Kevlar Innovations Impacting High-Tech Sportswear

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Sportswear: Evolution and Objectives

Kevlar, a high-performance synthetic fiber developed by DuPont in the 1960s, has revolutionized the sportswear industry since its introduction. Initially designed for military and industrial applications, Kevlar's exceptional strength-to-weight ratio and heat-resistant properties quickly caught the attention of sportswear manufacturers seeking innovative materials to enhance athletic performance.

The evolution of Kevlar in sportswear can be traced back to the 1970s when it was first incorporated into bicycle tires. This marked the beginning of a new era in sports equipment, showcasing Kevlar's potential to improve durability and performance. As research and development progressed, the applications of Kevlar in sportswear expanded rapidly, encompassing a wide range of products from protective gear to high-performance apparel.

Throughout the 1980s and 1990s, Kevlar found its way into various sports disciplines. In motorsports, it was used to create lightweight, impact-resistant helmets and body armor. The sailing industry adopted Kevlar for sails and rigging, capitalizing on its strength and resistance to UV degradation. Meanwhile, the material's cut-resistant properties made it ideal for fencing uniforms and protective gloves in various contact sports.

The turn of the millennium saw a surge in Kevlar's application in mainstream sportswear. Advanced manufacturing techniques allowed for the integration of Kevlar fibers into fabrics, creating garments that were not only protective but also comfortable and stylish. This breakthrough led to the development of high-performance athletic wear that offered enhanced durability, abrasion resistance, and thermal regulation.

In recent years, the objectives for Kevlar innovations in sportswear have become increasingly focused on sustainability and customization. Researchers are exploring ways to make Kevlar production more environmentally friendly and to improve its recyclability. Additionally, there is a growing emphasis on developing Kevlar-based materials that can be tailored to specific sports and individual athlete needs, such as variable stiffness fabrics for targeted muscle support.

Looking ahead, the future of Kevlar in sportswear aims to push the boundaries of performance and functionality. Objectives include the development of smart fabrics that incorporate Kevlar with sensors and responsive technologies, enabling real-time monitoring of athlete performance and physiological data. There is also a drive towards creating ultra-lightweight Kevlar composites that can provide maximum protection with minimal bulk, catering to the ever-increasing demands of high-intensity sports.

The evolution of Kevlar in sportswear can be traced back to the 1970s when it was first incorporated into bicycle tires. This marked the beginning of a new era in sports equipment, showcasing Kevlar's potential to improve durability and performance. As research and development progressed, the applications of Kevlar in sportswear expanded rapidly, encompassing a wide range of products from protective gear to high-performance apparel.

Throughout the 1980s and 1990s, Kevlar found its way into various sports disciplines. In motorsports, it was used to create lightweight, impact-resistant helmets and body armor. The sailing industry adopted Kevlar for sails and rigging, capitalizing on its strength and resistance to UV degradation. Meanwhile, the material's cut-resistant properties made it ideal for fencing uniforms and protective gloves in various contact sports.

The turn of the millennium saw a surge in Kevlar's application in mainstream sportswear. Advanced manufacturing techniques allowed for the integration of Kevlar fibers into fabrics, creating garments that were not only protective but also comfortable and stylish. This breakthrough led to the development of high-performance athletic wear that offered enhanced durability, abrasion resistance, and thermal regulation.

In recent years, the objectives for Kevlar innovations in sportswear have become increasingly focused on sustainability and customization. Researchers are exploring ways to make Kevlar production more environmentally friendly and to improve its recyclability. Additionally, there is a growing emphasis on developing Kevlar-based materials that can be tailored to specific sports and individual athlete needs, such as variable stiffness fabrics for targeted muscle support.

Looking ahead, the future of Kevlar in sportswear aims to push the boundaries of performance and functionality. Objectives include the development of smart fabrics that incorporate Kevlar with sensors and responsive technologies, enabling real-time monitoring of athlete performance and physiological data. There is also a drive towards creating ultra-lightweight Kevlar composites that can provide maximum protection with minimal bulk, catering to the ever-increasing demands of high-intensity sports.

Market Demand for High-Performance Sportswear

The market demand for high-performance sportswear has been experiencing significant growth in recent years, driven by several key factors. Consumers are increasingly prioritizing health and fitness, leading to a surge in participation in various sports and physical activities. This trend has created a robust demand for sportswear that not only enhances performance but also provides comfort and durability.

The global sportswear market has been expanding at a steady pace, with a particular emphasis on high-tech materials and innovative designs. Athletes and fitness enthusiasts are seeking garments that offer advanced features such as moisture-wicking, temperature regulation, and improved aerodynamics. This demand extends beyond professional sports to amateur athletes and everyday consumers who value performance-oriented clothing for their workouts and leisure activities.

Kevlar, traditionally known for its use in protective gear and aerospace applications, has found a new niche in high-performance sportswear. Its exceptional strength-to-weight ratio and heat-resistant properties make it an attractive material for sportswear manufacturers looking to innovate and differentiate their products. The incorporation of Kevlar fibers into sportswear fabrics has opened up new possibilities for creating ultra-lightweight, durable, and protective garments.

The market has shown a strong appetite for sportswear that incorporates cutting-edge materials like Kevlar. Consumers are willing to pay premium prices for garments that promise enhanced performance and longevity. This trend is particularly evident in high-impact sports such as cycling, motorcycling, and extreme sports, where protective properties are crucial.

Furthermore, the growing awareness of sustainability in fashion has created a demand for durable, long-lasting sportswear. Kevlar's durability aligns well with this consumer preference, as it can potentially reduce the frequency of garment replacement and contribute to more sustainable consumption patterns in the sportswear industry.

The sportswear market's segmentation has also contributed to the demand for specialized, high-performance materials. Different sports and activities require specific performance attributes, and Kevlar's versatility allows it to be adapted for various applications, from reinforced areas in running shoes to protective layers in cycling jerseys.

As the lines between athletic wear and casual wear continue to blur, there is an increasing demand for sportswear that combines performance features with style. This trend, often referred to as "athleisure," has further expanded the potential market for high-tech sportswear incorporating materials like Kevlar, as consumers seek versatile garments that can transition from workout to casual settings.

The global sportswear market has been expanding at a steady pace, with a particular emphasis on high-tech materials and innovative designs. Athletes and fitness enthusiasts are seeking garments that offer advanced features such as moisture-wicking, temperature regulation, and improved aerodynamics. This demand extends beyond professional sports to amateur athletes and everyday consumers who value performance-oriented clothing for their workouts and leisure activities.

Kevlar, traditionally known for its use in protective gear and aerospace applications, has found a new niche in high-performance sportswear. Its exceptional strength-to-weight ratio and heat-resistant properties make it an attractive material for sportswear manufacturers looking to innovate and differentiate their products. The incorporation of Kevlar fibers into sportswear fabrics has opened up new possibilities for creating ultra-lightweight, durable, and protective garments.

The market has shown a strong appetite for sportswear that incorporates cutting-edge materials like Kevlar. Consumers are willing to pay premium prices for garments that promise enhanced performance and longevity. This trend is particularly evident in high-impact sports such as cycling, motorcycling, and extreme sports, where protective properties are crucial.

Furthermore, the growing awareness of sustainability in fashion has created a demand for durable, long-lasting sportswear. Kevlar's durability aligns well with this consumer preference, as it can potentially reduce the frequency of garment replacement and contribute to more sustainable consumption patterns in the sportswear industry.

The sportswear market's segmentation has also contributed to the demand for specialized, high-performance materials. Different sports and activities require specific performance attributes, and Kevlar's versatility allows it to be adapted for various applications, from reinforced areas in running shoes to protective layers in cycling jerseys.

As the lines between athletic wear and casual wear continue to blur, there is an increasing demand for sportswear that combines performance features with style. This trend, often referred to as "athleisure," has further expanded the potential market for high-tech sportswear incorporating materials like Kevlar, as consumers seek versatile garments that can transition from workout to casual settings.

Current Kevlar Applications and Challenges in Sportswear

Kevlar, a high-strength synthetic fiber developed by DuPont, has found extensive applications in the sportswear industry due to its exceptional properties. In the realm of high-tech sportswear, Kevlar is primarily utilized for its lightweight, high tensile strength, and abrasion-resistant characteristics. Current applications include reinforcement in athletic shoes, protective gear for extreme sports, and high-performance apparel for activities such as cycling, mountaineering, and motorsports.

In athletic footwear, Kevlar is incorporated into the upper material and sole construction to enhance durability and provide better support. It is particularly beneficial in areas prone to wear and tear, such as the toe box and heel counter. For protective gear, Kevlar is used in impact-resistant padding for sports like skateboarding, snowboarding, and American football, offering superior protection without compromising mobility.

High-performance apparel leveraging Kevlar includes cycling shorts with reinforced panels to prevent abrasion during falls, mountaineering jackets with Kevlar-reinforced elbows and shoulders for durability against rock surfaces, and motorsports suits that provide both abrasion resistance and fire protection. The fiber's heat-resistant properties make it ideal for these high-risk sports environments.

Despite its widespread adoption, Kevlar faces several challenges in the sportswear industry. One significant issue is the fiber's inherent stiffness, which can compromise comfort and flexibility in garments. Manufacturers are continually working to develop blending techniques and fabric constructions that maintain Kevlar's protective properties while improving wearability and comfort.

Another challenge lies in the cost-effectiveness of Kevlar-based sportswear. The high production costs of Kevlar fibers translate to premium pricing for end products, limiting mass-market adoption. This has led to ongoing research into more cost-efficient production methods and the exploration of alternative high-performance fibers that could offer similar benefits at a lower cost.

Environmental concerns also pose a challenge for Kevlar in sportswear. The fiber is not biodegradable, raising sustainability issues in an increasingly eco-conscious market. Efforts are underway to develop recycling processes for Kevlar-containing products and to explore bio-based alternatives that could provide comparable performance with reduced environmental impact.

Lastly, there is a continuous push for innovation to expand Kevlar's functionality in sportswear. Current research focuses on enhancing the fiber's moisture-wicking properties, improving its UV resistance for outdoor applications, and developing smart textile integrations that could incorporate sensors or adaptive properties into Kevlar-based fabrics.

In athletic footwear, Kevlar is incorporated into the upper material and sole construction to enhance durability and provide better support. It is particularly beneficial in areas prone to wear and tear, such as the toe box and heel counter. For protective gear, Kevlar is used in impact-resistant padding for sports like skateboarding, snowboarding, and American football, offering superior protection without compromising mobility.

High-performance apparel leveraging Kevlar includes cycling shorts with reinforced panels to prevent abrasion during falls, mountaineering jackets with Kevlar-reinforced elbows and shoulders for durability against rock surfaces, and motorsports suits that provide both abrasion resistance and fire protection. The fiber's heat-resistant properties make it ideal for these high-risk sports environments.

Despite its widespread adoption, Kevlar faces several challenges in the sportswear industry. One significant issue is the fiber's inherent stiffness, which can compromise comfort and flexibility in garments. Manufacturers are continually working to develop blending techniques and fabric constructions that maintain Kevlar's protective properties while improving wearability and comfort.

Another challenge lies in the cost-effectiveness of Kevlar-based sportswear. The high production costs of Kevlar fibers translate to premium pricing for end products, limiting mass-market adoption. This has led to ongoing research into more cost-efficient production methods and the exploration of alternative high-performance fibers that could offer similar benefits at a lower cost.

Environmental concerns also pose a challenge for Kevlar in sportswear. The fiber is not biodegradable, raising sustainability issues in an increasingly eco-conscious market. Efforts are underway to develop recycling processes for Kevlar-containing products and to explore bio-based alternatives that could provide comparable performance with reduced environmental impact.

Lastly, there is a continuous push for innovation to expand Kevlar's functionality in sportswear. Current research focuses on enhancing the fiber's moisture-wicking properties, improving its UV resistance for outdoor applications, and developing smart textile integrations that could incorporate sensors or adaptive properties into Kevlar-based fabrics.

Existing Kevlar Integration Methods in Sportswear

01 Kevlar-reinforced impact-resistant structures

Kevlar fibers are incorporated into various structures to enhance impact resistance. These structures can include protective gear, vehicle components, and building materials. The high tensile strength and low weight of Kevlar make it an ideal material for absorbing and dissipating impact energy, improving overall safety and durability.- Kevlar-reinforced impact-resistant structures: Kevlar fibers are incorporated into various structures to enhance impact resistance. These structures can include protective gear, vehicle components, and building materials. The high tensile strength and low weight of Kevlar make it an ideal material for absorbing and dissipating impact energy, improving overall safety and durability.

- Kevlar composites for ballistic protection: Kevlar is used in composite materials designed for ballistic protection. These composites often combine Kevlar with other materials to create lightweight yet highly effective armor for personal protection, vehicle armor, and military applications. The unique properties of Kevlar allow for the development of flexible and rigid armor solutions.

- Kevlar-enhanced sporting equipment: Sporting equipment incorporates Kevlar to improve impact resistance and performance. This includes items such as helmets, protective pads, and high-performance sports gear. The addition of Kevlar helps to reduce the risk of injury while maintaining lightweight and flexible properties essential for athletic activities.

- Kevlar applications in aerospace and automotive industries: Kevlar is utilized in aerospace and automotive industries to enhance the impact resistance of critical components. This includes the use of Kevlar in aircraft fuselages, automotive body panels, and other parts subject to high-stress environments. The material's high strength-to-weight ratio contributes to improved fuel efficiency and safety in these applications.

- Kevlar-based impact-absorbing materials for consumer products: Consumer products incorporate Kevlar-based materials to improve impact resistance and durability. This includes items such as smartphone cases, luggage, and outdoor equipment. The use of Kevlar in these products provides enhanced protection against drops, impacts, and other forms of physical stress, extending the lifespan of the items.

02 Kevlar composites for ballistic protection

Kevlar is used in composite materials designed for ballistic protection. These composites often combine Kevlar with other materials to create lightweight yet highly effective armor for personal protection, vehicle armor, and military applications. The layered structure of these composites helps to dissipate the energy of incoming projectiles.Expand Specific Solutions03 Impact-resistant Kevlar-based fabrics

Specialized fabrics incorporating Kevlar fibers are developed for impact-resistant applications. These fabrics can be used in protective clothing, sports equipment, and industrial safety gear. The unique properties of Kevlar allow for the creation of flexible yet highly durable fabrics that can withstand significant impact forces.Expand Specific Solutions04 Kevlar-enhanced impact absorption systems

Impact absorption systems utilizing Kevlar are designed for various applications. These systems can include shock-absorbing materials, energy-dissipating structures, and cushioning elements. The incorporation of Kevlar fibers or composites helps to improve the overall impact resistance and energy absorption capabilities of these systems.Expand Specific Solutions05 Kevlar-reinforced impact-resistant coatings

Coatings incorporating Kevlar fibers or particles are developed to enhance impact resistance of surfaces. These coatings can be applied to various substrates, including metals, plastics, and composites, to improve their durability and impact resistance. The addition of Kevlar to the coating formulation helps to distribute impact forces and prevent damage to the underlying material.Expand Specific Solutions

Key Players in Kevlar-Enhanced Sportswear Market

The Kevlar innovations in high-tech sportswear market is in a growth phase, with increasing demand for advanced performance apparel. The global market size for high-performance sportswear is expanding rapidly, driven by consumer interest in durable, lightweight, and protective athletic gear. Technologically, the field is advancing, with companies like Under Armour and ASICS leading innovation. These firms are integrating Kevlar into their products to enhance durability and performance. Other players such as New Balance and Adidas are also exploring Kevlar applications, indicating a competitive landscape with ongoing research and development. The technology's maturity is progressing, with continuous improvements in Kevlar-based fabric formulations and manufacturing processes.

Under Armour, Inc.

Technical Solution: Under Armour has developed innovative Kevlar-infused sportswear, focusing on enhancing durability and performance. Their technology integrates Kevlar fibers into fabric blends, creating lightweight yet highly resistant materials. This approach has led to the creation of products like the UA Storm Armour Fleece® with Kevlar, which offers superior abrasion resistance while maintaining breathability[1]. The company has also applied Kevlar in footwear, developing the UA ClutchFit® technology that uses a Kevlar-infused synthetic leather upper to provide both flexibility and strength[2].

Strengths: Enhanced durability and performance, lightweight materials, versatile application across various sportswear categories. Weaknesses: Potentially higher production costs, limited to high-end product lines.

ASICS Corp.

Technical Solution: ASICS has integrated Kevlar into their high-performance sportswear, focusing on enhancing durability and protection in their running and tennis product lines. The company has developed a proprietary technology called "Kevlar Reinforced Mesh," which incorporates Kevlar fibers into strategic areas of their shoes to improve durability without adding significant weight[7]. In their tennis shoes, ASICS uses Kevlar-reinforced panels in high-wear areas to extend the product lifespan. The company has also experimented with Kevlar-infused fabrics in their apparel line, particularly for compression gear and protective equipment for sports like rugby and American football[8].

Strengths: Targeted application in high-wear areas, improved product longevity, balanced approach to weight and durability. Weaknesses: Limited to specific product categories, potential increase in production costs.

Breakthrough Kevlar Innovations for Sportswear

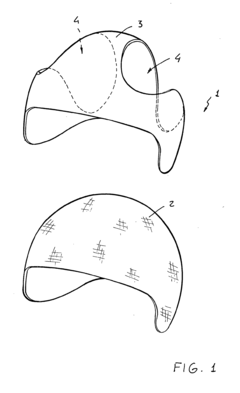

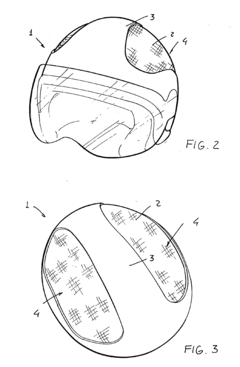

Method for decorating and reinforcing a high strength safety helmet and helmet made thereby

PatentInactiveEP1300089A1

Innovation

- A method involving layering high-strength fibers like carbon and Kevlar in a mold, followed by applying a thermoplastic overcap that provides reinforcement and aesthetic enhancement by exposing selected regions while integrating conventional safety features.

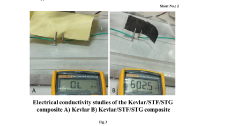

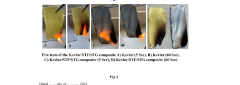

An improved process for fabricating kevlar fabric composite for multifunctional soft body armor

PatentPendingIN202321039845A

Innovation

- A composite material process involving Kevlar fabric impregnated with shear thickening fluid (STF) and shear-stiffening gel (STG), utilizing metal phosphate and carbon nanotubes, to enhance impact resistance, electrical conductivity, and flame retardancy, while allowing for temperature regulation.

Environmental Impact of Kevlar in Sportswear

The environmental impact of Kevlar in sportswear is a complex issue that requires careful consideration. Kevlar, a high-strength synthetic fiber, has revolutionized the sportswear industry by providing lightweight, durable, and high-performance materials. However, its production and use have significant environmental implications that must be addressed.

The manufacturing process of Kevlar is energy-intensive and involves the use of harmful chemicals, contributing to greenhouse gas emissions and potential environmental contamination. The production of Kevlar requires substantial amounts of petroleum-based resources, which are non-renewable and contribute to the depletion of fossil fuels. Additionally, the chemical processes involved in Kevlar production generate hazardous waste that requires proper disposal to prevent environmental pollution.

On the positive side, the durability and longevity of Kevlar-enhanced sportswear can lead to reduced consumption and waste in the long term. Garments and equipment made with Kevlar tend to last longer, potentially decreasing the need for frequent replacements and thus reducing overall resource consumption and waste generation.

However, the end-of-life disposal of Kevlar-containing products presents challenges. Kevlar is not biodegradable and can persist in the environment for extended periods. While recycling technologies for Kevlar exist, they are not yet widely implemented, leading to most Kevlar-enhanced sportswear ending up in landfills or incineration facilities.

The use of Kevlar in sportswear also impacts water systems. During washing, synthetic fibers like Kevlar can shed microfibers that enter waterways, contributing to microplastic pollution in oceans and freshwater bodies. This poses risks to aquatic ecosystems and potentially enters the food chain.

Efforts are being made to mitigate the environmental impact of Kevlar in sportswear. Research is ongoing to develop more sustainable production methods, including the use of bio-based precursors and energy-efficient manufacturing processes. Additionally, innovations in recycling technologies are being explored to improve the circularity of Kevlar-containing products.

The sportswear industry is also investigating alternatives to Kevlar that offer similar performance characteristics with reduced environmental impact. These include bio-based fibers and recycled materials that can provide comparable strength and durability while minimizing the ecological footprint.

In conclusion, while Kevlar has undoubtedly enhanced the performance and durability of sportswear, its environmental impact remains a significant concern. Balancing the benefits of Kevlar's unique properties with the need for environmental sustainability will be crucial for the future of high-tech sportswear. This will likely involve a combination of improved production methods, enhanced recycling capabilities, and the development of eco-friendly alternatives.

The manufacturing process of Kevlar is energy-intensive and involves the use of harmful chemicals, contributing to greenhouse gas emissions and potential environmental contamination. The production of Kevlar requires substantial amounts of petroleum-based resources, which are non-renewable and contribute to the depletion of fossil fuels. Additionally, the chemical processes involved in Kevlar production generate hazardous waste that requires proper disposal to prevent environmental pollution.

On the positive side, the durability and longevity of Kevlar-enhanced sportswear can lead to reduced consumption and waste in the long term. Garments and equipment made with Kevlar tend to last longer, potentially decreasing the need for frequent replacements and thus reducing overall resource consumption and waste generation.

However, the end-of-life disposal of Kevlar-containing products presents challenges. Kevlar is not biodegradable and can persist in the environment for extended periods. While recycling technologies for Kevlar exist, they are not yet widely implemented, leading to most Kevlar-enhanced sportswear ending up in landfills or incineration facilities.

The use of Kevlar in sportswear also impacts water systems. During washing, synthetic fibers like Kevlar can shed microfibers that enter waterways, contributing to microplastic pollution in oceans and freshwater bodies. This poses risks to aquatic ecosystems and potentially enters the food chain.

Efforts are being made to mitigate the environmental impact of Kevlar in sportswear. Research is ongoing to develop more sustainable production methods, including the use of bio-based precursors and energy-efficient manufacturing processes. Additionally, innovations in recycling technologies are being explored to improve the circularity of Kevlar-containing products.

The sportswear industry is also investigating alternatives to Kevlar that offer similar performance characteristics with reduced environmental impact. These include bio-based fibers and recycled materials that can provide comparable strength and durability while minimizing the ecological footprint.

In conclusion, while Kevlar has undoubtedly enhanced the performance and durability of sportswear, its environmental impact remains a significant concern. Balancing the benefits of Kevlar's unique properties with the need for environmental sustainability will be crucial for the future of high-tech sportswear. This will likely involve a combination of improved production methods, enhanced recycling capabilities, and the development of eco-friendly alternatives.

Durability and Lifecycle Analysis of Kevlar Sportswear

The durability and lifecycle analysis of Kevlar sportswear reveals significant advancements in high-performance athletic apparel. Kevlar, known for its exceptional strength-to-weight ratio, has been successfully integrated into various sportswear applications, enhancing both durability and functionality.

Kevlar-infused sportswear demonstrates remarkable resistance to abrasion, tears, and punctures. This characteristic is particularly beneficial in high-impact sports such as cycling, mountaineering, and extreme sports, where gear is subjected to intense wear and tear. The material's ability to withstand repeated stress and strain contributes to extended product lifespans, reducing the frequency of replacements and ultimately lowering the environmental impact of sportswear production.

Lifecycle assessments of Kevlar sportswear indicate a higher initial production cost compared to traditional materials. However, the extended durability often results in a lower total cost of ownership over time. This longevity factor aligns with growing consumer demands for sustainable and long-lasting products in the athletic wear market.

The integration of Kevlar fibers into sportswear fabrics has led to innovative manufacturing techniques. Blending Kevlar with other materials like nylon or polyester creates hybrid fabrics that balance durability with comfort and flexibility. These advancements have expanded the application of Kevlar beyond protective gear into everyday athletic wear, including running shoes, compression garments, and outdoor apparel.

Environmental considerations play a crucial role in the lifecycle analysis of Kevlar sportswear. While the production of Kevlar is energy-intensive, its durability contributes to a reduced need for frequent replacements, potentially offsetting the initial environmental impact. End-of-life management for Kevlar products remains a challenge, as the material is not biodegradable and requires specialized recycling processes.

Recent innovations in Kevlar sportswear focus on enhancing recyclability and reducing the environmental footprint. Researchers are exploring bio-based alternatives and developing more efficient recycling methods for Kevlar-containing products. These efforts aim to improve the overall sustainability profile of Kevlar sportswear throughout its lifecycle.

The durability of Kevlar sportswear also translates to improved performance for athletes. The material's resistance to wear ensures consistent protection and support over extended periods, allowing athletes to focus on their performance without concerns about equipment degradation. This reliability factor has contributed to the growing adoption of Kevlar-enhanced products in professional sports and high-endurance activities.

Kevlar-infused sportswear demonstrates remarkable resistance to abrasion, tears, and punctures. This characteristic is particularly beneficial in high-impact sports such as cycling, mountaineering, and extreme sports, where gear is subjected to intense wear and tear. The material's ability to withstand repeated stress and strain contributes to extended product lifespans, reducing the frequency of replacements and ultimately lowering the environmental impact of sportswear production.

Lifecycle assessments of Kevlar sportswear indicate a higher initial production cost compared to traditional materials. However, the extended durability often results in a lower total cost of ownership over time. This longevity factor aligns with growing consumer demands for sustainable and long-lasting products in the athletic wear market.

The integration of Kevlar fibers into sportswear fabrics has led to innovative manufacturing techniques. Blending Kevlar with other materials like nylon or polyester creates hybrid fabrics that balance durability with comfort and flexibility. These advancements have expanded the application of Kevlar beyond protective gear into everyday athletic wear, including running shoes, compression garments, and outdoor apparel.

Environmental considerations play a crucial role in the lifecycle analysis of Kevlar sportswear. While the production of Kevlar is energy-intensive, its durability contributes to a reduced need for frequent replacements, potentially offsetting the initial environmental impact. End-of-life management for Kevlar products remains a challenge, as the material is not biodegradable and requires specialized recycling processes.

Recent innovations in Kevlar sportswear focus on enhancing recyclability and reducing the environmental footprint. Researchers are exploring bio-based alternatives and developing more efficient recycling methods for Kevlar-containing products. These efforts aim to improve the overall sustainability profile of Kevlar sportswear throughout its lifecycle.

The durability of Kevlar sportswear also translates to improved performance for athletes. The material's resistance to wear ensures consistent protection and support over extended periods, allowing athletes to focus on their performance without concerns about equipment degradation. This reliability factor has contributed to the growing adoption of Kevlar-enhanced products in professional sports and high-endurance activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!