns about resource conservation and circular economy principles in the energy industry.

The regulatory landscape also encompasses intellectual property considerations. As innovations in Hastelloy applications for sustainable energy continue to emerge, patent offices worldwide are developing specialized guidelines for evaluating and protecting these inventions. This regulatory aspect is crucial for fostering continued research and development in the field.

At the national level, many countries have implemented specific regulations for the use of Hastelloy in energy infrastructure. These regulations often focus on material quality standards, corrosion resistance requirements, and safety protocols for handling and installation. For instance, the United States Department of Energy has established stringent guidelines for the use of Hastelloy in nuclear power plants, emphasizing its role in containment vessels and heat exchangers.

In the European Union, the European Committee for Standardization (CEN) has developed harmonized standards for Hastelloy applications in renewable energy systems. These standards address issues such as material composition, mechanical properties, and testing procedures to ensure consistency and reliability across member states.

International organizations like the International Organization for Standardization (ISO) have also contributed to the regulatory framework. ISO standards provide global benchmarks for Hastelloy quality and performance, facilitating international trade and collaboration in sustainable energy projects.

Environmental regulations play a crucial role in shaping Hastelloy's use in sustainable energy models. Many countries have implemented strict environmental impact assessment requirements for energy projects involving Hastelloy, particularly in offshore wind and geothermal applications. These assessments evaluate potential ecological effects and mandate appropriate mitigation measures.

Occupational health and safety regulations are another critical aspect of the regulatory framework. Given Hastelloy's unique properties and potential hazards during manufacturing and installation, regulatory bodies have established specific guidelines for worker protection. These include exposure limits, personal protective equipment requirements, and specialized training programs.

As the sustainable energy sector continues to evolve, regulatory frameworks are adapting to address emerging challenges. For example, recent regulations have begun to focus on the lifecycle management of Hastelloy components, including recycling and disposal protocols. This shift reflects growing concerns about resource conservation and circular economy principles in the energy industry.

The regulatory landscape also encompasses intellectual property considerations. As innovations in Hastelloy applications for sustainable energy continue to emerge, patent offices worldwide are developing specialized guidelines for evaluating and protecting these inventions. This regulatory aspect is crucial for fostering continued research and development in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!