How to Integrate Kevlar with Advanced Carbon Fiber Solutions?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar-Carbon Fiber Integration Background and Objectives

The integration of Kevlar with advanced carbon fiber solutions represents a significant leap in materials science, combining the strengths of two revolutionary materials to create composites with exceptional properties. This technological fusion aims to address the growing demand for lightweight, high-strength materials in various industries, including aerospace, automotive, and defense.

Kevlar, a para-aramid synthetic fiber developed by DuPont in the 1960s, is renowned for its high tensile strength-to-weight ratio and heat resistance. Carbon fiber, on the other hand, has been at the forefront of composite materials since the 1970s, offering unparalleled strength and stiffness while maintaining a low weight profile. The convergence of these two materials seeks to leverage their complementary properties, potentially revolutionizing the field of advanced composites.

The primary objective of integrating Kevlar with carbon fiber is to create a hybrid material that combines the best attributes of both components. This integration aims to enhance impact resistance, improve fatigue performance, and increase overall durability while maintaining the lightweight characteristics that make both materials so valuable. By doing so, researchers and engineers hope to overcome some of the limitations associated with using either material independently.

The evolution of this technology can be traced back to the early 2000s when initial experiments in hybrid composites began. Since then, the field has seen steady progress, driven by advancements in manufacturing processes, a deeper understanding of material interfaces, and the development of novel binding agents. The current technological landscape is characterized by ongoing research into optimizing the integration process, exploring various layering techniques, and investigating the potential of nanocomposites.

As we look towards the future, the integration of Kevlar and carbon fiber presents numerous opportunities for innovation. Key areas of focus include improving the bonding between the two materials at the molecular level, developing more efficient and cost-effective manufacturing methods, and expanding the range of applications for these hybrid composites. The ultimate goal is to create a new class of materials that can meet the increasingly demanding requirements of modern engineering challenges.

This technological pursuit is not without its challenges. Researchers must overcome issues related to interfacial adhesion, stress distribution, and long-term performance under various environmental conditions. Additionally, there is a need to develop standardized testing and quality control methods specific to these hybrid materials to ensure consistency and reliability in their production and application.

Kevlar, a para-aramid synthetic fiber developed by DuPont in the 1960s, is renowned for its high tensile strength-to-weight ratio and heat resistance. Carbon fiber, on the other hand, has been at the forefront of composite materials since the 1970s, offering unparalleled strength and stiffness while maintaining a low weight profile. The convergence of these two materials seeks to leverage their complementary properties, potentially revolutionizing the field of advanced composites.

The primary objective of integrating Kevlar with carbon fiber is to create a hybrid material that combines the best attributes of both components. This integration aims to enhance impact resistance, improve fatigue performance, and increase overall durability while maintaining the lightweight characteristics that make both materials so valuable. By doing so, researchers and engineers hope to overcome some of the limitations associated with using either material independently.

The evolution of this technology can be traced back to the early 2000s when initial experiments in hybrid composites began. Since then, the field has seen steady progress, driven by advancements in manufacturing processes, a deeper understanding of material interfaces, and the development of novel binding agents. The current technological landscape is characterized by ongoing research into optimizing the integration process, exploring various layering techniques, and investigating the potential of nanocomposites.

As we look towards the future, the integration of Kevlar and carbon fiber presents numerous opportunities for innovation. Key areas of focus include improving the bonding between the two materials at the molecular level, developing more efficient and cost-effective manufacturing methods, and expanding the range of applications for these hybrid composites. The ultimate goal is to create a new class of materials that can meet the increasingly demanding requirements of modern engineering challenges.

This technological pursuit is not without its challenges. Researchers must overcome issues related to interfacial adhesion, stress distribution, and long-term performance under various environmental conditions. Additionally, there is a need to develop standardized testing and quality control methods specific to these hybrid materials to ensure consistency and reliability in their production and application.

Market Analysis for Hybrid Composite Materials

The market for hybrid composite materials, particularly those integrating Kevlar with advanced carbon fiber solutions, is experiencing significant growth and transformation. This trend is driven by the increasing demand for lightweight, high-strength materials across various industries, including aerospace, automotive, defense, and sports equipment manufacturing.

In the aerospace sector, the market for hybrid composites is expanding rapidly due to the need for fuel-efficient aircraft. These materials offer an excellent strength-to-weight ratio, enabling manufacturers to reduce overall aircraft weight while maintaining structural integrity. The automotive industry is also adopting hybrid composites to meet stringent fuel efficiency standards and enhance vehicle performance.

The defense sector represents another key market for Kevlar-carbon fiber hybrid composites. These materials are crucial in developing advanced body armor, vehicle protection systems, and lightweight military equipment. The superior impact resistance of Kevlar combined with the high strength and stiffness of carbon fibers makes these hybrids ideal for protective applications.

In the sports and recreation industry, hybrid composites are gaining traction in the production of high-performance equipment such as bicycles, tennis rackets, and protective gear. The market in this sector is driven by consumer demand for products that offer enhanced durability, performance, and comfort.

The global market for hybrid composites is geographically diverse, with North America, Europe, and Asia-Pacific emerging as key regions. North America leads in terms of technological advancements and adoption, particularly in aerospace and defense applications. Europe follows closely, with a strong focus on automotive and renewable energy sectors. The Asia-Pacific region is experiencing rapid growth, driven by increasing industrialization and infrastructure development.

Market analysts project a compound annual growth rate (CAGR) for the hybrid composite market that outpaces traditional materials. This growth is attributed to ongoing research and development efforts to improve material properties, reduce production costs, and expand applications. The integration of Kevlar with advanced carbon fiber solutions is expected to play a significant role in this market expansion.

However, challenges remain in the widespread adoption of these materials. High production costs, complex manufacturing processes, and the need for specialized equipment can limit market penetration, particularly in price-sensitive industries. Additionally, the recyclability and end-of-life disposal of hybrid composites present environmental concerns that need to be addressed to ensure sustainable market growth.

Despite these challenges, the market outlook for hybrid composites remains positive. Ongoing technological advancements, increasing awareness of the benefits of lightweight materials, and stringent regulations promoting fuel efficiency and safety are expected to drive continued market expansion in the coming years.

In the aerospace sector, the market for hybrid composites is expanding rapidly due to the need for fuel-efficient aircraft. These materials offer an excellent strength-to-weight ratio, enabling manufacturers to reduce overall aircraft weight while maintaining structural integrity. The automotive industry is also adopting hybrid composites to meet stringent fuel efficiency standards and enhance vehicle performance.

The defense sector represents another key market for Kevlar-carbon fiber hybrid composites. These materials are crucial in developing advanced body armor, vehicle protection systems, and lightweight military equipment. The superior impact resistance of Kevlar combined with the high strength and stiffness of carbon fibers makes these hybrids ideal for protective applications.

In the sports and recreation industry, hybrid composites are gaining traction in the production of high-performance equipment such as bicycles, tennis rackets, and protective gear. The market in this sector is driven by consumer demand for products that offer enhanced durability, performance, and comfort.

The global market for hybrid composites is geographically diverse, with North America, Europe, and Asia-Pacific emerging as key regions. North America leads in terms of technological advancements and adoption, particularly in aerospace and defense applications. Europe follows closely, with a strong focus on automotive and renewable energy sectors. The Asia-Pacific region is experiencing rapid growth, driven by increasing industrialization and infrastructure development.

Market analysts project a compound annual growth rate (CAGR) for the hybrid composite market that outpaces traditional materials. This growth is attributed to ongoing research and development efforts to improve material properties, reduce production costs, and expand applications. The integration of Kevlar with advanced carbon fiber solutions is expected to play a significant role in this market expansion.

However, challenges remain in the widespread adoption of these materials. High production costs, complex manufacturing processes, and the need for specialized equipment can limit market penetration, particularly in price-sensitive industries. Additionally, the recyclability and end-of-life disposal of hybrid composites present environmental concerns that need to be addressed to ensure sustainable market growth.

Despite these challenges, the market outlook for hybrid composites remains positive. Ongoing technological advancements, increasing awareness of the benefits of lightweight materials, and stringent regulations promoting fuel efficiency and safety are expected to drive continued market expansion in the coming years.

Current Challenges in Kevlar-Carbon Fiber Hybridization

The integration of Kevlar with advanced carbon fiber solutions presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving optimal bonding between Kevlar and carbon fiber materials. These two substances have inherently different chemical structures and surface properties, making it difficult to create a strong, durable interface between them without compromising the individual strengths of each material.

Another major challenge lies in maintaining the desired mechanical properties of the hybrid material. While both Kevlar and carbon fiber are known for their high strength-to-weight ratios, they exhibit different behaviors under stress. Kevlar is highly resistant to impact and has excellent tensile strength, while carbon fiber excels in stiffness and compressive strength. Balancing these properties in a hybrid material to achieve the best of both worlds remains a complex task.

The manufacturing process itself poses significant hurdles. Traditional methods used for producing carbon fiber composites may not be directly applicable to Kevlar-carbon fiber hybrids. Developing new manufacturing techniques that can effectively combine these materials while ensuring consistent quality and performance across large-scale production is an ongoing challenge.

Weight optimization is another critical issue. While both materials are lightweight, the addition of Kevlar to carbon fiber composites can potentially increase the overall weight of the final product. Engineers must find ways to integrate Kevlar strategically to enhance specific properties without significantly compromising the weight advantage that makes carbon fiber so attractive in various applications.

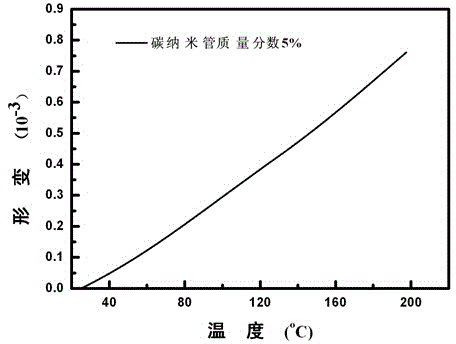

Thermal management presents yet another challenge. Carbon fiber and Kevlar have different thermal expansion coefficients, which can lead to internal stresses and potential delamination in hybrid structures when exposed to temperature fluctuations. Addressing this issue is crucial for applications in aerospace and automotive industries where materials are subjected to extreme temperature variations.

Cost-effectiveness remains a significant barrier to widespread adoption of Kevlar-carbon fiber hybrids. Both materials are relatively expensive, and the additional processing required to integrate them effectively can further drive up costs. Developing economically viable production methods that can justify the enhanced performance of these hybrid materials is an ongoing challenge for manufacturers.

Lastly, ensuring long-term durability and performance of Kevlar-carbon fiber hybrids under various environmental conditions is a complex task. These materials may be exposed to UV radiation, moisture, chemicals, and other degrading factors in real-world applications. Creating hybrid solutions that maintain their superior properties over extended periods and under diverse conditions is crucial for their successful implementation in high-performance applications.

Another major challenge lies in maintaining the desired mechanical properties of the hybrid material. While both Kevlar and carbon fiber are known for their high strength-to-weight ratios, they exhibit different behaviors under stress. Kevlar is highly resistant to impact and has excellent tensile strength, while carbon fiber excels in stiffness and compressive strength. Balancing these properties in a hybrid material to achieve the best of both worlds remains a complex task.

The manufacturing process itself poses significant hurdles. Traditional methods used for producing carbon fiber composites may not be directly applicable to Kevlar-carbon fiber hybrids. Developing new manufacturing techniques that can effectively combine these materials while ensuring consistent quality and performance across large-scale production is an ongoing challenge.

Weight optimization is another critical issue. While both materials are lightweight, the addition of Kevlar to carbon fiber composites can potentially increase the overall weight of the final product. Engineers must find ways to integrate Kevlar strategically to enhance specific properties without significantly compromising the weight advantage that makes carbon fiber so attractive in various applications.

Thermal management presents yet another challenge. Carbon fiber and Kevlar have different thermal expansion coefficients, which can lead to internal stresses and potential delamination in hybrid structures when exposed to temperature fluctuations. Addressing this issue is crucial for applications in aerospace and automotive industries where materials are subjected to extreme temperature variations.

Cost-effectiveness remains a significant barrier to widespread adoption of Kevlar-carbon fiber hybrids. Both materials are relatively expensive, and the additional processing required to integrate them effectively can further drive up costs. Developing economically viable production methods that can justify the enhanced performance of these hybrid materials is an ongoing challenge for manufacturers.

Lastly, ensuring long-term durability and performance of Kevlar-carbon fiber hybrids under various environmental conditions is a complex task. These materials may be exposed to UV radiation, moisture, chemicals, and other degrading factors in real-world applications. Creating hybrid solutions that maintain their superior properties over extended periods and under diverse conditions is crucial for their successful implementation in high-performance applications.

Existing Kevlar-Carbon Fiber Integration Methods

01 Composite materials combining Kevlar and carbon fiber

Kevlar and carbon fiber are often combined to create high-performance composite materials. These composites leverage the strength and lightweight properties of both materials, resulting in products with enhanced durability, impact resistance, and reduced weight. Such composites find applications in aerospace, automotive, and sporting goods industries.- Composite materials combining Kevlar and carbon fiber: Kevlar and carbon fiber are often combined to create high-performance composite materials. These composites leverage the strength and lightweight properties of both materials, resulting in products with enhanced durability, impact resistance, and weight reduction. Such composites find applications in aerospace, automotive, and sporting goods industries.

- Protective gear and equipment using Kevlar and carbon fiber: Kevlar and carbon fiber are utilized in the production of various protective gear and equipment. This includes body armor, helmets, and impact-resistant components for sports and safety applications. The combination of these materials provides excellent protection against impacts, cuts, and ballistic threats while maintaining flexibility and comfort.

- Reinforcement of structures with Kevlar and carbon fiber: Kevlar and carbon fiber are employed to reinforce various structures, enhancing their strength and reducing weight. This technique is used in construction, civil engineering, and infrastructure projects. The reinforcement can be applied to concrete structures, bridges, and buildings to improve their load-bearing capacity and resistance to environmental factors.

- Manufacturing processes for Kevlar and carbon fiber products: Specialized manufacturing processes are developed for producing Kevlar and carbon fiber products. These processes include advanced weaving techniques, resin infusion methods, and automated layup systems. The manufacturing techniques aim to optimize the properties of the final product while ensuring cost-effectiveness and scalability in production.

- Innovative applications of Kevlar and carbon fiber in emerging technologies: Kevlar and carbon fiber are being explored for use in emerging technologies and novel applications. This includes their integration into smart textiles, wearable electronics, and energy storage devices. The unique properties of these materials are leveraged to create innovative solutions in fields such as renewable energy, space exploration, and advanced transportation systems.

02 Protective gear and equipment using Kevlar and carbon fiber

Kevlar and carbon fiber are utilized in the production of protective gear and equipment. These materials are incorporated into items such as helmets, body armor, and sports equipment to provide superior protection against impacts and penetration while maintaining lightweight characteristics.Expand Specific Solutions03 Reinforcement of structures with Kevlar and carbon fiber

Kevlar and carbon fiber are employed to reinforce various structures, including buildings, bridges, and industrial components. These materials enhance the structural integrity, load-bearing capacity, and resistance to environmental factors, while minimizing additional weight to the reinforced structures.Expand Specific Solutions04 Manufacturing processes for Kevlar and carbon fiber products

Specialized manufacturing processes are developed for producing Kevlar and carbon fiber products. These processes may include advanced weaving techniques, resin infusion methods, and precision molding to create complex shapes and optimize the performance characteristics of the final products.Expand Specific Solutions05 Innovative applications of Kevlar and carbon fiber in emerging technologies

Kevlar and carbon fiber are being explored for use in emerging technologies and novel applications. These may include energy storage devices, advanced sensors, and next-generation transportation systems, leveraging the unique properties of these materials to drive innovation in various fields.Expand Specific Solutions

Key Players in Advanced Composite Industry

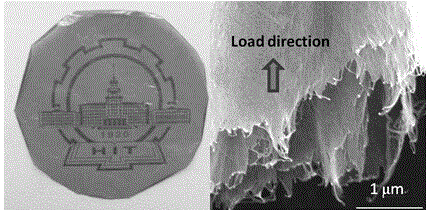

The integration of Kevlar with advanced carbon fiber solutions is at a critical juncture in the materials science industry. This technology is in a mature development stage, with significant market potential due to the growing demand for high-performance composites in aerospace, automotive, and defense sectors. The global market for these advanced materials is expanding rapidly, driven by the need for lightweight, strong, and durable materials. Key players in this field include academic institutions like Harbin Institute of Technology and Donghua University, which are conducting cutting-edge research, as well as industry leaders such as Toray Industries and Resonac Holdings Corp. These companies are investing heavily in R&D to develop innovative hybrid materials that combine the strengths of Kevlar and carbon fibers, aiming to create next-generation composites with enhanced properties and applications.

Airbus Operations GmbH

Technical Solution: Airbus has developed a sophisticated approach to integrating Kevlar with advanced carbon fiber solutions for aerospace applications. Their method involves a multi-layer composite structure that strategically incorporates Kevlar layers within a predominantly carbon fiber matrix[1]. This integration is achieved through an advanced resin infusion process that ensures optimal bonding between the different fiber types. Airbus's technique includes the use of 3D woven preforms that combine Kevlar and carbon fibers in specific orientations to enhance impact resistance and damage tolerance[2]. The company has also developed specialized automated layup systems to precisely control the placement of Kevlar and carbon fiber layers, ensuring consistency and reducing manufacturing time[3]. This integrated composite system is designed to meet the stringent weight and performance requirements of modern aircraft structures while improving safety and durability.

Strengths: Excellent weight-to-strength ratio, enhanced impact resistance, and improved damage tolerance for aerospace applications. Weaknesses: High development and production costs, complex certification process for aviation use.

Toray Industries, Inc.

Technical Solution: Toray has developed an innovative approach to integrate Kevlar with advanced carbon fiber solutions. Their method involves a hybrid composite system that combines Kevlar aramid fibers with high-performance carbon fibers[1]. This integration is achieved through a proprietary resin matrix that allows for optimal bonding between the two materials. The resulting composite exhibits enhanced impact resistance and improved fatigue performance compared to traditional carbon fiber composites[2]. Toray's process includes a specialized layup technique that alternates layers of Kevlar and carbon fiber prepregs, followed by a carefully controlled curing process to ensure uniform integration[3]. This method allows for tailored mechanical properties, balancing the high strength and stiffness of carbon fibers with the excellent toughness and damage tolerance of Kevlar.

Strengths: Superior impact resistance, improved fatigue life, and customizable mechanical properties. Weaknesses: Potentially higher production costs and more complex manufacturing process compared to single-material composites.

Innovative Approaches in Hybrid Composite Design

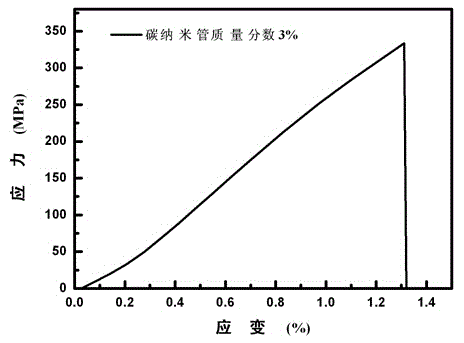

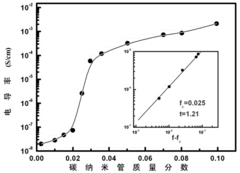

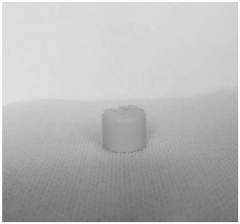

Preparation method of carbon nano tube-Kevlar nanofiber composite film

PatentInactiveCN104559175A

Innovation

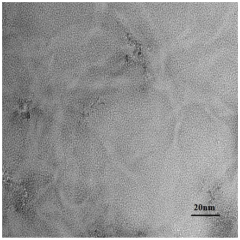

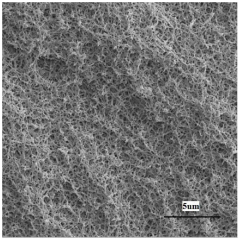

- Using deprotonation treatment and layer-by-layer self-assembly methods, combined with vacuum filtration-assisted layer-by-layer assembly, a carbon nanotube-Kevlar nanofiber composite film was prepared, which improved the dispersion and dispersion of carbon nanotubes in Kevlar fibers. Mechanical, electrical and thermal properties of materials.

Preparation method of polyimide/aramid nanofiber multifunctional composite heat insulation aerogel

PatentActiveCN114989479A

Innovation

- Using the preparation method of polyimide/aramid nanofiber multifunctional composite thermal insulation aerogel, Kevlar49 is processed through liquid nitrogen embrittlement, grinding into chips, and freeze-drying processes to form aramid nanofibers with high chemical activity on the surface. , and mixed with polyimide to form a three-dimensional network structure with excellent mechanical properties through hydrogen bonding, combined with trimethylethoxysilane modification to improve hydrophobic properties.

Environmental Impact of Hybrid Composites

The integration of Kevlar with advanced carbon fiber solutions to create hybrid composites has significant environmental implications that warrant careful consideration. These hybrid materials offer potential benefits in terms of reduced weight and enhanced performance, which can lead to improved fuel efficiency and reduced emissions in various applications, particularly in the transportation sector. However, the environmental impact of these composites extends beyond their use phase and encompasses their entire lifecycle.

The production of hybrid Kevlar-carbon fiber composites involves energy-intensive processes, including the synthesis of raw materials and the manufacturing of the final product. While carbon fiber production is known for its high energy consumption and associated carbon emissions, the addition of Kevlar introduces further complexity to the environmental equation. The aramid fibers used in Kevlar production require petrochemical feedstocks and involve chemical processes that may have environmental consequences if not properly managed.

One of the key environmental challenges associated with hybrid composites is their end-of-life management. Unlike traditional materials, these advanced composites are difficult to recycle due to their complex structure and the strong bonding between different components. The current recycling technologies for carbon fiber composites are still in their infancy, and the addition of Kevlar further complicates the recycling process. This raises concerns about the potential accumulation of these materials in landfills or the need for energy-intensive disposal methods.

On the positive side, the durability and longevity of hybrid Kevlar-carbon fiber composites can contribute to a reduction in material replacement frequency, potentially offsetting some of the environmental costs associated with their production. Additionally, the lightweight nature of these materials can lead to significant fuel savings over the lifetime of products incorporating them, particularly in aerospace and automotive applications. This weight reduction can translate into lower greenhouse gas emissions and reduced overall environmental impact during the use phase.

The environmental impact of hybrid composites also extends to the realm of resource depletion. While carbon fiber is derived from abundant precursors like polyacrylonitrile, the production of Kevlar relies on limited petroleum resources. As global demand for these advanced materials grows, there is a need to consider sustainable sourcing strategies and the development of bio-based alternatives to mitigate the long-term environmental consequences of resource extraction.

In conclusion, the environmental impact of integrating Kevlar with advanced carbon fiber solutions is multifaceted, encompassing both potential benefits and challenges. As research and development in this field progress, it is crucial to prioritize lifecycle assessments, sustainable production methods, and innovative recycling technologies to maximize the environmental benefits of these hybrid composites while minimizing their negative impacts.

The production of hybrid Kevlar-carbon fiber composites involves energy-intensive processes, including the synthesis of raw materials and the manufacturing of the final product. While carbon fiber production is known for its high energy consumption and associated carbon emissions, the addition of Kevlar introduces further complexity to the environmental equation. The aramid fibers used in Kevlar production require petrochemical feedstocks and involve chemical processes that may have environmental consequences if not properly managed.

One of the key environmental challenges associated with hybrid composites is their end-of-life management. Unlike traditional materials, these advanced composites are difficult to recycle due to their complex structure and the strong bonding between different components. The current recycling technologies for carbon fiber composites are still in their infancy, and the addition of Kevlar further complicates the recycling process. This raises concerns about the potential accumulation of these materials in landfills or the need for energy-intensive disposal methods.

On the positive side, the durability and longevity of hybrid Kevlar-carbon fiber composites can contribute to a reduction in material replacement frequency, potentially offsetting some of the environmental costs associated with their production. Additionally, the lightweight nature of these materials can lead to significant fuel savings over the lifetime of products incorporating them, particularly in aerospace and automotive applications. This weight reduction can translate into lower greenhouse gas emissions and reduced overall environmental impact during the use phase.

The environmental impact of hybrid composites also extends to the realm of resource depletion. While carbon fiber is derived from abundant precursors like polyacrylonitrile, the production of Kevlar relies on limited petroleum resources. As global demand for these advanced materials grows, there is a need to consider sustainable sourcing strategies and the development of bio-based alternatives to mitigate the long-term environmental consequences of resource extraction.

In conclusion, the environmental impact of integrating Kevlar with advanced carbon fiber solutions is multifaceted, encompassing both potential benefits and challenges. As research and development in this field progress, it is crucial to prioritize lifecycle assessments, sustainable production methods, and innovative recycling technologies to maximize the environmental benefits of these hybrid composites while minimizing their negative impacts.

Performance Testing and Quality Assurance

Performance testing and quality assurance are critical aspects of integrating Kevlar with advanced carbon fiber solutions. The process begins with rigorous material characterization, including tensile strength, modulus of elasticity, and impact resistance tests. These tests are conducted on both individual components and the integrated composite to ensure optimal performance.

Standardized testing protocols, such as ASTM D3039 for tensile properties and ASTM D7136 for impact resistance, are employed to evaluate the mechanical properties of the Kevlar-carbon fiber composite. Additionally, fatigue testing is performed to assess the long-term durability of the integrated material under cyclic loading conditions.

Non-destructive testing methods, such as ultrasonic scanning and X-ray computed tomography, are utilized to inspect the internal structure of the composite. These techniques help identify potential defects, such as voids, delaminations, or fiber misalignment, which could compromise the material's performance.

Environmental testing is another crucial aspect of quality assurance. The integrated Kevlar-carbon fiber composite is subjected to various environmental conditions, including temperature extremes, humidity, and UV exposure, to evaluate its resistance to degradation and ensure consistent performance across diverse operating environments.

Chemical resistance testing is conducted to assess the material's ability to withstand exposure to various solvents, fuels, and other potentially corrosive substances. This is particularly important for applications in aerospace, automotive, and marine industries where the composite may encounter harsh chemical environments.

Microscopic analysis, including scanning electron microscopy (SEM) and transmission electron microscopy (TEM), is employed to examine the interface between Kevlar and carbon fibers. This analysis helps optimize the bonding between the two materials and ensures effective load transfer throughout the composite structure.

Quality control measures are implemented throughout the manufacturing process to maintain consistency and reliability. This includes monitoring key parameters such as fiber orientation, resin content, and curing conditions. Statistical process control techniques are applied to identify and address any deviations from established quality standards.

Finally, full-scale prototype testing is conducted to validate the performance of the integrated Kevlar-carbon fiber solution in real-world applications. This may involve simulating specific use cases and conducting field trials to ensure the material meets or exceeds the required performance specifications.

Standardized testing protocols, such as ASTM D3039 for tensile properties and ASTM D7136 for impact resistance, are employed to evaluate the mechanical properties of the Kevlar-carbon fiber composite. Additionally, fatigue testing is performed to assess the long-term durability of the integrated material under cyclic loading conditions.

Non-destructive testing methods, such as ultrasonic scanning and X-ray computed tomography, are utilized to inspect the internal structure of the composite. These techniques help identify potential defects, such as voids, delaminations, or fiber misalignment, which could compromise the material's performance.

Environmental testing is another crucial aspect of quality assurance. The integrated Kevlar-carbon fiber composite is subjected to various environmental conditions, including temperature extremes, humidity, and UV exposure, to evaluate its resistance to degradation and ensure consistent performance across diverse operating environments.

Chemical resistance testing is conducted to assess the material's ability to withstand exposure to various solvents, fuels, and other potentially corrosive substances. This is particularly important for applications in aerospace, automotive, and marine industries where the composite may encounter harsh chemical environments.

Microscopic analysis, including scanning electron microscopy (SEM) and transmission electron microscopy (TEM), is employed to examine the interface between Kevlar and carbon fibers. This analysis helps optimize the bonding between the two materials and ensures effective load transfer throughout the composite structure.

Quality control measures are implemented throughout the manufacturing process to maintain consistency and reliability. This includes monitoring key parameters such as fiber orientation, resin content, and curing conditions. Statistical process control techniques are applied to identify and address any deviations from established quality standards.

Finally, full-scale prototype testing is conducted to validate the performance of the integrated Kevlar-carbon fiber solution in real-world applications. This may involve simulating specific use cases and conducting field trials to ensure the material meets or exceeds the required performance specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!