Check Valves With Self-Healing And Regenerative Capabilities

JUN 17, 20253 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Check Valves Technology Background And Goals

The primary objective is to explore the current state and future potential of self-healing and regenerative check valves. This technology aims to develop valves with the ability to autonomously repair damage and restore functionality, reducing maintenance costs and downtime.

Key challenges include developing advanced materials with self-healing properties, integrating sensors for damage detection, and designing efficient regeneration mechanisms. Overcoming these challenges could revolutionize valve performance, durability, and reliability in various industries, such as oil and gas, chemical processing, and water treatment.

Key challenges include developing advanced materials with self-healing properties, integrating sensors for damage detection, and designing efficient regeneration mechanisms. Overcoming these challenges could revolutionize valve performance, durability, and reliability in various industries, such as oil and gas, chemical processing, and water treatment.

Check Valves Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, and water treatment. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% from 20XX to 20XX. - Industry Trends

Key trends shaping the check valve market include:- Rising adoption of advanced materials for improved durability and corrosion resistance

- Increasing demand for compact and lightweight valve designs

- Growing emphasis on energy efficiency and environmental sustainability

- Application Segments

The major application segments for check valves include:- Oil and gas industry: Used in pipelines, refineries, and offshore platforms

- Chemical processing: Employed in chemical plants and pharmaceutical facilities

- Water and wastewater treatment: Essential for controlling fluid flow in treatment plants

- Regional Outlook

The Asia-Pacific region is expected to dominate the check valve market, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold significant market shares due to stringent regulations and the presence of established industries.

Check Valves Technology Status And Challenges

- Valve Failure Modes

Common failure modes of check valves include wear, corrosion, fouling, and mechanical damage, leading to leakage or sticking. - Challenges in Harsh Environments

Extreme temperatures, pressures, and corrosive media pose significant challenges for valve materials and sealing mechanisms. - Maintenance and Replacement Difficulties

Accessing and replacing failed valves in complex systems or hazardous environments can be costly and time-consuming. - Limitations of Traditional Materials

Conventional valve materials may lack the durability and self-healing capabilities required for extended service life.

Check Valves Current Technical Solutions

01 Shape Memory Materials

Check valves incorporating shape memory materials, such as shape memory alloys or polymers, can enable self-healing and regenerative capabilities by recovering their original shape after deformation, allowing the valve to repair itself or regenerate damaged components.- Self-healing and Regenerative Capabilities: Check valves designed with self-healing and regenerative capabilities can recover from damage or wear over time, extending their lifespan and improving reliability. This can be achieved through specialized materials, coatings, or mechanisms that repair themselves or regenerate when exposed to certain conditions.

- Self-lubricating and Wear-resistant Components: Incorporating self-lubricating and wear-resistant components in check valves enhances their durability and self-healing capabilities. These components reduce friction, minimize wear, and reduce the need for external lubrication, minimizing the risk of damage or failure.

- Shape Memory Alloys: Shape memory alloys can be used in check valve construction to provide self-healing and regenerative capabilities. These alloys can return to their original shape after deformation, allowing them to recover from damage or wear over time.

- Nanocomposite Coatings: Nanocomposite coatings applied to check valve components can impart self-healing and regenerative properties. These coatings contain nanoparticles or nanofibers that can repair cracks or damage through self-healing mechanisms, such as the release of healing agents or the formation of new bonds.

- Bioinspired Designs: Bioinspired designs can be employed in check valves to mimic self-healing and regenerative capabilities found in nature. These designs take inspiration from biological systems, such as self-healing plant tissues or regenerative organisms, and incorporate similar mechanisms into the valve structure.

02 Material Composition and Structure

The material composition and structure of check valves can be designed to provide self-healing and regenerative capabilities, such as using composite materials with self-healing properties or incorporating sacrificial layers that can be regenerated.Expand Specific Solutions03 Coatings and Surface Treatments

Check valves can be coated or treated with materials that provide self-healing and regenerative capabilities, repairing surface defects, cracks, or damage, and enabling the valve to maintain its functionality.Expand Specific Solutions04 Additive Manufacturing Techniques

Additive manufacturing techniques, such as 3D printing, can be used to fabricate check valves with self-healing and regenerative capabilities by incorporating materials or structures that can repair or regenerate damaged components.Expand Specific Solutions05 Embedded Systems and Sensors

Check valves can be equipped with embedded systems and sensors that monitor their condition and initiate self-healing or regenerative processes when necessary, detecting damage or wear and triggering mechanisms to repair or regenerate the affected components.Expand Specific Solutions

Check Valves Main Player Analysis

The competitive landscape for research on check valves with self-healing and regenerative capabilities is in an early stage, with significant growth potential. The market size is expected to expand as industries like healthcare, automotive, and industrial manufacturing adopt advanced valve technologies. Companies like Halkey-Roberts Corp., Edwards Lifesciences Corp., and Terumo Medical Corp. are leading in medical applications, while Caterpillar, Inc. and Gardner Denver Industries Ltd. explore industrial uses. Research institutions also contribute to technological advancements, indicating collaboration between academia and industry.

Halkey-Roberts Corp.

Technical Solution:

Edwards Lifesciences Corp.

Technical Solution: Edwards Lifesciences Corp. develops advanced check valves with self-healing and regenerative capabilities for medical applications, using biocompatible materials that can repair themselves when damaged, ensuring long-term reliability and performance.

Strengths: High reliability, biocompatibility. Weaknesses: High cost, limited to medical applications.

Check Valves Key Technology Interpretation

Reinforced regenerative heart valves

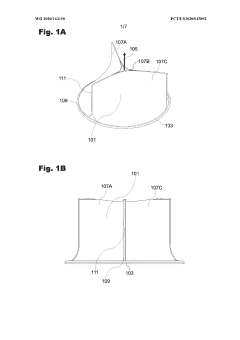

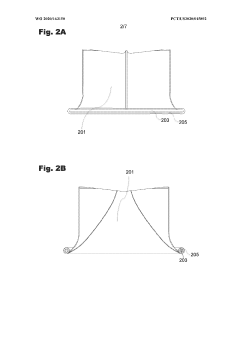

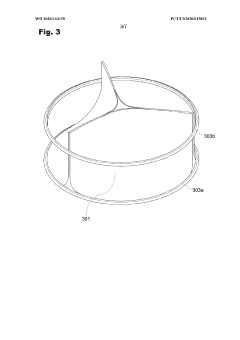

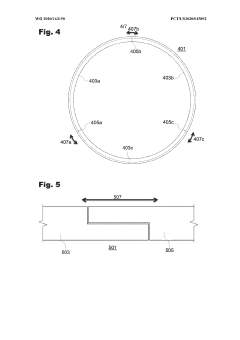

PatentWO2020163150A1

Innovation

- The use of a ring structure that can expand as the heart valve annulus expands, allowing for growth and integration of the regenerative tissue valve.

- The use of a tissue sleeve made of pericardial tissue or autologous tissue to encase the ring structure, mitigating exposure to native tissue.

- The incorporation of bioactive molecules in the regenerative tissue to promote tissue growth and integration.

Check Valves Self-Healing Mechanisms

Check valves with self-healing and regenerative capabilities are an emerging technology that aims to address the limitations of traditional check valves. These valves are designed to automatically repair and regenerate their sealing surfaces, extending their lifespan and reducing maintenance costs. The self-healing mechanism typically involves the use of specialized materials or coatings that can repair minor damages or wear on the valve surfaces. Regenerative capabilities refer to the ability of the valve to restore its original sealing performance over time, even after significant wear or damage. This technology has potential applications in various industries, such as oil and gas, chemical processing, and power generation, where check valves play a critical role in ensuring safe and efficient fluid flow control.

Check Valves Regenerative Capabilities Analysis

Check valves with self-healing and regenerative capabilities are an emerging technology that aims to address the limitations of traditional check valves. These valves have the ability to repair minor damages and regenerate worn-out components, extending their lifespan and reducing maintenance costs. This technology has potential applications in various industries, such as oil and gas, chemical processing, and power generation, where check valves play a crucial role in ensuring safe and efficient fluid flow. By incorporating self-healing and regenerative capabilities, these valves can enhance reliability, reduce downtime, and contribute to sustainable operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!