How Biofertilizers Revolutionize Waste‑to‑Energy Conversion Models?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biofertilizer Evolution

Biofertilizers have undergone a remarkable evolution since their inception, transforming from simple organic amendments to sophisticated biotechnological products. The journey began in the early 20th century with the discovery of nitrogen-fixing bacteria in legume root nodules. This breakthrough laid the foundation for harnessing microbial capabilities to enhance soil fertility and crop productivity.

In the 1950s and 1960s, research on plant growth-promoting rhizobacteria (PGPR) gained momentum, leading to the development of the first commercial biofertilizer products. These early formulations primarily focused on nitrogen fixation and phosphate solubilization. The 1970s saw a shift towards more diverse microbial consortia, incorporating multiple beneficial microorganisms to address various plant nutritional needs.

The 1980s and 1990s marked a significant leap in biofertilizer technology with the advent of genetic engineering. Scientists began to explore ways to enhance the efficiency of microbial strains through genetic modifications, aiming to improve their colonization abilities and nutrient mobilization capacities. This period also witnessed the integration of mycorrhizal fungi into biofertilizer formulations, expanding the range of nutrients that could be made available to plants.

The turn of the millennium brought about a paradigm shift in biofertilizer development. With growing environmental concerns and the push for sustainable agriculture, researchers began exploring the potential of biofertilizers in waste management and energy production. This led to the concept of integrating biofertilizers into waste-to-energy conversion models, a revolutionary approach that addresses multiple challenges simultaneously.

Recent years have seen rapid advancements in biofertilizer technology, driven by breakthroughs in microbial genomics and metabolomics. Scientists are now able to identify and cultivate previously unculturable microorganisms, expanding the repertoire of beneficial strains available for biofertilizer production. Moreover, the application of nanotechnology has enabled the development of nano-biofertilizers, which offer improved efficiency and targeted nutrient delivery.

The evolution of biofertilizers has also been marked by a shift towards multi-functional products. Modern biofertilizers not only enhance nutrient availability but also provide additional benefits such as biocontrol against pathogens, improved stress tolerance, and enhanced soil structure. This holistic approach aligns well with the principles of circular economy and sustainable resource management.

As we look to the future, the evolution of biofertilizers is poised to continue at an accelerated pace. The integration of artificial intelligence and machine learning in biofertilizer research promises to unlock new potentials, enabling the design of customized formulations tailored to specific crop-soil-climate combinations. Furthermore, the convergence of biofertilizer technology with waste-to-energy systems represents a frontier in sustainable agriculture and renewable energy production, offering innovative solutions to global challenges in food security and environmental sustainability.

In the 1950s and 1960s, research on plant growth-promoting rhizobacteria (PGPR) gained momentum, leading to the development of the first commercial biofertilizer products. These early formulations primarily focused on nitrogen fixation and phosphate solubilization. The 1970s saw a shift towards more diverse microbial consortia, incorporating multiple beneficial microorganisms to address various plant nutritional needs.

The 1980s and 1990s marked a significant leap in biofertilizer technology with the advent of genetic engineering. Scientists began to explore ways to enhance the efficiency of microbial strains through genetic modifications, aiming to improve their colonization abilities and nutrient mobilization capacities. This period also witnessed the integration of mycorrhizal fungi into biofertilizer formulations, expanding the range of nutrients that could be made available to plants.

The turn of the millennium brought about a paradigm shift in biofertilizer development. With growing environmental concerns and the push for sustainable agriculture, researchers began exploring the potential of biofertilizers in waste management and energy production. This led to the concept of integrating biofertilizers into waste-to-energy conversion models, a revolutionary approach that addresses multiple challenges simultaneously.

Recent years have seen rapid advancements in biofertilizer technology, driven by breakthroughs in microbial genomics and metabolomics. Scientists are now able to identify and cultivate previously unculturable microorganisms, expanding the repertoire of beneficial strains available for biofertilizer production. Moreover, the application of nanotechnology has enabled the development of nano-biofertilizers, which offer improved efficiency and targeted nutrient delivery.

The evolution of biofertilizers has also been marked by a shift towards multi-functional products. Modern biofertilizers not only enhance nutrient availability but also provide additional benefits such as biocontrol against pathogens, improved stress tolerance, and enhanced soil structure. This holistic approach aligns well with the principles of circular economy and sustainable resource management.

As we look to the future, the evolution of biofertilizers is poised to continue at an accelerated pace. The integration of artificial intelligence and machine learning in biofertilizer research promises to unlock new potentials, enabling the design of customized formulations tailored to specific crop-soil-climate combinations. Furthermore, the convergence of biofertilizer technology with waste-to-energy systems represents a frontier in sustainable agriculture and renewable energy production, offering innovative solutions to global challenges in food security and environmental sustainability.

Waste-to-Energy Market

The waste-to-energy market has experienced significant growth in recent years, driven by increasing global waste generation and the need for sustainable waste management solutions. This market encompasses various technologies that convert waste materials into usable forms of energy, including incineration, gasification, anaerobic digestion, and landfill gas recovery.

The global waste-to-energy market was valued at approximately $35 billion in 2019 and is projected to reach $50 billion by 2027, growing at a CAGR of around 4.6% during the forecast period. This growth is primarily attributed to the rising urbanization, industrialization, and population growth, which have led to increased waste generation and the need for efficient disposal methods.

Europe currently dominates the waste-to-energy market, accounting for the largest share of global installations. Countries like Germany, Sweden, and Denmark have well-established waste-to-energy infrastructures and supportive government policies. Asia-Pacific is expected to witness the fastest growth in the coming years, with China and India leading the expansion due to rapid urbanization and government initiatives to address waste management challenges.

The market is characterized by a mix of established players and new entrants, with companies like Covanta Holding Corporation, Veolia Environment, Suez Environment, and Waste Management Inc. holding significant market shares. These companies are continuously investing in research and development to improve technology efficiency and reduce emissions.

Thermal waste-to-energy technologies, particularly incineration, currently dominate the market. However, biological waste-to-energy processes, such as anaerobic digestion, are gaining traction due to their ability to handle organic waste more efficiently and produce valuable by-products like biogas and fertilizers.

The integration of biofertilizers into waste-to-energy conversion models represents a promising development in the market. This approach not only addresses waste management issues but also contributes to sustainable agriculture by producing nutrient-rich fertilizers as a by-product of the energy generation process.

Challenges facing the waste-to-energy market include high initial investment costs, stringent environmental regulations, and public opposition to waste treatment facilities. However, technological advancements, such as improved emission control systems and more efficient conversion processes, are helping to address these concerns and drive market growth.

The global waste-to-energy market was valued at approximately $35 billion in 2019 and is projected to reach $50 billion by 2027, growing at a CAGR of around 4.6% during the forecast period. This growth is primarily attributed to the rising urbanization, industrialization, and population growth, which have led to increased waste generation and the need for efficient disposal methods.

Europe currently dominates the waste-to-energy market, accounting for the largest share of global installations. Countries like Germany, Sweden, and Denmark have well-established waste-to-energy infrastructures and supportive government policies. Asia-Pacific is expected to witness the fastest growth in the coming years, with China and India leading the expansion due to rapid urbanization and government initiatives to address waste management challenges.

The market is characterized by a mix of established players and new entrants, with companies like Covanta Holding Corporation, Veolia Environment, Suez Environment, and Waste Management Inc. holding significant market shares. These companies are continuously investing in research and development to improve technology efficiency and reduce emissions.

Thermal waste-to-energy technologies, particularly incineration, currently dominate the market. However, biological waste-to-energy processes, such as anaerobic digestion, are gaining traction due to their ability to handle organic waste more efficiently and produce valuable by-products like biogas and fertilizers.

The integration of biofertilizers into waste-to-energy conversion models represents a promising development in the market. This approach not only addresses waste management issues but also contributes to sustainable agriculture by producing nutrient-rich fertilizers as a by-product of the energy generation process.

Challenges facing the waste-to-energy market include high initial investment costs, stringent environmental regulations, and public opposition to waste treatment facilities. However, technological advancements, such as improved emission control systems and more efficient conversion processes, are helping to address these concerns and drive market growth.

Biofertilizer Challenges

Despite the promising potential of biofertilizers in revolutionizing waste-to-energy conversion models, several significant challenges hinder their widespread adoption and effectiveness. One of the primary obstacles is the variability in biofertilizer quality and performance. The efficacy of biofertilizers can be inconsistent due to factors such as microbial strain selection, production processes, and storage conditions. This inconsistency makes it difficult for farmers and energy producers to rely on biofertilizers as a stable input in their waste-to-energy conversion systems.

Another major challenge is the limited shelf life of many biofertilizer products. The living microorganisms in biofertilizers are sensitive to environmental conditions, and their viability can decrease rapidly over time. This short shelf life complicates storage, transportation, and distribution logistics, potentially leading to reduced effectiveness when applied in the field or integrated into waste-to-energy processes.

The lack of standardization in biofertilizer production and application methods also poses a significant hurdle. Without uniform guidelines and quality control measures, it becomes challenging to ensure consistent results across different geographical regions and agricultural systems. This lack of standardization can lead to skepticism among potential users and slow down the integration of biofertilizers into established waste-to-energy conversion models.

Environmental factors present another set of challenges for biofertilizer implementation. Soil conditions, climate, and existing microbial populations can significantly impact the performance of biofertilizers. Adapting biofertilizer formulations to diverse environmental conditions while maintaining their waste-to-energy conversion potential requires extensive research and development efforts.

The economic viability of biofertilizers in waste-to-energy conversion models is also a concern. While biofertilizers offer long-term benefits, their initial costs and the potential need for specialized application equipment can be prohibitive for some users. Additionally, the economic returns from biofertilizer use in waste-to-energy systems may not be immediately apparent, making it difficult to justify the investment for some stakeholders.

Regulatory hurdles and lack of awareness further complicate the adoption of biofertilizers in waste-to-energy conversion. Many countries lack clear regulatory frameworks for biofertilizer approval and use, creating uncertainty for manufacturers and users alike. Moreover, limited awareness among farmers and energy producers about the benefits and proper use of biofertilizers in waste-to-energy systems hampers their widespread adoption.

Addressing these challenges requires a multifaceted approach involving continued research, development of improved formulations, establishment of quality standards, and education of stakeholders. Overcoming these obstacles will be crucial in realizing the full potential of biofertilizers to revolutionize waste-to-energy conversion models and contribute to sustainable agricultural and energy practices.

Another major challenge is the limited shelf life of many biofertilizer products. The living microorganisms in biofertilizers are sensitive to environmental conditions, and their viability can decrease rapidly over time. This short shelf life complicates storage, transportation, and distribution logistics, potentially leading to reduced effectiveness when applied in the field or integrated into waste-to-energy processes.

The lack of standardization in biofertilizer production and application methods also poses a significant hurdle. Without uniform guidelines and quality control measures, it becomes challenging to ensure consistent results across different geographical regions and agricultural systems. This lack of standardization can lead to skepticism among potential users and slow down the integration of biofertilizers into established waste-to-energy conversion models.

Environmental factors present another set of challenges for biofertilizer implementation. Soil conditions, climate, and existing microbial populations can significantly impact the performance of biofertilizers. Adapting biofertilizer formulations to diverse environmental conditions while maintaining their waste-to-energy conversion potential requires extensive research and development efforts.

The economic viability of biofertilizers in waste-to-energy conversion models is also a concern. While biofertilizers offer long-term benefits, their initial costs and the potential need for specialized application equipment can be prohibitive for some users. Additionally, the economic returns from biofertilizer use in waste-to-energy systems may not be immediately apparent, making it difficult to justify the investment for some stakeholders.

Regulatory hurdles and lack of awareness further complicate the adoption of biofertilizers in waste-to-energy conversion. Many countries lack clear regulatory frameworks for biofertilizer approval and use, creating uncertainty for manufacturers and users alike. Moreover, limited awareness among farmers and energy producers about the benefits and proper use of biofertilizers in waste-to-energy systems hampers their widespread adoption.

Addressing these challenges requires a multifaceted approach involving continued research, development of improved formulations, establishment of quality standards, and education of stakeholders. Overcoming these obstacles will be crucial in realizing the full potential of biofertilizers to revolutionize waste-to-energy conversion models and contribute to sustainable agricultural and energy practices.

Current Biofertilizer

01 Biofertilizer production from organic waste

This approach involves converting organic waste materials into biofertilizers through various processes such as composting or anaerobic digestion. The resulting biofertilizers can be used to enhance soil fertility and crop productivity while simultaneously addressing waste management issues.- Biofertilizer production from organic waste: This approach involves converting organic waste materials into biofertilizers through various processes such as composting or anaerobic digestion. The resulting biofertilizers can be used to enhance soil fertility and crop productivity while simultaneously addressing waste management issues.

- Integrated waste-to-energy and biofertilizer systems: These systems combine waste-to-energy technologies with biofertilizer production, maximizing resource recovery from waste streams. The process typically involves energy generation through methods like anaerobic digestion or incineration, with the residual materials being converted into biofertilizers.

- Microbial-based biofertilizer production: This method utilizes specific microorganisms to convert waste materials into biofertilizers. The microbes break down organic matter, releasing nutrients and producing beneficial compounds that enhance soil health and plant growth.

- Bioenergy crop residue conversion to biofertilizers: This approach focuses on converting residues from bioenergy crop production into biofertilizers. The process helps close the nutrient cycle by returning valuable organic matter and nutrients to the soil, improving sustainability in bioenergy systems.

- Algae-based biofertilizer and bioenergy production: This innovative method involves cultivating algae using waste streams, then processing the algal biomass to produce both bioenergy and biofertilizers. The approach offers a dual benefit of waste treatment and resource recovery, contributing to circular economy principles.

02 Integrated waste-to-energy and biofertilizer systems

These systems combine waste-to-energy technologies with biofertilizer production, maximizing resource recovery from waste streams. The process typically involves energy generation through methods like anaerobic digestion or incineration, with the residual materials being converted into biofertilizers.Expand Specific Solutions03 Microbial-based biofertilizer production

This method utilizes specific microorganisms to convert waste materials into biofertilizers. The microbes break down organic matter, releasing nutrients and producing compounds that enhance soil health and plant growth. This approach can be integrated with waste-to-energy processes for improved efficiency.Expand Specific Solutions04 Thermochemical conversion of waste to biofertilizers

This process involves using thermochemical methods such as pyrolysis or gasification to convert waste materials into biofertilizers and energy products. The high-temperature treatment breaks down organic matter, producing biochar or ash that can be used as a soil amendment and fertilizer.Expand Specific Solutions05 Algae-based biofertilizer and bioenergy production

This innovative approach uses algae to treat wastewater and produce biofertilizers and bioenergy simultaneously. The algae consume nutrients from the waste, producing biomass that can be used as a fertilizer or converted into biofuels, creating a circular economy model for waste management.Expand Specific Solutions

Key Industry Players

The biofertilizer market is in a growth phase, driven by increasing demand for sustainable agricultural practices and waste management solutions. The global market size is projected to expand significantly, with estimates ranging from $3-4 billion by 2026. Technological maturity varies across different biofertilizer types, with some well-established products and others still in development. Companies like PrairieChar, Inc. and Valagro SpA are leading innovation in micro-carbon and biostimulant technologies, while research institutions such as the University of Grenoble and King Abdullah University of Science & Technology are advancing the field through cutting-edge studies. The industry is characterized by a mix of established players and emerging startups, indicating a dynamic and competitive landscape.

PrairieChar, Inc.

Technical Solution: PrairieChar has developed an innovative biofertilizer production process that revolutionizes waste-to-energy conversion. Their technology utilizes a proprietary pyrolysis process to convert agricultural waste into biochar, which serves as a carbon-negative soil amendment and biofertilizer. The process simultaneously produces syngas, which can be used for energy generation. PrairieChar's system can process various feedstocks, including crop residues and animal manure, creating a closed-loop system for agricultural waste management[1][3]. The resulting biochar-based biofertilizer enhances soil fertility, increases water retention, and promotes microbial activity, leading to improved crop yields and reduced chemical fertilizer dependency[2].

Strengths: Carbon-negative process, dual output of biofertilizer and energy, versatile feedstock utilization. Weaknesses: Potential high initial investment costs, reliance on consistent agricultural waste supply.

Accelergy Corp.

Technical Solution: Accelergy Corp. has pioneered a waste-to-energy conversion model that integrates biofertilizer production. Their technology employs a catalytic hydrothermal conversion process to transform organic waste into high-value biofuels and biofertilizers. The process operates at lower temperatures compared to traditional thermochemical methods, reducing energy input and increasing overall efficiency[4]. Accelergy's system can handle a wide range of organic wastes, including municipal solid waste and industrial organic byproducts. The resulting liquid biofertilizer is rich in nutrients and organic matter, promoting sustainable agriculture practices[5]. Additionally, the process generates biogas, which can be used for on-site energy production or upgraded to renewable natural gas.

Strengths: Energy-efficient process, diverse waste stream compatibility, production of both liquid biofertilizer and biofuels. Weaknesses: Potential complexity in process control, may require specialized handling of liquid fertilizer products.

Innovative Processes

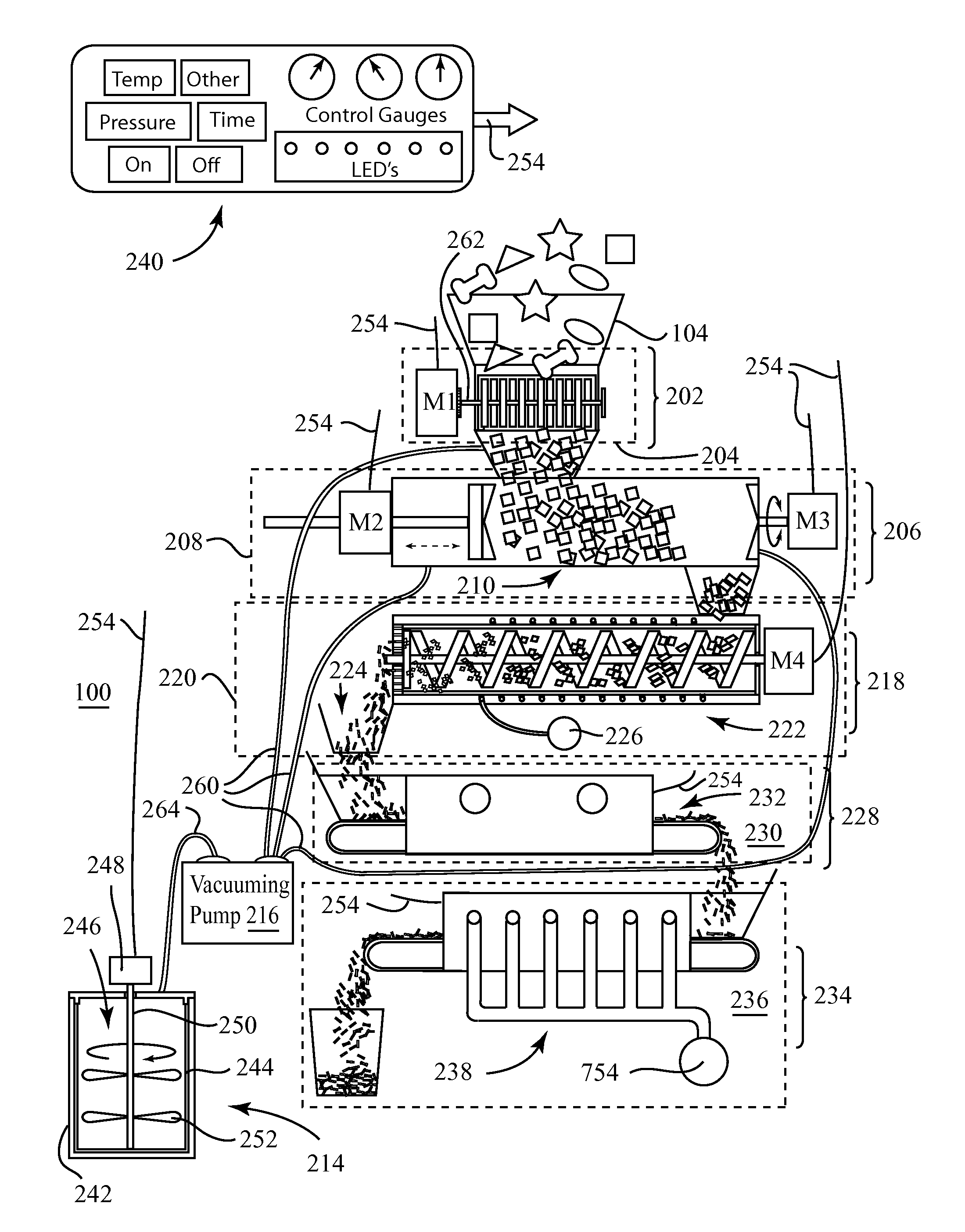

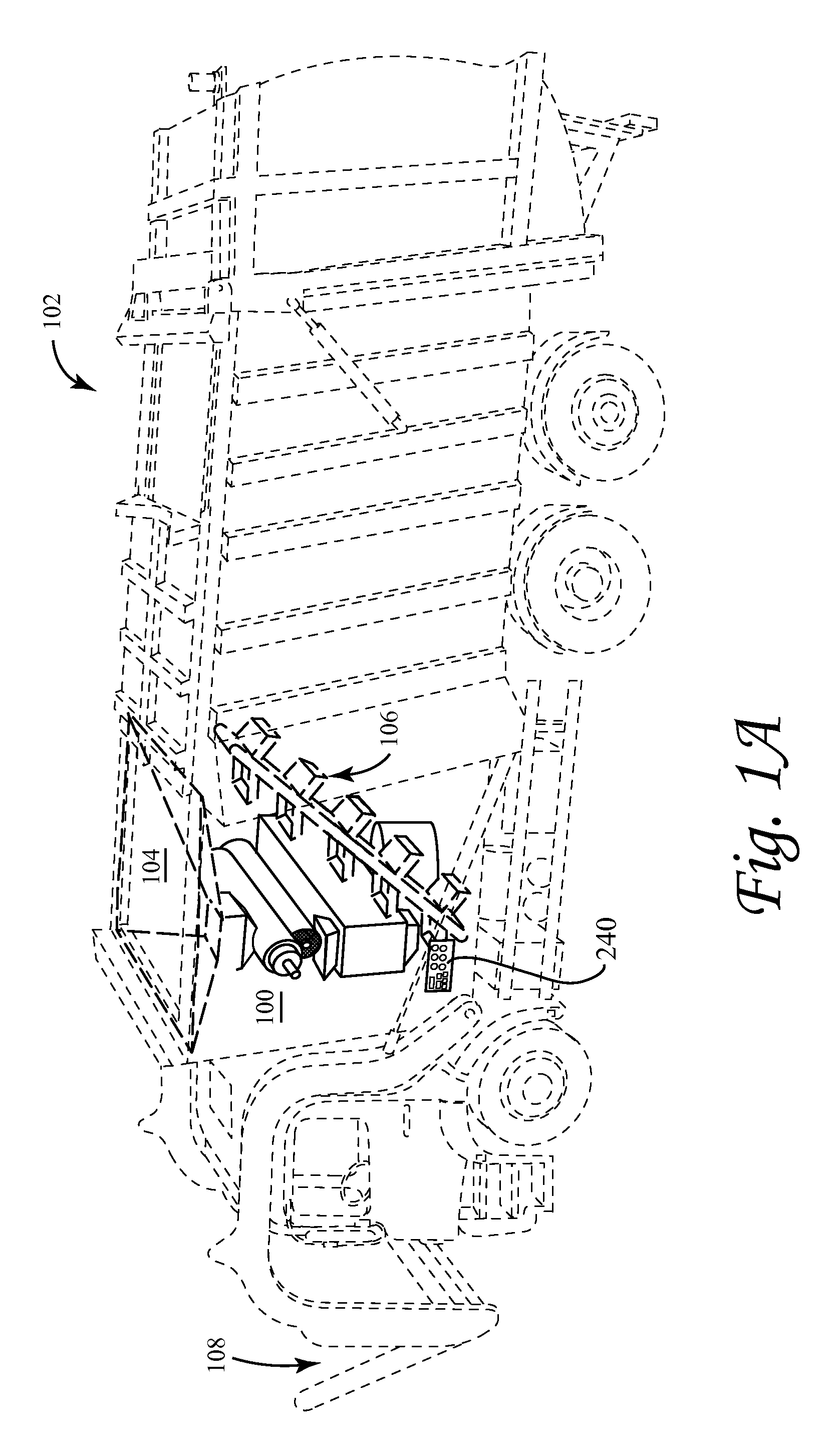

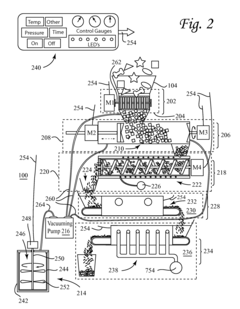

Device for conversion of waste to sources of energy or fertilizer and a method thereof

PatentInactiveUS9423178B2

Innovation

- A compact, multi-stage device for continuous waste conversion to energy or fertilizer, featuring stages for size reduction, dehydration, grinding, compression, drying, and cooling, with a controller managing each stage, allowing for efficient on-site or mobile operation.

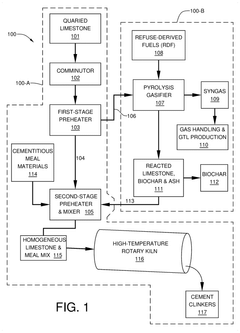

Waste-to-energy production conjoined with portland cement production

PatentPendingUS20240409459A1

Innovation

- Integration of waste-to-energy (WTE) process with Portland cement production (PCP) to reduce harmful emissions and improve resource utilization.

- Utilization of pre-heated comminuted limestone from PCP as a fluxing agent and sorbent in the WTE process to remove impurities and harmful compounds.

- Recycling of ash, char waste, and reacted calcium compounds from WTE process back into PCP as secondary cement meal feedstock.

Environmental Impact

The integration of biofertilizers into waste-to-energy conversion models presents a significant opportunity for enhancing environmental sustainability. By leveraging the natural processes of microorganisms, biofertilizers offer a dual benefit of waste management and energy production while minimizing ecological impact.

One of the primary environmental advantages of biofertilizer-based waste-to-energy systems is the reduction of greenhouse gas emissions. Traditional waste management methods, such as landfilling or incineration, often result in the release of methane and carbon dioxide. In contrast, biofertilizer production and application can sequester carbon in the soil, effectively reducing the carbon footprint of waste management processes.

The use of biofertilizers also contributes to soil health improvement. As organic matter is converted into nutrient-rich fertilizer, it enhances soil structure, water retention capacity, and microbial activity. This leads to increased soil fertility and reduced reliance on synthetic fertilizers, which are often associated with water pollution and soil degradation.

Water conservation is another crucial environmental benefit of biofertilizer-integrated waste-to-energy models. The process typically requires less water compared to traditional waste treatment methods, and the resulting biofertilizers can improve soil water retention, reducing the need for irrigation in agricultural applications.

Furthermore, the adoption of biofertilizers in waste-to-energy conversion helps to mitigate the problem of nutrient runoff. By efficiently recycling nutrients from organic waste, these systems reduce the risk of excess nutrients entering water bodies, which can lead to eutrophication and harmful algal blooms.

The circular economy aspect of biofertilizer production from waste also contributes to resource conservation. By transforming waste into valuable agricultural inputs, this approach reduces the demand for virgin resources and minimizes the environmental impact associated with their extraction and processing.

Biodiversity preservation is an often-overlooked benefit of biofertilizer use in waste-to-energy systems. The improved soil health resulting from biofertilizer application can support a more diverse ecosystem of soil microorganisms, insects, and plants, contributing to overall ecosystem resilience.

In conclusion, the integration of biofertilizers into waste-to-energy conversion models offers a multifaceted approach to environmental protection. From reducing greenhouse gas emissions and improving soil health to conserving water and promoting biodiversity, this innovative approach aligns with global sustainability goals and represents a significant step towards more environmentally friendly waste management and energy production practices.

One of the primary environmental advantages of biofertilizer-based waste-to-energy systems is the reduction of greenhouse gas emissions. Traditional waste management methods, such as landfilling or incineration, often result in the release of methane and carbon dioxide. In contrast, biofertilizer production and application can sequester carbon in the soil, effectively reducing the carbon footprint of waste management processes.

The use of biofertilizers also contributes to soil health improvement. As organic matter is converted into nutrient-rich fertilizer, it enhances soil structure, water retention capacity, and microbial activity. This leads to increased soil fertility and reduced reliance on synthetic fertilizers, which are often associated with water pollution and soil degradation.

Water conservation is another crucial environmental benefit of biofertilizer-integrated waste-to-energy models. The process typically requires less water compared to traditional waste treatment methods, and the resulting biofertilizers can improve soil water retention, reducing the need for irrigation in agricultural applications.

Furthermore, the adoption of biofertilizers in waste-to-energy conversion helps to mitigate the problem of nutrient runoff. By efficiently recycling nutrients from organic waste, these systems reduce the risk of excess nutrients entering water bodies, which can lead to eutrophication and harmful algal blooms.

The circular economy aspect of biofertilizer production from waste also contributes to resource conservation. By transforming waste into valuable agricultural inputs, this approach reduces the demand for virgin resources and minimizes the environmental impact associated with their extraction and processing.

Biodiversity preservation is an often-overlooked benefit of biofertilizer use in waste-to-energy systems. The improved soil health resulting from biofertilizer application can support a more diverse ecosystem of soil microorganisms, insects, and plants, contributing to overall ecosystem resilience.

In conclusion, the integration of biofertilizers into waste-to-energy conversion models offers a multifaceted approach to environmental protection. From reducing greenhouse gas emissions and improving soil health to conserving water and promoting biodiversity, this innovative approach aligns with global sustainability goals and represents a significant step towards more environmentally friendly waste management and energy production practices.

Economic Feasibility

The economic feasibility of biofertilizers in revolutionizing waste-to-energy conversion models is a critical aspect that requires thorough analysis. The integration of biofertilizers into waste management systems presents a promising opportunity for sustainable resource utilization and energy production. However, the economic viability of such models depends on various factors that need careful consideration.

One of the primary economic advantages of biofertilizer-based waste-to-energy models is the potential for cost reduction in waste management. Traditional waste disposal methods often incur significant expenses related to landfill operations, transportation, and environmental compliance. By incorporating biofertilizers, municipalities and industries can potentially reduce these costs while simultaneously generating valuable products.

The production of biofertilizers from organic waste streams can create new revenue streams for waste management facilities. These biofertilizers can be sold to agricultural sectors, landscaping businesses, and individual consumers, providing an additional source of income. This diversification of revenue can help offset the initial investment costs associated with implementing biofertilizer production systems.

However, the economic feasibility of these models also faces several challenges. The initial capital investment required for setting up biofertilizer production facilities can be substantial. This includes costs for equipment, infrastructure, and specialized personnel. The return on investment period may be longer compared to traditional waste management methods, which could deter some stakeholders from adopting this approach.

Market demand and pricing for biofertilizers play a crucial role in determining economic viability. While there is growing interest in sustainable agricultural practices, the market for biofertilizers is still developing in many regions. Fluctuations in demand and competition from conventional fertilizers can impact the profitability of biofertilizer production.

Operational costs, including energy consumption, labor, and maintenance, must be carefully managed to ensure long-term economic sustainability. Efficient process design and optimization are essential to minimize these costs and maximize the output of high-quality biofertilizers.

Regulatory frameworks and government policies significantly influence the economic feasibility of biofertilizer-based waste-to-energy models. Supportive policies, such as subsidies for renewable energy production or incentives for sustainable waste management, can enhance the economic attractiveness of these systems. Conversely, stringent regulations or lack of policy support may pose challenges to implementation and profitability.

The scalability of biofertilizer production is another important economic consideration. The ability to scale operations to match local waste generation and market demand is crucial for maintaining economic viability. Flexible and modular system designs can help address this challenge by allowing for gradual expansion and adaptation to changing market conditions.

In conclusion, while biofertilizers show promise in revolutionizing waste-to-energy conversion models, their economic feasibility depends on a complex interplay of factors. Careful analysis of local market conditions, regulatory environments, and operational costs is essential for developing successful and sustainable biofertilizer-based waste management strategies.

One of the primary economic advantages of biofertilizer-based waste-to-energy models is the potential for cost reduction in waste management. Traditional waste disposal methods often incur significant expenses related to landfill operations, transportation, and environmental compliance. By incorporating biofertilizers, municipalities and industries can potentially reduce these costs while simultaneously generating valuable products.

The production of biofertilizers from organic waste streams can create new revenue streams for waste management facilities. These biofertilizers can be sold to agricultural sectors, landscaping businesses, and individual consumers, providing an additional source of income. This diversification of revenue can help offset the initial investment costs associated with implementing biofertilizer production systems.

However, the economic feasibility of these models also faces several challenges. The initial capital investment required for setting up biofertilizer production facilities can be substantial. This includes costs for equipment, infrastructure, and specialized personnel. The return on investment period may be longer compared to traditional waste management methods, which could deter some stakeholders from adopting this approach.

Market demand and pricing for biofertilizers play a crucial role in determining economic viability. While there is growing interest in sustainable agricultural practices, the market for biofertilizers is still developing in many regions. Fluctuations in demand and competition from conventional fertilizers can impact the profitability of biofertilizer production.

Operational costs, including energy consumption, labor, and maintenance, must be carefully managed to ensure long-term economic sustainability. Efficient process design and optimization are essential to minimize these costs and maximize the output of high-quality biofertilizers.

Regulatory frameworks and government policies significantly influence the economic feasibility of biofertilizer-based waste-to-energy models. Supportive policies, such as subsidies for renewable energy production or incentives for sustainable waste management, can enhance the economic attractiveness of these systems. Conversely, stringent regulations or lack of policy support may pose challenges to implementation and profitability.

The scalability of biofertilizer production is another important economic consideration. The ability to scale operations to match local waste generation and market demand is crucial for maintaining economic viability. Flexible and modular system designs can help address this challenge by allowing for gradual expansion and adaptation to changing market conditions.

In conclusion, while biofertilizers show promise in revolutionizing waste-to-energy conversion models, their economic feasibility depends on a complex interplay of factors. Careful analysis of local market conditions, regulatory environments, and operational costs is essential for developing successful and sustainable biofertilizer-based waste management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!