Biomimetic Surface Modification Techniques

Biomimetic Surface Modification Goals and Background

By establishing a solid understanding of the technology's background and aspirations, this section lays the foundation for further analysis and strategic planning in subsequent sections of the report. It sets the context for evaluating market demands, assessing current technological challenges, and exploring future research directions that could propel the field of biomimetic surface modification techniques to new heights.

Market Demand for Biomimetic Surface Technologies

- Growing Demand for Biomimetic Surfaces The market demand for biomimetic surface technologies is driven by the need for advanced materials with improved properties such as self-cleaning, anti-fouling, and anti-corrosion capabilities.

- Diverse Applications

These technologies have applications across various industries, including:

- Medical devices and implants for improved biocompatibility and reduced risk of infection

- Marine and industrial equipment for enhanced corrosion resistance and reduced biofouling

- Building materials and coatings for self-cleaning and anti-fouling properties

- Market Potential and Growth The global market for biomimetic surface technologies is projected to experience significant growth, driven by increasing demand for sustainable and high-performance materials across various sectors.

- Regulatory and Environmental Factors The adoption of biomimetic surface technologies is influenced by regulatory frameworks and environmental concerns, as these technologies offer eco-friendly alternatives to traditional coatings and treatments.

Current State and Challenges in Biomimetic Surface Modification

- Current Challenges

Lack of scalability and cost-effectiveness for large-scale applications. Existing techniques often require complex processes or specialized equipment, limiting their commercial viability. - Technical Limitations

Difficulty in precisely controlling surface topography and chemistry at the nanoscale. Many techniques struggle to achieve the desired level of precision and uniformity. - Environmental Concerns

Some surface modification methods involve hazardous chemicals or generate toxic byproducts, raising environmental and safety concerns that need to be addressed. - Durability and Longevity

Ensuring long-term stability and performance of biomimetic surfaces under various operating conditions, such as wear, corrosion, and environmental exposure, remains a challenge. - Multifunctional Properties

Developing surfaces with multiple desired properties (e.g., self-cleaning, anti-fouling, and anti-corrosion) simultaneously is complex and often requires trade-offs.

Existing Biomimetic Surface Modification Solutions

01 Hierarchical Biomimetic Surfaces

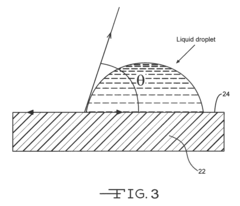

Biomimetic surfaces with hierarchical structures inspired by nature, like lotus leaves or shark skin, can provide improved properties like self-cleaning, anti-fouling, and drag reduction. These hierarchical structures can be created using techniques such as etching, lithography, or additive manufacturing.- Hierarchical Biomimetic Surfaces: Biomimetic surfaces with hierarchical structures inspired by natural surfaces like lotus leaves or butterfly wings can provide improved properties like self-cleaning, anti-fouling, and superhydrophobicity. These structures can be created using techniques like etching, lithography, or additive manufacturing.

- Micro/Nanopattern Biomimetic Surfaces: Biomimetic surfaces with micro or nanopatterns inspired by natural surfaces like shark skin or insect wings can provide improved properties like drag reduction, anti-biofouling, or enhanced wettability. These patterns can be created using techniques like lithography, etching, or imprinting.

- Stimuli-Responsive Biomimetic Surfaces: Biomimetic surfaces can be designed to exhibit stimuli-responsive properties like changes in wettability, adhesion, or surface topography in response to external stimuli like temperature, pH, or light, mimicking adaptive behavior of natural systems for applications like microfluidics, sensors, or smart coatings.

- Anti-Fouling Biomimetic Surfaces: Biomimetic surfaces can be engineered to have anti-fouling properties, preventing accumulation of unwanted materials like bacteria, proteins, or marine organisms, inspired by natural surfaces like shark skin or mussel adhesive proteins, for applications like medical devices, marine coatings, or water treatment.

- Mechanically Enhanced Biomimetic Surfaces: Biomimetic surfaces can be designed to exhibit enhanced mechanical properties like high strength, toughness, or wear resistance, inspired by natural materials like nacre or bone, created using techniques like layer-by-layer assembly, biomineralization, or additive manufacturing for applications like protective coatings, structural materials, or tribological surfaces.

02 Superhydrophobic Biomimetic Surfaces

Biomimetic surfaces can be engineered to exhibit superhydrophobic properties, mimicking natural surfaces like lotus leaves or water strider legs, repelling water and liquids for applications like self-cleaning, anti-fouling, and anti-icing.Expand Specific Solutions03 Anti-Fouling Biomimetic Surfaces

Biomimetic surfaces can be designed to prevent accumulation of unwanted materials like bacteria, algae, or marine organisms, mimicking anti-fouling properties of natural surfaces like shark skin or mollusk shells.Expand Specific Solutions04 Tribological Biomimetic Surfaces

Biomimetic surfaces can be engineered to have improved tribological properties like reduced friction, wear resistance, and lubrication, mimicking natural surfaces like animal joints or plant leaves.Expand Specific Solutions05 Optical Biomimetic Surfaces

Biomimetic surfaces can be designed to have improved optical properties like anti-reflection, self-cleaning, or structural coloration, mimicking natural surfaces like moth eyes or butterfly wings.Expand Specific Solutions

Key Players in Biomimetic Surface Technology

Greatbatch Ltd.

The University of Queensland

Core Innovations in Biomimetic Surface Technologies

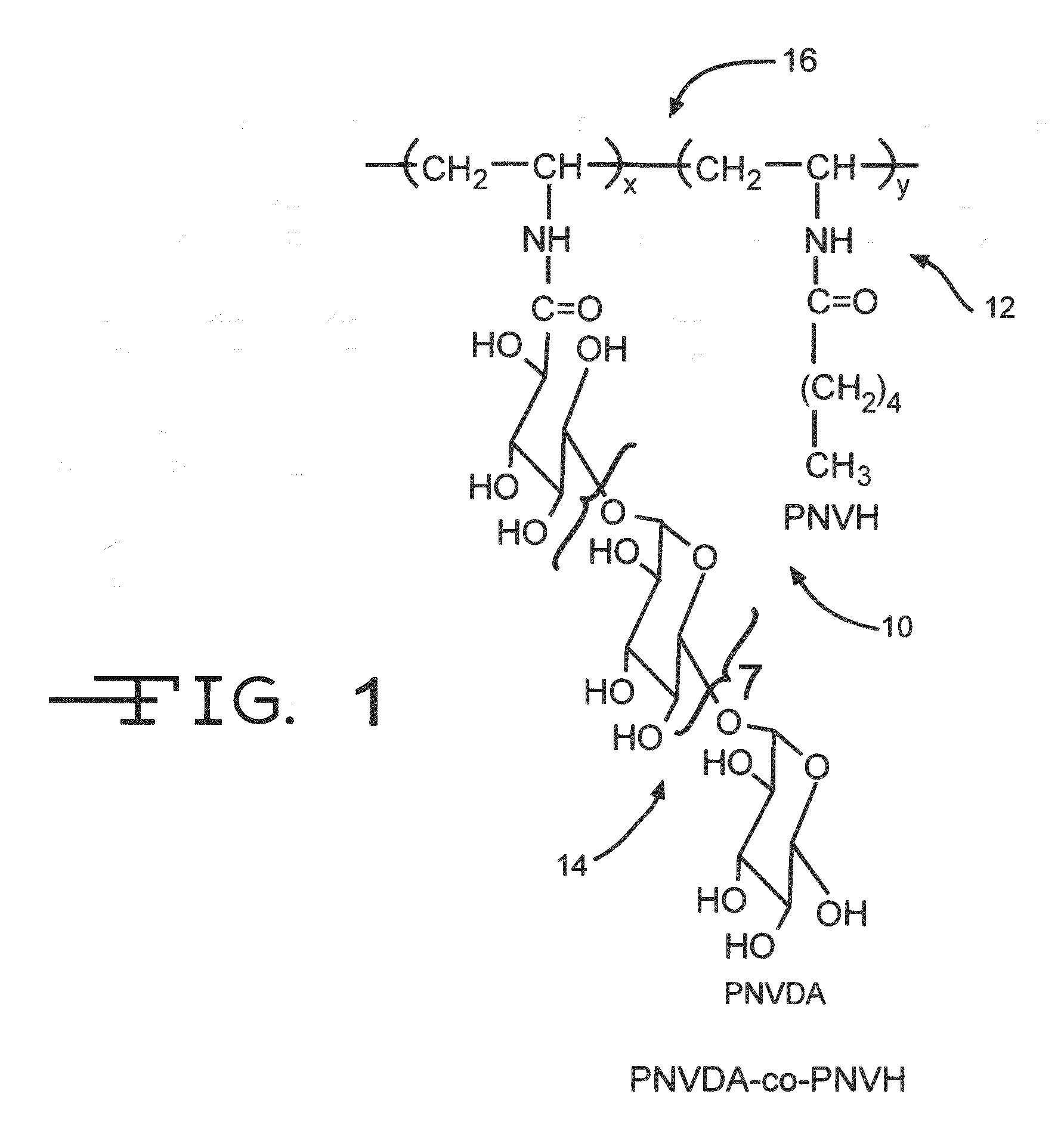

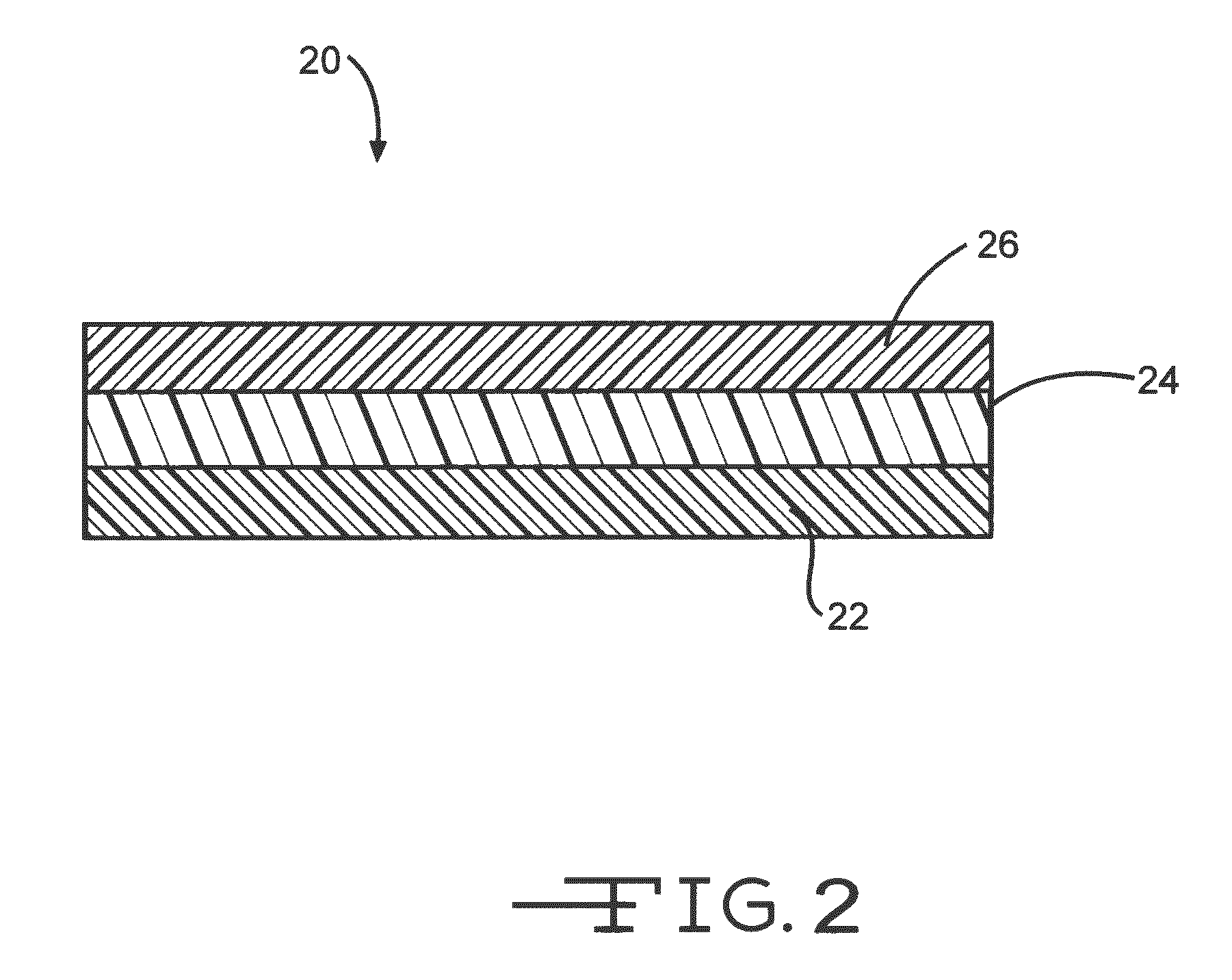

- Modifying the medical device substrate surface to improve adhesion of biomimetic surfactants, reducing the risk of thrombosis.

- Applying a tie layer of hydrophobic material on the substrate surface or incorporating a hydrophobic dopant in the polymeric substrate to create a hydrophobically modified surface.

- Enhancing the biomimetic surfactant bonding strength through the hydrophobically modified surface.

Regulatory Landscape for Biomimetic Surface Modifications Technologies

The regulatory landscape for biomimetic surface modifications technologies is a complex and evolving area. Various regulatory bodies, such as the FDA, EPA, and REACH, have established guidelines and standards governing the use of biomimetic materials in different industries. Compliance with these regulations is crucial for ensuring safety, efficacy, and environmental sustainability. Key considerations include toxicity assessments, biocompatibility testing, and eco-toxicological evaluations. Additionally, intellectual property rights and patenting strategies play a significant role in shaping the competitive landscape. As this field continues to advance, stakeholders must stay vigilant and adaptable to navigate the dynamic regulatory environment.