Kevlar as a Key Element in Emerging Energy Solutions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Energy: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has long been recognized for its exceptional mechanical properties. Initially utilized in applications such as bulletproof vests and aerospace components, Kevlar's potential in the energy sector has recently gained significant attention. This shift in focus aligns with the global push towards sustainable and efficient energy solutions, where advanced materials play a crucial role.

The evolution of Kevlar's application in energy technologies can be traced back to the early 2000s when researchers began exploring its unique properties for energy storage and conversion systems. Its high tensile strength, low weight, and resistance to chemical and thermal degradation make it an ideal candidate for various energy-related applications. As the world grapples with the challenges of climate change and the need for clean energy alternatives, Kevlar has emerged as a key element in developing innovative solutions.

In recent years, the energy sector has witnessed a surge in research and development activities aimed at harnessing Kevlar's properties for enhancing the performance and durability of energy systems. From improving the efficiency of fuel cells to reinforcing wind turbine blades, Kevlar's versatility has opened up new avenues for addressing critical energy challenges. The material's ability to withstand extreme conditions while maintaining its structural integrity has made it particularly valuable in harsh operating environments often encountered in energy production and storage facilities.

The primary objective of incorporating Kevlar into emerging energy solutions is to overcome existing limitations in material performance and to enable the development of more efficient, durable, and sustainable energy technologies. By leveraging Kevlar's unique properties, researchers and engineers aim to enhance the overall efficiency of energy conversion processes, extend the lifespan of energy infrastructure, and reduce the environmental impact of energy production and consumption.

As we delve deeper into the potential applications of Kevlar in the energy sector, it becomes evident that this advanced material has the capacity to revolutionize various aspects of energy technology. From improving the performance of lithium-ion batteries to enhancing the durability of solar panels, Kevlar's integration into energy solutions promises to address some of the most pressing challenges facing the industry today. The ongoing research and development efforts in this field are expected to yield significant breakthroughs in the coming years, potentially reshaping the landscape of sustainable energy technologies.

The evolution of Kevlar's application in energy technologies can be traced back to the early 2000s when researchers began exploring its unique properties for energy storage and conversion systems. Its high tensile strength, low weight, and resistance to chemical and thermal degradation make it an ideal candidate for various energy-related applications. As the world grapples with the challenges of climate change and the need for clean energy alternatives, Kevlar has emerged as a key element in developing innovative solutions.

In recent years, the energy sector has witnessed a surge in research and development activities aimed at harnessing Kevlar's properties for enhancing the performance and durability of energy systems. From improving the efficiency of fuel cells to reinforcing wind turbine blades, Kevlar's versatility has opened up new avenues for addressing critical energy challenges. The material's ability to withstand extreme conditions while maintaining its structural integrity has made it particularly valuable in harsh operating environments often encountered in energy production and storage facilities.

The primary objective of incorporating Kevlar into emerging energy solutions is to overcome existing limitations in material performance and to enable the development of more efficient, durable, and sustainable energy technologies. By leveraging Kevlar's unique properties, researchers and engineers aim to enhance the overall efficiency of energy conversion processes, extend the lifespan of energy infrastructure, and reduce the environmental impact of energy production and consumption.

As we delve deeper into the potential applications of Kevlar in the energy sector, it becomes evident that this advanced material has the capacity to revolutionize various aspects of energy technology. From improving the performance of lithium-ion batteries to enhancing the durability of solar panels, Kevlar's integration into energy solutions promises to address some of the most pressing challenges facing the industry today. The ongoing research and development efforts in this field are expected to yield significant breakthroughs in the coming years, potentially reshaping the landscape of sustainable energy technologies.

Market Demand Analysis for Kevlar-Based Energy Solutions

The market demand for Kevlar-based energy solutions has been steadily growing, driven by the increasing need for lightweight, durable, and high-performance materials in the energy sector. Kevlar, known for its exceptional strength-to-weight ratio and heat-resistant properties, is finding new applications in various energy-related fields.

In the renewable energy sector, Kevlar is gaining traction as a key component in wind turbine blades. The material's high tensile strength and low weight contribute to larger, more efficient turbine designs, enabling increased energy production. Market analysts project a compound annual growth rate (CAGR) of 8.4% for the global wind turbine materials market between 2021 and 2026, with Kevlar playing a significant role in this expansion.

The automotive industry's shift towards electric vehicles (EVs) has also created new opportunities for Kevlar-based solutions. The material is being utilized in battery casings and protective shields, enhancing safety and performance while reducing overall vehicle weight. As the global EV market is expected to grow at a CAGR of 29% from 2021 to 2026, the demand for Kevlar in this sector is poised for substantial growth.

In the field of energy storage, Kevlar is emerging as a promising material for advanced battery technologies. Its use in separator membranes for lithium-ion batteries has shown potential to improve battery life and safety. The global lithium-ion battery market is forecasted to reach $129.3 billion by 2027, presenting a significant opportunity for Kevlar-based solutions.

The oil and gas industry is another sector where Kevlar is finding increased application. Its use in reinforced pipes, hoses, and cables for offshore drilling operations has led to improved durability and safety in harsh environments. Despite the global push towards renewable energy, the oil and gas sector continues to invest in advanced materials, with the market for composite materials in this industry expected to grow at a CAGR of 5.8% from 2020 to 2025.

Emerging applications in the aerospace and defense sectors are also contributing to the growing demand for Kevlar in energy-related solutions. The material's use in fuel cells, thermal management systems, and protective gear for energy infrastructure is opening new market opportunities.

However, the market for Kevlar-based energy solutions faces challenges, including high production costs and competition from alternative materials. Despite these obstacles, the unique properties of Kevlar continue to drive innovation and market expansion across various energy sectors, indicating a promising future for Kevlar-based technologies in the evolving energy landscape.

In the renewable energy sector, Kevlar is gaining traction as a key component in wind turbine blades. The material's high tensile strength and low weight contribute to larger, more efficient turbine designs, enabling increased energy production. Market analysts project a compound annual growth rate (CAGR) of 8.4% for the global wind turbine materials market between 2021 and 2026, with Kevlar playing a significant role in this expansion.

The automotive industry's shift towards electric vehicles (EVs) has also created new opportunities for Kevlar-based solutions. The material is being utilized in battery casings and protective shields, enhancing safety and performance while reducing overall vehicle weight. As the global EV market is expected to grow at a CAGR of 29% from 2021 to 2026, the demand for Kevlar in this sector is poised for substantial growth.

In the field of energy storage, Kevlar is emerging as a promising material for advanced battery technologies. Its use in separator membranes for lithium-ion batteries has shown potential to improve battery life and safety. The global lithium-ion battery market is forecasted to reach $129.3 billion by 2027, presenting a significant opportunity for Kevlar-based solutions.

The oil and gas industry is another sector where Kevlar is finding increased application. Its use in reinforced pipes, hoses, and cables for offshore drilling operations has led to improved durability and safety in harsh environments. Despite the global push towards renewable energy, the oil and gas sector continues to invest in advanced materials, with the market for composite materials in this industry expected to grow at a CAGR of 5.8% from 2020 to 2025.

Emerging applications in the aerospace and defense sectors are also contributing to the growing demand for Kevlar in energy-related solutions. The material's use in fuel cells, thermal management systems, and protective gear for energy infrastructure is opening new market opportunities.

However, the market for Kevlar-based energy solutions faces challenges, including high production costs and competition from alternative materials. Despite these obstacles, the unique properties of Kevlar continue to drive innovation and market expansion across various energy sectors, indicating a promising future for Kevlar-based technologies in the evolving energy landscape.

Current Challenges in Kevlar Energy Applications

Despite Kevlar's remarkable properties and potential in energy applications, several challenges currently hinder its widespread adoption and optimal utilization in emerging energy solutions. One of the primary obstacles is the high production cost associated with Kevlar manufacturing. The complex synthesis process and specialized equipment required contribute to elevated expenses, limiting its cost-effectiveness in large-scale energy projects.

Another significant challenge lies in the integration of Kevlar with other materials and systems in energy applications. While Kevlar exhibits exceptional strength and durability, achieving seamless compatibility with diverse components in energy storage, transmission, and generation systems remains a technical hurdle. This integration challenge often necessitates extensive research and development efforts to optimize performance and reliability.

The environmental impact of Kevlar production and disposal presents an additional concern. The synthesis of Kevlar involves energy-intensive processes and the use of potentially harmful chemicals. As sustainability becomes increasingly crucial in energy solutions, addressing the ecological footprint of Kevlar throughout its lifecycle is paramount. Furthermore, the limited recyclability of Kevlar poses challenges in terms of waste management and circular economy principles.

Scalability issues also persist in Kevlar energy applications. While the material shows promise in laboratory settings and small-scale demonstrations, translating these successes to industrial-scale implementations often encounters unforeseen complications. Factors such as maintaining consistent quality, ensuring uniform properties across large production batches, and adapting manufacturing processes for mass production contribute to scalability challenges.

The long-term durability and performance of Kevlar in diverse energy environments require further investigation. Although Kevlar demonstrates excellent resistance to various environmental factors, its behavior under prolonged exposure to extreme conditions, such as high temperatures, chemical exposure, and mechanical stress in energy systems, needs comprehensive evaluation. Ensuring the material's reliability and longevity in these demanding applications is crucial for widespread adoption.

Lastly, the limited availability of specialized expertise in Kevlar applications for energy solutions hampers innovation and implementation. The interdisciplinary nature of integrating Kevlar into energy systems demands a unique skill set combining materials science, energy engineering, and system design. Bridging this knowledge gap and fostering collaboration between experts from diverse fields is essential to overcome current challenges and unlock the full potential of Kevlar in emerging energy solutions.

Another significant challenge lies in the integration of Kevlar with other materials and systems in energy applications. While Kevlar exhibits exceptional strength and durability, achieving seamless compatibility with diverse components in energy storage, transmission, and generation systems remains a technical hurdle. This integration challenge often necessitates extensive research and development efforts to optimize performance and reliability.

The environmental impact of Kevlar production and disposal presents an additional concern. The synthesis of Kevlar involves energy-intensive processes and the use of potentially harmful chemicals. As sustainability becomes increasingly crucial in energy solutions, addressing the ecological footprint of Kevlar throughout its lifecycle is paramount. Furthermore, the limited recyclability of Kevlar poses challenges in terms of waste management and circular economy principles.

Scalability issues also persist in Kevlar energy applications. While the material shows promise in laboratory settings and small-scale demonstrations, translating these successes to industrial-scale implementations often encounters unforeseen complications. Factors such as maintaining consistent quality, ensuring uniform properties across large production batches, and adapting manufacturing processes for mass production contribute to scalability challenges.

The long-term durability and performance of Kevlar in diverse energy environments require further investigation. Although Kevlar demonstrates excellent resistance to various environmental factors, its behavior under prolonged exposure to extreme conditions, such as high temperatures, chemical exposure, and mechanical stress in energy systems, needs comprehensive evaluation. Ensuring the material's reliability and longevity in these demanding applications is crucial for widespread adoption.

Lastly, the limited availability of specialized expertise in Kevlar applications for energy solutions hampers innovation and implementation. The interdisciplinary nature of integrating Kevlar into energy systems demands a unique skill set combining materials science, energy engineering, and system design. Bridging this knowledge gap and fostering collaboration between experts from diverse fields is essential to overcome current challenges and unlock the full potential of Kevlar in emerging energy solutions.

Existing Kevlar-Based Energy Solutions

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar fibers significantly improves the mechanical properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the development of protective gear such as bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and lightweight nature make it ideal for creating armor that offers superior protection against ballistic threats while maintaining mobility.

- Kevlar in textile applications: Kevlar fibers are incorporated into various textile products to enhance their strength, heat resistance, and cut resistance. These applications include protective clothing, industrial gloves, and high-performance sportswear. The integration of Kevlar improves the overall durability and functionality of these textile products.

- Kevlar-enhanced structural components: Kevlar is used to reinforce structural components in various industries, including construction, marine, and aerospace. By incorporating Kevlar fibers or fabrics into structural elements, engineers can create lighter, stronger, and more durable components that offer improved performance and longevity.

- Kevlar in advanced manufacturing processes: Innovative manufacturing processes are being developed to incorporate Kevlar into various products and materials. These processes include advanced weaving techniques, 3D printing with Kevlar-reinforced filaments, and novel composite fabrication methods. These advancements enable the creation of complex geometries and customized Kevlar-enhanced products for specific applications.

02 Kevlar in protective gear and clothing

Kevlar is extensively used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.Expand Specific Solutions03 Kevlar-based fire-resistant materials

Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and building materials to enhance fire protection and safety.Expand Specific Solutions04 Kevlar in automotive applications

Kevlar is employed in various automotive components to reduce weight while maintaining strength. It is used in tires, belts, hoses, and body panels to improve fuel efficiency and overall vehicle performance.Expand Specific Solutions05 Kevlar in aerospace and marine industries

Kevlar finds applications in aerospace and marine industries for its high strength-to-weight ratio. It is used in aircraft components, spacecraft heat shields, and boat hulls to enhance performance and durability in extreme conditions.Expand Specific Solutions

Key Players in Kevlar-Energy Industry

The Kevlar market in emerging energy solutions is in a growth phase, driven by increasing demand for lightweight, high-strength materials in renewable energy applications. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, Kevlar applications in energy solutions are advancing rapidly, with companies like DuPont, Teijin, and Kolon Industries leading innovation. Research institutions such as Nanjing University of Science & Technology and Wuhan University of Technology are contributing to material improvements and novel applications. While established players dominate, emerging companies like Shandong Dongyue Future Hydrogen Energy Materials Co., Ltd. are entering the market with specialized solutions, indicating a maturing but still dynamic competitive landscape.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has been exploring the use of Kevlar in energy solutions, particularly in the oil and gas industry. They have developed Kevlar-reinforced flexible pipes for offshore oil and gas extraction, which offer superior strength and corrosion resistance compared to traditional materials [4]. These pipes can withstand high pressures and temperatures in deep-sea environments, improving the efficiency and safety of offshore operations. Shell is also investigating the use of Kevlar composites in hydrogen storage tanks for fuel cell vehicles, taking advantage of Kevlar's high strength-to-weight ratio and low permeability to hydrogen [5]. Furthermore, the company is researching Kevlar-based membranes for gas separation and purification processes in refineries, which could significantly enhance energy efficiency in fuel production [6].

Strengths: Extensive experience in energy sector, global reach, substantial R&D budget. Weaknesses: Primary focus on fossil fuels may limit innovation in renewable energy applications of Kevlar.

Alliance for Sustainable Energy LLC

Technical Solution: The Alliance for Sustainable Energy, which manages the National Renewable Energy Laboratory (NREL), has been at the forefront of integrating Kevlar into emerging energy solutions. They have developed Kevlar-based composite materials for wind turbine blades, significantly reducing weight while maintaining strength and durability [7]. This innovation allows for larger, more efficient wind turbines. The Alliance has also explored the use of Kevlar in advanced solar panel designs, where it serves as a protective layer against environmental factors, extending the lifespan of photovoltaic cells [8]. Additionally, they are researching Kevlar-enhanced energy storage solutions, including improved separators for next-generation batteries and reinforced casings for high-pressure hydrogen storage tanks [9].

Strengths: Strong focus on renewable energy, access to cutting-edge research facilities, collaboration with multiple industry partners. Weaknesses: Dependence on government funding may limit some commercial applications.

Core Innovations in Kevlar for Energy

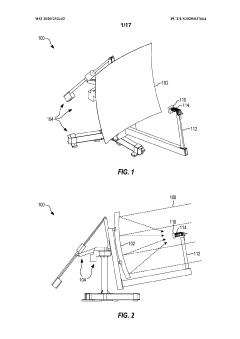

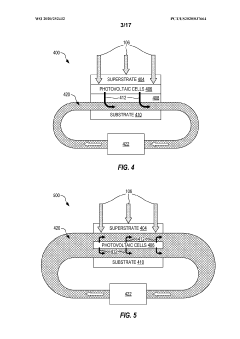

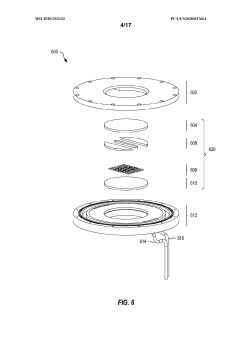

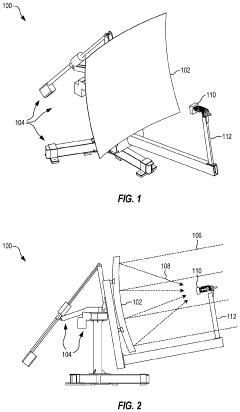

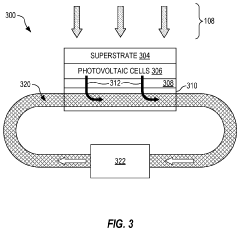

Spectrum-splitting concentrator photovoltaic module with direct fluid cooling, and associated methods

PatentWO2020252432A1

Innovation

- A spectrum-splitting concentrator photovoltaic module with direct fluid cooling, where PV cells are fully immersed in a flowing heat transfer fluid, allowing both front and rear faces to come into contact, enhancing heat extraction efficiency and eliminating the need for conductive backplanes, thereby optimizing PV cell performance and transmitting unabsorbed infrared light to a thermal receiver.

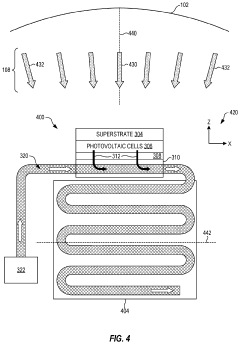

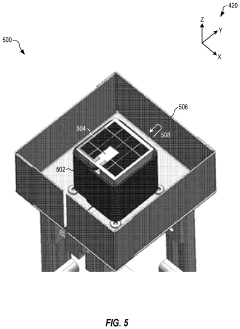

Hybrid receiver for concentrated photovoltaic-thermal power systems, and associated methods

PatentActiveUS12015378B2

Innovation

- A hybrid concentrator photovoltaic-thermal (CPVT) system that integrates a CPV module with a thermal module acting as both a thermal receiver and cooling system, using the same heat transfer fluid to absorb waste heat from PV cells and generate thermal power, thereby increasing efficiency by utilizing waste heat for high-temperature process applications.

Environmental Impact of Kevlar in Energy Solutions

The environmental impact of Kevlar in energy solutions is a critical consideration as this advanced material finds increasing applications in sustainable technologies. Kevlar, known for its exceptional strength-to-weight ratio, contributes significantly to the development of lightweight and durable components in various energy systems.

In wind energy, Kevlar-reinforced turbine blades offer enhanced performance and longevity. These blades are more resistant to fatigue and environmental stresses, potentially extending the operational life of wind turbines. This durability translates to reduced material consumption and waste generation over time, aligning with circular economy principles.

For solar energy applications, Kevlar's incorporation in photovoltaic panel backsheets improves their resistance to harsh weather conditions. This enhanced durability leads to longer-lasting solar installations, reducing the need for frequent replacements and minimizing electronic waste associated with damaged panels.

In the realm of energy storage, Kevlar's use in advanced battery separators contributes to safer and more efficient energy storage solutions. By improving the structural integrity of batteries, Kevlar helps prevent thermal runaway and extends battery life cycles, potentially reducing the environmental impact of battery production and disposal.

However, the production of Kevlar itself raises environmental concerns. The manufacturing process involves energy-intensive steps and the use of strong acids, which can have negative environmental implications if not properly managed. Efforts to improve the sustainability of Kevlar production, such as developing more eco-friendly synthesis methods and implementing closed-loop manufacturing systems, are ongoing.

The end-of-life management of Kevlar-containing energy products is another crucial aspect. While Kevlar's durability extends product lifespans, it also presents challenges in recycling and disposal. Research into effective recycling techniques for Kevlar-reinforced composites is essential to mitigate potential environmental impacts and promote a circular economy approach in the energy sector.

Overall, the environmental impact of Kevlar in energy solutions is multifaceted. Its ability to enhance the performance and longevity of energy technologies contributes to sustainability goals. However, addressing the environmental challenges associated with its production and end-of-life management remains crucial for maximizing its positive impact on emerging energy solutions.

In wind energy, Kevlar-reinforced turbine blades offer enhanced performance and longevity. These blades are more resistant to fatigue and environmental stresses, potentially extending the operational life of wind turbines. This durability translates to reduced material consumption and waste generation over time, aligning with circular economy principles.

For solar energy applications, Kevlar's incorporation in photovoltaic panel backsheets improves their resistance to harsh weather conditions. This enhanced durability leads to longer-lasting solar installations, reducing the need for frequent replacements and minimizing electronic waste associated with damaged panels.

In the realm of energy storage, Kevlar's use in advanced battery separators contributes to safer and more efficient energy storage solutions. By improving the structural integrity of batteries, Kevlar helps prevent thermal runaway and extends battery life cycles, potentially reducing the environmental impact of battery production and disposal.

However, the production of Kevlar itself raises environmental concerns. The manufacturing process involves energy-intensive steps and the use of strong acids, which can have negative environmental implications if not properly managed. Efforts to improve the sustainability of Kevlar production, such as developing more eco-friendly synthesis methods and implementing closed-loop manufacturing systems, are ongoing.

The end-of-life management of Kevlar-containing energy products is another crucial aspect. While Kevlar's durability extends product lifespans, it also presents challenges in recycling and disposal. Research into effective recycling techniques for Kevlar-reinforced composites is essential to mitigate potential environmental impacts and promote a circular economy approach in the energy sector.

Overall, the environmental impact of Kevlar in energy solutions is multifaceted. Its ability to enhance the performance and longevity of energy technologies contributes to sustainability goals. However, addressing the environmental challenges associated with its production and end-of-life management remains crucial for maximizing its positive impact on emerging energy solutions.

Regulatory Framework for Advanced Materials in Energy

The regulatory framework for advanced materials in energy applications, particularly concerning Kevlar's use in emerging energy solutions, is a complex and evolving landscape. As Kevlar finds increasing applications in energy storage, transmission, and generation systems, regulatory bodies are adapting to ensure safety, environmental protection, and sustainable development.

At the federal level, the U.S. Department of Energy (DOE) plays a crucial role in setting standards and guidelines for advanced materials in energy applications. The DOE's Office of Energy Efficiency and Renewable Energy (EERE) has established specific regulations for the use of high-performance materials like Kevlar in energy systems, focusing on durability, efficiency, and safety aspects.

The Environmental Protection Agency (EPA) also contributes to the regulatory framework, particularly in terms of environmental impact assessment and lifecycle analysis of advanced materials. For Kevlar, this includes regulations on production processes, potential emissions, and end-of-life disposal or recycling.

On the international stage, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have developed standards that influence the use of advanced materials in energy applications. These standards often serve as benchmarks for national regulations and industry practices.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of Kevlar and similar materials in energy solutions. This comprehensive framework ensures that the potential risks associated with these materials are adequately assessed and managed throughout their lifecycle.

As Kevlar's applications in energy solutions expand, regulatory bodies are increasingly focusing on performance standards and safety certifications. For instance, the use of Kevlar in composite materials for wind turbine blades is subject to rigorous testing and certification processes to ensure structural integrity and longevity.

The regulatory landscape also addresses the intersection of advanced materials and emerging technologies. For example, as Kevlar finds applications in next-generation battery technologies, regulations are being developed to address safety concerns, performance standards, and recycling protocols specific to these innovative energy storage solutions.

Looking ahead, the regulatory framework is likely to evolve further, with a growing emphasis on circular economy principles. This may lead to new regulations governing the recyclability and reusability of Kevlar-based components in energy systems, promoting sustainable practices in the advanced materials sector.

At the federal level, the U.S. Department of Energy (DOE) plays a crucial role in setting standards and guidelines for advanced materials in energy applications. The DOE's Office of Energy Efficiency and Renewable Energy (EERE) has established specific regulations for the use of high-performance materials like Kevlar in energy systems, focusing on durability, efficiency, and safety aspects.

The Environmental Protection Agency (EPA) also contributes to the regulatory framework, particularly in terms of environmental impact assessment and lifecycle analysis of advanced materials. For Kevlar, this includes regulations on production processes, potential emissions, and end-of-life disposal or recycling.

On the international stage, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have developed standards that influence the use of advanced materials in energy applications. These standards often serve as benchmarks for national regulations and industry practices.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of Kevlar and similar materials in energy solutions. This comprehensive framework ensures that the potential risks associated with these materials are adequately assessed and managed throughout their lifecycle.

As Kevlar's applications in energy solutions expand, regulatory bodies are increasingly focusing on performance standards and safety certifications. For instance, the use of Kevlar in composite materials for wind turbine blades is subject to rigorous testing and certification processes to ensure structural integrity and longevity.

The regulatory landscape also addresses the intersection of advanced materials and emerging technologies. For example, as Kevlar finds applications in next-generation battery technologies, regulations are being developed to address safety concerns, performance standards, and recycling protocols specific to these innovative energy storage solutions.

Looking ahead, the regulatory framework is likely to evolve further, with a growing emphasis on circular economy principles. This may lead to new regulations governing the recyclability and reusability of Kevlar-based components in energy systems, promoting sustainable practices in the advanced materials sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!