Innovative Uses of Kevlar in Protective Packaging Solutions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Packaging: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in 1965, has revolutionized numerous industries with its exceptional properties. Initially designed for use in automotive tires, Kevlar's applications have expanded significantly over the years, including its innovative use in protective packaging solutions. This technical research report aims to explore the background and objectives of utilizing Kevlar in packaging applications, focusing on its potential to enhance protection and durability in various sectors.

The evolution of Kevlar in packaging stems from the growing demand for advanced materials that can provide superior protection for sensitive and high-value products during transportation and storage. As global supply chains become more complex and products increasingly fragile, traditional packaging materials often fall short in meeting the stringent requirements for impact resistance, puncture protection, and overall durability.

Kevlar's unique molecular structure, consisting of strong intermolecular hydrogen bonds, contributes to its exceptional strength-to-weight ratio, making it an ideal candidate for protective packaging applications. Its ability to absorb and dissipate energy upon impact, coupled with its resistance to cuts and tears, positions Kevlar as a promising solution for addressing the limitations of conventional packaging materials.

The primary objective of incorporating Kevlar into packaging solutions is to enhance the protection of goods across various industries, including electronics, aerospace, automotive, and medical equipment. By leveraging Kevlar's properties, manufacturers aim to develop packaging that can withstand extreme conditions, reduce product damage during transit, and ultimately minimize financial losses associated with shipping and handling.

Another key goal is to explore Kevlar's potential in creating lightweight yet robust packaging solutions. This aligns with the growing emphasis on sustainability in the packaging industry, as lighter materials can contribute to reduced fuel consumption and lower carbon emissions during transportation. Additionally, the durability of Kevlar-enhanced packaging may lead to increased reusability, further supporting environmental sustainability efforts.

Research and development efforts in this field are focused on optimizing Kevlar's integration into various packaging formats, such as protective liners, cushioning materials, and reinforced containers. Scientists and engineers are investigating methods to combine Kevlar with other materials to create hybrid solutions that maximize protection while minimizing costs and environmental impact.

As the packaging industry continues to evolve, the exploration of Kevlar's capabilities in this sector represents a significant technological trend. The successful implementation of Kevlar-based packaging solutions has the potential to transform logistics and supply chain management, offering enhanced product protection and potentially revolutionizing the way fragile and high-value items are transported globally.

The evolution of Kevlar in packaging stems from the growing demand for advanced materials that can provide superior protection for sensitive and high-value products during transportation and storage. As global supply chains become more complex and products increasingly fragile, traditional packaging materials often fall short in meeting the stringent requirements for impact resistance, puncture protection, and overall durability.

Kevlar's unique molecular structure, consisting of strong intermolecular hydrogen bonds, contributes to its exceptional strength-to-weight ratio, making it an ideal candidate for protective packaging applications. Its ability to absorb and dissipate energy upon impact, coupled with its resistance to cuts and tears, positions Kevlar as a promising solution for addressing the limitations of conventional packaging materials.

The primary objective of incorporating Kevlar into packaging solutions is to enhance the protection of goods across various industries, including electronics, aerospace, automotive, and medical equipment. By leveraging Kevlar's properties, manufacturers aim to develop packaging that can withstand extreme conditions, reduce product damage during transit, and ultimately minimize financial losses associated with shipping and handling.

Another key goal is to explore Kevlar's potential in creating lightweight yet robust packaging solutions. This aligns with the growing emphasis on sustainability in the packaging industry, as lighter materials can contribute to reduced fuel consumption and lower carbon emissions during transportation. Additionally, the durability of Kevlar-enhanced packaging may lead to increased reusability, further supporting environmental sustainability efforts.

Research and development efforts in this field are focused on optimizing Kevlar's integration into various packaging formats, such as protective liners, cushioning materials, and reinforced containers. Scientists and engineers are investigating methods to combine Kevlar with other materials to create hybrid solutions that maximize protection while minimizing costs and environmental impact.

As the packaging industry continues to evolve, the exploration of Kevlar's capabilities in this sector represents a significant technological trend. The successful implementation of Kevlar-based packaging solutions has the potential to transform logistics and supply chain management, offering enhanced product protection and potentially revolutionizing the way fragile and high-value items are transported globally.

Market Analysis for Kevlar-Enhanced Packaging

The market for Kevlar-enhanced packaging solutions has been experiencing significant growth in recent years, driven by the increasing demand for high-performance protective materials across various industries. Kevlar, a synthetic fiber known for its exceptional strength-to-weight ratio and heat resistance, has found innovative applications in the packaging sector, particularly in protective packaging solutions.

The global protective packaging market, which includes Kevlar-enhanced products, is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2028. This growth is primarily attributed to the rising e-commerce sector, increasing urbanization, and the growing need for safe transportation of fragile and high-value goods. The Kevlar-enhanced packaging segment is expected to outpace the overall market growth, with a CAGR of 7.2% during the same period.

Key industries driving the demand for Kevlar-enhanced packaging include electronics, automotive, aerospace, and healthcare. The electronics industry, in particular, has shown a strong appetite for advanced protective packaging solutions due to the increasing shipment of sensitive electronic components and devices. The automotive sector is another significant consumer, utilizing Kevlar-enhanced packaging for the transportation of critical parts and components.

Geographically, North America and Europe currently dominate the Kevlar-enhanced packaging market, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, expanding e-commerce markets, and increasing adoption of advanced packaging technologies in countries like China, Japan, and South Korea.

The market landscape for Kevlar-enhanced packaging is characterized by a mix of established players and innovative start-ups. Major companies in this space include DuPont, the original developer of Kevlar, as well as packaging giants like Sealed Air Corporation and Sonoco Products Company. These companies are continuously investing in research and development to create novel Kevlar-based packaging solutions that offer superior protection and sustainability.

Consumer trends are also shaping the Kevlar-enhanced packaging market. There is a growing demand for sustainable packaging solutions, prompting manufacturers to explore ways to incorporate recycled Kevlar fibers or develop biodegradable alternatives. Additionally, the trend towards lightweight packaging that maintains high protective properties is driving innovation in Kevlar-based composites and hybrid materials.

In conclusion, the market for Kevlar-enhanced packaging solutions presents significant opportunities for growth and innovation. As industries continue to seek advanced protective packaging options, the unique properties of Kevlar position it as a key material in meeting these evolving needs. The market's future will likely be shaped by ongoing technological advancements, sustainability concerns, and the expanding application areas for Kevlar-enhanced packaging across diverse sectors.

The global protective packaging market, which includes Kevlar-enhanced products, is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2028. This growth is primarily attributed to the rising e-commerce sector, increasing urbanization, and the growing need for safe transportation of fragile and high-value goods. The Kevlar-enhanced packaging segment is expected to outpace the overall market growth, with a CAGR of 7.2% during the same period.

Key industries driving the demand for Kevlar-enhanced packaging include electronics, automotive, aerospace, and healthcare. The electronics industry, in particular, has shown a strong appetite for advanced protective packaging solutions due to the increasing shipment of sensitive electronic components and devices. The automotive sector is another significant consumer, utilizing Kevlar-enhanced packaging for the transportation of critical parts and components.

Geographically, North America and Europe currently dominate the Kevlar-enhanced packaging market, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, expanding e-commerce markets, and increasing adoption of advanced packaging technologies in countries like China, Japan, and South Korea.

The market landscape for Kevlar-enhanced packaging is characterized by a mix of established players and innovative start-ups. Major companies in this space include DuPont, the original developer of Kevlar, as well as packaging giants like Sealed Air Corporation and Sonoco Products Company. These companies are continuously investing in research and development to create novel Kevlar-based packaging solutions that offer superior protection and sustainability.

Consumer trends are also shaping the Kevlar-enhanced packaging market. There is a growing demand for sustainable packaging solutions, prompting manufacturers to explore ways to incorporate recycled Kevlar fibers or develop biodegradable alternatives. Additionally, the trend towards lightweight packaging that maintains high protective properties is driving innovation in Kevlar-based composites and hybrid materials.

In conclusion, the market for Kevlar-enhanced packaging solutions presents significant opportunities for growth and innovation. As industries continue to seek advanced protective packaging options, the unique properties of Kevlar position it as a key material in meeting these evolving needs. The market's future will likely be shaped by ongoing technological advancements, sustainability concerns, and the expanding application areas for Kevlar-enhanced packaging across diverse sectors.

Current Challenges in Protective Packaging

The protective packaging industry faces several significant challenges in its current landscape. One of the primary issues is the increasing demand for more robust and lightweight materials that can withstand extreme conditions while maintaining cost-effectiveness. Traditional packaging solutions often struggle to meet these evolving requirements, particularly in industries such as aerospace, automotive, and electronics, where product protection during transportation and storage is critical.

Environmental concerns pose another substantial challenge for the protective packaging sector. With growing awareness of ecological issues, there is mounting pressure to develop sustainable packaging solutions that minimize environmental impact. This shift necessitates the use of recyclable or biodegradable materials, which can be challenging to implement without compromising on protective qualities.

The rise of e-commerce has dramatically altered the packaging landscape, creating new challenges for protective packaging. Products now need to withstand the rigors of individual shipping rather than bulk transportation, leading to increased instances of damage during transit. This shift requires packaging solutions that can adapt to various product sizes and shapes while providing adequate protection against impacts, vibrations, and temperature fluctuations.

Cost considerations remain a persistent challenge in the protective packaging industry. As companies seek to optimize their supply chains and reduce overall expenses, there is a constant push for more cost-effective packaging solutions. This demand often conflicts with the need for enhanced protection and sustainability, creating a complex balancing act for packaging designers and manufacturers.

Another significant challenge is the need for packaging solutions that can protect against multiple threats simultaneously. Modern products, especially in the technology sector, require protection from physical damage and environmental factors such as moisture, static electricity, and temperature extremes. Developing materials and designs that can address all these concerns effectively and efficiently is an ongoing challenge for the industry.

Regulatory compliance adds another layer of complexity to protective packaging challenges. With varying standards and regulations across different regions and industries, packaging solutions must be adaptable to meet diverse requirements while maintaining their protective properties. This necessitates continuous innovation and testing to ensure compliance without sacrificing performance or cost-effectiveness.

Environmental concerns pose another substantial challenge for the protective packaging sector. With growing awareness of ecological issues, there is mounting pressure to develop sustainable packaging solutions that minimize environmental impact. This shift necessitates the use of recyclable or biodegradable materials, which can be challenging to implement without compromising on protective qualities.

The rise of e-commerce has dramatically altered the packaging landscape, creating new challenges for protective packaging. Products now need to withstand the rigors of individual shipping rather than bulk transportation, leading to increased instances of damage during transit. This shift requires packaging solutions that can adapt to various product sizes and shapes while providing adequate protection against impacts, vibrations, and temperature fluctuations.

Cost considerations remain a persistent challenge in the protective packaging industry. As companies seek to optimize their supply chains and reduce overall expenses, there is a constant push for more cost-effective packaging solutions. This demand often conflicts with the need for enhanced protection and sustainability, creating a complex balancing act for packaging designers and manufacturers.

Another significant challenge is the need for packaging solutions that can protect against multiple threats simultaneously. Modern products, especially in the technology sector, require protection from physical damage and environmental factors such as moisture, static electricity, and temperature extremes. Developing materials and designs that can address all these concerns effectively and efficiently is an ongoing challenge for the industry.

Regulatory compliance adds another layer of complexity to protective packaging challenges. With varying standards and regulations across different regions and industries, packaging solutions must be adaptable to meet diverse requirements while maintaining their protective properties. This necessitates continuous innovation and testing to ensure compliance without sacrificing performance or cost-effectiveness.

Existing Kevlar-Based Packaging Solutions

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.- Kevlar-reinforced composite materials: Kevlar fibers are incorporated into various composite materials to enhance strength, durability, and impact resistance. These composites find applications in protective gear, aerospace components, and automotive parts. The combination of Kevlar with other materials like resins or polymers creates lightweight yet robust structures.

- Kevlar-based protective equipment: Kevlar is extensively used in the development of personal protective equipment, including bulletproof vests, helmets, and gloves. Its high tensile strength and heat-resistant properties make it ideal for creating lightweight yet effective protective gear for military, law enforcement, and industrial applications.

- Kevlar in textile and fabric applications: Kevlar fibers are integrated into various textiles and fabrics to improve their strength, cut resistance, and durability. These enhanced fabrics are used in manufacturing protective clothing, high-performance sportswear, and industrial textiles that require exceptional strength-to-weight ratios.

- Kevlar-enhanced construction materials: Kevlar is utilized in construction materials to improve their structural integrity and resistance to environmental factors. It is incorporated into concrete, building panels, and reinforcement materials to enhance strength, reduce weight, and increase the overall durability of structures.

- Kevlar in automotive and transportation applications: Kevlar is employed in various automotive and transportation components to reduce weight while maintaining strength and safety. It is used in tire reinforcement, brake pads, and body panels to improve fuel efficiency, enhance performance, and increase the overall durability of vehicles.

02 Kevlar in protective gear and clothing

Kevlar is widely used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.Expand Specific Solutions03 Kevlar-based fire-resistant materials

Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and other applications requiring heat and flame resistance.Expand Specific Solutions04 Kevlar in automotive and aerospace applications

Kevlar is employed in various automotive and aerospace components to reduce weight while maintaining strength. It is used in tires, body panels, and structural parts to improve fuel efficiency and performance.Expand Specific Solutions05 Kevlar in sporting goods and recreational equipment

Kevlar is incorporated into sporting goods and recreational equipment to enhance durability and performance. Applications include bicycle tires, tennis rackets, and kayaks, where its lightweight and high-strength properties are beneficial.Expand Specific Solutions

Key Players in Kevlar and Packaging Industries

The innovative use of Kevlar in protective packaging solutions is in a growth phase, with increasing market size due to rising demand for high-performance materials in various industries. The technology's maturity is advancing, with established players like DuPont de Nemours, Inc., the original developer of Kevlar, leading the way. Other key players such as Honeywell and Teijin are also contributing to the field's development. Research institutions like Beijing Institute of Technology and Northeastern University are actively involved in exploring new applications. The competitive landscape is diverse, including both large corporations and specialized materials companies, indicating a dynamic and evolving market with potential for further innovation and expansion.

China Textile Academy

Technical Solution: The China Textile Academy has been at the forefront of research in Kevlar applications for protective packaging in the Asian market. They have developed innovative techniques for incorporating Kevlar fibers into textile-based packaging materials, creating flexible yet highly durable protective solutions [13]. Their research includes the development of Kevlar-reinforced nonwoven fabrics that can be used as protective liners or wraps for fragile items. The Academy has also explored the use of Kevlar in 3D-knitted structures, creating impact-resistant packaging with optimized cushioning properties [14]. Additionally, they have investigated the potential of Kevlar-based smart packaging materials that can monitor and report on the condition of packaged goods during transit [15].

Strengths: Strong research capabilities, expertise in textile engineering, and ability to adapt solutions for the Asian market. Weaknesses: Limited commercial production capabilities, potential challenges in scaling up research findings to industrial applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont, the inventor of Kevlar, has developed innovative protective packaging solutions using this high-strength material. Their approach involves creating multi-layered composite structures that combine Kevlar with other materials to enhance protection. For example, they've introduced Kevlar-reinforced bubble wrap that offers superior puncture resistance and cushioning [1]. DuPont has also developed Kevlar-based honeycomb structures for impact-resistant packaging, which provide excellent energy absorption while maintaining a lightweight profile [2]. Additionally, they've incorporated Kevlar fibers into biodegradable packaging materials, addressing both protection and sustainability concerns [3].

Strengths: Unparalleled expertise in Kevlar applications, strong R&D capabilities, and a wide range of patented technologies. Weaknesses: Higher cost compared to traditional packaging materials, which may limit adoption in price-sensitive markets.

Innovative Kevlar Composites for Packaging

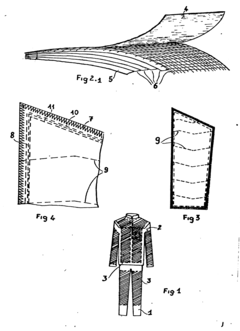

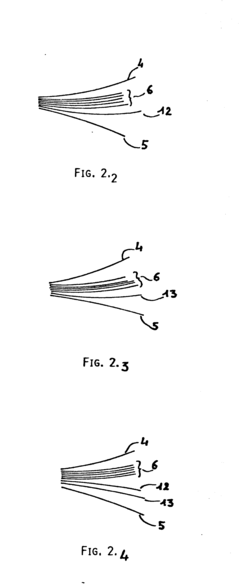

Work and safety garment

PatentInactiveEP0202183A1

Innovation

- A work clothing design featuring layers of fabric fixed together with strategically placed seams that break under tension, ensuring immediate chain engagement and stopping without excessive bulk, using materials like KEVLAR for enhanced protection and comfort.

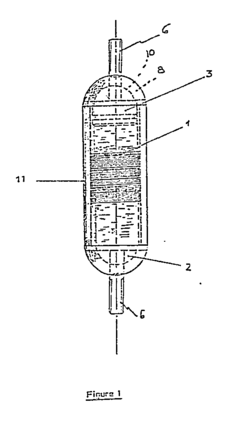

Vessel for liquids under high pression

PatentInactiveEP0319439A3

Innovation

- The design features semi-cylindrical plugs with grooves housing flexible bundles of Kevlar fibers outside the tank body, distributing mechanical stresses evenly and eliminating the need for internal tie rods, allowing for efficient force transmission and reduced material costs.

Environmental Impact of Kevlar in Packaging

The environmental impact of Kevlar in packaging is a complex issue that requires careful consideration of both its benefits and potential drawbacks. Kevlar, a high-strength synthetic fiber developed by DuPont, offers exceptional durability and protective properties, making it an attractive option for innovative packaging solutions. However, its environmental footprint must be thoroughly examined to ensure sustainable use in the packaging industry.

One of the primary environmental advantages of Kevlar in packaging is its potential to reduce material consumption. Due to its superior strength-to-weight ratio, Kevlar-based packaging can be designed to be thinner and lighter than traditional alternatives while maintaining or even improving protective qualities. This reduction in material usage can lead to decreased resource extraction, energy consumption, and transportation-related emissions throughout the supply chain.

Furthermore, the durability of Kevlar-enhanced packaging may contribute to extended product lifecycles and reduced waste generation. Packaging solutions incorporating Kevlar are less likely to fail during transit or storage, potentially decreasing the need for replacement packaging and minimizing product damage. This longevity can result in fewer discarded packaging materials and damaged goods entering the waste stream.

However, the environmental impact of Kevlar production must be considered. The manufacturing process involves energy-intensive steps and the use of chemical solvents, which can contribute to greenhouse gas emissions and potential chemical pollution if not properly managed. Additionally, the raw materials used in Kevlar production, primarily derived from petroleum, raise concerns about resource depletion and the reliance on non-renewable fossil fuels.

End-of-life considerations for Kevlar-based packaging present both challenges and opportunities. While Kevlar itself is not biodegradable, research into recycling technologies for aramid fibers shows promise. Advanced mechanical and chemical recycling methods are being developed to recover and repurpose Kevlar fibers, potentially creating a closed-loop system for packaging materials. However, the widespread implementation of these recycling processes remains a challenge.

The environmental impact of Kevlar in packaging also extends to its potential influence on packaging design and consumer behavior. The material's unique properties may enable the creation of reusable packaging solutions, encouraging a shift away from single-use packaging models. This transition could significantly reduce overall packaging waste and promote more sustainable consumption patterns.

In conclusion, the environmental impact of Kevlar in packaging is multifaceted, with potential benefits in material reduction and durability balanced against concerns regarding production processes and end-of-life management. As the packaging industry continues to innovate with Kevlar, it is crucial to prioritize sustainable manufacturing practices, invest in recycling technologies, and design packaging solutions that maximize the material's environmental benefits while minimizing its drawbacks.

One of the primary environmental advantages of Kevlar in packaging is its potential to reduce material consumption. Due to its superior strength-to-weight ratio, Kevlar-based packaging can be designed to be thinner and lighter than traditional alternatives while maintaining or even improving protective qualities. This reduction in material usage can lead to decreased resource extraction, energy consumption, and transportation-related emissions throughout the supply chain.

Furthermore, the durability of Kevlar-enhanced packaging may contribute to extended product lifecycles and reduced waste generation. Packaging solutions incorporating Kevlar are less likely to fail during transit or storage, potentially decreasing the need for replacement packaging and minimizing product damage. This longevity can result in fewer discarded packaging materials and damaged goods entering the waste stream.

However, the environmental impact of Kevlar production must be considered. The manufacturing process involves energy-intensive steps and the use of chemical solvents, which can contribute to greenhouse gas emissions and potential chemical pollution if not properly managed. Additionally, the raw materials used in Kevlar production, primarily derived from petroleum, raise concerns about resource depletion and the reliance on non-renewable fossil fuels.

End-of-life considerations for Kevlar-based packaging present both challenges and opportunities. While Kevlar itself is not biodegradable, research into recycling technologies for aramid fibers shows promise. Advanced mechanical and chemical recycling methods are being developed to recover and repurpose Kevlar fibers, potentially creating a closed-loop system for packaging materials. However, the widespread implementation of these recycling processes remains a challenge.

The environmental impact of Kevlar in packaging also extends to its potential influence on packaging design and consumer behavior. The material's unique properties may enable the creation of reusable packaging solutions, encouraging a shift away from single-use packaging models. This transition could significantly reduce overall packaging waste and promote more sustainable consumption patterns.

In conclusion, the environmental impact of Kevlar in packaging is multifaceted, with potential benefits in material reduction and durability balanced against concerns regarding production processes and end-of-life management. As the packaging industry continues to innovate with Kevlar, it is crucial to prioritize sustainable manufacturing practices, invest in recycling technologies, and design packaging solutions that maximize the material's environmental benefits while minimizing its drawbacks.

Cost-Benefit Analysis of Kevlar Packaging Solutions

The cost-benefit analysis of Kevlar packaging solutions reveals a complex interplay of factors that must be carefully considered by manufacturers and end-users alike. On the cost side, Kevlar-based packaging materials are significantly more expensive than traditional alternatives such as cardboard, plastic, or standard bubble wrap. The raw material cost of Kevlar fibers is substantially higher due to the complex manufacturing process and limited production capacity. Additionally, integrating Kevlar into existing packaging designs often requires specialized equipment and expertise, further increasing initial investment costs for companies.

However, the benefits of Kevlar packaging solutions can potentially outweigh these higher upfront costs in certain applications. The exceptional strength-to-weight ratio of Kevlar allows for thinner, lighter packaging that still provides superior protection against impacts, punctures, and tears. This can lead to reduced shipping costs and improved logistics efficiency, especially for high-value or fragile items. The durability of Kevlar-based packaging also enables potential reuse, reducing long-term packaging expenses and aligning with sustainability goals.

For industries dealing with sensitive or hazardous materials, Kevlar packaging offers enhanced safety features that can mitigate risks and potential liabilities. The material's resistance to chemicals and extreme temperatures expands its applicability in sectors such as pharmaceuticals and electronics, where maintaining product integrity is crucial. These protective properties can result in fewer damaged goods, lower insurance premiums, and improved customer satisfaction, all of which contribute positively to the overall cost-benefit equation.

The longevity of Kevlar packaging solutions presents another important consideration. While the initial cost is higher, the extended lifespan of Kevlar-based materials can result in lower total cost of ownership over time. This is particularly relevant for reusable packaging in closed-loop supply chains or for products with long storage requirements. The reduced need for replacement and waste management can offset the higher acquisition costs, especially as environmental regulations become more stringent.

It's important to note that the cost-benefit ratio varies significantly depending on the specific application and industry context. For high-volume, low-value goods, the premium cost of Kevlar packaging may be difficult to justify. However, for industries such as aerospace, defense, or luxury goods, where product protection is paramount, the benefits can far outweigh the costs. Companies must conduct thorough analyses of their specific use cases, considering factors such as product value, transportation risks, regulatory requirements, and environmental impact to determine if Kevlar packaging solutions offer a favorable return on investment.

However, the benefits of Kevlar packaging solutions can potentially outweigh these higher upfront costs in certain applications. The exceptional strength-to-weight ratio of Kevlar allows for thinner, lighter packaging that still provides superior protection against impacts, punctures, and tears. This can lead to reduced shipping costs and improved logistics efficiency, especially for high-value or fragile items. The durability of Kevlar-based packaging also enables potential reuse, reducing long-term packaging expenses and aligning with sustainability goals.

For industries dealing with sensitive or hazardous materials, Kevlar packaging offers enhanced safety features that can mitigate risks and potential liabilities. The material's resistance to chemicals and extreme temperatures expands its applicability in sectors such as pharmaceuticals and electronics, where maintaining product integrity is crucial. These protective properties can result in fewer damaged goods, lower insurance premiums, and improved customer satisfaction, all of which contribute positively to the overall cost-benefit equation.

The longevity of Kevlar packaging solutions presents another important consideration. While the initial cost is higher, the extended lifespan of Kevlar-based materials can result in lower total cost of ownership over time. This is particularly relevant for reusable packaging in closed-loop supply chains or for products with long storage requirements. The reduced need for replacement and waste management can offset the higher acquisition costs, especially as environmental regulations become more stringent.

It's important to note that the cost-benefit ratio varies significantly depending on the specific application and industry context. For high-volume, low-value goods, the premium cost of Kevlar packaging may be difficult to justify. However, for industries such as aerospace, defense, or luxury goods, where product protection is paramount, the benefits can far outweigh the costs. Companies must conduct thorough analyses of their specific use cases, considering factors such as product value, transportation risks, regulatory requirements, and environmental impact to determine if Kevlar packaging solutions offer a favorable return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!