Optimizing Chiller Efficiency in Mixed-Use Developments

JAN 23, 20269 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiller Technology Background and Efficiency Goals

Chiller systems have served as the cornerstone of commercial and industrial cooling infrastructure for over a century, with their fundamental operating principles rooted in vapor-compression refrigeration cycles first commercialized in the early 1900s. The evolution from reciprocating compressors to centrifugal and screw configurations marked significant efficiency milestones throughout the mid-20th century. Modern chiller technology has progressively integrated variable speed drives, advanced refrigerants, and digital control systems, transforming these machines from simple mechanical devices into sophisticated energy management platforms capable of real-time optimization.

Mixed-use developments present unique operational challenges that distinguish them from single-purpose facilities. These complexes typically combine residential, commercial, office, and retail spaces within integrated structures, creating highly variable and often unpredictable cooling load profiles. The simultaneous operation of diverse occupancy patterns—from early morning residential demands to midday commercial peaks and evening entertainment loads—requires chiller systems to maintain efficiency across an exceptionally wide operating range. Traditional chiller designs optimized for steady-state conditions frequently underperform in these dynamic environments, operating at partial loads where efficiency degradation becomes pronounced.

The primary efficiency goal for chiller systems in mixed-use developments centers on maintaining optimal coefficient of performance across the entire load spectrum, particularly in the 30-70% capacity range where these systems spend the majority of operational hours. Current industry benchmarks target integrated part-load values exceeding 0.60 kW per ton, representing approximately 25-30% improvement over conventional constant-speed systems. Beyond energy consumption metrics, efficiency objectives increasingly encompass demand response capabilities, enabling chillers to modulate operation in alignment with grid conditions and dynamic electricity pricing structures.

Emerging efficiency targets also address the total system approach, recognizing that chiller performance cannot be isolated from condenser water systems, distribution networks, and terminal equipment. Advanced developments pursue holistic optimization strategies that balance component-level efficiency with system-wide energy consumption, incorporating predictive analytics and machine learning algorithms to anticipate load patterns and preemptively adjust operating parameters. These integrated approaches aim to achieve 40-50% energy reductions compared to baseline systems while maintaining thermal comfort across diverse occupancy zones.

Mixed-use developments present unique operational challenges that distinguish them from single-purpose facilities. These complexes typically combine residential, commercial, office, and retail spaces within integrated structures, creating highly variable and often unpredictable cooling load profiles. The simultaneous operation of diverse occupancy patterns—from early morning residential demands to midday commercial peaks and evening entertainment loads—requires chiller systems to maintain efficiency across an exceptionally wide operating range. Traditional chiller designs optimized for steady-state conditions frequently underperform in these dynamic environments, operating at partial loads where efficiency degradation becomes pronounced.

The primary efficiency goal for chiller systems in mixed-use developments centers on maintaining optimal coefficient of performance across the entire load spectrum, particularly in the 30-70% capacity range where these systems spend the majority of operational hours. Current industry benchmarks target integrated part-load values exceeding 0.60 kW per ton, representing approximately 25-30% improvement over conventional constant-speed systems. Beyond energy consumption metrics, efficiency objectives increasingly encompass demand response capabilities, enabling chillers to modulate operation in alignment with grid conditions and dynamic electricity pricing structures.

Emerging efficiency targets also address the total system approach, recognizing that chiller performance cannot be isolated from condenser water systems, distribution networks, and terminal equipment. Advanced developments pursue holistic optimization strategies that balance component-level efficiency with system-wide energy consumption, incorporating predictive analytics and machine learning algorithms to anticipate load patterns and preemptively adjust operating parameters. These integrated approaches aim to achieve 40-50% energy reductions compared to baseline systems while maintaining thermal comfort across diverse occupancy zones.

Market Demand for Energy-Efficient HVAC in Mixed-Use Buildings

The global shift toward sustainable building practices has significantly elevated market demand for energy-efficient HVAC systems in mixed-use developments. These complex structures, which integrate residential, commercial, and retail spaces within a single footprint, present unique challenges that conventional HVAC solutions struggle to address effectively. Property developers and building owners increasingly recognize that optimized chiller systems represent a critical investment area, driven by both regulatory pressures and economic incentives.

Stringent energy codes and green building certifications such as LEED, BREEAM, and local energy performance standards have become mandatory in many jurisdictions. These regulations compel developers to adopt advanced HVAC technologies that demonstrate measurable efficiency improvements. Mixed-use developments, with their diverse occupancy patterns and varying thermal loads across different zones, require sophisticated chiller optimization strategies to meet these compliance requirements while maintaining occupant comfort.

Economic factors further amplify market demand. Energy costs constitute a substantial portion of operational expenses in mixed-use buildings, often representing the largest controllable cost category. Building operators face mounting pressure to reduce utility expenditures while simultaneously meeting tenant expectations for reliable climate control. The potential for significant operational savings through chiller efficiency optimization creates compelling business cases that drive technology adoption and investment decisions.

The rise of smart building technologies and Internet of Things integration has expanded market expectations beyond basic efficiency metrics. Stakeholders now demand predictive maintenance capabilities, real-time performance monitoring, and adaptive control systems that respond dynamically to occupancy patterns and external conditions. This technological evolution has created new market segments focused on intelligent chiller management solutions specifically designed for the operational complexity inherent in mixed-use environments.

Tenant and consumer preferences increasingly favor environmentally responsible buildings, influencing leasing decisions and property valuations. Corporate tenants particularly seek spaces that align with their sustainability commitments and ESG reporting requirements. This demand-side pressure reinforces the market imperative for building owners to invest in high-performance HVAC systems that deliver verifiable energy efficiency outcomes. The convergence of regulatory mandates, economic incentives, technological capabilities, and stakeholder expectations has established a robust and expanding market for energy-efficient HVAC solutions tailored to mixed-use development challenges.

Stringent energy codes and green building certifications such as LEED, BREEAM, and local energy performance standards have become mandatory in many jurisdictions. These regulations compel developers to adopt advanced HVAC technologies that demonstrate measurable efficiency improvements. Mixed-use developments, with their diverse occupancy patterns and varying thermal loads across different zones, require sophisticated chiller optimization strategies to meet these compliance requirements while maintaining occupant comfort.

Economic factors further amplify market demand. Energy costs constitute a substantial portion of operational expenses in mixed-use buildings, often representing the largest controllable cost category. Building operators face mounting pressure to reduce utility expenditures while simultaneously meeting tenant expectations for reliable climate control. The potential for significant operational savings through chiller efficiency optimization creates compelling business cases that drive technology adoption and investment decisions.

The rise of smart building technologies and Internet of Things integration has expanded market expectations beyond basic efficiency metrics. Stakeholders now demand predictive maintenance capabilities, real-time performance monitoring, and adaptive control systems that respond dynamically to occupancy patterns and external conditions. This technological evolution has created new market segments focused on intelligent chiller management solutions specifically designed for the operational complexity inherent in mixed-use environments.

Tenant and consumer preferences increasingly favor environmentally responsible buildings, influencing leasing decisions and property valuations. Corporate tenants particularly seek spaces that align with their sustainability commitments and ESG reporting requirements. This demand-side pressure reinforces the market imperative for building owners to invest in high-performance HVAC systems that deliver verifiable energy efficiency outcomes. The convergence of regulatory mandates, economic incentives, technological capabilities, and stakeholder expectations has established a robust and expanding market for energy-efficient HVAC solutions tailored to mixed-use development challenges.

Current Chiller Performance Challenges in Mixed-Use Developments

Mixed-use developments present unique operational complexities for chiller systems due to their diverse occupancy patterns and varying thermal loads. Commercial spaces typically demand peak cooling during business hours, while residential units require consistent climate control throughout evenings and weekends. This temporal mismatch creates significant challenges in load prediction and system optimization, often resulting in chillers operating at suboptimal efficiency points or cycling frequently between different capacity levels.

The heterogeneous nature of space utilization further complicates performance management. Retail areas generate substantial heat loads from lighting and occupant density, office spaces produce equipment-related thermal gains, and residential zones exhibit weather-dependent cooling demands. Traditional chiller control strategies struggle to accommodate these simultaneous yet conflicting requirements, leading to energy waste through oversized equipment selection or inefficient part-load operation. Many existing systems lack the granular monitoring capabilities needed to identify specific performance bottlenecks across different building zones.

Equipment aging and maintenance deficiencies compound these operational challenges. Chiller performance naturally degrades over time due to fouling in heat exchangers, refrigerant charge issues, and mechanical wear. In mixed-use environments, maintenance scheduling becomes particularly difficult as service interruptions must accommodate multiple stakeholder groups with different tolerance levels for downtime. This often results in reactive rather than preventive maintenance approaches, allowing minor inefficiencies to escalate into major performance problems.

Integration limitations between legacy building management systems and modern chiller controls create additional barriers to optimization. Many mixed-use developments feature equipment from multiple manufacturers installed across different construction phases, resulting in fragmented control architectures that prevent holistic system optimization. Data silos prevent operators from gaining comprehensive visibility into system performance, making it difficult to implement advanced control strategies or identify opportunities for efficiency improvements.

The economic structure of mixed-use developments also introduces performance challenges. Split ownership models and complex utility allocation arrangements can misalign incentives for efficiency investments, as capital expenditure responsibilities may not correspond with operational cost benefits. This organizational fragmentation often impedes the implementation of comprehensive optimization strategies that would benefit overall building performance.

The heterogeneous nature of space utilization further complicates performance management. Retail areas generate substantial heat loads from lighting and occupant density, office spaces produce equipment-related thermal gains, and residential zones exhibit weather-dependent cooling demands. Traditional chiller control strategies struggle to accommodate these simultaneous yet conflicting requirements, leading to energy waste through oversized equipment selection or inefficient part-load operation. Many existing systems lack the granular monitoring capabilities needed to identify specific performance bottlenecks across different building zones.

Equipment aging and maintenance deficiencies compound these operational challenges. Chiller performance naturally degrades over time due to fouling in heat exchangers, refrigerant charge issues, and mechanical wear. In mixed-use environments, maintenance scheduling becomes particularly difficult as service interruptions must accommodate multiple stakeholder groups with different tolerance levels for downtime. This often results in reactive rather than preventive maintenance approaches, allowing minor inefficiencies to escalate into major performance problems.

Integration limitations between legacy building management systems and modern chiller controls create additional barriers to optimization. Many mixed-use developments feature equipment from multiple manufacturers installed across different construction phases, resulting in fragmented control architectures that prevent holistic system optimization. Data silos prevent operators from gaining comprehensive visibility into system performance, making it difficult to implement advanced control strategies or identify opportunities for efficiency improvements.

The economic structure of mixed-use developments also introduces performance challenges. Split ownership models and complex utility allocation arrangements can misalign incentives for efficiency investments, as capital expenditure responsibilities may not correspond with operational cost benefits. This organizational fragmentation often impedes the implementation of comprehensive optimization strategies that would benefit overall building performance.

Existing Chiller Efficiency Enhancement Solutions

01 Variable speed compressor control systems

Chiller efficiency can be improved through the implementation of variable speed drive systems for compressors. These systems allow the compressor to operate at optimal speeds based on cooling demand, reducing energy consumption during partial load conditions. Advanced control algorithms monitor system parameters and adjust compressor speed accordingly to maintain efficiency across varying load conditions. This approach significantly reduces energy waste compared to traditional fixed-speed compressor systems.- Variable speed compressor control systems: Chiller efficiency can be improved through the implementation of variable speed drive systems for compressors. These systems allow the compressor to operate at optimal speeds based on cooling demand, reducing energy consumption during partial load conditions. Advanced control algorithms monitor system parameters and adjust compressor speed accordingly to maintain efficiency across varying load conditions. This approach significantly reduces energy waste compared to traditional fixed-speed compressor systems.

- Heat exchanger optimization and design improvements: Enhanced heat exchanger designs contribute to improved chiller efficiency by maximizing heat transfer rates while minimizing pressure drops. This includes the use of advanced tube configurations, enhanced surface geometries, and optimized flow patterns. Improved heat exchanger performance allows for better thermal exchange between refrigerant and water circuits, resulting in reduced compressor work and lower energy consumption. Material selection and coating technologies also play a role in maintaining long-term efficiency.

- Refrigerant management and advanced refrigeration cycles: Chiller efficiency can be enhanced through the use of advanced refrigerants and optimized refrigeration cycles. This includes the implementation of economizer cycles, multi-stage compression, and subcooling techniques that improve the coefficient of performance. Proper refrigerant charge management and leak detection systems ensure optimal system operation. The selection of environmentally friendly refrigerants with favorable thermodynamic properties also contributes to overall system efficiency.

- Intelligent monitoring and predictive maintenance systems: Implementation of smart monitoring systems with sensors and data analytics enables real-time performance tracking and predictive maintenance for chillers. These systems collect operational data including temperatures, pressures, flow rates, and power consumption to identify efficiency degradation and potential failures before they occur. Machine learning algorithms can optimize operating parameters and provide recommendations for maintenance activities. This proactive approach minimizes downtime and maintains peak efficiency throughout the equipment lifecycle.

- Condenser water system optimization: Efficiency improvements can be achieved through optimization of condenser water systems, including cooling tower operation, water treatment, and flow control. Proper management of condenser water temperature directly impacts chiller efficiency, as lower condenser temperatures reduce compressor lift and energy consumption. Variable speed pumping systems, optimized water distribution, and advanced cooling tower controls contribute to maintaining optimal condenser conditions. Integration of free cooling capabilities during favorable ambient conditions further enhances overall system efficiency.

02 Heat exchanger optimization and design improvements

Enhanced heat exchanger designs contribute to improved chiller efficiency by maximizing heat transfer rates while minimizing pressure drops. This includes the use of advanced tube configurations, enhanced surface geometries, and optimized flow patterns. Improved heat exchanger performance allows for better thermal exchange between refrigerant and water circuits, resulting in reduced compressor work and lower energy consumption. Material selection and coating technologies also play a role in maintaining long-term efficiency.Expand Specific Solutions03 Advanced refrigerant management and control

Efficient refrigerant management systems optimize chiller performance through precise control of refrigerant flow, pressure, and temperature. This includes the use of electronic expansion valves, subcooling and superheating control, and refrigerant distribution optimization. Advanced monitoring systems detect and prevent refrigerant leaks while ensuring optimal charge levels. These technologies help maintain peak efficiency by ensuring the refrigeration cycle operates at optimal conditions across all operating ranges.Expand Specific Solutions04 Integrated control and monitoring systems

Smart control systems integrate multiple sensors and algorithms to optimize overall chiller plant efficiency. These systems monitor parameters such as temperature, pressure, flow rates, and power consumption in real-time, making automatic adjustments to maintain optimal performance. Predictive maintenance capabilities identify potential issues before they impact efficiency. The integration of building management systems allows for coordinated operation of multiple chillers and optimization of the entire cooling system based on actual demand patterns.Expand Specific Solutions05 Condenser and evaporator performance enhancement

Improvements in condenser and evaporator design and operation directly impact chiller efficiency. This includes optimized water flow management, fouling prevention systems, and enhanced cleaning mechanisms. Advanced designs incorporate features such as variable water flow control, improved tube bundle arrangements, and enhanced surface treatments. Maintaining clean heat transfer surfaces and optimal approach temperatures ensures maximum heat transfer efficiency, reducing the temperature lift required by the compressor and thereby improving overall system coefficient of performance.Expand Specific Solutions

Key Players in Chiller and Building HVAC Industry

The chiller efficiency optimization market for mixed-use developments is experiencing robust growth, driven by increasing energy costs and sustainability mandates. The industry has reached a mature stage with established players like Carrier Corp., Mitsubishi Electric Corp., and Vertiv Corp. leading technological innovation. Market competition intensifies as Chinese manufacturers including Gree Electric Appliances, Haier Smart Home Co., and Shenzhen Envicool Technology expand globally with cost-effective solutions. Technology maturity varies significantly: multinational corporations like Honeywell International Technologies, Siemens, and LG Electronics demonstrate advanced IoT-integrated systems and predictive maintenance capabilities, while emerging players focus on specialized applications. Research institutions such as Southeast University and Wuhan University of Science & Technology contribute to next-generation efficiency algorithms. The convergence of smart building technologies with traditional HVAC systems creates opportunities for integrated solutions providers, positioning the market at a critical inflection point between conventional and intelligent climate control systems.

Haier Smart Home Co., Ltd.

Technical Solution: Haier has developed intelligent chiller systems tailored for mixed-use developments through their IoT-based smart building platform. Their solution employs modular magnetic levitation centrifugal chillers with COP values reaching 9.0 under optimal conditions. The system utilizes AI-driven load forecasting algorithms that analyze historical usage patterns across different zones (residential, office, retail) to predict cooling demands 24-48 hours in advance. Their proprietary control system dynamically adjusts chiller staging and sequencing based on real-time occupancy data from integrated sensors throughout the building. The platform features cloud-based energy management dashboards providing facility managers with granular visibility into energy consumption by zone and time period. Haier's solution also incorporates free cooling economizer modes and variable primary flow designs to maximize efficiency during partial load conditions common in mixed-use environments.

Strengths: Cost-effective solution with strong IoT integration, flexible modular design, excellent performance at partial loads. Weaknesses: Limited presence in international markets outside Asia, relatively newer technology with shorter operational track record compared to established competitors.

Carrier Corp.

Technical Solution: Carrier has developed advanced chiller optimization solutions specifically designed for mixed-use developments, incorporating variable speed drive technology and intelligent control systems. Their AquaEdge centrifugal chillers utilize magnetic bearing technology to eliminate friction losses, achieving IPLV ratings up to 0.18 kW/ton. The system integrates predictive analytics and IoT-enabled sensors to continuously monitor building loads across residential, commercial, and retail spaces, automatically adjusting compressor speed, condenser water flow, and evaporator parameters in real-time. Their building management integration allows for demand-based cooling distribution, optimizing energy consumption across diverse occupancy patterns typical in mixed-use facilities. The solution includes advanced heat recovery capabilities to redirect waste heat from cooling operations to domestic hot water systems or space heating in residential units.

Strengths: Industry-leading efficiency ratings, proven track record in large-scale mixed-use projects, comprehensive integration capabilities. Weaknesses: Higher initial capital investment, complex installation requirements, dependency on skilled maintenance personnel.

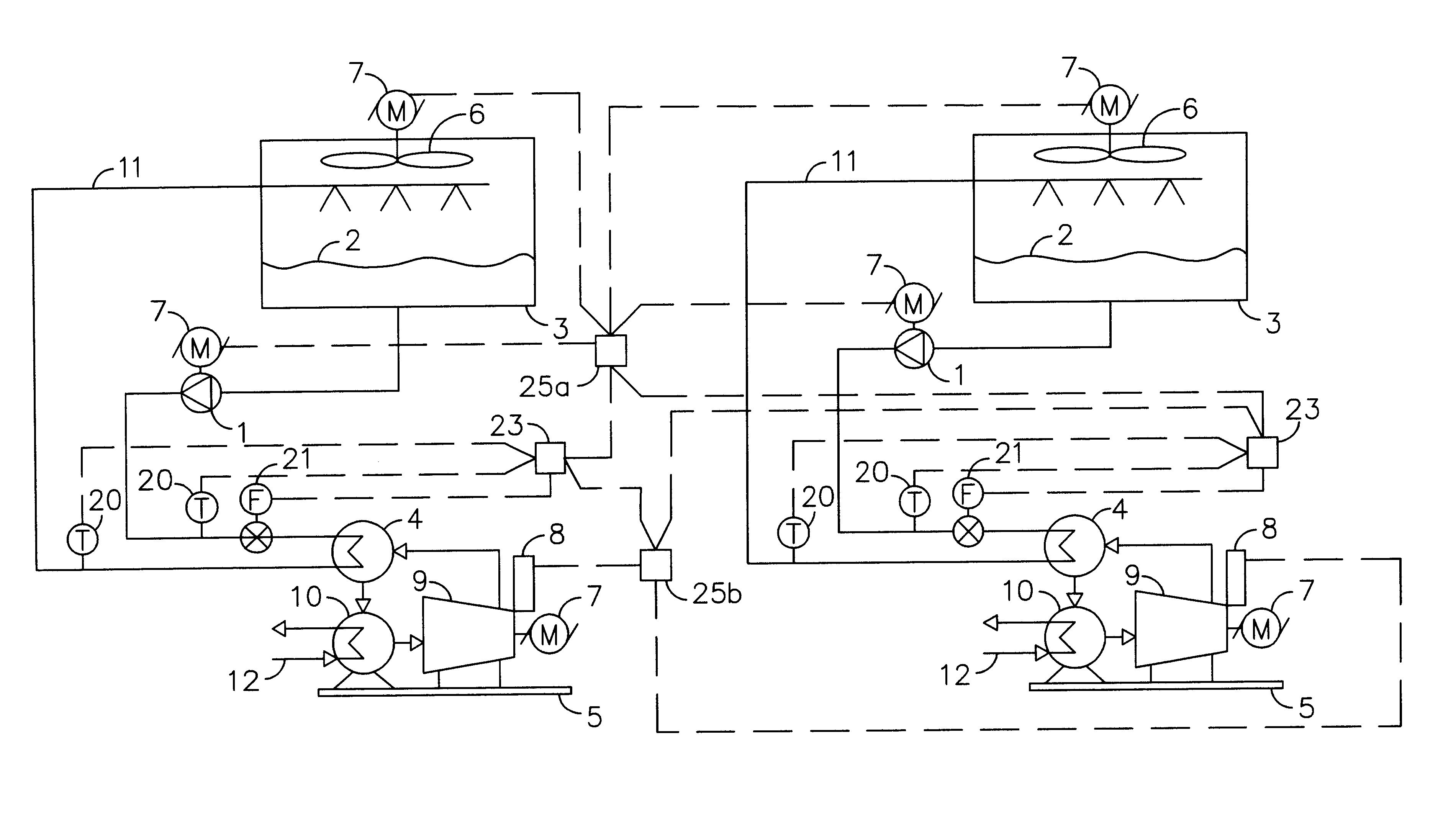

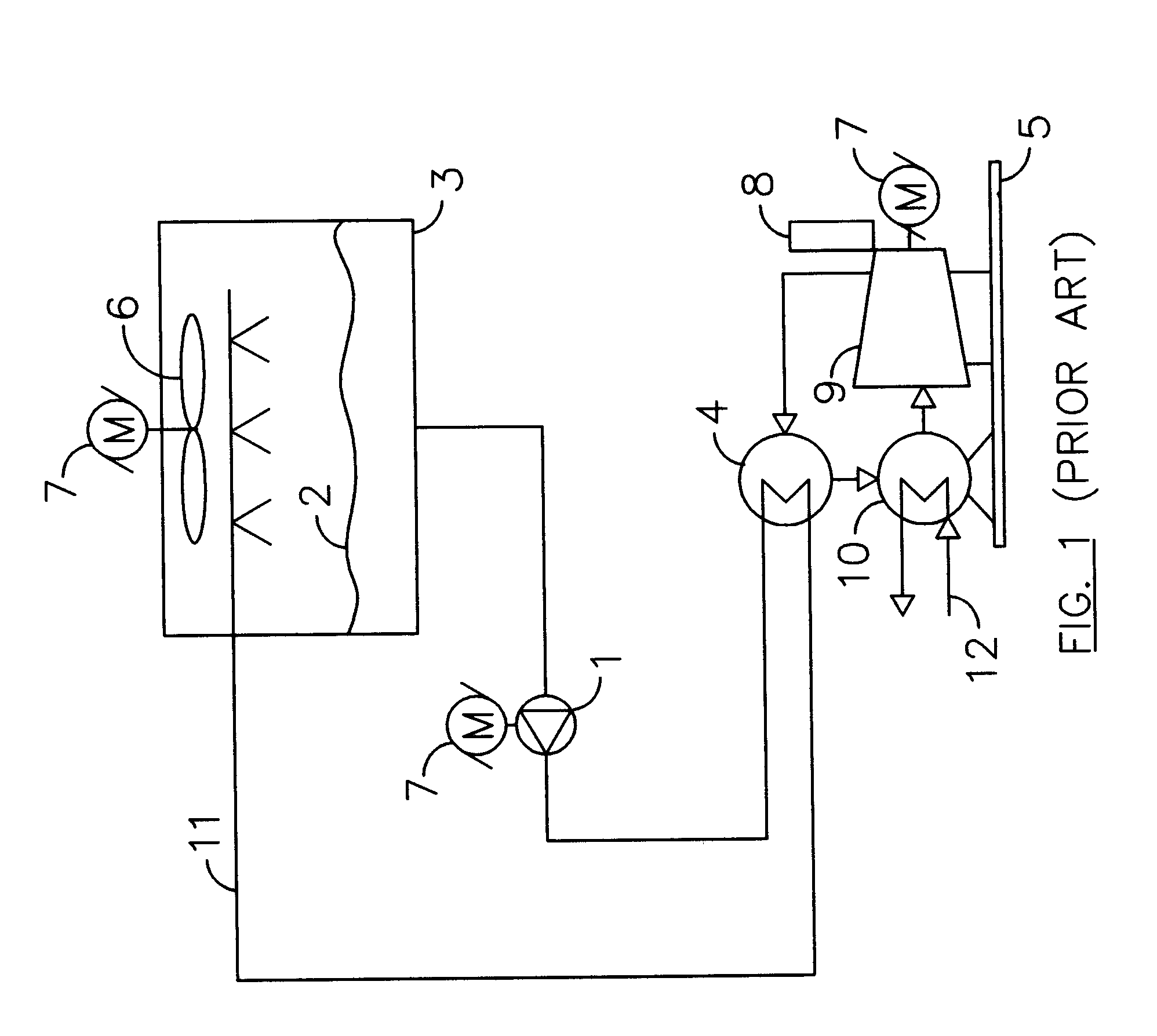

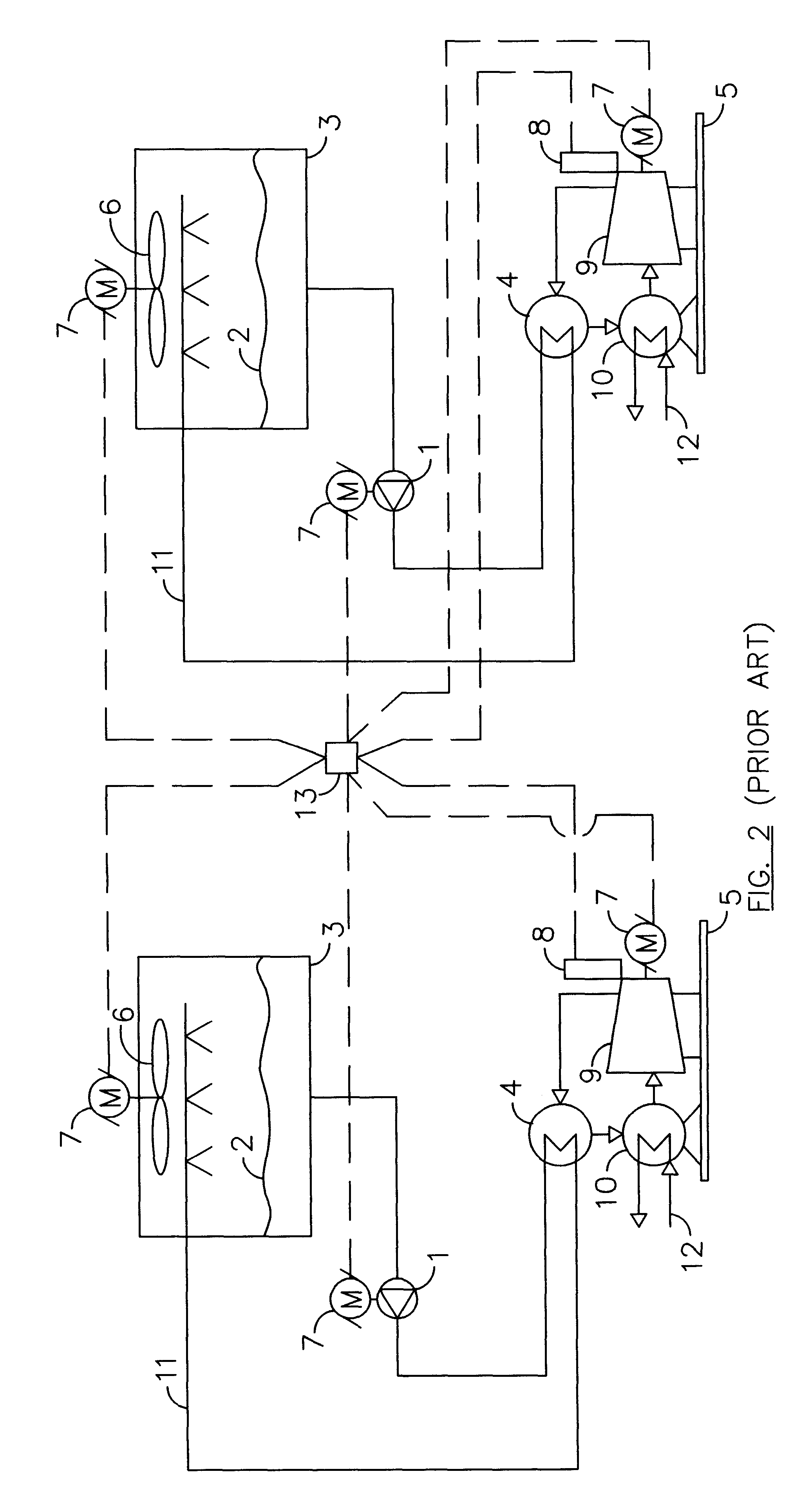

Core Innovations in Variable Load Chiller Control

Method to optimize chiller plant operation

PatentInactiveUS6718779B1

Innovation

- A computerized controller system that uses temperature sensors and flow meters to maintain a constant temperature difference across the refrigerant condenser, controlling cooling fluid pump and cooling tower fan speeds based on measured parameters, allowing for flexible operation and integration with existing chiller plants without requiring proprietary access or complex setups.

Chiller controller for optimized efficiency

PatentPendingUS20220373210A1

Innovation

- A method and system that determine the thermal load and current efficiency of a chiller group, generate performance curves for each chiller to relate thermal transfer rate with power consumption parameters, and strategically bring online or offline chillers to optimize efficiency, using a weighted average of estimated efficiencies to decide staging operations.

Energy Regulations for Mixed-Use Building Systems

Energy regulations governing mixed-use building systems have evolved significantly over the past two decades, driven by global climate commitments and the imperative to reduce carbon emissions from the built environment. These regulatory frameworks establish minimum performance standards for HVAC systems, including chillers, while promoting energy-efficient design practices in buildings that combine residential, commercial, and retail functions. The complexity of mixed-use developments presents unique regulatory challenges, as different occupancy types often fall under distinct energy codes and compliance pathways.

In the United States, ASHRAE Standard 90.1 serves as the foundational energy code for commercial buildings, with many states adopting it as mandatory or using it as the basis for local amendments. This standard prescribes minimum efficiency requirements for water-cooled and air-cooled chillers based on capacity and type, measured in kW/ton or COP metrics. The International Energy Conservation Code (IECC) provides parallel requirements, particularly for residential portions of mixed-use projects. European Union directives, notably the Energy Performance of Buildings Directive (EPBD) and Ecodesign regulations, establish comparable frameworks that mandate energy performance certificates and set efficiency thresholds for cooling equipment.

Compliance pathways typically include prescriptive requirements, which specify minimum equipment efficiencies and system configurations, and performance-based approaches that allow flexibility through whole-building energy modeling. For mixed-use developments, the latter often proves advantageous, enabling designers to demonstrate compliance through integrated system optimization rather than meeting individual component requirements. Many jurisdictions now require buildings above certain size thresholds to undergo energy audits or commissioning processes to verify that installed systems achieve design intent.

Recent regulatory trends emphasize operational efficiency beyond equipment specifications. Building energy management systems, real-time monitoring requirements, and periodic performance reporting are increasingly mandated to ensure sustained efficiency throughout a building's lifecycle. Some progressive jurisdictions have introduced building performance standards that set absolute energy use intensity targets, compelling owners to optimize chiller operations continuously rather than merely meeting installation requirements. These evolving regulations create both compliance obligations and opportunities for innovation in chiller system design and control strategies within mixed-use developments.

In the United States, ASHRAE Standard 90.1 serves as the foundational energy code for commercial buildings, with many states adopting it as mandatory or using it as the basis for local amendments. This standard prescribes minimum efficiency requirements for water-cooled and air-cooled chillers based on capacity and type, measured in kW/ton or COP metrics. The International Energy Conservation Code (IECC) provides parallel requirements, particularly for residential portions of mixed-use projects. European Union directives, notably the Energy Performance of Buildings Directive (EPBD) and Ecodesign regulations, establish comparable frameworks that mandate energy performance certificates and set efficiency thresholds for cooling equipment.

Compliance pathways typically include prescriptive requirements, which specify minimum equipment efficiencies and system configurations, and performance-based approaches that allow flexibility through whole-building energy modeling. For mixed-use developments, the latter often proves advantageous, enabling designers to demonstrate compliance through integrated system optimization rather than meeting individual component requirements. Many jurisdictions now require buildings above certain size thresholds to undergo energy audits or commissioning processes to verify that installed systems achieve design intent.

Recent regulatory trends emphasize operational efficiency beyond equipment specifications. Building energy management systems, real-time monitoring requirements, and periodic performance reporting are increasingly mandated to ensure sustained efficiency throughout a building's lifecycle. Some progressive jurisdictions have introduced building performance standards that set absolute energy use intensity targets, compelling owners to optimize chiller operations continuously rather than merely meeting installation requirements. These evolving regulations create both compliance obligations and opportunities for innovation in chiller system design and control strategies within mixed-use developments.

Integration Strategies for Diverse Load Profiles

Mixed-use developments present unique challenges for chiller system optimization due to the inherently diverse and often conflicting load profiles of residential, commercial, and retail spaces. Effective integration strategies must address the temporal and spatial variations in cooling demands while maintaining system efficiency across all operational scenarios. The fundamental approach involves implementing flexible system architectures that can dynamically respond to fluctuating loads without compromising performance in any single zone.

Central to successful integration is the deployment of variable primary flow systems combined with intelligent load distribution algorithms. These systems enable real-time adjustment of chiller staging and sequencing based on instantaneous demand patterns from different building zones. By incorporating predictive analytics that account for occupancy schedules, weather forecasts, and historical consumption data, operators can anticipate load transitions and optimize chiller operation proactively rather than reactively.

Thermal energy storage represents another critical integration strategy, particularly for managing peak demand disparities between daytime commercial operations and evening residential usage. Ice storage or chilled water tanks can be charged during off-peak periods when residential loads are minimal, then discharged during commercial peak hours, effectively smoothing the aggregate load profile and allowing chillers to operate closer to their optimal efficiency points for extended periods.

Zone-level control strategies must be carefully coordinated with central plant operations to prevent system conflicts. Implementing dedicated air handling units with independent temperature and humidity control for different use types allows for customized comfort parameters while maintaining centralized chiller efficiency. This requires sophisticated building management systems capable of balancing zone-level demands with plant-level optimization objectives.

The integration of renewable energy sources and waste heat recovery systems adds another dimension to load profile management. Solar thermal systems can offset daytime commercial cooling loads, while heat recovery from data centers or commercial kitchens can serve residential domestic hot water needs, reducing overall energy consumption and improving system economics. These strategies require careful hydraulic design and control integration to ensure seamless operation across diverse load conditions while maximizing the utilization of available energy resources.

Central to successful integration is the deployment of variable primary flow systems combined with intelligent load distribution algorithms. These systems enable real-time adjustment of chiller staging and sequencing based on instantaneous demand patterns from different building zones. By incorporating predictive analytics that account for occupancy schedules, weather forecasts, and historical consumption data, operators can anticipate load transitions and optimize chiller operation proactively rather than reactively.

Thermal energy storage represents another critical integration strategy, particularly for managing peak demand disparities between daytime commercial operations and evening residential usage. Ice storage or chilled water tanks can be charged during off-peak periods when residential loads are minimal, then discharged during commercial peak hours, effectively smoothing the aggregate load profile and allowing chillers to operate closer to their optimal efficiency points for extended periods.

Zone-level control strategies must be carefully coordinated with central plant operations to prevent system conflicts. Implementing dedicated air handling units with independent temperature and humidity control for different use types allows for customized comfort parameters while maintaining centralized chiller efficiency. This requires sophisticated building management systems capable of balancing zone-level demands with plant-level optimization objectives.

The integration of renewable energy sources and waste heat recovery systems adds another dimension to load profile management. Solar thermal systems can offset daytime commercial cooling loads, while heat recovery from data centers or commercial kitchens can serve residential domestic hot water needs, reducing overall energy consumption and improving system economics. These strategies require careful hydraulic design and control integration to ensure seamless operation across diverse load conditions while maximizing the utilization of available energy resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!