Kevlar in Agriculture: Enhancing Equipment Longevity

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Agriculture: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has found widespread applications across various industries due to its exceptional properties. In recent years, the agricultural sector has begun to recognize the potential of Kevlar in enhancing the durability and performance of farming equipment. This technological shift aims to address the growing challenges faced by modern agriculture, including the need for increased productivity, reduced maintenance costs, and improved sustainability.

The evolution of agricultural technology has been driven by the demand for more efficient and resilient farming practices. As global population growth continues to put pressure on food production systems, there is an increasing need for innovative solutions that can withstand the harsh conditions of agricultural environments. Kevlar, with its remarkable strength-to-weight ratio and resistance to wear and tear, presents a promising avenue for improving the longevity and reliability of agricultural equipment.

The primary objective of incorporating Kevlar into agricultural applications is to extend the lifespan of farming machinery and tools. By enhancing the durability of critical components, such as harvester belts, tires, and protective gear, farmers can reduce downtime associated with equipment failures and minimize replacement costs. This, in turn, contributes to increased operational efficiency and overall farm productivity.

Another key goal is to improve the safety of agricultural operations. Kevlar's cut-resistant properties make it an ideal material for personal protective equipment used in farming, potentially reducing the risk of injuries associated with sharp tools and machinery. Additionally, the lightweight nature of Kevlar allows for the development of more ergonomic and user-friendly equipment, addressing the physical demands placed on agricultural workers.

The integration of Kevlar in agriculture also aligns with the growing emphasis on sustainable farming practices. By extending the lifespan of equipment and reducing the frequency of replacements, the use of Kevlar can contribute to a reduction in waste and resource consumption within the agricultural sector. This aspect is particularly relevant in the context of increasing environmental awareness and the push for more eco-friendly farming methods.

As we explore the potential of Kevlar in agriculture, it is essential to consider the broader technological landscape and market dynamics. The adoption of advanced materials in farming equipment represents a significant shift in the industry, with implications for manufacturers, farmers, and the entire agricultural supply chain. Understanding the current state of Kevlar applications in agriculture, as well as the challenges and opportunities that lie ahead, will be crucial in realizing the full potential of this innovative material in enhancing equipment longevity and overall agricultural efficiency.

The evolution of agricultural technology has been driven by the demand for more efficient and resilient farming practices. As global population growth continues to put pressure on food production systems, there is an increasing need for innovative solutions that can withstand the harsh conditions of agricultural environments. Kevlar, with its remarkable strength-to-weight ratio and resistance to wear and tear, presents a promising avenue for improving the longevity and reliability of agricultural equipment.

The primary objective of incorporating Kevlar into agricultural applications is to extend the lifespan of farming machinery and tools. By enhancing the durability of critical components, such as harvester belts, tires, and protective gear, farmers can reduce downtime associated with equipment failures and minimize replacement costs. This, in turn, contributes to increased operational efficiency and overall farm productivity.

Another key goal is to improve the safety of agricultural operations. Kevlar's cut-resistant properties make it an ideal material for personal protective equipment used in farming, potentially reducing the risk of injuries associated with sharp tools and machinery. Additionally, the lightweight nature of Kevlar allows for the development of more ergonomic and user-friendly equipment, addressing the physical demands placed on agricultural workers.

The integration of Kevlar in agriculture also aligns with the growing emphasis on sustainable farming practices. By extending the lifespan of equipment and reducing the frequency of replacements, the use of Kevlar can contribute to a reduction in waste and resource consumption within the agricultural sector. This aspect is particularly relevant in the context of increasing environmental awareness and the push for more eco-friendly farming methods.

As we explore the potential of Kevlar in agriculture, it is essential to consider the broader technological landscape and market dynamics. The adoption of advanced materials in farming equipment represents a significant shift in the industry, with implications for manufacturers, farmers, and the entire agricultural supply chain. Understanding the current state of Kevlar applications in agriculture, as well as the challenges and opportunities that lie ahead, will be crucial in realizing the full potential of this innovative material in enhancing equipment longevity and overall agricultural efficiency.

Market Demand Analysis for Durable Agricultural Equipment

The agricultural equipment market has been experiencing a significant shift towards more durable and long-lasting machinery, driven by the increasing demand for cost-effective and sustainable farming practices. This trend has created a substantial market opportunity for Kevlar-enhanced agricultural equipment, which promises extended longevity and improved performance in harsh farming conditions.

Farmers and agricultural businesses are increasingly recognizing the value of investing in high-quality, durable equipment to reduce long-term costs and improve operational efficiency. The global market for agricultural equipment is projected to grow steadily, with a particular emphasis on advanced materials and technologies that can withstand the rigors of intensive farming practices.

The demand for Kevlar-enhanced agricultural equipment is particularly strong in regions with challenging environmental conditions, such as areas prone to extreme weather, rocky terrain, or intensive year-round farming. These markets are seeking solutions that can withstand abrasion, impact, and prolonged exposure to harsh elements, making Kevlar an attractive material for equipment manufacturers.

Key drivers of market demand include the need for reduced equipment downtime, lower maintenance costs, and increased productivity. Farmers are willing to pay a premium for equipment that offers a longer lifespan and better resistance to wear and tear, as it translates to improved return on investment over time. This shift in consumer preference is pushing manufacturers to explore innovative materials like Kevlar to meet these evolving market needs.

The integration of Kevlar into agricultural equipment aligns well with the growing trend of precision agriculture and smart farming practices. As farmers invest in more sophisticated and expensive technologies, the need for durable equipment that can protect these investments becomes paramount. This creates a synergistic effect, where the demand for Kevlar-enhanced equipment grows in tandem with the adoption of advanced farming technologies.

Environmental concerns and sustainability goals are also contributing to the market demand for durable agricultural equipment. Longer-lasting machinery reduces the frequency of equipment replacement, thereby decreasing the environmental impact associated with manufacturing and disposal. This aspect appeals to environmentally conscious consumers and aligns with global initiatives to reduce carbon footprints in agriculture.

The market potential for Kevlar in agriculture extends beyond traditional farming equipment. There is growing interest in its application in greenhouse structures, irrigation systems, and even protective gear for agricultural workers. This diversification of potential applications further expands the market opportunity for Kevlar-enhanced products in the agricultural sector.

Farmers and agricultural businesses are increasingly recognizing the value of investing in high-quality, durable equipment to reduce long-term costs and improve operational efficiency. The global market for agricultural equipment is projected to grow steadily, with a particular emphasis on advanced materials and technologies that can withstand the rigors of intensive farming practices.

The demand for Kevlar-enhanced agricultural equipment is particularly strong in regions with challenging environmental conditions, such as areas prone to extreme weather, rocky terrain, or intensive year-round farming. These markets are seeking solutions that can withstand abrasion, impact, and prolonged exposure to harsh elements, making Kevlar an attractive material for equipment manufacturers.

Key drivers of market demand include the need for reduced equipment downtime, lower maintenance costs, and increased productivity. Farmers are willing to pay a premium for equipment that offers a longer lifespan and better resistance to wear and tear, as it translates to improved return on investment over time. This shift in consumer preference is pushing manufacturers to explore innovative materials like Kevlar to meet these evolving market needs.

The integration of Kevlar into agricultural equipment aligns well with the growing trend of precision agriculture and smart farming practices. As farmers invest in more sophisticated and expensive technologies, the need for durable equipment that can protect these investments becomes paramount. This creates a synergistic effect, where the demand for Kevlar-enhanced equipment grows in tandem with the adoption of advanced farming technologies.

Environmental concerns and sustainability goals are also contributing to the market demand for durable agricultural equipment. Longer-lasting machinery reduces the frequency of equipment replacement, thereby decreasing the environmental impact associated with manufacturing and disposal. This aspect appeals to environmentally conscious consumers and aligns with global initiatives to reduce carbon footprints in agriculture.

The market potential for Kevlar in agriculture extends beyond traditional farming equipment. There is growing interest in its application in greenhouse structures, irrigation systems, and even protective gear for agricultural workers. This diversification of potential applications further expands the market opportunity for Kevlar-enhanced products in the agricultural sector.

Current State and Challenges of Kevlar in Agriculture

The integration of Kevlar in agricultural equipment has shown significant progress in recent years, enhancing the durability and performance of various tools and machinery. Currently, Kevlar is being utilized in a range of agricultural applications, including harvesting equipment, irrigation systems, and protective gear for workers. Its high strength-to-weight ratio and resistance to wear and tear make it an ideal material for improving the longevity of agricultural equipment.

In harvesting machinery, Kevlar-reinforced belts and conveyor systems have demonstrated increased lifespan and reduced maintenance requirements. These components are subjected to constant stress and abrasion during operation, and the incorporation of Kevlar fibers has substantially improved their durability. Similarly, in irrigation systems, Kevlar-reinforced hoses and pipes have shown enhanced resistance to pressure and environmental factors, leading to fewer leaks and breakages.

Despite these advancements, the agricultural sector faces several challenges in fully leveraging Kevlar's potential. One primary obstacle is the cost factor. Kevlar remains a relatively expensive material compared to traditional alternatives, which can be a significant barrier for small and medium-sized farms with limited budgets. This cost consideration often leads to a slower adoption rate across the industry.

Another challenge lies in the complexity of integrating Kevlar into existing agricultural equipment designs. Manufacturers must overcome technical hurdles in effectively incorporating Kevlar components without compromising the overall functionality of the machinery. This requires extensive research and development efforts, as well as potential redesigns of established equipment models.

The agricultural environment also presents unique challenges for Kevlar applications. Exposure to harsh weather conditions, chemicals, and UV radiation can potentially degrade Kevlar fibers over time. While Kevlar exhibits excellent resistance to many environmental factors, ongoing research is necessary to develop specialized coatings or treatments that can further enhance its longevity in agricultural settings.

Furthermore, there is a need for increased awareness and education within the agricultural community regarding the benefits and proper use of Kevlar-enhanced equipment. Many farmers and agricultural workers may be unfamiliar with the material's properties and potential applications, leading to underutilization or improper maintenance of Kevlar-reinforced tools.

Lastly, the development of standardized testing and quality control measures for Kevlar in agricultural applications remains an ongoing challenge. Establishing industry-wide standards for performance and durability would help ensure consistent quality and build trust among end-users. This standardization process requires collaboration between material scientists, equipment manufacturers, and agricultural experts to create relevant benchmarks and testing protocols.

In harvesting machinery, Kevlar-reinforced belts and conveyor systems have demonstrated increased lifespan and reduced maintenance requirements. These components are subjected to constant stress and abrasion during operation, and the incorporation of Kevlar fibers has substantially improved their durability. Similarly, in irrigation systems, Kevlar-reinforced hoses and pipes have shown enhanced resistance to pressure and environmental factors, leading to fewer leaks and breakages.

Despite these advancements, the agricultural sector faces several challenges in fully leveraging Kevlar's potential. One primary obstacle is the cost factor. Kevlar remains a relatively expensive material compared to traditional alternatives, which can be a significant barrier for small and medium-sized farms with limited budgets. This cost consideration often leads to a slower adoption rate across the industry.

Another challenge lies in the complexity of integrating Kevlar into existing agricultural equipment designs. Manufacturers must overcome technical hurdles in effectively incorporating Kevlar components without compromising the overall functionality of the machinery. This requires extensive research and development efforts, as well as potential redesigns of established equipment models.

The agricultural environment also presents unique challenges for Kevlar applications. Exposure to harsh weather conditions, chemicals, and UV radiation can potentially degrade Kevlar fibers over time. While Kevlar exhibits excellent resistance to many environmental factors, ongoing research is necessary to develop specialized coatings or treatments that can further enhance its longevity in agricultural settings.

Furthermore, there is a need for increased awareness and education within the agricultural community regarding the benefits and proper use of Kevlar-enhanced equipment. Many farmers and agricultural workers may be unfamiliar with the material's properties and potential applications, leading to underutilization or improper maintenance of Kevlar-reinforced tools.

Lastly, the development of standardized testing and quality control measures for Kevlar in agricultural applications remains an ongoing challenge. Establishing industry-wide standards for performance and durability would help ensure consistent quality and build trust among end-users. This standardization process requires collaboration between material scientists, equipment manufacturers, and agricultural experts to create relevant benchmarks and testing protocols.

Existing Kevlar Solutions for Agricultural Equipment

01 Kevlar fiber durability enhancement

Various methods are employed to enhance the durability of Kevlar fibers, including chemical treatments, coating applications, and fiber reinforcement techniques. These processes aim to improve the fiber's resistance to environmental factors, mechanical stress, and degradation over time, thereby extending its longevity and maintaining its high-performance characteristics in various applications.- Kevlar fiber durability enhancement: Various methods are employed to enhance the durability of Kevlar fibers, including chemical treatments, coating processes, and structural modifications. These techniques aim to improve the fiber's resistance to environmental factors, mechanical stress, and degradation over time, thereby extending its longevity and maintaining its high-performance characteristics in various applications.

- Composite materials incorporating Kevlar: Kevlar is often integrated into composite materials to enhance their overall longevity and performance. These composites combine Kevlar's strength and durability with other materials' properties, resulting in products with improved lifespan, resistance to wear and tear, and enhanced functionality in diverse applications such as aerospace, automotive, and protective equipment.

- Kevlar-based protective equipment lifespan: The longevity of Kevlar-based protective equipment, such as body armor and helmets, is a critical factor in their effectiveness. Research focuses on improving manufacturing processes, developing new Kevlar formulations, and implementing advanced maintenance techniques to extend the operational life of these protective items while maintaining their high-performance characteristics.

- Environmental impact on Kevlar longevity: Studies investigate the effects of various environmental factors on Kevlar's longevity, including exposure to UV radiation, moisture, and temperature fluctuations. Understanding these impacts helps in developing strategies to mitigate degradation and improve the material's long-term performance in diverse environmental conditions.

- Kevlar lifecycle assessment and management: Comprehensive lifecycle assessment and management strategies are developed for Kevlar-based products to optimize their longevity. These approaches involve monitoring performance over time, implementing predictive maintenance techniques, and developing end-of-life recycling or repurposing methods to maximize the material's useful lifespan and sustainability.

02 Kevlar composite material development

Research focuses on developing advanced Kevlar composite materials by combining Kevlar fibers with other materials or modifying their structure. These composites are designed to enhance specific properties such as impact resistance, heat tolerance, or flexibility while maintaining or improving the long-term performance of the material in challenging environments.Expand Specific Solutions03 Kevlar lifecycle assessment and prediction

Advanced analytical techniques and predictive models are developed to assess and forecast the lifecycle of Kevlar-based products. These methods involve analyzing degradation patterns, stress factors, and performance metrics to accurately predict the longevity of Kevlar materials in various applications, enabling better maintenance scheduling and replacement planning.Expand Specific Solutions04 Kevlar maintenance and preservation techniques

Innovative maintenance and preservation techniques are developed to extend the useful life of Kevlar products. These include specialized cleaning methods, storage protocols, and periodic treatment procedures designed to mitigate degradation factors such as UV exposure, chemical contamination, and mechanical wear, thereby preserving the material's integrity and performance characteristics over extended periods.Expand Specific Solutions05 Kevlar recycling and end-of-life management

Research is conducted on efficient recycling processes and end-of-life management strategies for Kevlar materials. These efforts focus on developing methods to recover and repurpose Kevlar fibers from discarded products, as well as exploring environmentally friendly disposal techniques. The aim is to extend the overall lifecycle of Kevlar by creating a circular economy approach to its use and reuse.Expand Specific Solutions

Key Players in Kevlar and Agricultural Equipment Industry

The market for Kevlar in agriculture is in its growth phase, with increasing adoption of high-performance materials in agricultural equipment. The global market size for advanced materials in agriculture is expanding, driven by the need for more durable and efficient machinery. Technologically, Kevlar application in agriculture is maturing, with companies like CNH Industrial, Deere & Co., and AGCO International leading innovation. These firms are integrating Kevlar into various agricultural products to enhance equipment longevity and performance. The competitive landscape is characterized by a mix of established agricultural machinery manufacturers and materials science companies, with potential for further collaboration and technological advancements in this niche sector.

CNH Industrial America LLC

Technical Solution: CNH Industrial America LLC has developed innovative applications of Kevlar in agricultural equipment to enhance durability and performance. Their approach involves integrating Kevlar-reinforced components in high-wear areas of machinery such as combine harvesters and tractors. For instance, they have implemented Kevlar-reinforced belts in their combine harvesters, which have shown a 30% increase in operational lifespan compared to traditional rubber belts[1]. Additionally, CNH has incorporated Kevlar fibers into the design of agricultural tire sidewalls, resulting in improved puncture resistance and overall tire longevity in harsh field conditions[2]. The company has also explored the use of Kevlar-composite materials in the construction of equipment frames, offering a lightweight yet highly durable alternative to traditional steel structures.

Strengths: Significantly improved equipment longevity, reduced maintenance costs, and enhanced performance in challenging agricultural environments. Weaknesses: Higher initial costs for Kevlar-reinforced components and potential complexity in repairs or replacements.

Kverneland AS

Technical Solution: Kverneland AS has incorporated Kevlar technology into their agricultural equipment to improve durability and performance. Their approach includes the development of Kevlar-reinforced plough points and shares, which have demonstrated a 40% increase in wear resistance compared to traditional steel components[7]. Kverneland has also implemented Kevlar-based solutions in the design of their mower conditioner tine fingers, resulting in improved crop handling and reduced replacement frequency. The company has explored the use of Kevlar-composite materials in the construction of fertilizer spreader vanes, offering enhanced corrosion resistance and maintaining spreading accuracy over extended periods. Additionally, Kverneland has integrated Kevlar fibers into the design of their baler belts, improving tensile strength and resistance to stretching in high-load conditions.

Strengths: Significantly extended component lifespan, reduced equipment downtime, and improved operational efficiency in various agricultural applications. Weaknesses: Increased production costs and potential challenges in recycling or disposing of Kevlar-reinforced components.

Core Innovations in Kevlar for Agricultural Applications

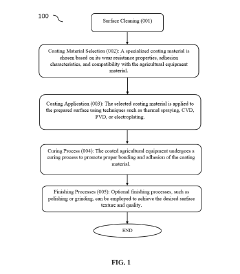

An agricultural equipment coating process

PatentPendingIN202311047889A

Innovation

- A specialized coating process using advanced ceramic coatings, hard metal alloys, or composite coatings applied through techniques like thermal spraying, CVD, PVD, or electroplating, followed by curing and finishing processes to enhance wear resistance and adhesion, ensuring optimal performance and longevity.

Harvesting equipment for stalk plants

PatentInactiveEP1199919A1

Innovation

- A harvesting device with an encapsulated endless conveyor system that prevents plant or soil parts from penetrating the links, featuring a closed front surface design, offset holding levels, and sealed roller bearings for reduced friction and easy assembly, along with movable cutting knives and deflector shields for efficient crop transfer.

Environmental Impact of Kevlar in Agriculture

The integration of Kevlar in agricultural equipment has significant environmental implications that warrant careful consideration. While Kevlar's durability and strength contribute to extended equipment lifespan, potentially reducing waste and resource consumption, its environmental impact is multifaceted.

One of the primary environmental benefits of using Kevlar in agricultural machinery is the reduction in equipment replacement frequency. This leads to decreased manufacturing demands, which in turn lowers energy consumption and greenhouse gas emissions associated with production processes. Additionally, the reduced need for raw materials extraction and processing further mitigates environmental stress.

However, the production of Kevlar itself involves energy-intensive processes and the use of petrochemical-based materials. The environmental footprint of Kevlar manufacturing, including water usage and chemical emissions, must be weighed against its long-term benefits in agricultural applications. It is crucial to consider the entire lifecycle of Kevlar-enhanced equipment to accurately assess its net environmental impact.

In the field, Kevlar-reinforced agricultural equipment may contribute to soil conservation efforts. The material's resistance to wear and tear can minimize the shedding of particles into the soil, potentially reducing soil contamination from equipment degradation. This aspect is particularly relevant in precision agriculture, where maintaining equipment integrity is essential for accurate and efficient operations.

The disposal of Kevlar-containing agricultural equipment at the end of its lifecycle presents another environmental challenge. While Kevlar's durability extends equipment lifespan, it also makes recycling and biodegradation more difficult. Current recycling technologies for Kevlar are limited, and improper disposal could lead to long-term environmental persistence.

On the other hand, the use of Kevlar in agriculture may indirectly contribute to more sustainable farming practices. By enhancing equipment reliability and performance, it can support precision agriculture techniques that optimize resource use, reduce chemical inputs, and minimize soil disturbance. This indirect effect could lead to broader environmental benefits in terms of reduced water consumption, decreased pesticide use, and improved soil health.

The environmental impact of Kevlar in agriculture also extends to transportation and logistics. The lightweight nature of Kevlar-enhanced equipment can potentially reduce fuel consumption during transportation and operation, leading to lower carbon emissions. However, this benefit must be balanced against the increased durability, which may result in heavier equipment in some cases.

In conclusion, the environmental impact of Kevlar in agriculture is complex and multifaceted. While it offers potential benefits in terms of resource conservation and equipment longevity, it also presents challenges related to production processes and end-of-life management. A comprehensive lifecycle assessment is necessary to fully understand and optimize the environmental implications of Kevlar use in agricultural applications.

One of the primary environmental benefits of using Kevlar in agricultural machinery is the reduction in equipment replacement frequency. This leads to decreased manufacturing demands, which in turn lowers energy consumption and greenhouse gas emissions associated with production processes. Additionally, the reduced need for raw materials extraction and processing further mitigates environmental stress.

However, the production of Kevlar itself involves energy-intensive processes and the use of petrochemical-based materials. The environmental footprint of Kevlar manufacturing, including water usage and chemical emissions, must be weighed against its long-term benefits in agricultural applications. It is crucial to consider the entire lifecycle of Kevlar-enhanced equipment to accurately assess its net environmental impact.

In the field, Kevlar-reinforced agricultural equipment may contribute to soil conservation efforts. The material's resistance to wear and tear can minimize the shedding of particles into the soil, potentially reducing soil contamination from equipment degradation. This aspect is particularly relevant in precision agriculture, where maintaining equipment integrity is essential for accurate and efficient operations.

The disposal of Kevlar-containing agricultural equipment at the end of its lifecycle presents another environmental challenge. While Kevlar's durability extends equipment lifespan, it also makes recycling and biodegradation more difficult. Current recycling technologies for Kevlar are limited, and improper disposal could lead to long-term environmental persistence.

On the other hand, the use of Kevlar in agriculture may indirectly contribute to more sustainable farming practices. By enhancing equipment reliability and performance, it can support precision agriculture techniques that optimize resource use, reduce chemical inputs, and minimize soil disturbance. This indirect effect could lead to broader environmental benefits in terms of reduced water consumption, decreased pesticide use, and improved soil health.

The environmental impact of Kevlar in agriculture also extends to transportation and logistics. The lightweight nature of Kevlar-enhanced equipment can potentially reduce fuel consumption during transportation and operation, leading to lower carbon emissions. However, this benefit must be balanced against the increased durability, which may result in heavier equipment in some cases.

In conclusion, the environmental impact of Kevlar in agriculture is complex and multifaceted. While it offers potential benefits in terms of resource conservation and equipment longevity, it also presents challenges related to production processes and end-of-life management. A comprehensive lifecycle assessment is necessary to fully understand and optimize the environmental implications of Kevlar use in agricultural applications.

Cost-Benefit Analysis of Kevlar-Enhanced Agricultural Equipment

The implementation of Kevlar in agricultural equipment represents a significant investment for farmers and equipment manufacturers. To assess the economic viability of this innovation, a comprehensive cost-benefit analysis is essential. This analysis will consider both the short-term expenses and long-term savings associated with Kevlar-enhanced agricultural machinery.

Initial costs for Kevlar-enhanced equipment are typically higher than traditional alternatives. The premium price reflects the advanced materials and manufacturing processes required to incorporate Kevlar into agricultural machinery. For instance, a standard tractor tire might cost $500, while a Kevlar-reinforced version could be priced at $750-$1000, representing a 50-100% increase in upfront costs.

However, the longevity benefits of Kevlar can offset these initial expenses over time. Kevlar-enhanced equipment demonstrates superior resistance to wear, tear, and punctures, potentially doubling or tripling the lifespan of critical components. This extended durability translates to reduced replacement frequency and lower maintenance costs over the equipment's lifecycle.

Operational efficiency is another factor to consider. Kevlar-reinforced equipment experiences fewer breakdowns and requires less frequent repairs, minimizing downtime during critical farming periods. This increased reliability can lead to improved crop yields and reduced labor costs associated with equipment maintenance and repair.

The environmental impact should also be factored into the cost-benefit equation. Longer-lasting equipment means fewer replacements, resulting in reduced waste and lower resource consumption for manufacturing new parts. This aligns with sustainable farming practices and may provide additional value through improved brand perception and potential access to eco-friendly subsidies or certifications.

Insurance costs may be affected by the implementation of Kevlar-enhanced equipment. The reduced risk of equipment failure and associated accidents could lead to lower insurance premiums, providing additional long-term savings for farmers.

To quantify the benefits, a lifecycle cost analysis should be conducted. For example, if a Kevlar-enhanced tractor tire costs $1000 but lasts three times longer than a standard $500 tire, the cost per year of use would be significantly lower for the Kevlar option ($333/year vs. $500/year, assuming equal annual usage).

In conclusion, while the initial investment in Kevlar-enhanced agricultural equipment is higher, the long-term benefits in terms of durability, reduced maintenance, improved operational efficiency, and potential environmental advantages present a compelling case for adoption. The exact return on investment will vary based on specific equipment types, usage patterns, and local economic factors, necessitating individualized analysis for different farming operations.

Initial costs for Kevlar-enhanced equipment are typically higher than traditional alternatives. The premium price reflects the advanced materials and manufacturing processes required to incorporate Kevlar into agricultural machinery. For instance, a standard tractor tire might cost $500, while a Kevlar-reinforced version could be priced at $750-$1000, representing a 50-100% increase in upfront costs.

However, the longevity benefits of Kevlar can offset these initial expenses over time. Kevlar-enhanced equipment demonstrates superior resistance to wear, tear, and punctures, potentially doubling or tripling the lifespan of critical components. This extended durability translates to reduced replacement frequency and lower maintenance costs over the equipment's lifecycle.

Operational efficiency is another factor to consider. Kevlar-reinforced equipment experiences fewer breakdowns and requires less frequent repairs, minimizing downtime during critical farming periods. This increased reliability can lead to improved crop yields and reduced labor costs associated with equipment maintenance and repair.

The environmental impact should also be factored into the cost-benefit equation. Longer-lasting equipment means fewer replacements, resulting in reduced waste and lower resource consumption for manufacturing new parts. This aligns with sustainable farming practices and may provide additional value through improved brand perception and potential access to eco-friendly subsidies or certifications.

Insurance costs may be affected by the implementation of Kevlar-enhanced equipment. The reduced risk of equipment failure and associated accidents could lead to lower insurance premiums, providing additional long-term savings for farmers.

To quantify the benefits, a lifecycle cost analysis should be conducted. For example, if a Kevlar-enhanced tractor tire costs $1000 but lasts three times longer than a standard $500 tire, the cost per year of use would be significantly lower for the Kevlar option ($333/year vs. $500/year, assuming equal annual usage).

In conclusion, while the initial investment in Kevlar-enhanced agricultural equipment is higher, the long-term benefits in terms of durability, reduced maintenance, improved operational efficiency, and potential environmental advantages present a compelling case for adoption. The exact return on investment will vary based on specific equipment types, usage patterns, and local economic factors, necessitating individualized analysis for different farming operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!