Piezoelectricity For Prosthetics Feedback: Sensitivity, Safety And Washability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Technology Evolution and Objectives

Piezoelectric technology has evolved significantly since its discovery in 1880 by the Curie brothers. Initially limited to basic applications like sonar during World War I, piezoelectric materials have undergone substantial development through several distinct phases. Early applications primarily utilized natural crystals such as quartz, while the mid-20th century saw the emergence of synthetic piezoelectric ceramics like barium titanate and lead zirconate titanate (PZT), dramatically expanding application possibilities.

The 1990s marked a pivotal shift with the development of piezoelectric polymers, particularly polyvinylidene fluoride (PVDF), offering greater flexibility and biocompatibility compared to ceramic counterparts. This innovation opened new avenues in medical applications, including prosthetics. Recent advancements have focused on nanostructured piezoelectric materials and composites, providing enhanced sensitivity and durability while reducing reliance on lead-based compounds.

In the context of prosthetic feedback systems, piezoelectric technology has evolved from rudimentary pressure sensors to sophisticated haptic feedback mechanisms. Early prosthetic applications primarily utilized piezoelectric elements for basic pressure detection, whereas contemporary systems integrate these materials into complex sensory networks capable of detecting subtle variations in pressure, texture, and temperature.

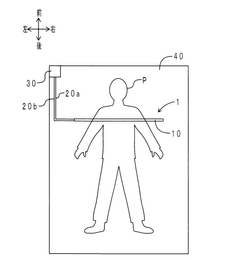

The primary objective of piezoelectric implementation in prosthetics is to restore sensory feedback to amputees, creating a bidirectional communication channel between the prosthetic device and the user's nervous system. This aims to overcome the significant limitation of conventional prosthetics: the absence of tactile sensation. By converting mechanical stimuli into electrical signals that can be interpreted by the nervous system, piezoelectric materials serve as artificial mechanoreceptors.

Current technological objectives focus on three critical parameters: sensitivity, safety, and washability. Sensitivity enhancement aims to detect forces across a wide dynamic range (from gentle touch to firm grip) while maintaining signal fidelity. Safety considerations include biocompatibility, electrical isolation, and long-term stability of materials in contact with skin. Washability objectives address the practical challenges of daily prosthetic use, requiring materials that maintain functionality despite exposure to moisture, detergents, and varying temperatures.

Future development trajectories target miniaturization of piezoelectric components, improved energy efficiency, and integration with neural interfaces. The ultimate goal remains creating prosthetic systems that provide naturalistic sensory feedback, enabling intuitive control and enhanced quality of life for users. This requires interdisciplinary collaboration between materials scientists, electrical engineers, and medical professionals to overcome current technological limitations.

The 1990s marked a pivotal shift with the development of piezoelectric polymers, particularly polyvinylidene fluoride (PVDF), offering greater flexibility and biocompatibility compared to ceramic counterparts. This innovation opened new avenues in medical applications, including prosthetics. Recent advancements have focused on nanostructured piezoelectric materials and composites, providing enhanced sensitivity and durability while reducing reliance on lead-based compounds.

In the context of prosthetic feedback systems, piezoelectric technology has evolved from rudimentary pressure sensors to sophisticated haptic feedback mechanisms. Early prosthetic applications primarily utilized piezoelectric elements for basic pressure detection, whereas contemporary systems integrate these materials into complex sensory networks capable of detecting subtle variations in pressure, texture, and temperature.

The primary objective of piezoelectric implementation in prosthetics is to restore sensory feedback to amputees, creating a bidirectional communication channel between the prosthetic device and the user's nervous system. This aims to overcome the significant limitation of conventional prosthetics: the absence of tactile sensation. By converting mechanical stimuli into electrical signals that can be interpreted by the nervous system, piezoelectric materials serve as artificial mechanoreceptors.

Current technological objectives focus on three critical parameters: sensitivity, safety, and washability. Sensitivity enhancement aims to detect forces across a wide dynamic range (from gentle touch to firm grip) while maintaining signal fidelity. Safety considerations include biocompatibility, electrical isolation, and long-term stability of materials in contact with skin. Washability objectives address the practical challenges of daily prosthetic use, requiring materials that maintain functionality despite exposure to moisture, detergents, and varying temperatures.

Future development trajectories target miniaturization of piezoelectric components, improved energy efficiency, and integration with neural interfaces. The ultimate goal remains creating prosthetic systems that provide naturalistic sensory feedback, enabling intuitive control and enhanced quality of life for users. This requires interdisciplinary collaboration between materials scientists, electrical engineers, and medical professionals to overcome current technological limitations.

Market Analysis for Haptic Feedback Prosthetics

The global market for haptic feedback prosthetics is experiencing significant growth, driven by technological advancements and increasing demand for more functional prosthetic devices. The market size for advanced prosthetics incorporating sensory feedback was valued at approximately $1.9 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate of 10.7%.

Piezoelectric technology for prosthetic feedback addresses a critical unmet need in the prosthetics market. Currently, over 40 million amputees worldwide require prosthetic solutions, with only about 5-10% having access to advanced prosthetics with any form of sensory feedback. This represents a substantial market opportunity for piezoelectric-based solutions that can provide realistic tactile sensations to users.

The primary market segments for haptic feedback prosthetics include upper limb prosthetics (accounting for approximately 35% of the market), lower limb prosthetics (45%), and specialized prosthetics (20%). Within these segments, the demand for enhanced sensory feedback is particularly strong in upper limb prosthetics, where fine motor control and object manipulation require sophisticated tactile information.

Regional analysis reveals that North America dominates the market with a 40% share, followed by Europe (30%), Asia-Pacific (20%), and rest of the world (10%). However, the Asia-Pacific region is expected to witness the fastest growth due to improving healthcare infrastructure, increasing disposable income, and growing awareness about advanced prosthetic technologies.

Key market drivers include the rising prevalence of amputations due to diabetes, vascular diseases, and trauma; increasing healthcare expenditure; growing focus on improving quality of life for amputees; and technological innovations in materials and electronics. The integration of piezoelectric materials in prosthetics addresses the crucial aspects of sensitivity, safety, and washability that consumers and healthcare providers prioritize.

Market challenges include high costs associated with advanced prosthetics (average cost ranging from $20,000 to $100,000 depending on functionality), limited reimbursement policies, and technical challenges in creating durable yet sensitive feedback mechanisms. The washability aspect of piezoelectric solutions presents a particular market advantage, as durability and maintenance remain significant concerns for prosthetic users.

Consumer preferences indicate strong demand for prosthetics that provide natural-feeling feedback (cited by 85% of users as "very important"), are safe for daily use, and require minimal maintenance. The ability of piezoelectric materials to withstand washing while maintaining sensitivity positions this technology favorably against competing solutions like microfluidics or traditional mechanical feedback systems.

Piezoelectric technology for prosthetic feedback addresses a critical unmet need in the prosthetics market. Currently, over 40 million amputees worldwide require prosthetic solutions, with only about 5-10% having access to advanced prosthetics with any form of sensory feedback. This represents a substantial market opportunity for piezoelectric-based solutions that can provide realistic tactile sensations to users.

The primary market segments for haptic feedback prosthetics include upper limb prosthetics (accounting for approximately 35% of the market), lower limb prosthetics (45%), and specialized prosthetics (20%). Within these segments, the demand for enhanced sensory feedback is particularly strong in upper limb prosthetics, where fine motor control and object manipulation require sophisticated tactile information.

Regional analysis reveals that North America dominates the market with a 40% share, followed by Europe (30%), Asia-Pacific (20%), and rest of the world (10%). However, the Asia-Pacific region is expected to witness the fastest growth due to improving healthcare infrastructure, increasing disposable income, and growing awareness about advanced prosthetic technologies.

Key market drivers include the rising prevalence of amputations due to diabetes, vascular diseases, and trauma; increasing healthcare expenditure; growing focus on improving quality of life for amputees; and technological innovations in materials and electronics. The integration of piezoelectric materials in prosthetics addresses the crucial aspects of sensitivity, safety, and washability that consumers and healthcare providers prioritize.

Market challenges include high costs associated with advanced prosthetics (average cost ranging from $20,000 to $100,000 depending on functionality), limited reimbursement policies, and technical challenges in creating durable yet sensitive feedback mechanisms. The washability aspect of piezoelectric solutions presents a particular market advantage, as durability and maintenance remain significant concerns for prosthetic users.

Consumer preferences indicate strong demand for prosthetics that provide natural-feeling feedback (cited by 85% of users as "very important"), are safe for daily use, and require minimal maintenance. The ability of piezoelectric materials to withstand washing while maintaining sensitivity positions this technology favorably against competing solutions like microfluidics or traditional mechanical feedback systems.

Current Challenges in Piezoelectric Prosthetic Interfaces

Despite significant advancements in piezoelectric technology for prosthetic feedback systems, several critical challenges continue to impede widespread adoption and optimal functionality. The integration of piezoelectric materials into prosthetic interfaces faces substantial technical hurdles that require innovative solutions. Sensitivity calibration remains a primary concern, as piezoelectric sensors must detect subtle pressure variations while filtering environmental noise. Current systems struggle to maintain consistent sensitivity across different user activities and environmental conditions, resulting in unreliable feedback that diminishes user experience.

Material durability presents another significant challenge. Piezoelectric elements incorporated into prosthetic interfaces are subjected to continuous mechanical stress, temperature fluctuations, and exposure to bodily fluids. These conditions accelerate material degradation, reducing sensor lifespan and necessitating frequent replacements. The brittleness of many piezoelectric ceramics makes them particularly vulnerable to cracking under the dynamic forces experienced during normal prosthetic use.

Safety considerations create additional complexity in design and implementation. Piezoelectric materials can generate relatively high voltages even from small mechanical deformations, potentially creating electrical safety hazards if insulation fails. Furthermore, some piezoelectric compounds contain lead and other toxic elements, raising biocompatibility concerns for long-term contact with skin and potential environmental impact during disposal.

Washability and moisture resistance represent persistent engineering challenges. Prosthetic devices require regular cleaning to maintain hygiene, but many piezoelectric systems are vulnerable to moisture damage. Current waterproofing solutions often compromise sensor sensitivity or increase bulk, creating an undesirable trade-off between functionality and maintenance requirements.

Power management issues further complicate piezoelectric interface design. While piezoelectric materials can generate electricity through mechanical deformation, harvesting this energy efficiently for feedback mechanisms remains difficult. Most systems still rely on external power sources, adding weight and complexity to prosthetic designs.

Signal processing limitations also hinder performance. Converting piezoelectric signals into meaningful tactile feedback requires sophisticated algorithms that can interpret various pressure patterns and translate them into appropriate sensory information. Current processing systems struggle with latency issues that create delays between physical contact and sensory feedback, disrupting the natural feel of the prosthetic interface.

Manufacturing scalability presents additional barriers to widespread implementation. Producing consistent, high-quality piezoelectric elements for prosthetic applications remains costly and technically challenging, particularly when customization is required for individual users' needs.

Material durability presents another significant challenge. Piezoelectric elements incorporated into prosthetic interfaces are subjected to continuous mechanical stress, temperature fluctuations, and exposure to bodily fluids. These conditions accelerate material degradation, reducing sensor lifespan and necessitating frequent replacements. The brittleness of many piezoelectric ceramics makes them particularly vulnerable to cracking under the dynamic forces experienced during normal prosthetic use.

Safety considerations create additional complexity in design and implementation. Piezoelectric materials can generate relatively high voltages even from small mechanical deformations, potentially creating electrical safety hazards if insulation fails. Furthermore, some piezoelectric compounds contain lead and other toxic elements, raising biocompatibility concerns for long-term contact with skin and potential environmental impact during disposal.

Washability and moisture resistance represent persistent engineering challenges. Prosthetic devices require regular cleaning to maintain hygiene, but many piezoelectric systems are vulnerable to moisture damage. Current waterproofing solutions often compromise sensor sensitivity or increase bulk, creating an undesirable trade-off between functionality and maintenance requirements.

Power management issues further complicate piezoelectric interface design. While piezoelectric materials can generate electricity through mechanical deformation, harvesting this energy efficiently for feedback mechanisms remains difficult. Most systems still rely on external power sources, adding weight and complexity to prosthetic designs.

Signal processing limitations also hinder performance. Converting piezoelectric signals into meaningful tactile feedback requires sophisticated algorithms that can interpret various pressure patterns and translate them into appropriate sensory information. Current processing systems struggle with latency issues that create delays between physical contact and sensory feedback, disrupting the natural feel of the prosthetic interface.

Manufacturing scalability presents additional barriers to widespread implementation. Producing consistent, high-quality piezoelectric elements for prosthetic applications remains costly and technically challenging, particularly when customization is required for individual users' needs.

Existing Piezoelectric Sensitivity Enhancement Methods

01 Enhancing piezoelectric sensitivity through material composition

Various material compositions can be used to enhance the sensitivity of piezoelectric devices. These include specific polymer blends, ceramic composites, and nanomaterials that exhibit improved piezoelectric properties. By optimizing the material composition, the conversion efficiency between mechanical energy and electrical energy can be significantly increased, resulting in more sensitive piezoelectric sensors and actuators.- Enhancing piezoelectric sensitivity through material composition: Various material compositions can be used to enhance the sensitivity of piezoelectric devices. These include specific polymer blends, ceramic composites, and nanomaterials that demonstrate improved piezoelectric coefficients. By optimizing the material composition, the electrical response to mechanical stimulation can be significantly increased, making these materials suitable for applications requiring high sensitivity such as sensors and energy harvesters.

- Safety features in piezoelectric wearable devices: Safety considerations for piezoelectric wearable technology include electrical insulation, biocompatibility of materials, and low-voltage operation. Designs incorporate protective layers to prevent direct contact between piezoelectric elements and skin, reducing risks of electrical shock or irritation. Additionally, encapsulation techniques are employed to ensure that potentially harmful materials in the piezoelectric components do not leach into the surrounding environment or come into contact with the user.

- Washable piezoelectric textiles and structures: Washable piezoelectric materials are developed by incorporating waterproof coatings, encapsulation methods, and flexible substrate integration. These techniques protect the piezoelectric elements from water damage while maintaining functionality after multiple washing cycles. Special attention is given to connection points and interfaces to ensure they remain intact during washing processes, making these materials suitable for smart textiles and wearable applications.

- Sensitivity enhancement through structural design: The sensitivity of piezoelectric devices can be enhanced through specific structural designs such as multilayer configurations, cantilever arrangements, and resonant structures. These designs amplify the mechanical stress applied to the piezoelectric material, resulting in increased electrical output. Additionally, micro-patterning and surface modifications can be employed to optimize the stress distribution across the piezoelectric elements, further improving sensitivity for sensing applications.

- Integration of piezoelectric elements in everyday products: Piezoelectric technology is being integrated into various everyday products through flexible mounting techniques, miniaturization, and seamless embedding methods. These approaches allow for the incorporation of piezoelectric elements into clothing, footwear, furniture, and electronic devices while maintaining user comfort and product functionality. Special attention is given to durability and reliability to ensure the piezoelectric components can withstand normal usage conditions.

02 Safety measures for piezoelectric devices

Safety considerations for piezoelectric devices include electrical insulation, encapsulation techniques, and biocompatibility for wearable applications. These measures prevent electrical hazards, protect users from direct contact with piezoelectric materials, and ensure that devices are safe for prolonged skin contact. Additionally, low-voltage designs and protective circuitry can be implemented to minimize safety risks in consumer applications.Expand Specific Solutions03 Washable piezoelectric textiles and wearables

Washable piezoelectric devices incorporate waterproof coatings, sealed enclosures, and flexible substrates that maintain functionality after exposure to moisture. These technologies enable the development of washable smart textiles and wearable devices that can withstand regular cleaning processes. Special attention is given to connection points and interfaces to ensure water resistance while maintaining electrical conductivity and piezoelectric performance.Expand Specific Solutions04 Structural design for improved piezoelectric performance

Innovative structural designs can enhance the performance of piezoelectric devices. These include multilayer configurations, cantilever structures, and resonant designs that amplify the piezoelectric effect. By optimizing the physical arrangement of piezoelectric materials and supporting components, both sensitivity and durability can be improved. These structural innovations are particularly important for applications requiring high sensitivity or operation in harsh environments.Expand Specific Solutions05 Environmental stability and durability of piezoelectric sensors

Techniques to improve the environmental stability and durability of piezoelectric sensors include protective coatings, temperature compensation mechanisms, and humidity-resistant designs. These approaches ensure consistent performance across varying environmental conditions and extend the operational lifespan of piezoelectric devices. Materials selection plays a crucial role in achieving long-term stability, with certain compositions offering superior resistance to degradation from environmental factors.Expand Specific Solutions

Leading Companies in Prosthetic Feedback Solutions

The piezoelectric prosthetics feedback market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. Market size remains modest but is expanding as prosthetic technologies advance, with projections suggesting significant growth potential as sensitivity and user experience improve. Technologically, the field is progressing from experimental to practical applications, with companies like Murata Manufacturing, Sumitomo Riko, and Sony Group leading in piezoelectric material development. Academic institutions including USC, Shanghai Jiao Tong University, and Harbin Institute of Technology are advancing fundamental research, while Jabil and AAC Technologies focus on implementation. Key challenges remain in balancing sensitivity with safety and washability requirements, which currently limit widespread adoption in everyday prosthetic applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric ceramic sensors and actuators specifically designed for prosthetic feedback systems. Their technology utilizes lead zirconate titanate (PZT) materials with optimized dopants to enhance sensitivity while maintaining durability. Murata's piezoelectric elements are engineered with a multilayer structure that improves force transmission efficiency and enables detection of subtle pressure changes (as low as 0.1N). Their proprietary manufacturing process creates ultrathin piezoelectric films (down to 15μm) that can be integrated into prosthetic liners without compromising comfort. The company has implemented specialized encapsulation techniques using biocompatible polymers that maintain sensitivity while providing IPX7 waterproofing standards, ensuring washability and long-term reliability in prosthetic applications.

Strengths: Industry-leading sensitivity-to-size ratio allows for minimal form factor while maintaining high signal quality; advanced waterproofing technology enables regular cleaning without performance degradation. Weaknesses: Higher production costs compared to conventional sensors; requires specialized interface electronics for optimal performance in prosthetic systems.

United States Department of Veterans Affairs

Technical Solution: The VA has developed a comprehensive piezoelectric feedback system for prosthetics through their Rehabilitation Research and Development Service. Their approach focuses on clinical applicability and patient outcomes rather than purely technical specifications. The VA's system utilizes a distributed array of polyvinylidene fluoride (PVDF) piezoelectric sensors embedded within a specially designed prosthetic liner that maintains skin contact while preventing pressure points. Their innovation includes a machine-washable connection system with magnetically coupled contacts that automatically disconnect during cleaning and reconnect when the prosthesis is reassembled. The signal processing architecture employs adaptive algorithms that learn individual user patterns to optimize feedback sensitivity based on activity levels and environmental conditions. Safety features include galvanic isolation between the sensor network and stimulation systems, preventing any potential electrical hazards. The VA's solution has undergone extensive clinical testing with veterans, demonstrating significant improvements in prosthetic control precision and reduction in phantom limb pain when compared to conventional systems without feedback.

Strengths: Extensively validated through clinical trials with diverse patient populations; designed with user maintenance in mind, requiring minimal technical expertise. Weaknesses: Currently optimized for lower limb applications with limited upper limb implementations; relies on specialized components that may have limited availability outside the VA system.

Key Patents in Biocompatible Piezoelectric Materials

Piezoelectric sensor

PatentWO2015064216A1

Innovation

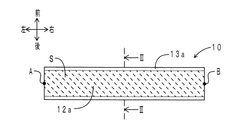

- A piezoelectric sensor design featuring a water-absorbing adhesive layer with a moisture-permeable adhesive layer, integrated with a piezoelectric element and corrosion-resistant electrode layers, which absorbs moisture without compromising signal integrity, ensuring secure attachment and reduced skin irritation.

Piezoelectric sensor and method for manufacturing same

PatentWO2020157999A1

Innovation

- A flexible piezoelectric sensor design featuring a piezoelectric layer with elastomer and piezoelectric particles, and an electrode layer made of elastomer with flaky conductive material, oriented to maintain high conductivity and flexibility, even when elongated, by aligning flaky conductive materials in the length direction and pressure bonding with the piezoelectric layer before crosslinking.

Biocompatibility Standards for Prosthetic Components

Biocompatibility standards for prosthetic components incorporating piezoelectric feedback systems must adhere to rigorous regulatory frameworks to ensure patient safety. The ISO 10993 series serves as the cornerstone for evaluating biological responses to medical devices, with specific attention to ISO 10993-1 for risk assessment and categorization of prosthetic components based on body contact duration and tissue interaction type.

For piezoelectric materials in prosthetics, FDA guidelines mandate comprehensive testing for cytotoxicity, sensitization, and irritation potential. These materials must demonstrate minimal adverse biological reactions when in prolonged contact with skin or subcutaneous tissues. The European Medical Device Regulation (MDR 2017/745) imposes additional requirements for CE marking, emphasizing long-term safety evaluation and post-market surveillance.

Material selection for piezoelectric components presents unique challenges due to their electrical properties. Lead zirconate titanate (PZT), while offering excellent piezoelectric performance, contains lead which raises biocompatibility concerns. Alternative lead-free piezoelectric materials such as barium titanate (BaTiO3) and polyvinylidene fluoride (PVDF) demonstrate improved biocompatibility profiles but may require performance trade-offs.

Encapsulation technologies play a critical role in ensuring biocompatibility while maintaining sensitivity. Medical-grade silicones, polyurethanes, and parylene coatings provide effective barriers against material leaching while allowing sufficient mechanical deformation for piezoelectric function. These encapsulants must maintain integrity during repeated washing cycles and exposure to cleaning agents commonly used for prosthetic maintenance.

The washability aspect introduces additional biocompatibility considerations, as cleaning agents may potentially degrade encapsulation materials over time. Standards such as AAMI TIR30 provide guidance on selection of compatible cleaning and disinfection methods. Manufacturers must validate that repeated exposure to these agents does not compromise the biocompatibility of the prosthetic system.

Electrical safety standards, including IEC 60601-1, establish requirements for leakage current limitations and electrical isolation, particularly relevant for piezoelectric components that generate electrical signals. These standards ensure that feedback mechanisms do not pose electrical hazards to users, even in cases of partial encapsulation failure or moisture ingress.

Testing protocols for biocompatibility must address both short-term and long-term effects, with particular emphasis on chronic inflammation, material degradation, and potential systemic toxicity from wear particles. The unique combination of mechanical stress, electrical activity, and washing cycles in piezoelectric prosthetic components necessitates customized testing approaches beyond standard biocompatibility protocols.

For piezoelectric materials in prosthetics, FDA guidelines mandate comprehensive testing for cytotoxicity, sensitization, and irritation potential. These materials must demonstrate minimal adverse biological reactions when in prolonged contact with skin or subcutaneous tissues. The European Medical Device Regulation (MDR 2017/745) imposes additional requirements for CE marking, emphasizing long-term safety evaluation and post-market surveillance.

Material selection for piezoelectric components presents unique challenges due to their electrical properties. Lead zirconate titanate (PZT), while offering excellent piezoelectric performance, contains lead which raises biocompatibility concerns. Alternative lead-free piezoelectric materials such as barium titanate (BaTiO3) and polyvinylidene fluoride (PVDF) demonstrate improved biocompatibility profiles but may require performance trade-offs.

Encapsulation technologies play a critical role in ensuring biocompatibility while maintaining sensitivity. Medical-grade silicones, polyurethanes, and parylene coatings provide effective barriers against material leaching while allowing sufficient mechanical deformation for piezoelectric function. These encapsulants must maintain integrity during repeated washing cycles and exposure to cleaning agents commonly used for prosthetic maintenance.

The washability aspect introduces additional biocompatibility considerations, as cleaning agents may potentially degrade encapsulation materials over time. Standards such as AAMI TIR30 provide guidance on selection of compatible cleaning and disinfection methods. Manufacturers must validate that repeated exposure to these agents does not compromise the biocompatibility of the prosthetic system.

Electrical safety standards, including IEC 60601-1, establish requirements for leakage current limitations and electrical isolation, particularly relevant for piezoelectric components that generate electrical signals. These standards ensure that feedback mechanisms do not pose electrical hazards to users, even in cases of partial encapsulation failure or moisture ingress.

Testing protocols for biocompatibility must address both short-term and long-term effects, with particular emphasis on chronic inflammation, material degradation, and potential systemic toxicity from wear particles. The unique combination of mechanical stress, electrical activity, and washing cycles in piezoelectric prosthetic components necessitates customized testing approaches beyond standard biocompatibility protocols.

Energy Harvesting Potential in Piezoelectric Prosthetics

Piezoelectric materials in prosthetics offer significant energy harvesting potential, transforming mechanical stress from normal movement into electrical energy. This capability represents a paradigm shift in prosthetic design, potentially enabling self-powered systems that reduce or eliminate the need for conventional batteries, thereby extending operational lifespans and reducing maintenance requirements.

The energy harvesting efficiency of piezoelectric materials in prosthetic applications varies considerably based on material composition, structural design, and implementation method. Current research indicates that advanced piezoelectric composites can achieve conversion efficiencies between 5-15% under optimal conditions, with newer materials pushing these boundaries further. For prosthetic applications, even modest energy generation can significantly supplement power requirements for sensory feedback systems.

Biomechanical analyses demonstrate that normal walking generates substantial mechanical energy at key prosthetic interface points. The heel strike phase alone can produce forces exceeding 120% of body weight, representing a rich energy source. Strategic placement of piezoelectric elements at these high-pressure zones can harvest energy without compromising user comfort or prosthetic functionality.

The harvested energy can be utilized in multiple ways within prosthetic systems. Primary applications include powering sensory feedback mechanisms, maintaining charge in supplementary batteries, and operating low-power monitoring systems. Advanced energy management circuits are essential to regulate the inconsistent power generation inherent in movement-based harvesting, ensuring stable voltage output for sensitive electronic components.

Recent technological advancements have introduced flexible piezoelectric materials that conform to anatomical contours while maintaining harvesting capabilities. These materials demonstrate improved durability under cyclical loading conditions typical in prosthetic use, with some newer composites showing minimal degradation after millions of compression cycles.

Scale-up considerations for commercial implementation include manufacturing standardization, cost reduction through material optimization, and integration protocols for existing prosthetic designs. Current cost-benefit analyses suggest that while initial implementation expenses may exceed traditional power solutions, the long-term operational benefits and reduced maintenance requirements present compelling economic advantages.

Environmental impact assessments indicate that self-powered prosthetics could significantly reduce battery waste, aligning with sustainability goals. Additionally, the reduced dependency on charging infrastructure makes these systems particularly valuable in regions with limited electrical grid access, potentially improving prosthetic adoption and usability in developing regions.

The energy harvesting efficiency of piezoelectric materials in prosthetic applications varies considerably based on material composition, structural design, and implementation method. Current research indicates that advanced piezoelectric composites can achieve conversion efficiencies between 5-15% under optimal conditions, with newer materials pushing these boundaries further. For prosthetic applications, even modest energy generation can significantly supplement power requirements for sensory feedback systems.

Biomechanical analyses demonstrate that normal walking generates substantial mechanical energy at key prosthetic interface points. The heel strike phase alone can produce forces exceeding 120% of body weight, representing a rich energy source. Strategic placement of piezoelectric elements at these high-pressure zones can harvest energy without compromising user comfort or prosthetic functionality.

The harvested energy can be utilized in multiple ways within prosthetic systems. Primary applications include powering sensory feedback mechanisms, maintaining charge in supplementary batteries, and operating low-power monitoring systems. Advanced energy management circuits are essential to regulate the inconsistent power generation inherent in movement-based harvesting, ensuring stable voltage output for sensitive electronic components.

Recent technological advancements have introduced flexible piezoelectric materials that conform to anatomical contours while maintaining harvesting capabilities. These materials demonstrate improved durability under cyclical loading conditions typical in prosthetic use, with some newer composites showing minimal degradation after millions of compression cycles.

Scale-up considerations for commercial implementation include manufacturing standardization, cost reduction through material optimization, and integration protocols for existing prosthetic designs. Current cost-benefit analyses suggest that while initial implementation expenses may exceed traditional power solutions, the long-term operational benefits and reduced maintenance requirements present compelling economic advantages.

Environmental impact assessments indicate that self-powered prosthetics could significantly reduce battery waste, aligning with sustainability goals. Additionally, the reduced dependency on charging infrastructure makes these systems particularly valuable in regions with limited electrical grid access, potentially improving prosthetic adoption and usability in developing regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!