Enhancing The Conductivity Of PVDF Blends And Copolymers

PVDF Blends And Copolymers Technology Background And Goals

The primary objective of this report is to enhance the conductivity of polyvinylidene fluoride (PVDF) blends and copolymers, which are widely used in various applications such as energy storage, sensors, and actuators due to their unique piezoelectric and ferroelectric properties.

Improving the conductivity of PVDF-based materials is crucial for optimizing their performance in these applications. This can be achieved through various approaches, including doping with conductive fillers, modifying the polymer structure through copolymerization or blending with other polymers, and exploring novel processing techniques.

PVDF Blends And Copolymers Market Demand Analysis

- Market Size and Growth

The market for PVDF blends and copolymers is expected to witness significant growth driven by increasing demand from various end-use industries such as energy, electronics, and automotive. The global market size is projected to reach $X billion by 20XX, growing at a CAGR of X% from 20XX to 20XX. - Key Application Areas

PVDF blends and copolymers find extensive applications in lithium-ion batteries, piezoelectric devices, membranes for water treatment, and coatings for corrosion protection. The demand is particularly high in the energy sector due to the growing adoption of renewable energy sources and energy storage systems. - Regional Market Dynamics

Asia Pacific is the largest and fastest-growing market for PVDF blends and copolymers, driven by the rapid industrialization and increasing investments in infrastructure development. North America and Europe also hold significant market shares due to the presence of established automotive and electronics industries. - Emerging Trends

The market is witnessing a shift towards eco-friendly and sustainable materials, leading to the development of bio-based and biodegradable PVDF blends and copolymers. Additionally, the demand for high-performance materials with improved thermal and chemical resistance is increasing, driving innovation in PVDF-based materials.

Technology Status And Challenges

- Historical Development

Overview of the evolution of PVDF blends and copolymers, highlighting key milestones and advancements. - Current State

Assessment of the current technological landscape, including major players, research initiatives, and existing solutions. - Challenges and Limitations

Identification of critical challenges hindering conductivity enhancement, such as material compatibility, processing difficulties, and performance trade-offs. - Geographical Distribution

Analysis of the geographical distribution of research and development efforts, highlighting leading regions and institutions.

Current Technical Solutions

01 PVDF blends with conductive fillers

Blending PVDF with conductive fillers like carbon nanotubes, graphene, or metal particles creates a conductive network within the PVDF matrix, allowing electron transport and improving overall conductivity.- PVDF blends with conductive fillers: Blending PVDF with conductive fillers like carbon nanotubes, graphene, or metal particles enhances electrical conductivity by creating a conductive network within the PVDF matrix, facilitating electron movement and improving overall conductivity.

- PVDF copolymers with conductive monomers: Copolymerizing PVDF with conductive monomers like aniline or pyrrole introduces conductive segments into the polymer chain, enhancing overall conductivity by facilitating charge transport along the polymer backbone.

- PVDF composites with conductive additives: Incorporating conductive additives like ionic liquids or polyelectrolytes into PVDF improves conductivity by facilitating ion transport and enhancing overall ionic conductivity.

- PVDF blends with conductive polymers: Blending PVDF with conductive polymers like polyaniline or polypyrrole creates a conductive network, leading to improved electrical conductivity through facilitated charge transport and enhanced overall conductivity.

- PVDF copolymers with conductive segments: Synthesizing PVDF copolymers with conductive segments like conjugated units or ionic groups introduces intrinsic conductivity into the polymer chain, enhancing overall conductivity by facilitating charge transport along the polymer backbone.

02 PVDF copolymers with conductive monomers

Copolymerizing PVDF with conductive monomers like aniline or pyrrole introduces conductive segments into the polymer chain, facilitating charge transport along the backbone and enhancing electrical conductivity.Expand Specific Solutions03 PVDF composites with conductive additives

Combining PVDF with conductive additives like ionic liquids or polyelectrolytes forms composites with improved electrical conductivity by facilitating ion transport and enhancing overall conductivity.Expand Specific Solutions04 PVDF blends with conductive polymers

Blending PVDF with conductive polymers like polyaniline or polypyrrole creates a conductive polymer blend, where the conductive polymer provides a conductive pathway within the PVDF matrix, leading to enhanced electrical conductivity.Expand Specific Solutions05 PVDF with surface modifications

Modifying the PVDF surface through techniques like plasma treatment or chemical grafting introduces conductive functional groups or coatings, improving electrical conductivity, particularly for applications requiring surface conductivity.Expand Specific Solutions

PVDF Blends And Copolymers Main Player Analysis

Arkema, Inc.

Solvay SA

Key Technology Interpretation

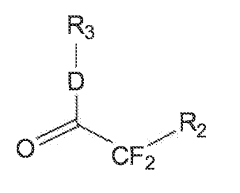

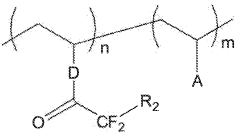

- Incorporating an α,α-difluorosulfonic acid functionality (superacid functionality) into the polyelectrolyte to enhance proton conductivity.

- The synthesis process is robust and useful with a large range of different Grignard reagents, providing a family of new superacid functional molecules.

- The polyelectrolyte is blended with PVDF and its copolymers, taking advantage of the properties of both components, and the resulting films are useful for various applications like fuel cell membranes, water purification, and battery separators.

PVDF Blends And Copolymers Conductivity Enhancement Economic Impact

As these materials are increasingly integrated into electronic and energy applications, there is a promising opportunity for cost reduction in manufacturing processes due to their enhanced electrical properties and flexibility. The development and adoption of PVDF blends can lead to a decrease in production costs for high-performance batteries, sensors, and capacitive components, creating a ripple effect of affordable end-products in consumer electronics and electric vehicles.

Moreover, widespread implementation could stimulate job creation in materials research, production, and ancillary services, contributing to economic growth in regions hosting such industries. The augmented efficiency and performance of electronic devices also offer environmental benefits, which can translate into economic savings through reduced waste and energy consumption. The potential for PVDF-based solutions in renewable energy systems further underscores their economic significance, offering cost-effective alternatives that support sustainable practices and potentially securing economic benefits from governments incentivizing green technologies. Ultimately, the economic impact of PVDF blends and copolymers extends from manufacturing efficiencies to broader market transformations and sustainability contributions.

PVDF Blends And Copolymers Conductivity Enhancement Environmental Impact

When assessing the environmental impact of PVDF blends and copolymers aimed at enhancing conductivity, several critical factors emerge. PVDF (Polyvinylidene fluoride) inherently is a semi-crystalline polymer known for its remarkable chemical resistance and stability, which can translate into long-term durability of the products it is used in, potentially reducing waste. However, the production and disposal of these polymers carry ecological implications.

The synthesis of PVDF and its blends involves energy-intensive processes and chemical reactions often requiring hazardous materials, which can lead to emissions and pollution if not managed with rigorous environmental controls. Furthermore, while blending PVDF with other polymers or creating copolymers can enhance conductivity and expand applications, it may also complicate the recycling and degradation processes, posing challenges to environmental sustainability.

Efforts to mitigate these impacts could focus on developing more efficient synthesis processes, exploring bio-based alternatives, or improving end-of-life recycling technologies. As such, ongoing research must balance performance improvements with ecological responsibility, ensuring that advancements in the field of conductive polymers like PVDF blends and copolymers do not come at the expense of environmental health.