Improving The Air Tightness Of Check Valves

Technology Background And Goals

The primary objective of this report is to improve the air tightness of check valves, which is crucial for maintaining system efficiency and preventing leakage in various applications. This research aims to address the challenges posed by factors such as wear, corrosion, and improper installation that can compromise the sealing performance of check valves over time.

Key goals include developing advanced sealing materials and coatings, optimizing valve design for enhanced sealing capabilities, and exploring innovative manufacturing techniques to ensure consistent quality and durability. Ultimately, the research seeks to provide practical solutions that can extend the service life of check valves, reduce maintenance costs, and enhance overall system reliability across various industries.

Technology Market Demand Analysis

The market demand for improving air tightness in various applications is driven by several factors. Firstly, energy efficiency has become a crucial consideration across industries, and enhancing air tightness plays a vital role in reducing energy consumption and associated costs. Buildings, vehicles, and other enclosed structures with poor air tightness experience higher energy losses due to uncontrolled air leakage, leading to increased heating, cooling, and ventilation requirements.

Secondly, the growing emphasis on sustainability and environmental consciousness has fueled the demand for air tightness solutions. Improved air tightness not only contributes to energy savings but also reduces greenhouse gas emissions associated with energy production and consumption. As governments and organizations worldwide implement stricter regulations and standards for energy efficiency and carbon footprint reduction, the need for effective air tightness measures has become more pressing.

Furthermore, the demand for improved indoor air quality has driven the adoption of air tightness technologies. Uncontrolled air leakage can lead to the infiltration of outdoor pollutants, moisture, and contaminants, compromising indoor air quality and potentially posing health risks. Air tightness solutions help maintain a controlled indoor environment, ensuring better air quality and occupant comfort.

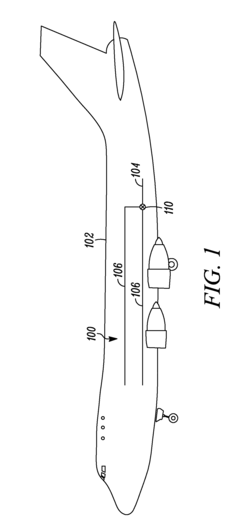

Additionally, the transportation sector, particularly the automotive and aerospace industries, has a significant demand for air tightness solutions. Improved air tightness in vehicles and aircraft can enhance aerodynamic performance, reduce noise levels, and improve fuel efficiency, contributing to both environmental and operational benefits.

It is important to note that the market demand for air tightness solutions varies across different regions and industries. Regions with stringent energy efficiency regulations, such as Europe and parts of North America, tend to have a higher demand for air tightness technologies. Similarly, industries with a strong focus on energy conservation and environmental sustainability, such as construction, manufacturing, and transportation, are likely to drive the adoption of air tightness solutions.

Technology Status And Challenges

- Valve Sealing Challenges Maintaining airtightness in check valves is crucial for efficient fluid flow control. However, factors like wear, corrosion, and material incompatibility can compromise sealing integrity over time.

- Sealing Material Limitations Conventional sealing materials like elastomers and metals may degrade or fail under extreme temperatures, pressures, or chemical environments, leading to leakage.

- Design Complexities Complex valve geometries and intricate sealing surfaces can make achieving consistent and reliable sealing difficult, especially in miniaturized or high-precision applications.

- Maintenance and Replacement Issues Frequent maintenance or replacement of sealing components can increase operational costs and downtime, particularly in inaccessible or hazardous environments.

Current Technical Solutions

01 Check Valve Structure for Air Tightness

The structure of the check valve plays a crucial role in ensuring air tightness, including the use of specialized sealing elements, precise valve seat geometry, and optimized valve closure mechanisms.- Check Valve Structure for Air Tightness: The structure of the check valve plays a crucial role in ensuring air tightness, including the use of specific sealing materials, valve seat geometries, and mechanisms for creating a tight closure.

- Check Valve Materials for Air Tightness: The choice of materials used in check valve construction, such as elastomers or polymers, can significantly impact their air tightness and ability to create an effective air-tight seal.

- Check Valve Sealing Mechanisms for Air Tightness: Various sealing mechanisms, including spring-loaded seals, lip seals, or specialized sealing arrangements, are employed in check valves to ensure air tightness when the valve is closed.

- Check Valve Testing and Inspection for Air Tightness: To ensure air tightness, various testing and inspection methods are employed, such as leak testing, pressure testing, or visual inspections to identify potential leakage paths or defects.

- Check Valve Applications Requiring Air Tightness: Check valves designed for air tightness are essential in applications where preventing air leakage is critical, such as pneumatic systems, vacuum systems, or systems requiring specific air pressure or air contamination prevention.

02 Materials and Coatings for Air-tight Check Valves

The choice of materials and coatings used in check valve construction, such as elastomers, specialized polymers, or surface coatings, can significantly impact their air tightness and resistance to air permeation.Expand Specific Solutions03 Check Valve Assembly and Installation for Air Tightness

Proper assembly and installation of check valves, including techniques like precise alignment, controlled torque application, and the use of specialized gaskets or sealants, are crucial for ensuring air tightness and preventing air leakage paths.Expand Specific Solutions04 Testing and Inspection Methods for Check Valve Air Tightness

Various testing and inspection methods, such as pressure decay tests, leak detection techniques using tracer gases, or visual inspections with specialized equipment, are employed to evaluate the air tightness of check valves.Expand Specific Solutions05 Maintenance and Repair Strategies for Air-tight Check Valves

To maintain air tightness over the lifetime of check valves, various maintenance and repair strategies are employed, including periodic inspections, replacement of sealing components, or refurbishment of valve surfaces to address wear, damage, or degradation.Expand Specific Solutions

Technology Main Player Analysis

Honeywell International Technologies Ltd.

Robert Bosch GmbH

Key Technology Interpretation

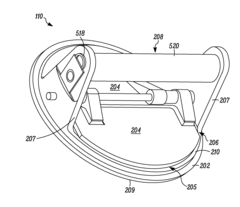

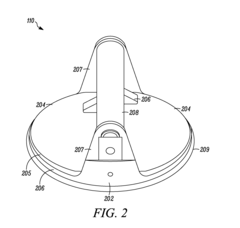

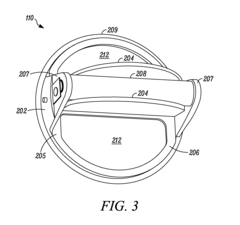

- The seat region of the check valve is made of elastomer material to reduce noise and wear when the flapper contacts the seat in the closed position.

- The check valve includes multiple flappers and a stop to improve sealing performance and control fluid flow.

- The check valve design aims to maintain high levels of durability and impact resistance while reducing noise and wear, requiring little or no maintenance.

Check Valve Air Tightness Improvement Economic Analysis

Improving the air tightness of check valves can have significant economic implications across various industries. These valves are critical in systems where preventing backflow is essential, such as in water supply, chemical processing, and oil and gas industries. Enhancing their air tightness can lead to increased efficiency, reduced leakage, and lower maintenance costs, directly impacting operational expenses. Furthermore, improved air tightness contributes to better energy efficiency by minimizing energy loss due to leakage, which is increasingly important in sectors facing rising energy costs and stringent environmental regulations. This not only conserves resources but also enhances the sustainability of industrial operations, aligning with global trends towards greener technologies.

In addition, there can be notable economic benefits in terms of product longevity and reliability, which can reduce the frequency of replacements and downtime associated with valve failures. Companies that invest in air-tight check valves might experience fewer disruptions and longer intervals between maintenance cycles, thus improving overall productivity and profitability. The market potential for advanced check valves with superior air tightness is significant as industries seek to optimize their processes and comply with regulatory standards. Consequently, firms that innovate in this area could capture new market segments, enhance their market position, and generate higher returns on their research and development investments.

Check Valve Air Tightness Improvement Policy And Regulatory Impact

The regulatory impact of improving the air tightness of check valves can significantly influence both industry operations and product development. Regulations typically focus on ensuring that these valves meet certain standards for safety, efficiency, and environmental compliance. Stringent regulations may require manufacturers to innovate rapidly to meet higher performance benchmarks. This could lead to additional research and development costs, impacting production timelines and costs.

Moreover, improved air tightness often correlates with enhanced energy efficiency and reduced emissions, aligning with global sustainability standards and positively affecting both regulatory and market acceptance. Compliance with regulations can provide companies with competitive advantages, offering market differentiation through superior product performance. However, non-compliance could result in severe penalties and loss of market access, underscoring the importance of adhering to regulatory guidelines.