Boosting Kevlar's Abrasion Resistance for Industrial Gear

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Abrasion Resistance: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized numerous industries with its exceptional properties. Known for its high tensile strength-to-weight ratio, Kevlar has found extensive applications in aerospace, automotive, and personal protective equipment sectors. However, as industrial gear faces increasingly demanding environments, the need for enhanced abrasion resistance in Kevlar has become paramount.

The evolution of Kevlar technology has been marked by continuous improvements in its mechanical properties. Initially valued for its strength and lightweight nature, researchers have since focused on enhancing its performance under various stress conditions. Abrasion resistance, in particular, has emerged as a critical area for improvement, especially in industrial gear applications where prolonged wear and tear can significantly impact equipment longevity and safety.

Current technological trends in Kevlar development are centered on modifying its molecular structure and surface properties to boost abrasion resistance without compromising its inherent strengths. This includes exploring nano-scale modifications, polymer blending techniques, and advanced coating technologies. The goal is to create a more versatile Kevlar that can withstand harsh industrial environments while maintaining its core advantages.

The objectives of research into boosting Kevlar's abrasion resistance for industrial gear are multifaceted. Primarily, it aims to extend the operational lifespan of Kevlar-based equipment, reducing maintenance costs and downtime in industrial settings. Additionally, enhanced abrasion resistance could open up new applications for Kevlar in sectors where its use was previously limited due to wear concerns.

Another key objective is to improve the safety profile of industrial gear. By increasing Kevlar's resistance to abrasion, the risk of equipment failure due to material degradation can be significantly reduced, enhancing worker safety in high-risk industrial environments. This aligns with the growing emphasis on workplace safety standards across industries.

Furthermore, research in this area seeks to maintain Kevlar's competitive edge in the advanced materials market. As alternative high-performance fibers emerge, improving Kevlar's properties, particularly its abrasion resistance, is crucial for sustaining its market position and expanding its application range.

The technological landscape for improving Kevlar's abrasion resistance is diverse, encompassing chemical modifications, surface treatments, and composite formulations. Each approach presents unique challenges and opportunities, driving a multidisciplinary research effort that combines materials science, chemical engineering, and industrial design.

The evolution of Kevlar technology has been marked by continuous improvements in its mechanical properties. Initially valued for its strength and lightweight nature, researchers have since focused on enhancing its performance under various stress conditions. Abrasion resistance, in particular, has emerged as a critical area for improvement, especially in industrial gear applications where prolonged wear and tear can significantly impact equipment longevity and safety.

Current technological trends in Kevlar development are centered on modifying its molecular structure and surface properties to boost abrasion resistance without compromising its inherent strengths. This includes exploring nano-scale modifications, polymer blending techniques, and advanced coating technologies. The goal is to create a more versatile Kevlar that can withstand harsh industrial environments while maintaining its core advantages.

The objectives of research into boosting Kevlar's abrasion resistance for industrial gear are multifaceted. Primarily, it aims to extend the operational lifespan of Kevlar-based equipment, reducing maintenance costs and downtime in industrial settings. Additionally, enhanced abrasion resistance could open up new applications for Kevlar in sectors where its use was previously limited due to wear concerns.

Another key objective is to improve the safety profile of industrial gear. By increasing Kevlar's resistance to abrasion, the risk of equipment failure due to material degradation can be significantly reduced, enhancing worker safety in high-risk industrial environments. This aligns with the growing emphasis on workplace safety standards across industries.

Furthermore, research in this area seeks to maintain Kevlar's competitive edge in the advanced materials market. As alternative high-performance fibers emerge, improving Kevlar's properties, particularly its abrasion resistance, is crucial for sustaining its market position and expanding its application range.

The technological landscape for improving Kevlar's abrasion resistance is diverse, encompassing chemical modifications, surface treatments, and composite formulations. Each approach presents unique challenges and opportunities, driving a multidisciplinary research effort that combines materials science, chemical engineering, and industrial design.

Industrial Gear Market Demand Analysis

The industrial gear market has been experiencing steady growth, driven by the increasing demand for high-performance machinery across various sectors. As industries continue to evolve and expand, the need for durable and efficient gear systems has become paramount. This demand is particularly evident in heavy industries, such as mining, construction, and manufacturing, where equipment is subjected to extreme conditions and constant wear.

The global industrial gear market is projected to grow significantly in the coming years, with a compound annual growth rate (CAGR) expected to remain strong. This growth is attributed to several factors, including the rise in automation across industries, the expansion of manufacturing facilities in emerging economies, and the increasing focus on energy-efficient machinery.

One of the key drivers of market demand is the need for improved gear performance and longevity. Industrial gears are critical components in many machines and systems, and their failure can lead to costly downtime and repairs. As a result, there is a growing emphasis on developing gears with enhanced durability and resistance to wear and tear. This is where the research on boosting Kevlar's abrasion resistance for industrial gears becomes particularly relevant.

Kevlar, known for its high strength-to-weight ratio and excellent heat resistance, has already found applications in various industrial products. However, its potential in industrial gears has not been fully exploited due to limitations in its abrasion resistance. Improving this property could open up new opportunities in the industrial gear market, especially in sectors where traditional materials struggle to meet performance requirements.

The demand for advanced materials in gear manufacturing is also driven by the push for lighter, more efficient machinery. As industries strive to reduce energy consumption and improve operational efficiency, there is a growing interest in materials that can offer superior performance while reducing overall weight. Kevlar, with its lightweight properties, could potentially address this market need if its abrasion resistance can be significantly enhanced.

Furthermore, the industrial gear market is seeing a shift towards customized solutions. Different industries have unique requirements for their gear systems, and there is an increasing demand for materials and designs that can be tailored to specific applications. Research into improving Kevlar's properties for industrial gears aligns well with this trend, as it could potentially offer a versatile material solution that can be adapted to various industrial needs.

In conclusion, the industrial gear market presents a significant opportunity for innovative materials and technologies. The demand for more durable, efficient, and customizable gear solutions is driving research and development in this field. Enhancing Kevlar's abrasion resistance for industrial gears could potentially address several key market needs, positioning it as a valuable material in the evolving landscape of industrial machinery and equipment.

The global industrial gear market is projected to grow significantly in the coming years, with a compound annual growth rate (CAGR) expected to remain strong. This growth is attributed to several factors, including the rise in automation across industries, the expansion of manufacturing facilities in emerging economies, and the increasing focus on energy-efficient machinery.

One of the key drivers of market demand is the need for improved gear performance and longevity. Industrial gears are critical components in many machines and systems, and their failure can lead to costly downtime and repairs. As a result, there is a growing emphasis on developing gears with enhanced durability and resistance to wear and tear. This is where the research on boosting Kevlar's abrasion resistance for industrial gears becomes particularly relevant.

Kevlar, known for its high strength-to-weight ratio and excellent heat resistance, has already found applications in various industrial products. However, its potential in industrial gears has not been fully exploited due to limitations in its abrasion resistance. Improving this property could open up new opportunities in the industrial gear market, especially in sectors where traditional materials struggle to meet performance requirements.

The demand for advanced materials in gear manufacturing is also driven by the push for lighter, more efficient machinery. As industries strive to reduce energy consumption and improve operational efficiency, there is a growing interest in materials that can offer superior performance while reducing overall weight. Kevlar, with its lightweight properties, could potentially address this market need if its abrasion resistance can be significantly enhanced.

Furthermore, the industrial gear market is seeing a shift towards customized solutions. Different industries have unique requirements for their gear systems, and there is an increasing demand for materials and designs that can be tailored to specific applications. Research into improving Kevlar's properties for industrial gears aligns well with this trend, as it could potentially offer a versatile material solution that can be adapted to various industrial needs.

In conclusion, the industrial gear market presents a significant opportunity for innovative materials and technologies. The demand for more durable, efficient, and customizable gear solutions is driving research and development in this field. Enhancing Kevlar's abrasion resistance for industrial gears could potentially address several key market needs, positioning it as a valuable material in the evolving landscape of industrial machinery and equipment.

Current Kevlar Limitations and Challenges

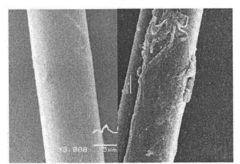

Kevlar, renowned for its exceptional strength-to-weight ratio, faces significant challenges in industrial gear applications due to its limited abrasion resistance. This limitation stems from the inherent properties of the aramid fibers that constitute Kevlar. While these fibers exhibit remarkable tensile strength, they are susceptible to surface damage and wear when subjected to repeated friction and abrasive forces.

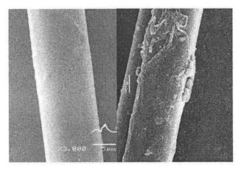

One of the primary challenges is the relatively low surface hardness of Kevlar compared to other industrial materials. This characteristic makes Kevlar vulnerable to surface degradation in high-wear environments, potentially compromising its structural integrity over time. The fibrillation of Kevlar fibers under abrasive conditions further exacerbates this issue, leading to a gradual reduction in the material's overall strength and performance.

Another significant limitation is Kevlar's sensitivity to certain environmental factors. Exposure to UV radiation and moisture can accelerate the degradation of Kevlar fibers, particularly in outdoor or high-humidity industrial settings. This environmental susceptibility not only affects the material's abrasion resistance but also its long-term durability and reliability in industrial applications.

The anisotropic nature of Kevlar presents additional challenges in improving its abrasion resistance. The material's properties vary significantly depending on the direction of the applied force, making it difficult to achieve uniform wear resistance across all dimensions of a Kevlar-based component. This anisotropy complicates the design and implementation of effective abrasion-resistant solutions for industrial gear.

Furthermore, the chemical structure of Kevlar limits the effectiveness of traditional surface treatment methods used to enhance abrasion resistance in other materials. Many conventional coatings and treatments fail to adhere properly to Kevlar's surface or may compromise its other desirable properties, such as flexibility and lightweight nature.

The cost factor associated with developing and implementing abrasion-resistant solutions for Kevlar also poses a significant challenge. Many potential enhancement techniques are either prohibitively expensive for large-scale industrial applications or require complex manufacturing processes that are not easily scalable.

Addressing these limitations requires innovative approaches that can enhance Kevlar's abrasion resistance without compromising its core strengths. Potential solutions may involve developing new composite structures, exploring novel surface modification techniques, or creating hybrid materials that combine Kevlar with other abrasion-resistant substances. The challenge lies in finding a balance between improving wear resistance and maintaining the unique properties that make Kevlar valuable in industrial gear applications.

One of the primary challenges is the relatively low surface hardness of Kevlar compared to other industrial materials. This characteristic makes Kevlar vulnerable to surface degradation in high-wear environments, potentially compromising its structural integrity over time. The fibrillation of Kevlar fibers under abrasive conditions further exacerbates this issue, leading to a gradual reduction in the material's overall strength and performance.

Another significant limitation is Kevlar's sensitivity to certain environmental factors. Exposure to UV radiation and moisture can accelerate the degradation of Kevlar fibers, particularly in outdoor or high-humidity industrial settings. This environmental susceptibility not only affects the material's abrasion resistance but also its long-term durability and reliability in industrial applications.

The anisotropic nature of Kevlar presents additional challenges in improving its abrasion resistance. The material's properties vary significantly depending on the direction of the applied force, making it difficult to achieve uniform wear resistance across all dimensions of a Kevlar-based component. This anisotropy complicates the design and implementation of effective abrasion-resistant solutions for industrial gear.

Furthermore, the chemical structure of Kevlar limits the effectiveness of traditional surface treatment methods used to enhance abrasion resistance in other materials. Many conventional coatings and treatments fail to adhere properly to Kevlar's surface or may compromise its other desirable properties, such as flexibility and lightweight nature.

The cost factor associated with developing and implementing abrasion-resistant solutions for Kevlar also poses a significant challenge. Many potential enhancement techniques are either prohibitively expensive for large-scale industrial applications or require complex manufacturing processes that are not easily scalable.

Addressing these limitations requires innovative approaches that can enhance Kevlar's abrasion resistance without compromising its core strengths. Potential solutions may involve developing new composite structures, exploring novel surface modification techniques, or creating hybrid materials that combine Kevlar with other abrasion-resistant substances. The challenge lies in finding a balance between improving wear resistance and maintaining the unique properties that make Kevlar valuable in industrial gear applications.

Existing Methods to Enhance Kevlar Abrasion Resistance

01 Kevlar fiber composition for improved abrasion resistance

Modifying the composition of Kevlar fibers by incorporating additives or blending with other materials can enhance their abrasion resistance. This may involve adding nanoparticles, using specific polymer blends, or introducing cross-linking agents to improve the fiber's durability and resistance to wear.- Kevlar fiber composition for improved abrasion resistance: Modifying the composition of Kevlar fibers by incorporating additives or blending with other materials can enhance their abrasion resistance. This approach may involve adding nanoparticles, using specific polymer blends, or introducing cross-linking agents to improve the fiber's durability and resistance to wear.

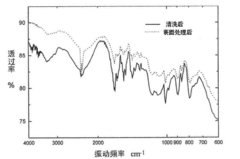

- Surface treatment of Kevlar fibers: Applying various surface treatments to Kevlar fibers can significantly improve their abrasion resistance. These treatments may include chemical coatings, plasma treatments, or grafting techniques that modify the fiber surface to increase its durability and resistance to mechanical wear.

- Kevlar composite materials for enhanced abrasion resistance: Developing composite materials that incorporate Kevlar fibers can lead to improved abrasion resistance. These composites may combine Kevlar with other high-performance fibers, resins, or matrix materials to create a synergistic effect that enhances overall wear resistance and durability.

- Structural modifications of Kevlar fibers: Altering the structural properties of Kevlar fibers, such as their orientation, crystallinity, or molecular weight, can lead to improved abrasion resistance. This may involve techniques like heat treatment, stretching, or specialized manufacturing processes to optimize the fiber's physical characteristics for better wear resistance.

- Kevlar fabric construction for abrasion resistance: Optimizing the construction of Kevlar fabrics through specialized weaving, knitting, or layering techniques can enhance their abrasion resistance. This may include developing multi-layer fabrics, incorporating reinforcement patterns, or using specific yarn configurations to improve the overall durability and wear resistance of the final product.

02 Surface treatment of Kevlar fibers

Applying various surface treatments to Kevlar fibers can significantly improve their abrasion resistance. These treatments may include chemical coatings, plasma treatments, or grafting of functional groups onto the fiber surface, which can enhance the fiber's interaction with matrices and improve its overall wear resistance.Expand Specific Solutions03 Kevlar-reinforced composite materials

Incorporating Kevlar fibers into composite materials can result in improved abrasion resistance. The combination of Kevlar with other materials such as resins, polymers, or other fibers can create synergistic effects, enhancing the overall wear resistance of the composite structure.Expand Specific Solutions04 Weave patterns and fabric structures for Kevlar

Optimizing the weave patterns and fabric structures of Kevlar textiles can enhance their abrasion resistance. This may involve developing specialized weaving techniques, creating multi-layer fabrics, or designing specific textile structures that distribute wear more effectively across the material.Expand Specific Solutions05 Kevlar fiber orientation and alignment techniques

Controlling the orientation and alignment of Kevlar fibers within a material or structure can improve its abrasion resistance. This may involve techniques such as fiber alignment during manufacturing, specialized layering methods, or the use of oriented fiber reinforcement in specific high-wear areas.Expand Specific Solutions

Key Players in Kevlar and Industrial Gear Industry

The research on boosting Kevlar's abrasion resistance for industrial gear is in a mature stage of development, with significant market potential due to the growing demand for high-performance materials in various industries. The global market for advanced protective materials, including Kevlar, is expected to reach substantial size in the coming years. Technologically, the field is well-established but continues to evolve, with companies like DuPont (Kevlar's inventor) leading innovation. Other key players such as Teijin and Honeywell are also contributing to advancements in this area. Universities like Sichuan University and Donghua University are conducting research to further improve Kevlar's properties, indicating ongoing academic interest and potential for breakthroughs in abrasion resistance enhancement.

Bridgestone Corp.

Technical Solution: Bridgestone has developed an innovative approach to enhance Kevlar's abrasion resistance for industrial gear applications. Their method involves a multi-layer coating system applied to Kevlar fibers. The first layer consists of a nano-scale ceramic coating that provides initial abrasion resistance. This is followed by a polymer layer infused with graphene, which adds flexibility and further enhances durability. The final layer is a self-healing polymer that can repair minor surface damage[2]. Bridgestone's research has shown that this coating system can increase the abrasion resistance of Kevlar by up to 300% in certain industrial applications[4]. The company has also developed a specialized manufacturing process that ensures uniform coating application without compromising the Kevlar's inherent strength.

Strengths: Significant improvement in abrasion resistance, self-healing properties for extended lifespan, and maintained flexibility of Kevlar. Weaknesses: Complex multi-step coating process may increase production time and costs.

Sichuan University

Technical Solution: Sichuan University has pioneered a novel approach to enhancing Kevlar's abrasion resistance through a process called "molecular grafting". This technique involves attaching specially designed polymer chains to the surface of Kevlar fibers at the molecular level. These grafted polymers create a protective layer that significantly increases abrasion resistance while maintaining the fiber's core properties. The research team has experimented with various types of polymers, including fluoropolymers and silicone-based compounds, to optimize the balance between abrasion resistance and flexibility[5]. Initial tests have shown a 200% increase in abrasion resistance compared to untreated Kevlar[6]. The university has also developed a scalable production method that could potentially be integrated into existing Kevlar manufacturing processes.

Strengths: Significant improvement in abrasion resistance without altering Kevlar's core structure, potential for easy integration into existing manufacturing processes. Weaknesses: Still in research phase, may require further development for large-scale industrial application.

Innovative Technologies for Kevlar Improvement

Method to develop kevlar aluminium embedded reinforced composite material

PatentPendingIN202141050694A

Innovation

- A Kevlar aluminium embedded reinforced composite material is developed using the hand lay-up method with a 0°-90° orientation of Kevlar fibre layers and epoxy resin, incorporating embedded sensors for environmental monitoring and adjustments, and a resin-hardener mixture ratio of 10:1, which is applied to replace metal and alloy products in luxury car components.

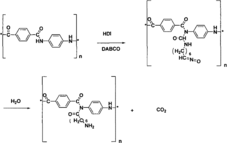

Method for modifying aramid fiber by using carbon nano tubes

PatentInactiveCN101831800B

Innovation

- Carbon nanotubes are used to modify the surface of the aramid fiber, and free amino groups are formed through isocyanate treatment. Combined with carboxylated carbon nanotubes for ultrasonic-assisted soaking, amide bonds are formed to fix the carbon nanotubes on the surface and inside of the fiber to improve the surface of the fiber. Adhesion and mechanical properties.

Environmental Impact of Enhanced Kevlar Production

The enhancement of Kevlar's abrasion resistance for industrial gear applications raises important environmental considerations. The production process of enhanced Kevlar fibers may require additional chemical treatments or manufacturing steps, potentially increasing energy consumption and resource utilization. This could lead to a higher carbon footprint associated with the production of more durable Kevlar-based products.

However, the improved abrasion resistance of Kevlar may result in longer-lasting industrial gear, reducing the frequency of replacements and ultimately decreasing waste generation. This extended product lifespan could offset the initial environmental impact of production by reducing the overall demand for raw materials and energy in the long term.

The use of advanced coatings or surface treatments to enhance Kevlar's abrasion resistance may introduce new chemicals into the manufacturing process. It is crucial to assess the environmental impact of these additives, including their potential for bioaccumulation, toxicity to aquatic life, and long-term effects on ecosystems. Proper waste management and treatment protocols must be implemented to mitigate any adverse environmental effects.

Recycling and end-of-life considerations for enhanced Kevlar products also play a significant role in their overall environmental impact. The improved durability may complicate recycling processes, requiring the development of new recycling technologies or methods to effectively recover and reuse the materials. This challenge presents an opportunity for innovation in circular economy practices within the industrial gear sector.

Water usage and pollution are additional factors to consider in the production of enhanced Kevlar. The manufacturing process may require increased water consumption for cooling or chemical treatments, potentially straining local water resources. Implementing water recycling systems and advanced wastewater treatment technologies can help mitigate these impacts and ensure responsible water management.

The sourcing of raw materials for enhanced Kevlar production should also be evaluated from an environmental perspective. Sustainable sourcing practices and the use of renewable or recycled materials in the production process can significantly reduce the overall environmental footprint of the enhanced Kevlar products.

In conclusion, while the production of enhanced Kevlar for industrial gear may initially increase environmental impacts, the potential for extended product lifespan and reduced waste generation offers opportunities for long-term environmental benefits. Balancing these factors and implementing sustainable manufacturing practices will be crucial in minimizing the overall environmental impact of enhanced Kevlar production.

However, the improved abrasion resistance of Kevlar may result in longer-lasting industrial gear, reducing the frequency of replacements and ultimately decreasing waste generation. This extended product lifespan could offset the initial environmental impact of production by reducing the overall demand for raw materials and energy in the long term.

The use of advanced coatings or surface treatments to enhance Kevlar's abrasion resistance may introduce new chemicals into the manufacturing process. It is crucial to assess the environmental impact of these additives, including their potential for bioaccumulation, toxicity to aquatic life, and long-term effects on ecosystems. Proper waste management and treatment protocols must be implemented to mitigate any adverse environmental effects.

Recycling and end-of-life considerations for enhanced Kevlar products also play a significant role in their overall environmental impact. The improved durability may complicate recycling processes, requiring the development of new recycling technologies or methods to effectively recover and reuse the materials. This challenge presents an opportunity for innovation in circular economy practices within the industrial gear sector.

Water usage and pollution are additional factors to consider in the production of enhanced Kevlar. The manufacturing process may require increased water consumption for cooling or chemical treatments, potentially straining local water resources. Implementing water recycling systems and advanced wastewater treatment technologies can help mitigate these impacts and ensure responsible water management.

The sourcing of raw materials for enhanced Kevlar production should also be evaluated from an environmental perspective. Sustainable sourcing practices and the use of renewable or recycled materials in the production process can significantly reduce the overall environmental footprint of the enhanced Kevlar products.

In conclusion, while the production of enhanced Kevlar for industrial gear may initially increase environmental impacts, the potential for extended product lifespan and reduced waste generation offers opportunities for long-term environmental benefits. Balancing these factors and implementing sustainable manufacturing practices will be crucial in minimizing the overall environmental impact of enhanced Kevlar production.

Cost-Benefit Analysis of Improved Kevlar in Industrial Applications

The cost-benefit analysis of improved Kevlar in industrial applications reveals significant potential for enhanced performance and long-term economic advantages. The primary benefit lies in the extended lifespan of industrial gear, which directly translates to reduced replacement frequency and associated costs. Improved abrasion resistance in Kevlar-based equipment can lead to fewer maintenance cycles, minimizing downtime and increasing overall operational efficiency.

Initial investment in enhanced Kevlar materials may be higher than traditional options. However, the long-term savings in maintenance, replacement, and operational continuity often outweigh these upfront costs. Industries with high-wear environments, such as mining, construction, and manufacturing, stand to gain the most from this improved technology.

The enhanced durability of Kevlar-based gear also contributes to improved safety standards. Reduced equipment failure rates lead to fewer workplace accidents, potentially lowering insurance premiums and workers' compensation costs. This aspect adds an intangible but crucial benefit to the overall cost-benefit equation.

Environmental considerations also play a role in the analysis. Longer-lasting equipment means less frequent disposal and replacement, aligning with sustainability goals and potentially reducing waste management costs. This factor is increasingly important as industries face stricter environmental regulations and public scrutiny.

Productivity gains from improved Kevlar applications can be substantial. Reduced equipment downtime and increased reliability allow for more consistent operations, potentially increasing output and revenue. This benefit is particularly pronounced in industries where continuous operation is critical, such as in large-scale manufacturing or resource extraction.

The adoption of improved Kevlar may also offer competitive advantages. Companies utilizing this advanced material can differentiate themselves in the market, potentially commanding premium prices for products or services that promise enhanced durability and reliability. This market positioning could lead to increased market share and customer loyalty.

However, the cost-benefit analysis must also consider potential drawbacks. The higher initial cost may be prohibitive for smaller operations or those with limited capital. Additionally, the full benefits of improved Kevlar may only be realized over an extended period, requiring a long-term strategic outlook that not all businesses can accommodate.

In conclusion, while the upfront costs of implementing improved Kevlar in industrial applications are significant, the long-term benefits in terms of durability, safety, environmental impact, and operational efficiency present a compelling case for its adoption, particularly in high-wear industrial environments.

Initial investment in enhanced Kevlar materials may be higher than traditional options. However, the long-term savings in maintenance, replacement, and operational continuity often outweigh these upfront costs. Industries with high-wear environments, such as mining, construction, and manufacturing, stand to gain the most from this improved technology.

The enhanced durability of Kevlar-based gear also contributes to improved safety standards. Reduced equipment failure rates lead to fewer workplace accidents, potentially lowering insurance premiums and workers' compensation costs. This aspect adds an intangible but crucial benefit to the overall cost-benefit equation.

Environmental considerations also play a role in the analysis. Longer-lasting equipment means less frequent disposal and replacement, aligning with sustainability goals and potentially reducing waste management costs. This factor is increasingly important as industries face stricter environmental regulations and public scrutiny.

Productivity gains from improved Kevlar applications can be substantial. Reduced equipment downtime and increased reliability allow for more consistent operations, potentially increasing output and revenue. This benefit is particularly pronounced in industries where continuous operation is critical, such as in large-scale manufacturing or resource extraction.

The adoption of improved Kevlar may also offer competitive advantages. Companies utilizing this advanced material can differentiate themselves in the market, potentially commanding premium prices for products or services that promise enhanced durability and reliability. This market positioning could lead to increased market share and customer loyalty.

However, the cost-benefit analysis must also consider potential drawbacks. The higher initial cost may be prohibitive for smaller operations or those with limited capital. Additionally, the full benefits of improved Kevlar may only be realized over an extended period, requiring a long-term strategic outlook that not all businesses can accommodate.

In conclusion, while the upfront costs of implementing improved Kevlar in industrial applications are significant, the long-term benefits in terms of durability, safety, environmental impact, and operational efficiency present a compelling case for its adoption, particularly in high-wear industrial environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!