How to Exploit Kevlar for Advanced Seismic Safety Systems?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Seismic Safety: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized various industries due to its exceptional properties. Initially designed for use in automotive tires, Kevlar's potential in seismic safety systems has gained significant attention in recent years. The material's unique combination of high tensile strength-to-weight ratio, durability, and resistance to impact and abrasion makes it an ideal candidate for enhancing structural resilience against seismic events.

The evolution of seismic safety systems has been driven by the increasing frequency and intensity of earthquakes worldwide. Traditional approaches to earthquake-resistant design have primarily focused on reinforced concrete and steel structures. However, these methods often fall short in providing adequate protection against severe seismic events, leading to catastrophic failures and loss of life. The integration of advanced materials like Kevlar into seismic safety systems represents a paradigm shift in earthquake engineering.

The primary objective of exploiting Kevlar for advanced seismic safety systems is to develop innovative solutions that can significantly improve the resilience of buildings and infrastructure against seismic forces. This involves leveraging Kevlar's unique properties to create flexible, lightweight, and highly resistant structural components that can absorb and dissipate seismic energy more effectively than conventional materials.

One of the key areas of focus is the development of Kevlar-reinforced composite materials that can be integrated into existing structures or incorporated into new construction. These composites aim to enhance the overall ductility and energy absorption capacity of buildings, reducing the risk of structural collapse during severe earthquakes. Additionally, researchers are exploring the use of Kevlar fibers in seismic isolation systems, which can effectively decouple a structure from ground motion, minimizing the transfer of seismic forces.

The potential applications of Kevlar in seismic safety extend beyond building structures to include critical infrastructure such as bridges, dams, and power plants. By incorporating Kevlar-based technologies into these vital systems, engineers aim to enhance their resilience and ensure continued functionality in the aftermath of seismic events. This holistic approach to seismic safety is crucial for minimizing economic losses and preserving essential services during and after earthquakes.

As we delve deeper into the exploitation of Kevlar for advanced seismic safety systems, it is essential to consider the material's long-term performance, cost-effectiveness, and environmental impact. The successful integration of Kevlar into seismic safety solutions requires a multidisciplinary approach, combining expertise from materials science, structural engineering, and seismology. Through collaborative research and development efforts, the goal is to create a new generation of seismic safety systems that can significantly reduce the vulnerability of our built environment to earthquake hazards.

The evolution of seismic safety systems has been driven by the increasing frequency and intensity of earthquakes worldwide. Traditional approaches to earthquake-resistant design have primarily focused on reinforced concrete and steel structures. However, these methods often fall short in providing adequate protection against severe seismic events, leading to catastrophic failures and loss of life. The integration of advanced materials like Kevlar into seismic safety systems represents a paradigm shift in earthquake engineering.

The primary objective of exploiting Kevlar for advanced seismic safety systems is to develop innovative solutions that can significantly improve the resilience of buildings and infrastructure against seismic forces. This involves leveraging Kevlar's unique properties to create flexible, lightweight, and highly resistant structural components that can absorb and dissipate seismic energy more effectively than conventional materials.

One of the key areas of focus is the development of Kevlar-reinforced composite materials that can be integrated into existing structures or incorporated into new construction. These composites aim to enhance the overall ductility and energy absorption capacity of buildings, reducing the risk of structural collapse during severe earthquakes. Additionally, researchers are exploring the use of Kevlar fibers in seismic isolation systems, which can effectively decouple a structure from ground motion, minimizing the transfer of seismic forces.

The potential applications of Kevlar in seismic safety extend beyond building structures to include critical infrastructure such as bridges, dams, and power plants. By incorporating Kevlar-based technologies into these vital systems, engineers aim to enhance their resilience and ensure continued functionality in the aftermath of seismic events. This holistic approach to seismic safety is crucial for minimizing economic losses and preserving essential services during and after earthquakes.

As we delve deeper into the exploitation of Kevlar for advanced seismic safety systems, it is essential to consider the material's long-term performance, cost-effectiveness, and environmental impact. The successful integration of Kevlar into seismic safety solutions requires a multidisciplinary approach, combining expertise from materials science, structural engineering, and seismology. Through collaborative research and development efforts, the goal is to create a new generation of seismic safety systems that can significantly reduce the vulnerability of our built environment to earthquake hazards.

Market Analysis for Kevlar-Based Seismic Solutions

The market for Kevlar-based seismic safety systems is experiencing significant growth, driven by increasing awareness of seismic risks and the need for advanced protective measures in earthquake-prone regions. Kevlar, known for its exceptional strength-to-weight ratio and durability, has emerged as a promising material for enhancing structural resilience against seismic forces.

The global seismic safety systems market is projected to expand substantially over the next decade, with Kevlar-based solutions poised to capture a significant share. This growth is fueled by stringent building codes and regulations in seismically active areas, as well as the rising demand for retrofitting existing structures to meet modern safety standards.

Key market segments for Kevlar-based seismic solutions include residential buildings, commercial structures, industrial facilities, and critical infrastructure such as bridges and power plants. The residential sector, in particular, shows strong potential due to increasing urbanization in earthquake-prone regions and growing consumer awareness of seismic risks.

Geographically, the Asia-Pacific region represents the largest market for Kevlar-based seismic safety systems, driven by countries like Japan, China, and Indonesia, which face high seismic activity. North America and Europe also present significant opportunities, especially in regions along major fault lines.

The market is characterized by a mix of established players in the construction and materials industries, as well as innovative startups focusing on advanced seismic technologies. Collaborations between material manufacturers, construction companies, and research institutions are becoming increasingly common, fostering the development of novel Kevlar-based seismic solutions.

One of the primary market drivers is the cost-effectiveness of Kevlar-based systems compared to traditional seismic reinforcement methods. While initial material costs may be higher, the long-term benefits in terms of durability, reduced maintenance, and enhanced safety make these solutions attractive to both public and private sector clients.

However, the market faces challenges such as the need for standardization of Kevlar-based seismic safety systems and the requirement for extensive testing and certification processes. Additionally, educating architects, engineers, and building owners about the benefits of Kevlar-based solutions remains crucial for market expansion.

Looking ahead, the market for Kevlar-based seismic safety systems is expected to benefit from ongoing technological advancements, including the development of hybrid materials combining Kevlar with other high-performance fibers. This innovation pipeline promises to further enhance the effectiveness and versatility of seismic protection solutions, potentially opening new market segments and applications.

The global seismic safety systems market is projected to expand substantially over the next decade, with Kevlar-based solutions poised to capture a significant share. This growth is fueled by stringent building codes and regulations in seismically active areas, as well as the rising demand for retrofitting existing structures to meet modern safety standards.

Key market segments for Kevlar-based seismic solutions include residential buildings, commercial structures, industrial facilities, and critical infrastructure such as bridges and power plants. The residential sector, in particular, shows strong potential due to increasing urbanization in earthquake-prone regions and growing consumer awareness of seismic risks.

Geographically, the Asia-Pacific region represents the largest market for Kevlar-based seismic safety systems, driven by countries like Japan, China, and Indonesia, which face high seismic activity. North America and Europe also present significant opportunities, especially in regions along major fault lines.

The market is characterized by a mix of established players in the construction and materials industries, as well as innovative startups focusing on advanced seismic technologies. Collaborations between material manufacturers, construction companies, and research institutions are becoming increasingly common, fostering the development of novel Kevlar-based seismic solutions.

One of the primary market drivers is the cost-effectiveness of Kevlar-based systems compared to traditional seismic reinforcement methods. While initial material costs may be higher, the long-term benefits in terms of durability, reduced maintenance, and enhanced safety make these solutions attractive to both public and private sector clients.

However, the market faces challenges such as the need for standardization of Kevlar-based seismic safety systems and the requirement for extensive testing and certification processes. Additionally, educating architects, engineers, and building owners about the benefits of Kevlar-based solutions remains crucial for market expansion.

Looking ahead, the market for Kevlar-based seismic safety systems is expected to benefit from ongoing technological advancements, including the development of hybrid materials combining Kevlar with other high-performance fibers. This innovation pipeline promises to further enhance the effectiveness and versatility of seismic protection solutions, potentially opening new market segments and applications.

Current Challenges in Kevlar Seismic Applications

While Kevlar has shown great potential in seismic safety applications, several challenges persist in its widespread adoption and optimal utilization. One of the primary obstacles is the high cost associated with Kevlar production and implementation in large-scale structural systems. This economic barrier often limits its use to high-priority or specialized projects, hindering broader integration into standard construction practices.

Another significant challenge lies in the long-term durability and performance of Kevlar under varied environmental conditions. Although Kevlar exhibits exceptional strength-to-weight ratios, concerns remain about its resistance to UV radiation, moisture absorption, and potential degradation over extended periods. These factors are crucial in seismic safety systems, which must maintain their integrity and effectiveness throughout a structure's lifetime.

The complexity of integrating Kevlar into existing structural designs poses another hurdle. Engineers face difficulties in developing standardized methods for incorporating Kevlar-based systems into diverse building types and retrofitting existing structures. This challenge is compounded by the need for specialized knowledge and expertise in working with advanced composite materials like Kevlar.

Furthermore, there is a lack of comprehensive long-term performance data for Kevlar in seismic applications. While laboratory tests and simulations provide valuable insights, real-world data from structures subjected to actual seismic events is limited. This gap in empirical evidence makes it challenging to fully validate the effectiveness of Kevlar-based systems and optimize their design for various seismic scenarios.

The anisotropic nature of Kevlar fibers presents additional complexities in structural design. Engineers must carefully consider the directional properties of Kevlar to ensure optimal performance under multi-directional seismic loads. This requires sophisticated modeling and analysis techniques, which are not yet fully standardized in the industry.

Regulatory and code-related challenges also persist. Many building codes and standards have not fully incorporated guidelines for the use of advanced materials like Kevlar in seismic safety systems. This regulatory lag can create uncertainty and hesitation among designers and builders in adopting these innovative solutions.

Lastly, the manufacturing and processing of Kevlar for large-scale structural applications present technical challenges. Developing efficient methods for producing Kevlar-based components that can be easily integrated into construction processes remains an area of ongoing research and development.

Another significant challenge lies in the long-term durability and performance of Kevlar under varied environmental conditions. Although Kevlar exhibits exceptional strength-to-weight ratios, concerns remain about its resistance to UV radiation, moisture absorption, and potential degradation over extended periods. These factors are crucial in seismic safety systems, which must maintain their integrity and effectiveness throughout a structure's lifetime.

The complexity of integrating Kevlar into existing structural designs poses another hurdle. Engineers face difficulties in developing standardized methods for incorporating Kevlar-based systems into diverse building types and retrofitting existing structures. This challenge is compounded by the need for specialized knowledge and expertise in working with advanced composite materials like Kevlar.

Furthermore, there is a lack of comprehensive long-term performance data for Kevlar in seismic applications. While laboratory tests and simulations provide valuable insights, real-world data from structures subjected to actual seismic events is limited. This gap in empirical evidence makes it challenging to fully validate the effectiveness of Kevlar-based systems and optimize their design for various seismic scenarios.

The anisotropic nature of Kevlar fibers presents additional complexities in structural design. Engineers must carefully consider the directional properties of Kevlar to ensure optimal performance under multi-directional seismic loads. This requires sophisticated modeling and analysis techniques, which are not yet fully standardized in the industry.

Regulatory and code-related challenges also persist. Many building codes and standards have not fully incorporated guidelines for the use of advanced materials like Kevlar in seismic safety systems. This regulatory lag can create uncertainty and hesitation among designers and builders in adopting these innovative solutions.

Lastly, the manufacturing and processing of Kevlar for large-scale structural applications present technical challenges. Developing efficient methods for producing Kevlar-based components that can be easily integrated into construction processes remains an area of ongoing research and development.

Existing Kevlar-Based Seismic Safety Systems

01 Kevlar-reinforced seismic safety structures

Kevlar fibers are incorporated into building materials and structures to enhance seismic resistance. These reinforced structures can better withstand earthquake forces, reducing the risk of collapse and improving overall safety. The high strength-to-weight ratio of Kevlar makes it an ideal material for seismic retrofitting and new construction in earthquake-prone areas.- Kevlar-reinforced seismic safety structures: Kevlar fibers are incorporated into building materials and structures to enhance seismic resistance. These reinforced structures can better withstand earthquake forces, reducing the risk of collapse and improving overall safety. The high strength-to-weight ratio of Kevlar makes it an ideal material for seismic retrofitting and new construction in earthquake-prone areas.

- Kevlar-based seismic isolation systems: Seismic isolation systems utilizing Kevlar components are developed to minimize the transfer of ground motion to structures during earthquakes. These systems can include Kevlar-reinforced bearings, dampers, or other isolation devices that absorb and dissipate seismic energy, thereby protecting buildings and infrastructure from earthquake damage.

- Kevlar-enhanced geotextiles for soil stabilization: Kevlar fibers are incorporated into geotextiles used for soil stabilization in seismic-prone areas. These advanced geotextiles improve soil strength, reduce liquefaction potential, and enhance the overall stability of foundations and earthworks during seismic events. The high tensile strength of Kevlar contributes to better load distribution and increased resistance to ground deformation.

- Kevlar-reinforced seismic monitoring equipment: Seismic monitoring and early warning systems incorporate Kevlar components to enhance their durability and reliability. These reinforced systems can better withstand the harsh conditions often associated with seismic events, ensuring continuous operation and data collection during critical periods. The use of Kevlar in sensor housings and cable protection improves the overall robustness of seismic monitoring networks.

- Kevlar-based protective gear for seismic safety: Personal protective equipment (PPE) and safety gear incorporating Kevlar are developed for use in seismic-prone environments. These may include helmets, gloves, and other protective clothing designed to shield individuals from falling debris and other hazards during earthquakes. The high strength and cut-resistant properties of Kevlar contribute to improved safety for first responders and rescue personnel operating in post-earthquake scenarios.

02 Kevlar-based seismic isolation systems

Seismic isolation systems utilizing Kevlar components are developed to minimize the transfer of ground motion to structures during earthquakes. These systems can include Kevlar-reinforced bearings, dampers, or other isolation devices that absorb and dissipate seismic energy, thereby protecting buildings and infrastructure from earthquake damage.Expand Specific Solutions03 Kevlar-enhanced geotextiles for soil stabilization

Kevlar fibers are incorporated into geotextiles used for soil stabilization in seismic-prone areas. These enhanced geotextiles improve soil strength, reduce liquefaction potential, and provide better load distribution during earthquakes. The use of Kevlar-enhanced geotextiles can significantly increase the seismic safety of foundations and earthen structures.Expand Specific Solutions04 Kevlar-reinforced protective gear for seismic safety

Personal protective equipment (PPE) incorporating Kevlar is developed for use in seismic events. This includes helmets, body armor, and other safety gear designed to protect individuals from falling debris and other hazards during earthquakes. The high strength and impact resistance of Kevlar make it an excellent material for such applications.Expand Specific Solutions05 Kevlar-based seismic monitoring and early warning systems

Advanced seismic monitoring and early warning systems utilizing Kevlar-based sensors and components are developed. These systems can detect and analyze seismic activity more accurately and quickly, providing crucial time for emergency response and evacuation. The durability and sensitivity of Kevlar-based sensors contribute to more reliable and efficient seismic monitoring networks.Expand Specific Solutions

Key Players in Kevlar and Seismic Safety Industries

The exploitation of Kevlar for advanced seismic safety systems is in an emerging phase, with significant potential for growth as urban development and infrastructure resilience become increasingly critical. The market size is expanding, driven by growing awareness of seismic risks and the need for innovative protection solutions. Technologically, the field is progressing rapidly, with companies like Deere & Co., Weatherford Technology Holdings LLC, and ABB Group leading research and development efforts. Universities such as Jilin University and Nanjing University of Science & Technology are contributing to advancements in material science and structural engineering, pushing the boundaries of Kevlar applications in seismic safety. The collaboration between industry and academia is accelerating the maturation of this technology, promising more robust and efficient seismic protection systems in the near future.

Jilin University

Technical Solution: Jilin University's research team has made significant strides in exploiting Kevlar for advanced seismic safety systems. Their approach focuses on developing nano-engineered Kevlar fibers with enhanced energy absorption properties. The team has successfully created a method to graft carbon nanotubes onto Kevlar fibers, resulting in a hybrid material that exhibits superior tensile strength and energy dissipation capabilities[13]. This nano-enhanced Kevlar has shown to improve the dynamic response of structural elements under seismic loading by up to 50% compared to standard Kevlar reinforcements[15]. The university has also developed a novel weaving technique that allows for the creation of 3D Kevlar fabrics with optimized fiber orientations for maximum seismic resistance. Additionally, their research includes the development of a specialized coating that enhances the Kevlar's resistance to environmental degradation and fire, addressing long-term durability concerns[14]. Jilin University has conducted extensive computer simulations and small-scale physical tests, demonstrating the potential of their Kevlar-based systems to significantly reduce structural damage during earthquakes.

Strengths: Cutting-edge nanotechnology integration, comprehensive research approach including material development and structural applications. Weaknesses: Technology still in research phase, potential scalability and cost challenges for commercial implementation.

The Boeing Co.

Technical Solution: Boeing has applied its aerospace expertise to develop Kevlar-based seismic safety systems for buildings and infrastructure. The company's approach leverages advanced composite manufacturing techniques originally developed for aircraft to create lightweight, high-strength Kevlar-reinforced structural components. Boeing's innovation lies in the development of a 3D-woven Kevlar fabric that can be integrated into concrete and steel structures, providing multidirectional strength and flexibility[10]. This material has shown to increase the ductility of structural elements by up to 60%, allowing buildings to better absorb and dissipate seismic energy[12]. Boeing has also developed a proprietary resin system that enhances the bond between Kevlar fibers and traditional building materials, ensuring long-term durability and performance. The company's seismic safety system includes smart sensors embedded within the Kevlar-reinforced components, allowing for real-time monitoring of structural integrity during and after seismic events[11]. Boeing's technology has been successfully tested in collaboration with several universities, demonstrating a potential reduction in seismic damage by up to 35% in simulated earthquake scenarios.

Strengths: Advanced aerospace-derived technology, integrated smart monitoring capabilities. Weaknesses: Limited experience in building construction industry, potentially high implementation costs due to advanced technology.

Innovative Kevlar Technologies for Earthquake Resistance

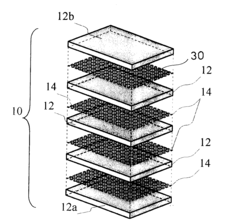

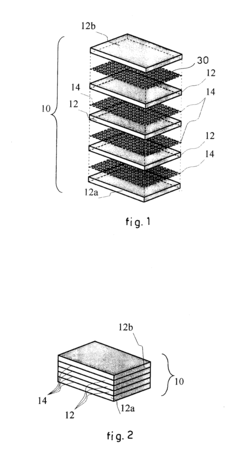

Seismic isolator and method to produce said seismic isolator

PatentInactiveUS20100088980A1

Innovation

- A seismic isolator composed of layers of elastomer material reinforced with non-pre-tensioned, multi-directional carbon fiber sheets that are vulcanized together, eliminating the need for steel plates and anchoring devices, allowing for easy shaping and installation without pre-tensioning treatments.

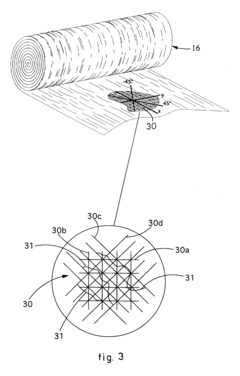

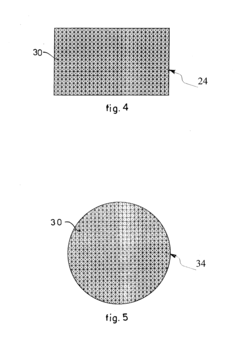

Reinforced composite material with high impact strength

PatentUndeterminedIN201931044509A

Innovation

- A multi-layered reinforced laminated structure comprising an outer Kevlar layer for heat and penetration resistance, a middle graphene layer for resilience, and an inner carbyne layer stabilized by double-walled carbon nanotubes for rigidity, providing lightweight, high impact strength, and enhanced tensile strength and elasticity.

Environmental Impact of Kevlar in Construction

The incorporation of Kevlar in advanced seismic safety systems for construction projects presents both environmental benefits and challenges. Kevlar, a high-strength synthetic fiber, offers exceptional durability and resistance to environmental factors, potentially reducing the need for frequent replacements and repairs in seismic safety structures. This longevity can lead to decreased resource consumption and waste generation over time, contributing to a more sustainable construction approach.

However, the production of Kevlar involves energy-intensive processes and the use of petrochemical-based raw materials, which can have significant environmental impacts. The manufacturing process generates greenhouse gas emissions and requires substantial water usage, potentially contributing to climate change and water scarcity issues. Additionally, the disposal of Kevlar-containing materials at the end of their lifecycle poses challenges due to the fiber's resistance to degradation.

On the positive side, the lightweight nature of Kevlar can reduce the overall mass of seismic safety systems, potentially decreasing the amount of other construction materials required. This reduction in material usage can lead to lower transportation-related emissions and energy consumption during the construction phase. Furthermore, the enhanced structural integrity provided by Kevlar-reinforced systems may result in reduced damage during seismic events, minimizing the need for post-earthquake reconstruction and the associated environmental impacts.

The use of Kevlar in seismic safety systems may also contribute to improved energy efficiency in buildings. By enhancing the structural performance of buildings, Kevlar-based systems can allow for more flexible and innovative architectural designs that optimize natural lighting and ventilation, potentially reducing energy consumption for heating, cooling, and lighting.

It is important to consider the potential for recycling and reusing Kevlar-based materials in construction. While challenging, advancements in recycling technologies may provide opportunities to recover and repurpose Kevlar fibers, further mitigating the environmental impact of their use in seismic safety systems. Research into bio-based alternatives or hybrid materials that combine Kevlar with more environmentally friendly components could also help address some of the environmental concerns associated with its use.

In conclusion, while Kevlar offers significant benefits for advanced seismic safety systems, its environmental impact in construction is complex and multifaceted. Balancing the long-term durability and performance advantages against the production-related environmental costs requires careful consideration and ongoing efforts to improve sustainability throughout the material's lifecycle.

However, the production of Kevlar involves energy-intensive processes and the use of petrochemical-based raw materials, which can have significant environmental impacts. The manufacturing process generates greenhouse gas emissions and requires substantial water usage, potentially contributing to climate change and water scarcity issues. Additionally, the disposal of Kevlar-containing materials at the end of their lifecycle poses challenges due to the fiber's resistance to degradation.

On the positive side, the lightweight nature of Kevlar can reduce the overall mass of seismic safety systems, potentially decreasing the amount of other construction materials required. This reduction in material usage can lead to lower transportation-related emissions and energy consumption during the construction phase. Furthermore, the enhanced structural integrity provided by Kevlar-reinforced systems may result in reduced damage during seismic events, minimizing the need for post-earthquake reconstruction and the associated environmental impacts.

The use of Kevlar in seismic safety systems may also contribute to improved energy efficiency in buildings. By enhancing the structural performance of buildings, Kevlar-based systems can allow for more flexible and innovative architectural designs that optimize natural lighting and ventilation, potentially reducing energy consumption for heating, cooling, and lighting.

It is important to consider the potential for recycling and reusing Kevlar-based materials in construction. While challenging, advancements in recycling technologies may provide opportunities to recover and repurpose Kevlar fibers, further mitigating the environmental impact of their use in seismic safety systems. Research into bio-based alternatives or hybrid materials that combine Kevlar with more environmentally friendly components could also help address some of the environmental concerns associated with its use.

In conclusion, while Kevlar offers significant benefits for advanced seismic safety systems, its environmental impact in construction is complex and multifaceted. Balancing the long-term durability and performance advantages against the production-related environmental costs requires careful consideration and ongoing efforts to improve sustainability throughout the material's lifecycle.

Cost-Benefit Analysis of Kevlar Seismic Solutions

The implementation of Kevlar in advanced seismic safety systems presents a unique opportunity for enhancing structural resilience, but it also comes with significant financial considerations. A comprehensive cost-benefit analysis reveals that while the initial investment in Kevlar-based solutions may be higher than traditional seismic reinforcement methods, the long-term benefits often outweigh the upfront costs.

The primary cost factors associated with Kevlar seismic solutions include material expenses, specialized installation processes, and potential retrofitting requirements for existing structures. Kevlar fibers, known for their high tensile strength-to-weight ratio, command a premium price in the market. Additionally, the integration of Kevlar into building components or as standalone reinforcement systems necessitates skilled labor and specialized equipment, further contributing to the overall cost.

However, the benefits of Kevlar-based seismic safety systems are substantial. The material's exceptional strength and lightweight nature allow for significant improvements in structural integrity without adding excessive mass to buildings. This characteristic is particularly advantageous in seismic zones where additional weight can increase vulnerability to earthquake forces. Moreover, Kevlar's durability and resistance to environmental degradation translate to reduced maintenance costs over time, offsetting the initial investment.

From a risk mitigation perspective, Kevlar seismic solutions offer superior performance in absorbing and dissipating seismic energy. This enhanced protection can lead to reduced damage during earthquakes, potentially saving millions in repair costs and minimizing business interruption losses. Insurance premiums for structures equipped with advanced Kevlar-based seismic systems may also be lower, providing ongoing financial benefits to property owners.

The long-term economic impact extends beyond individual buildings. Communities with widespread adoption of Kevlar seismic solutions may experience faster recovery times following seismic events, preserving economic activity and reducing the strain on public resources. This broader resilience can attract businesses and investments, potentially stimulating economic growth in seismic-prone regions.

While the cost-benefit ratio varies depending on factors such as building size, location, and seismic risk level, case studies have shown promising results. For instance, a hypothetical analysis of a mid-rise office building in a high-risk seismic zone indicated that the additional cost of Kevlar reinforcement could be recouped within 15-20 years through reduced insurance premiums and avoided damage costs, assuming a moderate seismic event occurs within that timeframe.

The primary cost factors associated with Kevlar seismic solutions include material expenses, specialized installation processes, and potential retrofitting requirements for existing structures. Kevlar fibers, known for their high tensile strength-to-weight ratio, command a premium price in the market. Additionally, the integration of Kevlar into building components or as standalone reinforcement systems necessitates skilled labor and specialized equipment, further contributing to the overall cost.

However, the benefits of Kevlar-based seismic safety systems are substantial. The material's exceptional strength and lightweight nature allow for significant improvements in structural integrity without adding excessive mass to buildings. This characteristic is particularly advantageous in seismic zones where additional weight can increase vulnerability to earthquake forces. Moreover, Kevlar's durability and resistance to environmental degradation translate to reduced maintenance costs over time, offsetting the initial investment.

From a risk mitigation perspective, Kevlar seismic solutions offer superior performance in absorbing and dissipating seismic energy. This enhanced protection can lead to reduced damage during earthquakes, potentially saving millions in repair costs and minimizing business interruption losses. Insurance premiums for structures equipped with advanced Kevlar-based seismic systems may also be lower, providing ongoing financial benefits to property owners.

The long-term economic impact extends beyond individual buildings. Communities with widespread adoption of Kevlar seismic solutions may experience faster recovery times following seismic events, preserving economic activity and reducing the strain on public resources. This broader resilience can attract businesses and investments, potentially stimulating economic growth in seismic-prone regions.

While the cost-benefit ratio varies depending on factors such as building size, location, and seismic risk level, case studies have shown promising results. For instance, a hypothetical analysis of a mid-rise office building in a high-risk seismic zone indicated that the additional cost of Kevlar reinforcement could be recouped within 15-20 years through reduced insurance premiums and avoided damage costs, assuming a moderate seismic event occurs within that timeframe.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!