Kevlar's Influence on Underwater Equipment Efficiency

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Underwater Tech: Background and Objectives

Kevlar, a synthetic fiber developed by DuPont in the 1960s, has revolutionized numerous industries due to its exceptional strength-to-weight ratio and durability. In the realm of underwater technology, Kevlar's influence has been particularly significant, reshaping the design and performance of various equipment used in marine environments.

The evolution of underwater technology has been driven by the need for more efficient, reliable, and durable equipment capable of withstanding the harsh conditions of the aquatic world. As exploration and research in marine environments intensified, the limitations of traditional materials became increasingly apparent, prompting the search for innovative solutions.

Kevlar's introduction to underwater applications marked a turning point in the field. Its unique properties, including high tensile strength, low weight, and resistance to corrosion, made it an ideal candidate for addressing many of the challenges faced in underwater operations. The material's ability to maintain its structural integrity under extreme pressure and in corrosive saltwater environments opened up new possibilities for equipment design and functionality.

The primary objective of incorporating Kevlar into underwater technology has been to enhance the efficiency and reliability of equipment used in various marine applications. This includes improving the performance of diving gear, underwater vehicles, sonar systems, and oceanographic research instruments. By leveraging Kevlar's properties, engineers and researchers aim to develop lighter, stronger, and more durable underwater equipment that can operate at greater depths and for extended periods.

Another key goal in the integration of Kevlar into underwater technology is to increase the safety of marine operations. The material's high strength and impact resistance contribute to the development of more robust protective gear for divers and submersible vehicles, reducing the risk of equipment failure in critical situations.

Furthermore, the use of Kevlar in underwater cable and tether systems has become a focus area for improving communication and power transmission in subsea operations. The material's strength and lightweight nature allow for longer cable runs and improved maneuverability of tethered equipment, enhancing the efficiency of underwater exploration and maintenance activities.

As research in marine environments continues to expand, the role of Kevlar in underwater technology is expected to grow. Current technological trends indicate a push towards deeper ocean exploration, longer-duration missions, and more autonomous underwater systems. These advancements will likely drive further innovations in Kevlar applications, potentially leading to the development of new composite materials that combine Kevlar with other advanced substances to meet the evolving demands of underwater operations.

The evolution of underwater technology has been driven by the need for more efficient, reliable, and durable equipment capable of withstanding the harsh conditions of the aquatic world. As exploration and research in marine environments intensified, the limitations of traditional materials became increasingly apparent, prompting the search for innovative solutions.

Kevlar's introduction to underwater applications marked a turning point in the field. Its unique properties, including high tensile strength, low weight, and resistance to corrosion, made it an ideal candidate for addressing many of the challenges faced in underwater operations. The material's ability to maintain its structural integrity under extreme pressure and in corrosive saltwater environments opened up new possibilities for equipment design and functionality.

The primary objective of incorporating Kevlar into underwater technology has been to enhance the efficiency and reliability of equipment used in various marine applications. This includes improving the performance of diving gear, underwater vehicles, sonar systems, and oceanographic research instruments. By leveraging Kevlar's properties, engineers and researchers aim to develop lighter, stronger, and more durable underwater equipment that can operate at greater depths and for extended periods.

Another key goal in the integration of Kevlar into underwater technology is to increase the safety of marine operations. The material's high strength and impact resistance contribute to the development of more robust protective gear for divers and submersible vehicles, reducing the risk of equipment failure in critical situations.

Furthermore, the use of Kevlar in underwater cable and tether systems has become a focus area for improving communication and power transmission in subsea operations. The material's strength and lightweight nature allow for longer cable runs and improved maneuverability of tethered equipment, enhancing the efficiency of underwater exploration and maintenance activities.

As research in marine environments continues to expand, the role of Kevlar in underwater technology is expected to grow. Current technological trends indicate a push towards deeper ocean exploration, longer-duration missions, and more autonomous underwater systems. These advancements will likely drive further innovations in Kevlar applications, potentially leading to the development of new composite materials that combine Kevlar with other advanced substances to meet the evolving demands of underwater operations.

Market Analysis for Kevlar-Enhanced Underwater Equipment

The market for Kevlar-enhanced underwater equipment has experienced significant growth in recent years, driven by increasing demand for high-performance materials in marine applications. Kevlar, a synthetic fiber known for its exceptional strength-to-weight ratio and durability, has found extensive use in various underwater equipment, including diving suits, submersible vehicles, and underwater cables.

The global market for Kevlar-enhanced underwater equipment is primarily segmented into three main categories: personal protective equipment (PPE), underwater vehicles and robotics, and marine infrastructure. In the PPE segment, Kevlar-reinforced diving suits and gloves have gained popularity among professional divers and military personnel due to their superior puncture resistance and thermal insulation properties. This segment has shown steady growth, particularly in regions with active offshore oil and gas industries.

The underwater vehicles and robotics sector has witnessed rapid expansion, fueled by advancements in deep-sea exploration and underwater maintenance operations. Kevlar composites are increasingly used in the construction of remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), providing enhanced structural integrity and reduced weight. This has led to improved operational efficiency and extended mission durations for these vehicles.

Marine infrastructure represents another significant market for Kevlar-enhanced products, with applications in underwater cables, pipelines, and offshore structures. The material's high tensile strength and resistance to corrosion make it an ideal choice for reinforcing these critical components, especially in harsh marine environments. As offshore wind farms and subsea communication networks continue to expand, the demand for Kevlar-enhanced infrastructure is expected to grow substantially.

Geographically, North America and Europe currently dominate the market for Kevlar-enhanced underwater equipment, owing to their advanced marine industries and substantial investments in oceanographic research. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing maritime activities and offshore energy projects in countries like China, Japan, and South Korea.

The market is characterized by a mix of established players and innovative startups. Major chemical companies that produce Kevlar, such as DuPont, collaborate with specialized equipment manufacturers to develop cutting-edge underwater products. This collaboration has resulted in continuous improvements in material properties and application techniques, further driving market growth.

Looking ahead, the market for Kevlar-enhanced underwater equipment is projected to maintain strong growth momentum. Factors such as increasing deep-sea exploration activities, growing investments in offshore renewable energy, and rising concerns about maritime security are expected to fuel demand. Additionally, ongoing research into new Kevlar composites and hybrid materials promises to expand the range of applications and enhance the performance of underwater equipment, potentially opening up new market opportunities in the coming years.

The global market for Kevlar-enhanced underwater equipment is primarily segmented into three main categories: personal protective equipment (PPE), underwater vehicles and robotics, and marine infrastructure. In the PPE segment, Kevlar-reinforced diving suits and gloves have gained popularity among professional divers and military personnel due to their superior puncture resistance and thermal insulation properties. This segment has shown steady growth, particularly in regions with active offshore oil and gas industries.

The underwater vehicles and robotics sector has witnessed rapid expansion, fueled by advancements in deep-sea exploration and underwater maintenance operations. Kevlar composites are increasingly used in the construction of remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), providing enhanced structural integrity and reduced weight. This has led to improved operational efficiency and extended mission durations for these vehicles.

Marine infrastructure represents another significant market for Kevlar-enhanced products, with applications in underwater cables, pipelines, and offshore structures. The material's high tensile strength and resistance to corrosion make it an ideal choice for reinforcing these critical components, especially in harsh marine environments. As offshore wind farms and subsea communication networks continue to expand, the demand for Kevlar-enhanced infrastructure is expected to grow substantially.

Geographically, North America and Europe currently dominate the market for Kevlar-enhanced underwater equipment, owing to their advanced marine industries and substantial investments in oceanographic research. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing maritime activities and offshore energy projects in countries like China, Japan, and South Korea.

The market is characterized by a mix of established players and innovative startups. Major chemical companies that produce Kevlar, such as DuPont, collaborate with specialized equipment manufacturers to develop cutting-edge underwater products. This collaboration has resulted in continuous improvements in material properties and application techniques, further driving market growth.

Looking ahead, the market for Kevlar-enhanced underwater equipment is projected to maintain strong growth momentum. Factors such as increasing deep-sea exploration activities, growing investments in offshore renewable energy, and rising concerns about maritime security are expected to fuel demand. Additionally, ongoing research into new Kevlar composites and hybrid materials promises to expand the range of applications and enhance the performance of underwater equipment, potentially opening up new market opportunities in the coming years.

Current Challenges in Kevlar Underwater Applications

Despite Kevlar's remarkable properties, its application in underwater equipment faces several significant challenges. One of the primary issues is water absorption. When exposed to aqueous environments, Kevlar fibers tend to absorb water, which can lead to a decrease in mechanical strength and overall performance. This absorption not only affects the material's structural integrity but also impacts its long-term durability in underwater applications.

Another challenge is the degradation of Kevlar under prolonged exposure to saltwater. The saline environment can cause hydrolysis of the polymer chains, leading to a gradual breakdown of the material's structure. This degradation process can significantly reduce the lifespan of Kevlar-based underwater equipment, necessitating more frequent replacements and increasing operational costs.

The high pressure encountered in deep-sea environments poses an additional challenge for Kevlar applications. While Kevlar exhibits excellent tensile strength, its performance under high compressive forces, such as those experienced at great depths, may be compromised. This limitation restricts the use of Kevlar in certain deep-sea equipment where maintaining structural integrity under extreme pressure is crucial.

Biofouling is another significant issue affecting Kevlar's efficiency in underwater applications. Marine organisms can attach and grow on Kevlar surfaces, potentially compromising the material's properties and the functionality of the equipment. This biological growth not only adds weight but can also create drag, reducing the hydrodynamic efficiency of underwater devices.

The manufacturing and processing of Kevlar for specific underwater applications present their own set of challenges. Creating complex shapes or integrating Kevlar with other materials for underwater use often requires specialized techniques. The difficulty in molding and shaping Kevlar can limit design flexibility and increase production costs for underwater equipment.

Lastly, the thermal properties of Kevlar in underwater environments pose challenges. While Kevlar has good heat resistance in air, its thermal conductivity and insulation properties may be affected differently underwater. This can impact the performance of equipment in varying temperature conditions, particularly in applications where thermal management is critical.

Addressing these challenges requires ongoing research and development efforts. Scientists and engineers are exploring various solutions, including surface treatments to reduce water absorption, developing new Kevlar composites with enhanced underwater properties, and investigating novel manufacturing techniques to overcome processing limitations. The resolution of these challenges is crucial for expanding the efficient use of Kevlar in underwater applications and improving the performance of marine equipment.

Another challenge is the degradation of Kevlar under prolonged exposure to saltwater. The saline environment can cause hydrolysis of the polymer chains, leading to a gradual breakdown of the material's structure. This degradation process can significantly reduce the lifespan of Kevlar-based underwater equipment, necessitating more frequent replacements and increasing operational costs.

The high pressure encountered in deep-sea environments poses an additional challenge for Kevlar applications. While Kevlar exhibits excellent tensile strength, its performance under high compressive forces, such as those experienced at great depths, may be compromised. This limitation restricts the use of Kevlar in certain deep-sea equipment where maintaining structural integrity under extreme pressure is crucial.

Biofouling is another significant issue affecting Kevlar's efficiency in underwater applications. Marine organisms can attach and grow on Kevlar surfaces, potentially compromising the material's properties and the functionality of the equipment. This biological growth not only adds weight but can also create drag, reducing the hydrodynamic efficiency of underwater devices.

The manufacturing and processing of Kevlar for specific underwater applications present their own set of challenges. Creating complex shapes or integrating Kevlar with other materials for underwater use often requires specialized techniques. The difficulty in molding and shaping Kevlar can limit design flexibility and increase production costs for underwater equipment.

Lastly, the thermal properties of Kevlar in underwater environments pose challenges. While Kevlar has good heat resistance in air, its thermal conductivity and insulation properties may be affected differently underwater. This can impact the performance of equipment in varying temperature conditions, particularly in applications where thermal management is critical.

Addressing these challenges requires ongoing research and development efforts. Scientists and engineers are exploring various solutions, including surface treatments to reduce water absorption, developing new Kevlar composites with enhanced underwater properties, and investigating novel manufacturing techniques to overcome processing limitations. The resolution of these challenges is crucial for expanding the efficient use of Kevlar in underwater applications and improving the performance of marine equipment.

Existing Kevlar Solutions for Underwater Efficiency

01 Kevlar reinforcement in composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries, improving overall efficiency and performance of the final products.- Kevlar-reinforced composite materials: Kevlar fibers are incorporated into various composite materials to enhance their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries, improving overall efficiency and performance of the final products.

- Kevlar-based protective gear: Kevlar is utilized in the manufacturing of protective gear such as bulletproof vests, helmets, and gloves. The high tensile strength and lightweight properties of Kevlar contribute to improved efficiency in personal protection equipment, offering enhanced safety without compromising mobility.

- Kevlar-enhanced industrial applications: Kevlar fibers are integrated into various industrial products to improve their efficiency and longevity. Applications include reinforced hoses, belts, and cables, where Kevlar's strength and heat resistance properties contribute to increased durability and performance in demanding environments.

- Kevlar-based filtration systems: Kevlar fibers are employed in advanced filtration systems to enhance efficiency in separating particles or contaminants from fluids. The high strength and chemical resistance of Kevlar contribute to improved filter performance and longevity in various industrial and environmental applications.

- Kevlar-reinforced sporting goods: Kevlar is incorporated into sporting goods and equipment to improve their efficiency and performance. Applications include reinforced bicycle frames, tennis rackets, and kayaks, where Kevlar's lightweight and high-strength properties contribute to enhanced durability and responsiveness in sports activities.

02 Kevlar-based protective gear

Kevlar is utilized in the production of high-performance protective gear, such as bulletproof vests, helmets, and other personal protective equipment. The efficiency of Kevlar in these applications is attributed to its high tensile strength-to-weight ratio and ability to absorb and dissipate energy from impacts.Expand Specific Solutions03 Kevlar in textile applications

Kevlar fibers are incorporated into various textile products to improve their strength, durability, and heat resistance. This includes applications in fire-resistant clothing, cut-resistant gloves, and high-performance sportswear, enhancing the efficiency and safety of these products.Expand Specific Solutions04 Kevlar-enhanced structural components

Kevlar is used to reinforce structural components in various industries, including construction, marine, and aerospace. The addition of Kevlar fibers improves the strength-to-weight ratio, corrosion resistance, and overall durability of these components, leading to increased efficiency and longevity.Expand Specific Solutions05 Kevlar in energy absorption applications

The high energy absorption capacity of Kevlar is utilized in various applications, such as impact-resistant structures, crash protection systems, and vibration damping materials. This property enhances the efficiency of safety systems and improves overall performance in dynamic environments.Expand Specific Solutions

Key Players in Kevlar and Underwater Equipment Industry

The competitive landscape for Kevlar's influence on underwater equipment efficiency is evolving rapidly, with the market in its growth phase. The global underwater equipment market is expanding, driven by increasing offshore exploration and underwater infrastructure development. Technological maturity varies across applications, with companies like Schlumberger, Subsea 7, and Halliburton leading in offshore energy solutions. Ocean University of China and Woods Hole Oceanographic Institution contribute to research advancements, while companies such as Thales and ATLAS ELEKTRONIK focus on naval applications. The integration of Kevlar in underwater equipment is progressing, with potential for significant efficiency improvements across various sectors, including oil and gas, marine research, and defense.

Schlumberger Canada Ltd.

Technical Solution: Schlumberger has developed advanced Kevlar-reinforced umbilicals for subsea operations, enhancing the efficiency of underwater equipment. Their proprietary design incorporates Kevlar fibers into the umbilical structure, providing superior tensile strength and reduced weight compared to traditional steel-reinforced umbilicals[1]. This innovation allows for deeper water operations and improved data transmission capabilities. The company has also integrated Kevlar into their wireline cables, enabling more precise well logging and intervention operations in challenging underwater environments[2]. Schlumberger's use of Kevlar extends to their seismic streamers, where the material's lightweight and durable properties contribute to improved data acquisition and reduced operational costs in marine seismic surveys[3].

Strengths: Enhanced depth capabilities, improved data transmission, and reduced operational costs. Weaknesses: Higher initial investment and potential limitations in extreme temperature environments.

Subsea 7 Ltd.

Technical Solution: Subsea 7 has pioneered the use of Kevlar in their flexible flowline systems for offshore oil and gas production. Their innovative approach involves incorporating Kevlar fibers into the pressure armor layer of flexible pipes, significantly increasing the pipe's pressure resistance while reducing overall weight[4]. This technology has enabled the company to develop ultra-deepwater flexible risers capable of operating at depths exceeding 3,000 meters. Additionally, Subsea 7 has implemented Kevlar-reinforced umbilicals in their remote operated vehicle (ROV) systems, enhancing maneuverability and operational range in challenging underwater environments[5]. The company has also developed Kevlar-based solutions for pipeline protection and stabilization, improving the longevity and reliability of subsea infrastructure[6].

Strengths: Increased operational depths, improved pressure resistance, and enhanced equipment longevity. Weaknesses: Higher material costs and potential challenges in repair and maintenance of Kevlar-reinforced components.

Core Innovations in Kevlar for Marine Use

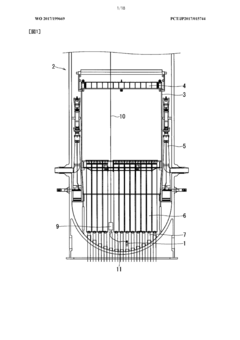

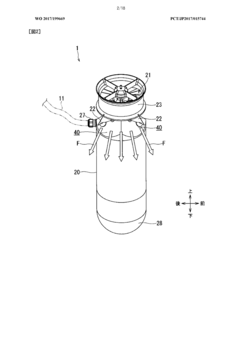

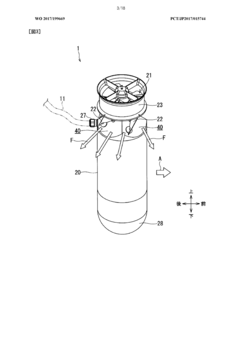

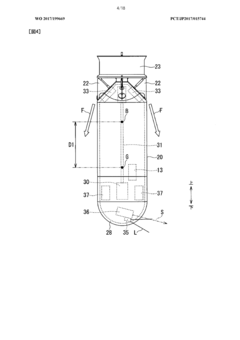

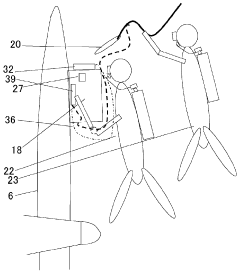

Underwater moving vehicle

PatentWO2017199669A1

Innovation

- The underwater vehicle design includes a vehicle body with weight adjusted to be either greater or lesser than buoyancy, combined with a thrust section using screw propellers to generate upward or downward thrust, and a water flow deflecting section using guide vanes to control movement and maintain position, enhancing maneuverability and stability.

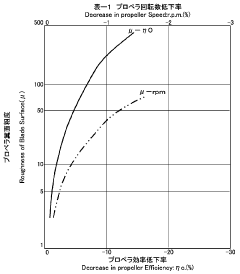

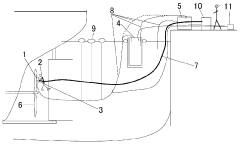

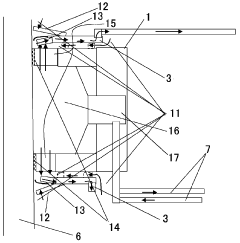

Underwater maintenance device

PatentWO2010090096A1

Innovation

- A portable underwater maintenance device with a water-permeable and elastic polishing disc that rotates at high speed, generating negative pressure to attract the polishing pad to the propeller, combined with an underwater roughness meter that can measure propeller roughness in water, allowing for effective polishing and measurement without docking the ship.

Environmental Impact of Kevlar in Marine Environments

The environmental impact of Kevlar in marine environments is a critical consideration as the use of this synthetic fiber in underwater equipment becomes more prevalent. Kevlar, known for its exceptional strength-to-weight ratio and durability, has found applications in various marine technologies, including underwater cables, protective gear, and reinforced structures. However, its introduction into aquatic ecosystems raises concerns about potential ecological consequences.

One of the primary environmental considerations is the long-term persistence of Kevlar in marine environments. Unlike natural fibers, Kevlar does not biodegrade easily, potentially leading to accumulation in marine sediments and water columns. This persistence may have implications for marine life, as particles or fragments of Kevlar could be ingested by various organisms, potentially entering the food chain.

The chemical stability of Kevlar under marine conditions is another aspect that warrants attention. While Kevlar is generally resistant to chemical degradation, prolonged exposure to saltwater and varying pH levels may lead to slow deterioration over time. This process could potentially release microscopic particles or chemical compounds into the water, the effects of which on marine ecosystems are not yet fully understood.

The physical presence of Kevlar-based equipment in marine environments may also impact local habitats. For instance, Kevlar-reinforced cables or structures could alter the seafloor topography or provide new substrates for marine organisms to colonize. This alteration of habitats could have both positive and negative effects on local biodiversity, depending on the specific ecological context.

Furthermore, the manufacturing process of Kevlar and its incorporation into marine equipment may have indirect environmental impacts. The production of Kevlar involves energy-intensive processes and the use of various chemicals, which could contribute to carbon emissions and potential chemical pollution if not properly managed. Additionally, the disposal or recycling of Kevlar-containing marine equipment at the end of its lifecycle presents challenges due to the material's durability and resistance to degradation.

Research into the environmental impact of Kevlar in marine settings is ongoing, with scientists focusing on long-term studies to assess its effects on water quality, marine life, and ecosystem dynamics. As the use of Kevlar in underwater applications continues to grow, it is crucial to develop sustainable practices for its production, use, and disposal to minimize potential negative impacts on marine environments.

One of the primary environmental considerations is the long-term persistence of Kevlar in marine environments. Unlike natural fibers, Kevlar does not biodegrade easily, potentially leading to accumulation in marine sediments and water columns. This persistence may have implications for marine life, as particles or fragments of Kevlar could be ingested by various organisms, potentially entering the food chain.

The chemical stability of Kevlar under marine conditions is another aspect that warrants attention. While Kevlar is generally resistant to chemical degradation, prolonged exposure to saltwater and varying pH levels may lead to slow deterioration over time. This process could potentially release microscopic particles or chemical compounds into the water, the effects of which on marine ecosystems are not yet fully understood.

The physical presence of Kevlar-based equipment in marine environments may also impact local habitats. For instance, Kevlar-reinforced cables or structures could alter the seafloor topography or provide new substrates for marine organisms to colonize. This alteration of habitats could have both positive and negative effects on local biodiversity, depending on the specific ecological context.

Furthermore, the manufacturing process of Kevlar and its incorporation into marine equipment may have indirect environmental impacts. The production of Kevlar involves energy-intensive processes and the use of various chemicals, which could contribute to carbon emissions and potential chemical pollution if not properly managed. Additionally, the disposal or recycling of Kevlar-containing marine equipment at the end of its lifecycle presents challenges due to the material's durability and resistance to degradation.

Research into the environmental impact of Kevlar in marine settings is ongoing, with scientists focusing on long-term studies to assess its effects on water quality, marine life, and ecosystem dynamics. As the use of Kevlar in underwater applications continues to grow, it is crucial to develop sustainable practices for its production, use, and disposal to minimize potential negative impacts on marine environments.

Regulatory Framework for Advanced Underwater Materials

The regulatory framework for advanced underwater materials, particularly in relation to Kevlar's influence on underwater equipment efficiency, is a complex and evolving landscape. As the use of high-performance materials in underwater applications continues to grow, governments and international bodies have recognized the need for comprehensive regulations to ensure safety, environmental protection, and fair competition.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides the overarching legal framework for maritime activities. While it does not specifically address advanced materials like Kevlar, it establishes principles for the protection of the marine environment and the conduct of scientific research, which indirectly impact the development and use of such materials in underwater equipment.

The International Maritime Organization (IMO) plays a crucial role in setting standards for maritime safety and environmental protection. Although the IMO has not yet developed specific regulations for advanced underwater materials, its guidelines on ship construction and equipment performance indirectly influence the use of materials like Kevlar in underwater applications.

National regulatory bodies, such as the United States Coast Guard and the European Maritime Safety Agency, have begun to address the use of advanced materials in underwater equipment. These agencies are developing guidelines and standards for the testing and certification of equipment incorporating materials like Kevlar, focusing on aspects such as durability, fire resistance, and environmental impact.

The regulatory approach to advanced underwater materials often involves a combination of performance-based standards and prescriptive requirements. Performance-based standards set specific goals for equipment efficiency and safety without mandating particular materials or designs. This approach allows for innovation while ensuring that equipment meets necessary safety and performance criteria.

Environmental regulations are increasingly shaping the use of advanced materials in underwater applications. Concerns about microplastic pollution and the potential long-term effects of synthetic fibers on marine ecosystems have led to stricter regulations on material degradation and disposal. Manufacturers using Kevlar and similar materials in underwater equipment must now demonstrate compliance with these environmental standards.

Occupational health and safety regulations also play a significant role in the regulatory framework for advanced underwater materials. As Kevlar and other high-performance materials are used in personal protective equipment for underwater workers, regulations governing their manufacture, testing, and use have become more stringent to ensure worker safety in challenging underwater environments.

The dynamic nature of technology development in this field necessitates an adaptive regulatory approach. Regulatory bodies are increasingly collaborating with industry stakeholders and research institutions to stay abreast of technological advancements and their potential impacts. This collaborative approach aims to create regulations that balance innovation with safety and environmental protection, ensuring that the benefits of materials like Kevlar in enhancing underwater equipment efficiency can be realized within a responsible regulatory framework.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides the overarching legal framework for maritime activities. While it does not specifically address advanced materials like Kevlar, it establishes principles for the protection of the marine environment and the conduct of scientific research, which indirectly impact the development and use of such materials in underwater equipment.

The International Maritime Organization (IMO) plays a crucial role in setting standards for maritime safety and environmental protection. Although the IMO has not yet developed specific regulations for advanced underwater materials, its guidelines on ship construction and equipment performance indirectly influence the use of materials like Kevlar in underwater applications.

National regulatory bodies, such as the United States Coast Guard and the European Maritime Safety Agency, have begun to address the use of advanced materials in underwater equipment. These agencies are developing guidelines and standards for the testing and certification of equipment incorporating materials like Kevlar, focusing on aspects such as durability, fire resistance, and environmental impact.

The regulatory approach to advanced underwater materials often involves a combination of performance-based standards and prescriptive requirements. Performance-based standards set specific goals for equipment efficiency and safety without mandating particular materials or designs. This approach allows for innovation while ensuring that equipment meets necessary safety and performance criteria.

Environmental regulations are increasingly shaping the use of advanced materials in underwater applications. Concerns about microplastic pollution and the potential long-term effects of synthetic fibers on marine ecosystems have led to stricter regulations on material degradation and disposal. Manufacturers using Kevlar and similar materials in underwater equipment must now demonstrate compliance with these environmental standards.

Occupational health and safety regulations also play a significant role in the regulatory framework for advanced underwater materials. As Kevlar and other high-performance materials are used in personal protective equipment for underwater workers, regulations governing their manufacture, testing, and use have become more stringent to ensure worker safety in challenging underwater environments.

The dynamic nature of technology development in this field necessitates an adaptive regulatory approach. Regulatory bodies are increasingly collaborating with industry stakeholders and research institutions to stay abreast of technological advancements and their potential impacts. This collaborative approach aims to create regulations that balance innovation with safety and environmental protection, ensuring that the benefits of materials like Kevlar in enhancing underwater equipment efficiency can be realized within a responsible regulatory framework.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!