Improving The Cleanliness Of Check Valves

Technology Background And Goals

Key aspects to cover include identifying the main technical hurdles hindering effective cleaning of check valves, evaluating the geographical distribution of relevant technologies, and exploring potential innovative approaches to address this issue. The analysis should provide insights into the core patents, research literature, and mainstream solutions currently employed in this domain.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valves and related products, including the breakdown by industry sectors and geographical regions. Provide projections for market growth over the next 5-10 years, considering factors like industrial expansion, infrastructure development, and regulatory changes. - Key Applications

Identify the major applications and industries that drive the demand for check valves, such as oil and gas, power generation, water and wastewater treatment, and chemical processing. Highlight any emerging applications or sectors that may create new market opportunities. - Customer Needs and Preferences

Assess the evolving needs and preferences of customers in different industries regarding check valve performance, reliability, maintenance requirements, and cleanliness standards. Identify any specific challenges or pain points that need to be addressed. - Regulatory and Industry Standards

Examine the relevant regulatory frameworks and industry standards that govern the design, manufacturing, and operation of check valves, particularly those related to cleanliness and contamination control. Highlight any upcoming changes or trends that may impact market demand.

Technology Status And Challenges

- Valve Fouling Issues

Check valves are prone to fouling, which can lead to valve failure and system downtime. Fouling can occur due to various factors, including corrosion, scaling, and accumulation of debris. - Maintenance Challenges

Maintaining check valve cleanliness is a significant challenge, especially in harsh environments or remote locations. Regular inspection and cleaning are often required, which can be time-consuming and costly. - Material Compatibility

The choice of valve materials plays a crucial role in preventing fouling. Incompatible materials can accelerate corrosion, scaling, and other fouling mechanisms, leading to reduced valve performance and lifespan. - Design Limitations

Conventional check valve designs may have inherent limitations in preventing fouling. Complex internal geometries, crevices, and stagnant flow areas can contribute to the accumulation of contaminants and debris.

Current Technical Solutions

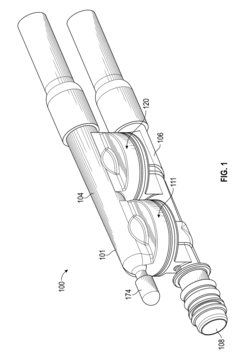

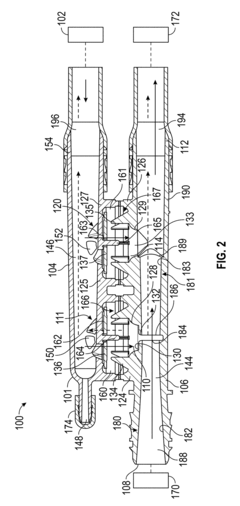

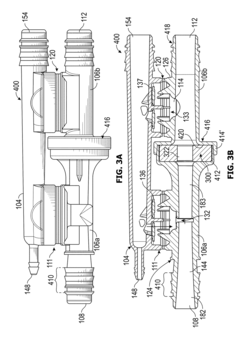

01 Check valve cleanliness through design features

Design features like filters, smooth surfaces, and minimized crevices help prevent debris buildup, facilitate cleaning, and improve cleanliness.- Check valve cleanliness through design features: Design features like filters, smooth surfaces, and minimized crevices or dead spaces help prevent contaminant buildup and ensure proper valve operation, improving cleanliness.

- Check valve cleaning methods and systems: Various cleaning methods like flushing with fluids, ultrasonic cleaning, and mechanical techniques aim to remove contaminants and ensure proper valve functioning.

- Check valve materials and coatings for improved cleanliness: Selecting materials with smooth surfaces, corrosion resistance, and coatings that prevent fouling or bacterial growth can help maintain valve cleanliness and prevent contamination.

- Check valve inspection and monitoring for cleanliness: Techniques like visual inspection, particle counting, and analytical methods allow for contaminant detection and assessment of valve cleanliness.

- Check valve cleaning validation and quality control: Processes for validating cleanliness after cleaning and implementing quality control measures help verify cleaning effectiveness and maintain consistent cleanliness levels.

02 Check valve cleaning methods and systems

Various cleaning methods like flushing with fluids, ultrasonic cleaning, and mechanical techniques aim to remove contaminants and ensure proper valve functioning.Expand Specific Solutions03 Check valve materials and coatings for improved cleanliness

Materials with smooth surfaces, corrosion resistance, low contaminant adhesion, and coatings can enhance cleanability and maintain cleanliness.Expand Specific Solutions04 Check valve inspection and monitoring for cleanliness

Techniques like visual inspection, particle counting, and analytical methods help identify contamination issues and ensure cleanliness requirements are met.Expand Specific Solutions05 Check valve cleaning validation and standards

Standards and validation processes, particularly in industries with stringent cleanliness requirements, help verify cleaning effectiveness and maintain consistent cleanliness levels.Expand Specific Solutions

Technology Main Player Analysis

Halkey-Roberts Corp.

Watts Regulator Co.

Key Technology Interpretation

- Reducing stress on the sealing member and extending the life of the check valve.

Check Valve Cleanliness Improvement Economic Analysis

Improving the cleanliness of check valves has significant economic implications across various industries. Check valves are crucial components in piping systems, ensuring the prevention of backflow and protecting equipment from damage caused by reverse flow. Maintaining their cleanliness is essential for optimal performance, prolonging their lifespan, and reducing maintenance costs.

In the oil and gas industry, where check valves are extensively used in pipelines and drilling operations, maintaining cleanliness can substantially reduce downtime and associated costs. Fouling and contamination in check valves can lead to malfunctions, leaks, or even complete failure, resulting in production disruptions and costly repairs or replacements.

Similarly, in the chemical and pharmaceutical industries, check valve cleanliness is critical for maintaining product purity and meeting stringent regulatory standards. Contamination in these sectors can compromise the quality of the final product, potentially leading to costly recalls, fines, and damage to a company's reputation.

Furthermore, improving check valve cleanliness can contribute to energy efficiency in various industrial processes. Clean check valves ensure smooth flow and minimize friction losses, reducing energy consumption and associated costs for pumping systems and other fluid handling equipment.

It is essential to consider the initial investment required for implementing cleanliness-enhancing solutions, such as specialized cleaning methods, coatings, or valve design modifications. However, these upfront costs can be offset by the long-term savings achieved through reduced maintenance, extended equipment life, and improved process efficiency.

Check Valve Cleanliness Improvement Policy And Regulatory Impact

Regarding the cleanliness of check valves, there are several policies and regulations that manufacturers need to comply with. These regulations aim to ensure the safety and reliability of check valves, particularly in critical applications such as power generation, oil and gas, and chemical processing.

The American Society of Mechanical Engineers (ASME) has established standards for the design, construction, and testing of check valves. The ASME B16.34 standard provides requirements for the materials, dimensions, pressure-temperature ratings, and performance testing of check valves. Manufacturers must adhere to these standards to ensure their products meet the necessary safety and quality criteria.

In addition, the Environmental Protection Agency (EPA) has regulations in place to minimize the environmental impact of industrial processes, including the use of check valves. The Clean Air Act and the Clean Water Act set limits on the emissions and discharges of pollutants, respectively. Check valve manufacturers must ensure that their products do not contribute to the release of harmful substances into the environment.

Furthermore, the Occupational Safety and Health Administration (OSHA) has regulations that address the safety of workers involved in the installation, maintenance, and operation of check valves. These regulations cover topics such as hazardous materials handling, personal protective equipment, and safe work practices.

Depending on the industry and application, there may be additional regulatory bodies and standards that govern the cleanliness and performance of check valves. For instance, in the food and beverage industry, the U.S. Food and Drug Administration (FDA) has strict regulations for equipment that comes into contact with food products, including check valves.

It is crucial for check valve manufacturers to stay up-to-date with the latest policies and regulations, as they can have a significant impact on the design, manufacturing, and testing processes. Failure to comply with these regulations can result in fines, legal actions, and potential harm to people and the environment.