Guaranteed Tightness Of Check Valves: A Technical Insight

Guaranteed Tightness Of Check Valves: Technology Background And Goals

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries such as oil and gas, power generation, and water treatment. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% during the forecast period. - Industry Trends

Key trends shaping the check valve market include:- Rising adoption of advanced materials for improved durability and corrosion resistance

- Increasing demand for compact and lightweight valve designs

- Growing emphasis on energy efficiency and environmental sustainability

- Application Segments

The check valve market is segmented based on applications, with major segments including:- Oil and Gas: Upstream, midstream, and downstream operations

- Power Generation: Fossil fuel, nuclear, and renewable energy plants

- Water and Wastewater Treatment: Municipal and industrial facilities

- Regional Outlook

The Asia-Pacific region is expected to dominate the check valve market, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold significant market shares due to stringent regulations and the presence of established industries.

Guaranteed Tightness Of Check Valves: Technology Status And Challenges

- Valve Tightness Fundamentals

Tightness refers to the ability of a valve to prevent leakage when closed. It is a critical factor in ensuring the safe and efficient operation of fluid systems. - Leakage Mechanisms

Leakage in check valves can occur due to various factors, including wear, corrosion, improper sealing, and manufacturing defects. Understanding these mechanisms is crucial for developing effective solutions. - Tightness Testing Methods

Various testing methods, such as hydrostatic testing, pneumatic testing, and helium leak testing, are employed to evaluate the tightness of check valves under different operating conditions. - Regulatory Standards

Tightness requirements for check valves are governed by industry-specific regulations and standards, which must be adhered to ensure compliance and safety. - Material Selection

The choice of materials for valve components, such as seals and seats, plays a significant role in achieving and maintaining tightness over the valve's service life.

Current Technical Solutions

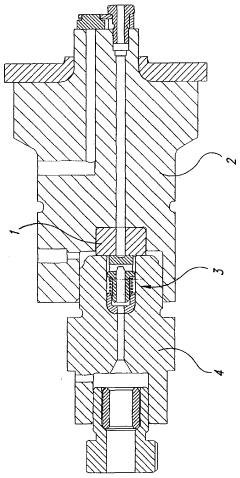

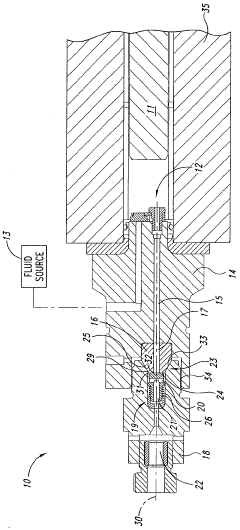

01 Check Valve Structure and Sealing Mechanism

Various valve designs incorporate sealing elements like seats, gaskets, or sealing surfaces to prevent backflow and maintain tightness.- Check Valve Structure and Sealing Mechanism: The design of the valve body, sealing surfaces, gaskets, and O-rings is crucial for achieving a tight seal. Proper material selection and manufacturing tolerances are essential.

- Check Valve Installation and Assembly: Correct alignment, proper torque application, and secure fastening of components are critical for maintaining tightness. Improper installation can lead to leaks or premature failure.

- Check Valve Maintenance and Inspection: Regular maintenance, sealing element replacement, cleaning, and visual inspections for wear or damage are essential to ensure continued tightness.

- Check Valve Materials and Coatings: Corrosion-resistant materials and coatings can help prevent degradation and maintain a tight seal over time.

- Check Valve Design and Operating Conditions: Optimizing the valve size, shape, and flow characteristics for specific operating conditions, such as pressure, temperature, and fluid properties, can help ensure tightness and prevent leakage.

02 Check Valve Materials and Coatings

Corrosion-resistant materials, elastomeric seals, and coatings that enhance sealing properties contribute to maintaining tightness over time.Expand Specific Solutions03 Check Valve Assembly and Installation

Correct alignment, torque specifications, and proper seating of components affect the valve's ability to seal effectively.Expand Specific Solutions04 Check Valve Maintenance and Testing

Inspections, cleaning, component replacement, leak testing, and performance verification help ensure continued tightness.Expand Specific Solutions05 Check Valve Design Enhancements

Innovative designs like double-sealing mechanisms, pressure-assisted sealing, or self-adjusting components can improve tightness and reduce leakage risk.Expand Specific Solutions

Main Player Analysis

Honeywell International Technologies Ltd.

Advance Valves Pvt Ltd.

Key Technology Interpretation

- The check valve has a frustoconical end region and a tapered mating surface that securely fits within the outlet check valve body, providing a secure and reliable sealing.

- The check valve seat is biased against an end surface by a spring and external pressure, ensuring a tight seal when the valve is closed.

- The poppet design allows pressurized fluid to flow through the check valve seat when the pressure is sufficient to overcome the biasing force, enabling efficient fluid flow.

Check Valve Tightness Improvement Economic Analysis

Check valve tightness is important for ensuring efficient and safe operation in various industrial applications. An economic analysis of tightness improvement strategies can provide valuable insights into cost-effective solutions. Key factors to consider include the potential for reduced leakage and associated costs, such as energy losses, environmental impacts, and maintenance expenses. Additionally, the analysis should evaluate the upfront investment required for implementing tightness enhancement measures, including material upgrades, design modifications, or installation of monitoring systems. By weighing the long-term benefits against the initial costs, the economic analysis can guide decision-making and prioritize the most viable tightness improvement strategies, ultimately optimizing operational efficiency and profitability.

Check Valve Tightness Improvement Policy And Regulatory Impact

Regulatory bodies have established stringent guidelines and standards to maintain the integrity and reliability of check valves. This policy aims to enhance the tightness of check valves through improved design, manufacturing processes, and testing methodologies. The impact of this policy is far-reaching, affecting industries like oil and gas, chemical processing, power generation, and water treatment. By implementing tighter check valves, the risk of leakage, backflow, and system failures can be minimized, leading to increased safety, reduced environmental impact, and optimized operational efficiency.