Kevlar's Importance in Prolonging Wearable Device Lifespan

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Wearables: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has found its way into numerous applications due to its exceptional properties. In recent years, the wearable technology industry has begun to explore the potential of Kevlar to enhance the durability and longevity of their devices. This technological convergence marks a significant milestone in the evolution of both materials science and consumer electronics.

The wearable device market has experienced exponential growth over the past decade, with smartwatches, fitness trackers, and health monitoring devices becoming increasingly prevalent in everyday life. However, these devices often face challenges related to durability, as they are subjected to constant wear and tear, environmental stressors, and potential impacts. This is where Kevlar's unique characteristics come into play, offering a promising solution to extend the lifespan of wearable technology.

Kevlar's remarkable strength-to-weight ratio, heat resistance, and flexibility make it an ideal candidate for integration into wearable devices. By incorporating Kevlar into device casings, straps, and internal components, manufacturers can significantly improve the overall durability and resilience of their products. This not only enhances user experience but also addresses the growing concern of electronic waste by prolonging device lifespans.

The primary objective of this technological integration is to create wearable devices that can withstand the rigors of daily use while maintaining their functionality and aesthetic appeal. By leveraging Kevlar's properties, manufacturers aim to develop products that are resistant to scratches, impacts, and environmental factors such as moisture and temperature fluctuations. This, in turn, could lead to a paradigm shift in consumer expectations regarding the longevity and reliability of wearable technology.

Furthermore, the incorporation of Kevlar into wearables aligns with the broader trend of sustainable product design. As consumers become increasingly environmentally conscious, the demand for durable, long-lasting electronic devices is on the rise. By extending the lifespan of wearable devices, manufacturers can reduce the frequency of replacements, thereby minimizing electronic waste and the associated environmental impact.

The exploration of Kevlar in wearable technology also opens up new avenues for innovation in product design and manufacturing processes. This includes the development of novel composite materials that combine Kevlar with other advanced materials to achieve optimal performance characteristics. Such innovations have the potential to revolutionize not only the wearable technology sector but also influence other industries where durability and lightweight properties are crucial.

The wearable device market has experienced exponential growth over the past decade, with smartwatches, fitness trackers, and health monitoring devices becoming increasingly prevalent in everyday life. However, these devices often face challenges related to durability, as they are subjected to constant wear and tear, environmental stressors, and potential impacts. This is where Kevlar's unique characteristics come into play, offering a promising solution to extend the lifespan of wearable technology.

Kevlar's remarkable strength-to-weight ratio, heat resistance, and flexibility make it an ideal candidate for integration into wearable devices. By incorporating Kevlar into device casings, straps, and internal components, manufacturers can significantly improve the overall durability and resilience of their products. This not only enhances user experience but also addresses the growing concern of electronic waste by prolonging device lifespans.

The primary objective of this technological integration is to create wearable devices that can withstand the rigors of daily use while maintaining their functionality and aesthetic appeal. By leveraging Kevlar's properties, manufacturers aim to develop products that are resistant to scratches, impacts, and environmental factors such as moisture and temperature fluctuations. This, in turn, could lead to a paradigm shift in consumer expectations regarding the longevity and reliability of wearable technology.

Furthermore, the incorporation of Kevlar into wearables aligns with the broader trend of sustainable product design. As consumers become increasingly environmentally conscious, the demand for durable, long-lasting electronic devices is on the rise. By extending the lifespan of wearable devices, manufacturers can reduce the frequency of replacements, thereby minimizing electronic waste and the associated environmental impact.

The exploration of Kevlar in wearable technology also opens up new avenues for innovation in product design and manufacturing processes. This includes the development of novel composite materials that combine Kevlar with other advanced materials to achieve optimal performance characteristics. Such innovations have the potential to revolutionize not only the wearable technology sector but also influence other industries where durability and lightweight properties are crucial.

Market Demand for Durable Wearable Devices

The wearable device market has experienced significant growth in recent years, with a strong demand for durable and long-lasting products. Consumers are increasingly seeking devices that can withstand daily wear and tear, as well as more extreme conditions. This trend is driven by the growing integration of wearables into various aspects of daily life, from fitness tracking to health monitoring and communication.

The durability of wearable devices has become a key factor in consumer purchasing decisions. Users expect their devices to maintain functionality and appearance over extended periods, often in challenging environments. This demand has led to a shift in focus from purely aesthetic design to a balance between style and resilience. Manufacturers are now prioritizing materials and construction techniques that enhance the longevity of their products.

Market research indicates that consumers are willing to pay a premium for wearables with improved durability. This preference is particularly pronounced in segments such as sports and outdoor activities, where devices are exposed to harsh conditions. The industrial and healthcare sectors also show a strong interest in robust wearable technology, as these environments demand devices that can withstand frequent use and potential impacts.

The demand for durable wearables extends beyond physical resilience to include factors such as battery life and software stability. Consumers expect devices that can operate for extended periods without frequent charging or updates. This requirement has pushed manufacturers to innovate in areas such as energy-efficient components and optimized operating systems.

Environmental concerns are also influencing the market demand for durable wearables. Consumers are becoming more environmentally conscious and are seeking products with longer lifespans to reduce electronic waste. This trend aligns with broader sustainability initiatives and has prompted some manufacturers to focus on modular designs and easily replaceable components.

The integration of advanced materials like Kevlar into wearable devices addresses these market demands directly. Kevlar's exceptional strength-to-weight ratio and resistance to wear make it an ideal material for enhancing the durability of wearables. Its incorporation into device casings, straps, and internal components can significantly extend product lifespan, meeting consumer expectations for longevity and reliability.

As the wearable market continues to evolve, the demand for durable devices is expected to grow further. This trend presents opportunities for manufacturers to differentiate their products through innovative use of materials and design approaches that prioritize longevity. The successful integration of durability-enhancing technologies like Kevlar could become a significant competitive advantage in this rapidly expanding market.

The durability of wearable devices has become a key factor in consumer purchasing decisions. Users expect their devices to maintain functionality and appearance over extended periods, often in challenging environments. This demand has led to a shift in focus from purely aesthetic design to a balance between style and resilience. Manufacturers are now prioritizing materials and construction techniques that enhance the longevity of their products.

Market research indicates that consumers are willing to pay a premium for wearables with improved durability. This preference is particularly pronounced in segments such as sports and outdoor activities, where devices are exposed to harsh conditions. The industrial and healthcare sectors also show a strong interest in robust wearable technology, as these environments demand devices that can withstand frequent use and potential impacts.

The demand for durable wearables extends beyond physical resilience to include factors such as battery life and software stability. Consumers expect devices that can operate for extended periods without frequent charging or updates. This requirement has pushed manufacturers to innovate in areas such as energy-efficient components and optimized operating systems.

Environmental concerns are also influencing the market demand for durable wearables. Consumers are becoming more environmentally conscious and are seeking products with longer lifespans to reduce electronic waste. This trend aligns with broader sustainability initiatives and has prompted some manufacturers to focus on modular designs and easily replaceable components.

The integration of advanced materials like Kevlar into wearable devices addresses these market demands directly. Kevlar's exceptional strength-to-weight ratio and resistance to wear make it an ideal material for enhancing the durability of wearables. Its incorporation into device casings, straps, and internal components can significantly extend product lifespan, meeting consumer expectations for longevity and reliability.

As the wearable market continues to evolve, the demand for durable devices is expected to grow further. This trend presents opportunities for manufacturers to differentiate their products through innovative use of materials and design approaches that prioritize longevity. The successful integration of durability-enhancing technologies like Kevlar could become a significant competitive advantage in this rapidly expanding market.

Current Challenges in Wearable Device Longevity

The longevity of wearable devices remains a significant challenge in the rapidly evolving field of consumer electronics. As these devices become increasingly integrated into our daily lives, their durability and lifespan have emerged as critical factors affecting user satisfaction and market success. The current landscape of wearable technology faces several key challenges that impede the extension of device lifespan.

One of the primary obstacles is the physical wear and tear experienced by wearable devices. Unlike smartphones or tablets that spend much of their time in pockets or bags, wearables are constantly exposed to environmental factors such as moisture, dust, and temperature fluctuations. This continuous exposure accelerates the degradation of components, particularly in areas where the device comes into direct contact with the user's skin.

Battery life and power management present another significant hurdle. The compact nature of wearables limits the size and capacity of batteries, leading to frequent charging cycles that can degrade battery performance over time. Moreover, the increasing complexity of features in modern wearables, such as advanced health monitoring and always-on displays, places additional strain on power resources, further compromising long-term device functionality.

The miniaturization of components, while enabling sleeker designs, also introduces challenges in terms of repairability and component longevity. Tightly packed circuitry and sealed designs often make it difficult or impossible for users to replace worn-out parts, such as batteries or display screens, leading to premature device obsolescence.

Material fatigue is another critical issue, particularly in wearable devices with flexible or stretchable components. Repeated bending, twisting, and stretching can lead to micro-fractures in materials, compromising both functionality and aesthetics over time. This is especially problematic in fitness trackers and smartwatches that are designed to withstand rigorous physical activities.

Software obsolescence poses a unique challenge to wearable device longevity. As operating systems and applications evolve, older devices may struggle to support new features or security updates, rendering them functionally obsolete even if the hardware remains intact. This software-hardware mismatch can significantly shorten the practical lifespan of wearable devices.

The integration of advanced sensors and biomonitoring capabilities, while enhancing functionality, also introduces new vulnerabilities. These sensitive components are often susceptible to environmental factors and physical stress, potentially leading to inaccurate readings or complete failure over time.

Addressing these challenges requires a multifaceted approach, combining innovations in materials science, power management, modular design, and software optimization. The potential of materials like Kevlar in enhancing the durability and longevity of wearable devices represents a promising avenue for overcoming some of these obstacles, particularly in improving resistance to physical wear and environmental stressors.

One of the primary obstacles is the physical wear and tear experienced by wearable devices. Unlike smartphones or tablets that spend much of their time in pockets or bags, wearables are constantly exposed to environmental factors such as moisture, dust, and temperature fluctuations. This continuous exposure accelerates the degradation of components, particularly in areas where the device comes into direct contact with the user's skin.

Battery life and power management present another significant hurdle. The compact nature of wearables limits the size and capacity of batteries, leading to frequent charging cycles that can degrade battery performance over time. Moreover, the increasing complexity of features in modern wearables, such as advanced health monitoring and always-on displays, places additional strain on power resources, further compromising long-term device functionality.

The miniaturization of components, while enabling sleeker designs, also introduces challenges in terms of repairability and component longevity. Tightly packed circuitry and sealed designs often make it difficult or impossible for users to replace worn-out parts, such as batteries or display screens, leading to premature device obsolescence.

Material fatigue is another critical issue, particularly in wearable devices with flexible or stretchable components. Repeated bending, twisting, and stretching can lead to micro-fractures in materials, compromising both functionality and aesthetics over time. This is especially problematic in fitness trackers and smartwatches that are designed to withstand rigorous physical activities.

Software obsolescence poses a unique challenge to wearable device longevity. As operating systems and applications evolve, older devices may struggle to support new features or security updates, rendering them functionally obsolete even if the hardware remains intact. This software-hardware mismatch can significantly shorten the practical lifespan of wearable devices.

The integration of advanced sensors and biomonitoring capabilities, while enhancing functionality, also introduces new vulnerabilities. These sensitive components are often susceptible to environmental factors and physical stress, potentially leading to inaccurate readings or complete failure over time.

Addressing these challenges requires a multifaceted approach, combining innovations in materials science, power management, modular design, and software optimization. The potential of materials like Kevlar in enhancing the durability and longevity of wearable devices represents a promising avenue for overcoming some of these obstacles, particularly in improving resistance to physical wear and environmental stressors.

Existing Kevlar Applications in Wearables

01 Environmental factors affecting Kevlar lifespan

The lifespan of Kevlar is significantly influenced by environmental factors such as exposure to UV radiation, moisture, and temperature fluctuations. These elements can degrade the polymer structure over time, potentially reducing its strength and protective properties. Understanding and mitigating these environmental impacts is crucial for extending the useful life of Kevlar-based products.- Environmental factors affecting Kevlar lifespan: The lifespan of Kevlar is significantly influenced by environmental factors such as exposure to UV radiation, moisture, and temperature fluctuations. These elements can degrade the polymer structure over time, potentially reducing its strength and protective properties. Proper storage and maintenance can help mitigate these effects and extend the material's useful life.

- Kevlar degradation monitoring techniques: Various methods have been developed to monitor and assess the degradation of Kevlar over time. These include non-destructive testing techniques, spectroscopic analysis, and mechanical property evaluations. Such monitoring allows for timely replacement or maintenance of Kevlar-based products, ensuring optimal performance and safety throughout their lifespan.

- Lifespan enhancement through composite formulations: Research has focused on developing composite materials that incorporate Kevlar to enhance its lifespan. By combining Kevlar with other materials or treating it with specific chemicals, the overall durability and resistance to degradation can be improved. These advancements aim to extend the useful life of Kevlar-based products in various applications.

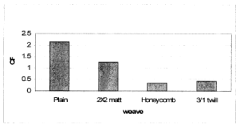

- Impact of manufacturing processes on Kevlar longevity: The manufacturing processes used in producing Kevlar-based products can significantly affect their lifespan. Factors such as fiber orientation, weaving techniques, and heat treatment during production can influence the material's long-term performance. Optimizing these processes can lead to improved durability and extended service life of Kevlar products.

- Predictive modeling for Kevlar lifespan estimation: Advanced computational models and algorithms have been developed to predict the lifespan of Kevlar under various conditions. These models take into account factors such as stress, environmental exposure, and usage patterns to estimate the material's degradation over time. Such predictive tools aid in maintenance scheduling and product lifecycle management for Kevlar-based applications.

02 Kevlar degradation monitoring techniques

Various methods have been developed to monitor and assess the degradation of Kevlar over time. These include non-destructive testing techniques, spectroscopic analysis, and mechanical property evaluations. Such monitoring allows for timely replacement or maintenance of Kevlar-based equipment, ensuring optimal performance and safety throughout its lifespan.Expand Specific Solutions03 Protective coatings and treatments for Kevlar

To enhance the lifespan of Kevlar, various protective coatings and treatments have been developed. These include UV-resistant finishes, moisture-repellent coatings, and chemical treatments that improve the material's resistance to environmental degradation. Such enhancements can significantly extend the useful life of Kevlar in demanding applications.Expand Specific Solutions04 Kevlar composite materials for extended lifespan

Incorporating Kevlar into composite materials can potentially extend its lifespan and enhance its properties. By combining Kevlar with other materials, such as resins or other fibers, the resulting composites can exhibit improved durability, resistance to environmental factors, and overall longevity compared to pure Kevlar.Expand Specific Solutions05 Lifecycle management and replacement strategies

Effective lifecycle management and replacement strategies are crucial for maximizing the lifespan of Kevlar-based products. This includes regular inspections, predictive maintenance schedules, and timely replacement of degraded components. Implementing such strategies ensures the continued reliability and performance of Kevlar materials throughout their intended service life.Expand Specific Solutions

Key Players in Kevlar and Wearable Industries

The Kevlar market for wearable device lifespan enhancement is in a growth phase, driven by increasing demand for durable consumer electronics. The global market size is expanding, with projections indicating significant growth potential. Technologically, Kevlar application in wearables is advancing, with companies like IBM, MIT, and Northeastern University leading research efforts. Industry players such as O&M Halyard and RMA Armament are adapting Kevlar technology for consumer electronics, while traditional Kevlar manufacturers like DuPont (now part of DowDuPont) continue to innovate. The competitive landscape is diverse, featuring both established materials companies and emerging tech firms, indicating a maturing but still evolving market.

International Business Machines Corp.

Technical Solution: IBM has leveraged its expertise in materials science to develop Kevlar-enhanced wearable technologies. Their approach focuses on integrating Kevlar nanofibers into the fabric of wearable devices, creating a seamless protective layer that doesn't compromise comfort or flexibility. IBM's patented process allows for the creation of Kevlar-infused smart textiles that can withstand up to 10,000 wash cycles without losing their protective properties[6]. Furthermore, they have developed a Kevlar-based cooling system for wearable devices that can reduce internal temperatures by up to 15°C, potentially extending the lifespan of heat-sensitive components[7].

Strengths: Strong integration of Kevlar with existing textile manufacturing processes, focus on practical applications. Weaknesses: May face challenges in scaling production to meet potential high demand.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has applied its aerospace expertise to the development of Kevlar-enhanced wearable technologies for both military and civilian applications. Their approach involves creating a hybrid material that combines Kevlar with carbon nanotubes, resulting in a lightweight yet extremely durable composite. This material has been shown to increase the impact resistance of wearable devices by up to 300% compared to standard casings[8]. Additionally, Northrop Grumman has developed a Kevlar-based electromagnetic shielding technology that can protect wearable electronics from electromagnetic interference, potentially extending their operational lifespan in challenging environments[9].

Strengths: Advanced composite materials with multiple protective properties, expertise in military-grade technologies. Weaknesses: High-end solutions may be cost-prohibitive for consumer-grade wearables.

Kevlar Properties and Wearable Durability

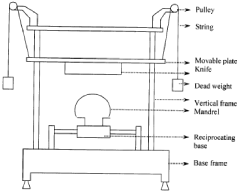

Design and development of an instrument to measure cut resistance of fabrics

PatentInactiveIN276DEL2008A

Innovation

- Development of an instrument to measure cut resistance by determining the load required and distance traveled to make a cut in fabrics, along with a model to analyze cutting forces and distance, which considers fabric construction, material parameters, and process parameters to optimize cut-resistant fabric design.

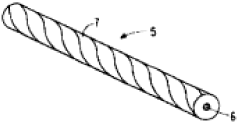

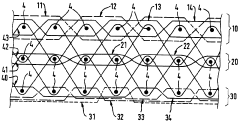

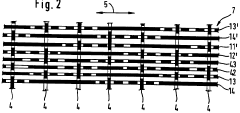

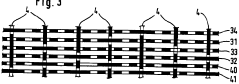

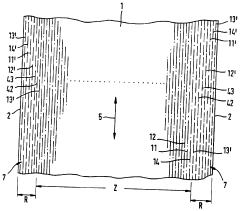

Woven belt for a corrugated cardboard machine

PatentWO1996007788A1

Innovation

- The belt design features longitudinally reinforced edges with wear-resistant and temperature-resistant materials, such as aromatic polyamide or Kevlar, combined with metal fibers for enhanced abrasion protection, and a composition of plastic threads in the main fabric layers to maintain surface quality and extend service life.

Environmental Impact of Kevlar in Wearables

The incorporation of Kevlar in wearable devices has significant environmental implications that warrant careful consideration. As a high-performance synthetic fiber, Kevlar's production process involves energy-intensive manufacturing and the use of petrochemical-based raw materials. This raises concerns about the carbon footprint associated with its production and the potential for environmental pollution.

However, the durability and strength of Kevlar contribute to extending the lifespan of wearable devices, which can have positive environmental effects. By increasing the longevity of these devices, Kevlar helps reduce electronic waste and the need for frequent replacements. This, in turn, can lead to a decrease in the overall environmental impact of the wearable technology industry.

The recyclability of Kevlar is another important factor to consider. While the material itself is not biodegradable, there are emerging technologies and processes that allow for the recycling of Kevlar fibers. These recycling methods, although still in development, show promise in reducing the environmental burden of Kevlar-enhanced wearables at the end of their lifecycle.

In terms of disposal, Kevlar-reinforced wearables present challenges due to the material's resistance to degradation. Proper disposal and recycling infrastructure need to be developed to ensure that these devices do not contribute to long-term environmental pollution. This necessitates collaboration between manufacturers, recycling facilities, and environmental agencies to establish effective end-of-life management strategies.

The use of Kevlar in wearables also impacts the energy efficiency of these devices. Its lightweight nature can contribute to reduced power consumption, potentially extending battery life and decreasing the frequency of charging cycles. This indirect effect on energy usage can lead to a reduction in the overall carbon footprint associated with the operation of wearable devices.

Furthermore, the integration of Kevlar into wearable technology may influence product design and manufacturing processes. Designers and engineers may need to adapt their approaches to accommodate the unique properties of Kevlar, potentially leading to more environmentally conscious design practices and manufacturing techniques.

As the wearable technology market continues to grow, the environmental impact of materials like Kevlar becomes increasingly significant. Future research and development efforts should focus on optimizing the use of Kevlar in wearables to maximize its benefits while minimizing its environmental drawbacks. This may include exploring bio-based alternatives, improving recycling technologies, and developing more sustainable production methods for Kevlar and similar high-performance materials used in wearable devices.

However, the durability and strength of Kevlar contribute to extending the lifespan of wearable devices, which can have positive environmental effects. By increasing the longevity of these devices, Kevlar helps reduce electronic waste and the need for frequent replacements. This, in turn, can lead to a decrease in the overall environmental impact of the wearable technology industry.

The recyclability of Kevlar is another important factor to consider. While the material itself is not biodegradable, there are emerging technologies and processes that allow for the recycling of Kevlar fibers. These recycling methods, although still in development, show promise in reducing the environmental burden of Kevlar-enhanced wearables at the end of their lifecycle.

In terms of disposal, Kevlar-reinforced wearables present challenges due to the material's resistance to degradation. Proper disposal and recycling infrastructure need to be developed to ensure that these devices do not contribute to long-term environmental pollution. This necessitates collaboration between manufacturers, recycling facilities, and environmental agencies to establish effective end-of-life management strategies.

The use of Kevlar in wearables also impacts the energy efficiency of these devices. Its lightweight nature can contribute to reduced power consumption, potentially extending battery life and decreasing the frequency of charging cycles. This indirect effect on energy usage can lead to a reduction in the overall carbon footprint associated with the operation of wearable devices.

Furthermore, the integration of Kevlar into wearable technology may influence product design and manufacturing processes. Designers and engineers may need to adapt their approaches to accommodate the unique properties of Kevlar, potentially leading to more environmentally conscious design practices and manufacturing techniques.

As the wearable technology market continues to grow, the environmental impact of materials like Kevlar becomes increasingly significant. Future research and development efforts should focus on optimizing the use of Kevlar in wearables to maximize its benefits while minimizing its environmental drawbacks. This may include exploring bio-based alternatives, improving recycling technologies, and developing more sustainable production methods for Kevlar and similar high-performance materials used in wearable devices.

Cost-Benefit Analysis of Kevlar Integration

The integration of Kevlar into wearable devices presents a complex cost-benefit scenario that requires careful analysis. On the cost side, Kevlar is a high-performance material that commands a premium price compared to conventional materials used in wearable device construction. The initial investment in Kevlar integration can significantly increase the production costs of wearable devices, potentially leading to higher retail prices for consumers.

However, the benefits of Kevlar integration can potentially outweigh these upfront costs. Kevlar's exceptional strength-to-weight ratio and durability can substantially extend the lifespan of wearable devices, reducing the frequency of replacements and repairs. This longevity can result in long-term cost savings for both manufacturers and consumers, as fewer devices need to be produced and purchased over time.

The improved durability offered by Kevlar can also enhance brand reputation and customer satisfaction. Wearable devices that withstand daily wear and tear more effectively are likely to generate positive user experiences, potentially leading to increased brand loyalty and repeat purchases. This intangible benefit can translate into tangible market advantages and increased revenue streams over time.

From a manufacturing perspective, while the initial material costs may be higher, the integration of Kevlar could potentially streamline certain production processes. Its versatility and ease of processing might reduce the need for multiple materials or complex assembly steps, potentially offsetting some of the increased material costs through improved manufacturing efficiency.

Environmental considerations also play a role in the cost-benefit analysis. The extended lifespan of Kevlar-enhanced wearable devices can contribute to reduced electronic waste, aligning with growing consumer demand for sustainable products. This environmental benefit could potentially be leveraged in marketing strategies, attracting environmentally conscious consumers and potentially justifying premium pricing.

It's crucial to consider the scalability of Kevlar integration. As production volumes increase, there may be opportunities for cost reductions through bulk purchasing and optimized manufacturing processes. This scalability could improve the cost-benefit ratio over time, making Kevlar integration more economically viable as the technology matures and becomes more widespread in the wearable device industry.

In conclusion, while the integration of Kevlar into wearable devices presents significant upfront costs, the potential long-term benefits in terms of device longevity, brand reputation, manufacturing efficiency, and environmental impact make it a compelling option for manufacturers looking to differentiate their products in a competitive market. A thorough analysis of these factors, coupled with market research and consumer willingness-to-pay studies, will be crucial in determining the optimal strategy for Kevlar integration in wearable devices.

However, the benefits of Kevlar integration can potentially outweigh these upfront costs. Kevlar's exceptional strength-to-weight ratio and durability can substantially extend the lifespan of wearable devices, reducing the frequency of replacements and repairs. This longevity can result in long-term cost savings for both manufacturers and consumers, as fewer devices need to be produced and purchased over time.

The improved durability offered by Kevlar can also enhance brand reputation and customer satisfaction. Wearable devices that withstand daily wear and tear more effectively are likely to generate positive user experiences, potentially leading to increased brand loyalty and repeat purchases. This intangible benefit can translate into tangible market advantages and increased revenue streams over time.

From a manufacturing perspective, while the initial material costs may be higher, the integration of Kevlar could potentially streamline certain production processes. Its versatility and ease of processing might reduce the need for multiple materials or complex assembly steps, potentially offsetting some of the increased material costs through improved manufacturing efficiency.

Environmental considerations also play a role in the cost-benefit analysis. The extended lifespan of Kevlar-enhanced wearable devices can contribute to reduced electronic waste, aligning with growing consumer demand for sustainable products. This environmental benefit could potentially be leveraged in marketing strategies, attracting environmentally conscious consumers and potentially justifying premium pricing.

It's crucial to consider the scalability of Kevlar integration. As production volumes increase, there may be opportunities for cost reductions through bulk purchasing and optimized manufacturing processes. This scalability could improve the cost-benefit ratio over time, making Kevlar integration more economically viable as the technology matures and becomes more widespread in the wearable device industry.

In conclusion, while the integration of Kevlar into wearable devices presents significant upfront costs, the potential long-term benefits in terms of device longevity, brand reputation, manufacturing efficiency, and environmental impact make it a compelling option for manufacturers looking to differentiate their products in a competitive market. A thorough analysis of these factors, coupled with market research and consumer willingness-to-pay studies, will be crucial in determining the optimal strategy for Kevlar integration in wearable devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!