How Antibacterial Coatings Support Cleanroom Environments

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Evolution and Objectives

Antibacterial coatings have evolved significantly over the past several decades, transforming from simple chemical applications to sophisticated engineered surfaces with targeted antimicrobial properties. The earliest iterations emerged in the 1950s with basic silver-based compounds, primarily used in medical settings. By the 1970s, these technologies expanded into industrial applications, including early cleanroom environments for electronics manufacturing.

The 1990s marked a pivotal shift with the introduction of nanotechnology-based antibacterial coatings, which dramatically improved efficacy while reducing material usage. This period saw the development of photocatalytic titanium dioxide coatings that could actively destroy bacterial cells when exposed to light. The early 2000s brought further innovation with the emergence of quaternary ammonium compounds and copper-based solutions that offered longer-lasting protection.

Recent technological breakthroughs have focused on smart coatings that respond to environmental triggers, releasing antimicrobial agents only when bacterial contamination is detected. These developments align with the growing demand for cleanroom environments across pharmaceutical manufacturing, semiconductor production, and advanced research facilities where even microscopic contamination can compromise product integrity.

The primary objective of modern antibacterial coating technology in cleanroom environments is to maintain continuous surface sterility without human intervention. This includes preventing biofilm formation, which can harbor resistant bacterial colonies and compromise cleanroom integrity. Secondary objectives include reducing the need for aggressive chemical cleaning protocols, extending the maintenance intervals for critical surfaces, and minimizing particle generation from cleaning activities.

Current research aims to develop coatings that can maintain efficacy for extended periods, often targeting operational lifespans of 3-5 years without reapplication. Another key objective is creating formulations that can withstand the rigorous cleaning protocols typical in cleanroom environments without degrading or losing antimicrobial properties.

The technology roadmap for antibacterial coatings in cleanrooms is increasingly focused on sustainability, with efforts to eliminate toxic compounds like heavy metals and persistent organic pollutants. This shift reflects both regulatory pressure and corporate environmental commitments. Simultaneously, researchers are exploring biomimetic approaches that replicate natural antibacterial mechanisms found in certain plant surfaces and animal tissues.

Future objectives include the development of transparent coatings compatible with optical equipment, conductive formulations for electronics manufacturing environments, and solutions that can be applied to complex geometries including HVAC components and filtration systems that are critical to cleanroom operation.

The 1990s marked a pivotal shift with the introduction of nanotechnology-based antibacterial coatings, which dramatically improved efficacy while reducing material usage. This period saw the development of photocatalytic titanium dioxide coatings that could actively destroy bacterial cells when exposed to light. The early 2000s brought further innovation with the emergence of quaternary ammonium compounds and copper-based solutions that offered longer-lasting protection.

Recent technological breakthroughs have focused on smart coatings that respond to environmental triggers, releasing antimicrobial agents only when bacterial contamination is detected. These developments align with the growing demand for cleanroom environments across pharmaceutical manufacturing, semiconductor production, and advanced research facilities where even microscopic contamination can compromise product integrity.

The primary objective of modern antibacterial coating technology in cleanroom environments is to maintain continuous surface sterility without human intervention. This includes preventing biofilm formation, which can harbor resistant bacterial colonies and compromise cleanroom integrity. Secondary objectives include reducing the need for aggressive chemical cleaning protocols, extending the maintenance intervals for critical surfaces, and minimizing particle generation from cleaning activities.

Current research aims to develop coatings that can maintain efficacy for extended periods, often targeting operational lifespans of 3-5 years without reapplication. Another key objective is creating formulations that can withstand the rigorous cleaning protocols typical in cleanroom environments without degrading or losing antimicrobial properties.

The technology roadmap for antibacterial coatings in cleanrooms is increasingly focused on sustainability, with efforts to eliminate toxic compounds like heavy metals and persistent organic pollutants. This shift reflects both regulatory pressure and corporate environmental commitments. Simultaneously, researchers are exploring biomimetic approaches that replicate natural antibacterial mechanisms found in certain plant surfaces and animal tissues.

Future objectives include the development of transparent coatings compatible with optical equipment, conductive formulations for electronics manufacturing environments, and solutions that can be applied to complex geometries including HVAC components and filtration systems that are critical to cleanroom operation.

Cleanroom Industry Demand Analysis

The cleanroom industry has experienced significant growth over the past decade, driven primarily by expanding applications in semiconductor manufacturing, pharmaceutical production, and medical device assembly. The global cleanroom market was valued at $4.0 billion in 2022 and is projected to reach $5.9 billion by 2027, representing a compound annual growth rate of 8.1%. This growth trajectory underscores the increasing demand for contamination-free environments across multiple sectors.

Within the cleanroom ecosystem, antibacterial coatings have emerged as a critical component, with their own market segment growing at approximately 10.3% annually. This accelerated growth reflects the heightened awareness of microbial contamination risks and the subsequent need for more effective preventive measures in controlled environments.

The pharmaceutical and biotechnology sectors currently represent the largest market share for cleanroom technologies at 38%, followed by semiconductor manufacturing at 27%. These industries maintain stringent cleanliness requirements, with many facilities operating at ISO Class 5 (Class 100) or cleaner. The COVID-19 pandemic has further intensified demand, particularly in vaccine production facilities and medical research laboratories.

Regional analysis reveals that North America and Europe collectively account for 58% of the global cleanroom market, though Asia-Pacific is demonstrating the fastest growth rate at 11.2% annually. This regional expansion is largely attributed to the rapid industrialization in countries like China, India, and Singapore, particularly in electronics manufacturing and pharmaceutical production.

Market research indicates that 73% of cleanroom facility managers consider microbial contamination control as their top priority, with 67% specifically citing surface contamination as a critical concern. This has directly translated to increased investment in advanced surface technologies, including antibacterial coatings.

The demand for antibacterial coatings in cleanroom environments is further driven by regulatory pressures, with agencies like the FDA and EMA implementing increasingly stringent cleanliness standards. Compliance requirements have evolved to emphasize continuous contamination control rather than periodic cleaning protocols, creating sustained demand for persistent antibacterial solutions.

Industry surveys reveal that facilities implementing comprehensive antibacterial coating systems report a 42% reduction in contamination incidents and a 28% decrease in cleaning frequency requirements. These operational benefits translate to significant cost savings, with an average return on investment period of 14 months for facilities that have adopted advanced coating technologies.

Within the cleanroom ecosystem, antibacterial coatings have emerged as a critical component, with their own market segment growing at approximately 10.3% annually. This accelerated growth reflects the heightened awareness of microbial contamination risks and the subsequent need for more effective preventive measures in controlled environments.

The pharmaceutical and biotechnology sectors currently represent the largest market share for cleanroom technologies at 38%, followed by semiconductor manufacturing at 27%. These industries maintain stringent cleanliness requirements, with many facilities operating at ISO Class 5 (Class 100) or cleaner. The COVID-19 pandemic has further intensified demand, particularly in vaccine production facilities and medical research laboratories.

Regional analysis reveals that North America and Europe collectively account for 58% of the global cleanroom market, though Asia-Pacific is demonstrating the fastest growth rate at 11.2% annually. This regional expansion is largely attributed to the rapid industrialization in countries like China, India, and Singapore, particularly in electronics manufacturing and pharmaceutical production.

Market research indicates that 73% of cleanroom facility managers consider microbial contamination control as their top priority, with 67% specifically citing surface contamination as a critical concern. This has directly translated to increased investment in advanced surface technologies, including antibacterial coatings.

The demand for antibacterial coatings in cleanroom environments is further driven by regulatory pressures, with agencies like the FDA and EMA implementing increasingly stringent cleanliness standards. Compliance requirements have evolved to emphasize continuous contamination control rather than periodic cleaning protocols, creating sustained demand for persistent antibacterial solutions.

Industry surveys reveal that facilities implementing comprehensive antibacterial coating systems report a 42% reduction in contamination incidents and a 28% decrease in cleaning frequency requirements. These operational benefits translate to significant cost savings, with an average return on investment period of 14 months for facilities that have adopted advanced coating technologies.

Current Antibacterial Coating Technologies and Limitations

Antibacterial coatings in cleanroom environments have evolved significantly over the past decade, with several distinct technologies currently dominating the market. Silver-based coatings remain the most widely implemented solution, utilizing silver ions' natural antimicrobial properties to disrupt bacterial cell membranes and inhibit DNA replication. These coatings typically incorporate silver nanoparticles or compounds into polymeric matrices, providing sustained release mechanisms that can maintain effectiveness for up to two years in optimal conditions.

Copper and copper alloy surfaces represent another established technology, offering broad-spectrum antimicrobial activity against bacteria, viruses, and fungi. Research indicates that copper ions can eliminate up to 99.9% of surface bacteria within two hours of exposure, making them particularly valuable in high-touch areas within cleanrooms. However, their application remains somewhat limited due to higher costs and potential compatibility issues with certain cleanroom processes.

Quaternary ammonium compound (QAC) coatings function through positively charged molecules that disrupt microbial cell membranes. These coatings can be applied to various surfaces and provide immediate antimicrobial action upon contact. Their relatively low cost and ease of application have made them popular in less critical cleanroom environments, though their effectiveness diminishes significantly over time, requiring frequent reapplication.

Photocatalytic coatings, typically based on titanium dioxide (TiO₂), represent a more advanced solution that activates under UV light exposure to generate reactive oxygen species that destroy microorganisms. These coatings offer the advantage of self-cleaning properties but face significant limitations in indoor environments with insufficient UV light exposure, limiting their practical application in many cleanroom settings.

Despite these technological advances, current antibacterial coating solutions face several critical limitations. Durability remains a primary concern, with most coatings demonstrating reduced efficacy after repeated cleaning cycles or exposure to harsh disinfectants commonly used in cleanroom environments. Studies indicate that many coatings lose 30-50% of their antimicrobial efficacy within six months of application under standard cleanroom maintenance protocols.

Compatibility issues also present significant challenges, as certain coatings may interfere with sensitive manufacturing processes or introduce unwanted particulates. This is particularly problematic in pharmaceutical and microelectronics cleanrooms where even minimal contamination can compromise product integrity. Additionally, the development of antimicrobial resistance poses a growing concern, with evidence suggesting that sub-lethal exposure to certain antimicrobial agents may accelerate bacterial adaptation and resistance.

Regulatory hurdles further complicate implementation, with varying standards across different regions and industries creating compliance challenges for global manufacturers. The lack of standardized testing protocols for evaluating long-term antimicrobial efficacy in cleanroom conditions specifically has also hindered meaningful comparison between different coating technologies.

Copper and copper alloy surfaces represent another established technology, offering broad-spectrum antimicrobial activity against bacteria, viruses, and fungi. Research indicates that copper ions can eliminate up to 99.9% of surface bacteria within two hours of exposure, making them particularly valuable in high-touch areas within cleanrooms. However, their application remains somewhat limited due to higher costs and potential compatibility issues with certain cleanroom processes.

Quaternary ammonium compound (QAC) coatings function through positively charged molecules that disrupt microbial cell membranes. These coatings can be applied to various surfaces and provide immediate antimicrobial action upon contact. Their relatively low cost and ease of application have made them popular in less critical cleanroom environments, though their effectiveness diminishes significantly over time, requiring frequent reapplication.

Photocatalytic coatings, typically based on titanium dioxide (TiO₂), represent a more advanced solution that activates under UV light exposure to generate reactive oxygen species that destroy microorganisms. These coatings offer the advantage of self-cleaning properties but face significant limitations in indoor environments with insufficient UV light exposure, limiting their practical application in many cleanroom settings.

Despite these technological advances, current antibacterial coating solutions face several critical limitations. Durability remains a primary concern, with most coatings demonstrating reduced efficacy after repeated cleaning cycles or exposure to harsh disinfectants commonly used in cleanroom environments. Studies indicate that many coatings lose 30-50% of their antimicrobial efficacy within six months of application under standard cleanroom maintenance protocols.

Compatibility issues also present significant challenges, as certain coatings may interfere with sensitive manufacturing processes or introduce unwanted particulates. This is particularly problematic in pharmaceutical and microelectronics cleanrooms where even minimal contamination can compromise product integrity. Additionally, the development of antimicrobial resistance poses a growing concern, with evidence suggesting that sub-lethal exposure to certain antimicrobial agents may accelerate bacterial adaptation and resistance.

Regulatory hurdles further complicate implementation, with varying standards across different regions and industries creating compliance challenges for global manufacturers. The lack of standardized testing protocols for evaluating long-term antimicrobial efficacy in cleanroom conditions specifically has also hindered meaningful comparison between different coating technologies.

Prevalent Antibacterial Coating Solutions for Cleanrooms

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize silver, copper, zinc, and other metals or their compounds to provide antimicrobial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes. Such coatings can be applied to various surfaces including medical devices, textiles, and industrial equipment to prevent bacterial colonization and biofilm formation. The effectiveness of these coatings depends on the controlled release of metal ions over time.- Metal-based antibacterial coatings: Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into coatings as nanoparticles, ions, or compounds that slowly release active metal ions to inhibit bacterial growth on surfaces. The mechanism typically involves disruption of bacterial cell membranes, interference with enzyme functions, or generation of reactive oxygen species. These coatings are particularly effective for medical devices, food processing equipment, and high-touch surfaces in healthcare settings.

- Polymer-based antimicrobial coatings: Polymer-based antimicrobial coatings incorporate antibacterial agents within polymer matrices that can be applied to various surfaces. These polymers can be designed to slowly release antimicrobial compounds or have inherent antibacterial properties through positively charged functional groups that disrupt bacterial cell membranes. Some formulations include quaternary ammonium compounds, chitosan derivatives, or other biocidal polymers. These coatings provide durable protection and can be engineered for specific release profiles and surface compatibility.

- Natural compound-based antibacterial coatings: Natural compound-based antibacterial coatings utilize plant extracts, essential oils, enzymes, and other naturally derived substances with antimicrobial properties. These environmentally friendly alternatives often contain compounds like polyphenols, terpenes, and flavonoids that can inhibit bacterial growth through various mechanisms. The coatings can be formulated to provide sustained release of the active compounds while maintaining their efficacy. Applications include food packaging, medical textiles, and consumer products where reduced chemical exposure is desired.

- Photocatalytic antibacterial coatings: Photocatalytic antibacterial coatings contain materials such as titanium dioxide or zinc oxide that generate reactive oxygen species when exposed to light. These reactive species can effectively kill bacteria by oxidizing their cell components. The coatings provide continuous antibacterial action as long as they are exposed to appropriate light wavelengths. Some advanced formulations are engineered to work under visible light rather than requiring UV exposure, expanding their practical applications to indoor environments, medical surfaces, and public facilities.

- Smart responsive antibacterial coatings: Smart responsive antibacterial coatings are designed to activate their antimicrobial properties in response to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These advanced coatings can remain dormant until needed, which helps prevent antimicrobial resistance and extends the coating's effective lifespan. Some formulations incorporate multiple mechanisms of action or self-healing properties to maintain long-term efficacy. Applications include implantable medical devices, wound dressings, and surfaces in environments with variable contamination risks.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that inhibit bacterial growth. These coatings can be designed with controlled release mechanisms or contact-killing properties. Various polymers such as polyurethanes, acrylics, and silicones can be modified with antibacterial compounds. These coatings offer advantages including durability, flexibility, and the ability to be applied to diverse substrates while maintaining long-term antimicrobial efficacy.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Antibacterial coatings derived from natural compounds utilize plant extracts, essential oils, enzymes, and other biological materials to combat bacterial growth. These environmentally friendly alternatives offer reduced toxicity compared to synthetic antimicrobials. Natural compounds like chitosan, plant polyphenols, and essential oils can be incorporated into coating formulations to provide antimicrobial properties. These coatings are particularly valuable in applications where biocompatibility and sustainability are important considerations.Expand Specific Solutions04 Nanoparticle-enhanced antibacterial coatings

Nanoparticle-enhanced antibacterial coatings incorporate nanoscale materials to improve antimicrobial efficacy. These nanoparticles, including metal nanoparticles, metal oxide nanoparticles, and carbon-based nanomaterials, provide increased surface area and unique physicochemical properties that enhance bacterial killing. The small size allows for better penetration into bacterial cells and improved dispersion within coating matrices. These advanced coatings can be engineered for specific release profiles and targeted antimicrobial activity.Expand Specific Solutions05 Multi-functional antibacterial coatings

Multi-functional antibacterial coatings combine antimicrobial properties with additional functionalities such as anti-fouling, self-cleaning, or self-healing capabilities. These advanced coatings often utilize multiple mechanisms of action to prevent bacterial attachment and proliferation while providing supplementary benefits. For example, coatings may incorporate both contact-killing agents and controlled-release antimicrobials, or combine antibacterial properties with hydrophobic surfaces that resist bacterial adhesion. This approach enhances overall performance and extends the useful life of the coating.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The antibacterial coatings market for cleanroom environments is in a growth phase, driven by increasing demand for contamination control in healthcare, pharmaceuticals, and electronics manufacturing. The global market size is expanding rapidly, with projections indicating substantial growth as hygiene standards become more stringent worldwide. Technologically, the field shows varying maturity levels, with established players like LG Chem, FUJIFILM, and Henkel offering advanced solutions, while companies such as Jiangsu Biosurf Biotech and Intrinsiq Materials focus on innovative nanoparticle-based formulations. Research institutions including California Institute of Technology and University of Houston are pushing boundaries in surface modification technologies, creating a competitive landscape where industrial manufacturers collaborate with academic partners to develop next-generation antimicrobial surfaces with enhanced durability and efficacy.

LG Chem Ltd.

Technical Solution: LG Chem has developed an innovative antimicrobial coating platform called BioProtect™ specifically engineered for cleanroom applications in pharmaceutical, semiconductor, and medical device manufacturing. Their technology utilizes a proprietary polymer blend incorporating quaternary ammonium compounds (QACs) and copper nanoparticles in a silane-modified polyurethane matrix. This dual-action approach provides both contact-killing properties through the QACs and ion-release antimicrobial effects from the copper nanoparticles[6]. The coating system achieves >99.99% reduction in common cleanroom contaminants including Staphylococcus aureus, Escherichia coli, and Aspergillus niger within 4 hours of contact. LG Chem's formulation features a self-stratifying application process where a single application separates into a highly adhesive base layer and a functional antimicrobial top layer during curing, simplifying application while maximizing performance. The coating maintains antimicrobial efficacy for up to 24 months under standard cleanroom operating conditions and withstands over 150 cleaning cycles with hydrogen peroxide vapor and quaternary ammonium disinfectants commonly used in cleanroom maintenance[8]. Their latest generation incorporates hydrophobic surface modification that reduces water contact angle to <15°, minimizing the potential for biofilm formation.

Strengths: Excellent chemical resistance against common cleanroom chemicals including isopropyl alcohol, hydrogen peroxide, and peracetic acid; rapid antimicrobial action with measurable results within 2 hours; compatible with standard spray application equipment. Weaknesses: Moderate abrasion resistance requiring careful handling protocols; potential for color shifting under extended UV exposure; requires controlled humidity during application process.

Jiangsu Biosurf Biotech Co., Ltd.

Technical Solution: Jiangsu Biosurf Biotech has pioneered a biomimetic approach to antimicrobial coatings for cleanroom environments with their BioShield™ technology platform. Their innovation centers on peptide-based antimicrobial agents covalently bonded to a modified siloxane polymer matrix, creating permanent, non-leaching antimicrobial surfaces. The peptide structures are designed to mimic natural antimicrobial peptides found in the immune systems of various organisms, disrupting microbial cell membranes through electrostatic interactions rather than chemical poisoning[7]. This mechanism provides broad-spectrum activity against bacteria, fungi, and certain enveloped viruses without promoting antimicrobial resistance. Their coatings achieve a >99.97% reduction in microbial contamination within 6 hours of exposure and maintain efficacy for up to 18 months in cleanroom environments. The application process utilizes a proprietary vapor deposition technique that creates an ultra-thin (0.5-2μm) conformal coating capable of treating complex geometries and sensitive electronic equipment without affecting functionality. The coating is particularly notable for its extremely low outgassing properties, with TVOC emissions below 10μg/m² per hour after curing, making it suitable for even the most stringent cleanroom classifications[9].

Strengths: Non-toxic, environmentally friendly formulation with no heavy metals or toxic chemicals; extremely thin application that doesn't alter dimensional tolerances of precision components; effective against antibiotic-resistant bacterial strains. Weaknesses: Higher initial cost compared to conventional antimicrobial treatments; requires specialized application equipment not widely available; limited color options (primarily transparent and light tints only).

Key Patents and Scientific Advancements in Surface Protection

Antimicrobial radiation curable coating

PatentInactiveUS20050080158A1

Innovation

- A radiation-curable polymeric coating incorporating a non-toxic antimicrobial agent, such as 2,4,4′-trichloro-2′-hydroxydiphenyl ether, within a urethane acrylate oligomer system that cross-links upon UV exposure, providing long-lasting protection without isocyanate groups and allowing for high-solids application.

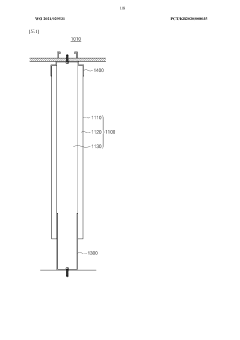

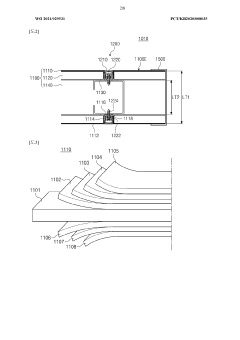

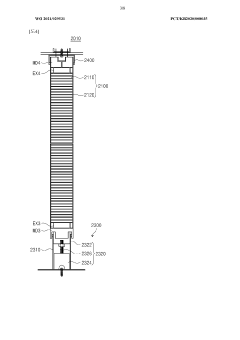

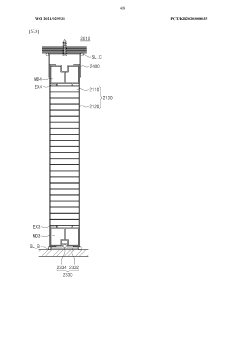

Antimicrobial panel structure

PatentWO2021029531A1

Innovation

- An antibacterial panel structure treated with an inorganic antibacterial agent on all exposed surfaces, including panels, connection units, ceiling supports, baseboards, and finish plates, ensuring a comprehensive antibacterial coating to prevent dust and bacterial adherence.

Regulatory Compliance and Standards

Regulatory compliance and standards play a pivotal role in the implementation and validation of antibacterial coatings within cleanroom environments. The stringent nature of cleanroom operations necessitates adherence to multiple regulatory frameworks that govern both the manufacturing processes and the materials used in these controlled environments. Organizations such as the International Organization for Standardization (ISO), the Food and Drug Administration (FDA), and the European Medicines Agency (EMA) have established comprehensive guidelines that directly impact antibacterial coating applications.

ISO 14644 series specifically addresses cleanroom classifications and monitoring requirements, with particular attention to surface particulate contamination in ISO 14644-9. This standard provides the foundation for evaluating the effectiveness of antibacterial coatings in maintaining required cleanliness levels. Additionally, ISO 22196 outlines standardized methods for measuring antibacterial activity on plastics and other non-porous surfaces, offering a crucial benchmark for coating performance validation.

For pharmaceutical and medical device cleanrooms, FDA regulations under 21 CFR Part 211 (Current Good Manufacturing Practice for Finished Pharmaceuticals) and 21 CFR Part 820 (Quality System Regulation) impose strict requirements on surface materials. These regulations mandate that surfaces must not release particulates, must withstand cleaning agents, and must not harbor microorganisms—all factors directly related to antibacterial coating functionality.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) similarly address surface requirements for cleanrooms involved in medical product manufacturing, with specific provisions regarding biocompatibility and leachable compounds from surface treatments. These considerations are particularly relevant when selecting antibacterial coating technologies.

Beyond regulatory compliance, industry standards such as IEST-RP-CC026 (Cleanroom Operations) provide detailed recommendations for surface cleaning protocols and material selection. The Association for the Advancement of Medical Instrumentation (AAMI) offers additional guidance through standards like AAMI ST79, which addresses steam sterilization and sterility assurance in healthcare facilities.

Certification processes for antibacterial coatings in cleanroom applications typically require extensive documentation of material safety data, leachable/extractable testing results, and antimicrobial efficacy studies. Many jurisdictions also require environmental impact assessments, particularly for coatings containing silver, copper, or other potentially bioaccumulative substances.

Emerging regulatory trends indicate increasing scrutiny of long-term efficacy claims and potential development of antimicrobial resistance. Several regulatory bodies are currently developing more specific guidelines for "smart" antibacterial surfaces that incorporate controlled-release mechanisms or responsive technologies, signaling a shift toward more sophisticated regulatory frameworks for next-generation cleanroom surface technologies.

ISO 14644 series specifically addresses cleanroom classifications and monitoring requirements, with particular attention to surface particulate contamination in ISO 14644-9. This standard provides the foundation for evaluating the effectiveness of antibacterial coatings in maintaining required cleanliness levels. Additionally, ISO 22196 outlines standardized methods for measuring antibacterial activity on plastics and other non-porous surfaces, offering a crucial benchmark for coating performance validation.

For pharmaceutical and medical device cleanrooms, FDA regulations under 21 CFR Part 211 (Current Good Manufacturing Practice for Finished Pharmaceuticals) and 21 CFR Part 820 (Quality System Regulation) impose strict requirements on surface materials. These regulations mandate that surfaces must not release particulates, must withstand cleaning agents, and must not harbor microorganisms—all factors directly related to antibacterial coating functionality.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) similarly address surface requirements for cleanrooms involved in medical product manufacturing, with specific provisions regarding biocompatibility and leachable compounds from surface treatments. These considerations are particularly relevant when selecting antibacterial coating technologies.

Beyond regulatory compliance, industry standards such as IEST-RP-CC026 (Cleanroom Operations) provide detailed recommendations for surface cleaning protocols and material selection. The Association for the Advancement of Medical Instrumentation (AAMI) offers additional guidance through standards like AAMI ST79, which addresses steam sterilization and sterility assurance in healthcare facilities.

Certification processes for antibacterial coatings in cleanroom applications typically require extensive documentation of material safety data, leachable/extractable testing results, and antimicrobial efficacy studies. Many jurisdictions also require environmental impact assessments, particularly for coatings containing silver, copper, or other potentially bioaccumulative substances.

Emerging regulatory trends indicate increasing scrutiny of long-term efficacy claims and potential development of antimicrobial resistance. Several regulatory bodies are currently developing more specific guidelines for "smart" antibacterial surfaces that incorporate controlled-release mechanisms or responsive technologies, signaling a shift toward more sophisticated regulatory frameworks for next-generation cleanroom surface technologies.

Environmental Impact and Sustainability Considerations

The environmental impact of antibacterial coatings in cleanroom environments represents a critical consideration as industries balance contamination control with sustainability goals. Traditional antibacterial agents often contain heavy metals such as silver, copper, and zinc oxide, which can persist in the environment long after disposal. These substances may accumulate in soil and water systems, potentially disrupting ecological balances and affecting aquatic organisms through bioaccumulation processes.

Recent lifecycle assessments of cleanroom antibacterial coatings reveal significant environmental footprints associated with their production, application, and disposal. Manufacturing processes for conventional antimicrobial agents typically require substantial energy inputs and generate hazardous waste streams. The application phase often involves volatile organic compounds (VOCs) that contribute to air pollution and pose occupational health risks to installation personnel.

Regulatory frameworks worldwide are increasingly restricting the use of certain biocidal substances due to their environmental persistence. The European Union's Biocidal Products Regulation and similar legislation in North America have accelerated the development of more environmentally benign alternatives. This regulatory pressure has become a significant driver for innovation in the antibacterial coatings sector.

Emerging sustainable alternatives include bio-based antimicrobial compounds derived from plant extracts, essential oils, and enzymes. These natural derivatives offer biodegradability advantages while maintaining effective antimicrobial properties. Chitosan, extracted from crustacean shells, represents a promising renewable resource that demonstrates broad-spectrum antimicrobial activity with minimal environmental impact.

Advanced manufacturing technologies are reducing the environmental footprint of antibacterial coating production. Water-based formulations have largely replaced solvent-based systems, significantly reducing VOC emissions. Additionally, precision application technologies minimize material waste and extend coating lifespans, improving overall sustainability metrics.

The end-of-life management of antibacterial coatings presents ongoing challenges. Current research focuses on developing recyclable substrate materials and biodegradable antimicrobial agents that decompose into non-toxic components. Some innovative approaches incorporate photocatalytic materials that break down organic contaminants under light exposure, potentially reducing cleaning chemical requirements and associated environmental impacts.

Carbon footprint considerations are increasingly influencing material selection and processing decisions. Life cycle analyses indicate that locally sourced materials and energy-efficient curing methods can substantially reduce the embodied carbon of antibacterial coating systems. Several manufacturers have implemented carbon offset programs specifically targeting their cleanroom product lines.

Recent lifecycle assessments of cleanroom antibacterial coatings reveal significant environmental footprints associated with their production, application, and disposal. Manufacturing processes for conventional antimicrobial agents typically require substantial energy inputs and generate hazardous waste streams. The application phase often involves volatile organic compounds (VOCs) that contribute to air pollution and pose occupational health risks to installation personnel.

Regulatory frameworks worldwide are increasingly restricting the use of certain biocidal substances due to their environmental persistence. The European Union's Biocidal Products Regulation and similar legislation in North America have accelerated the development of more environmentally benign alternatives. This regulatory pressure has become a significant driver for innovation in the antibacterial coatings sector.

Emerging sustainable alternatives include bio-based antimicrobial compounds derived from plant extracts, essential oils, and enzymes. These natural derivatives offer biodegradability advantages while maintaining effective antimicrobial properties. Chitosan, extracted from crustacean shells, represents a promising renewable resource that demonstrates broad-spectrum antimicrobial activity with minimal environmental impact.

Advanced manufacturing technologies are reducing the environmental footprint of antibacterial coating production. Water-based formulations have largely replaced solvent-based systems, significantly reducing VOC emissions. Additionally, precision application technologies minimize material waste and extend coating lifespans, improving overall sustainability metrics.

The end-of-life management of antibacterial coatings presents ongoing challenges. Current research focuses on developing recyclable substrate materials and biodegradable antimicrobial agents that decompose into non-toxic components. Some innovative approaches incorporate photocatalytic materials that break down organic contaminants under light exposure, potentially reducing cleaning chemical requirements and associated environmental impacts.

Carbon footprint considerations are increasingly influencing material selection and processing decisions. Life cycle analyses indicate that locally sourced materials and energy-efficient curing methods can substantially reduce the embodied carbon of antibacterial coating systems. Several manufacturers have implemented carbon offset programs specifically targeting their cleanroom product lines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!